Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for PIAB KCS Series

- Page 1 KCS SERIES ASSEMBLY MANUAL Rev: 02...

-

Page 2: Table Of Contents

INDEX GENERAL SAFETY INSTRUCTIONS ............................ 3 DANGEROUS AREAS ................................5 PICTOGRAMS................................... 6 R.E.S.S. APPLIED AND RESPECTED ............................ 7 INSTALLATION ..................................9 WORKING CYCLE DETAILS ..............................17 PARTS LIST ....................................18 MAINTENANCE ..................................21 PROBLEMS/SOLUTIONS ..............................22 ACCESSORIES ..................................23 TECHNICAL DATA ................................25 PNEUMATIC DIAGRAM ............................... -

Page 3: General Safety Instructions

GENERAL SAFETY INSTRUCTIONS The correct use of pneumatic malfunction. Install a filter upstream pneumatic/electrical supply, equipment within a system is the of the component; the filter grade discharge residual pressure. responsibility of the system designer should be at least 5 µm. Air or the person who determines its containing excessive quantities of Safety instructions... - Page 4 They must not be deformed; Have a uniform height over the entire gripping surface. Any height differences must be reported in the agreement. If they are not reported, Piab AB and / or Kenos will not be responsible for malfunction. Not intended use The gripper must not be used: For uses other than those established by the manufacturer or reported in this manual;...

-

Page 5: Dangerous Areas

DANGEROUS AREAS Areas with danger of crushing Areas with danger of air ejection Notes for the final manufacturer of machinery It is prohibited stopping or passing through the work area of the gripper module. In case of electrical or pneumatic supply failure, the load handled by the module is released. -

Page 6: Pictograms

PICTOGRAMS PIC. DESCRIPTION Generic danger. Warning! Danger of crushing or entrapment of upper limbs! Danger of air ejection or expulsion of particles! Pictograms related to the operator's qualification highlighted in this manual PIC. DESCRIPTION PICTOGRAMS Generic manual: operator without specific skills, able to perform only simple tasks on the orders of qualified technicians. -

Page 7: Applied And Respected

4. R.E.S.S. APPLIED AND RESPECTED Essential Health and Safety Requirement Compliance 1 ESSENTIAL SAFETY AND PROTECTION OF HEALTH 1.1 General considerations 1.1.1 definitions √ 1.1.2 Principles of safety integration √ 1.1.3 Materials and products √ 1.1.4 Lighting 1.1.5 Design of machinery to facilitate its handling √... - Page 8 Essential Health and Safety Requirement Compliance 1.5 Risks due to other hazards 1.5.1 Electric Power 1.5.2 Static Energy 1.5.3 Energy supply other than electricity √ 1.5.4 Assembly errors 1.5.5 Extreme temperatures 1.5.6 Fire 1.5.7 Explosion 1.5.8 Noise √ 1.5.9 Vibrations 1.5.10 Radiation 1.5.11 External Radiation 1.5.12 laser radiation...

-

Page 9: Installation

INSTALLATION Mounting on the adapter system The pump unit is mounted on the special adapter system. Pos. Description Special adapter system Pump unit Adapter fixing screws b. Quick change system The pump unit and the gripper modules are connected by a quick change system. Attention: the point 1 need to be aligned with the indication B. - Page 10 Ejector exhaust The blue arrows show the exhaust air flow, DO NOT COVER the silencer. d. Pneumatic connection basic version Pos. Description Compressed air connection G1/8” for vacuum (1a) Compressed air connection G 1/8” for blow-off (1b) or vacuum monitoring Pump unit Foam gripper unit Bag cup unit...

- Page 11 Connecting integrated solenoid valve (V1 / V3) with vacuum sensor version Pos. Description Compressed air connection G 1/8” for solenoid valve Compressed air connection G 1/8” for blow off or vacuum monitoring Solenoid valve, vacuum, N.C. / N.O. Vacuum sensor Connector M8 3 pin male Solenoid valves characteristics Fluid...

- Page 12 Push-turn slotted locking type (Type D) Round head combination screw Round head combination screw M3x31, Matt nickel plated While pressing, turn in the direction of the arrow. If it is M3x31, Matt nickel plated not turned, it can be opened in the same way as the non-locking type.

- Page 13 ► M8 connector has an indication of IP65 (enclosure) that give protection to dust and water. Take note, however, that the product is not designed to be used in contact with water. ► Do not use a tool to mount the connector, as this may cause damage. Only tighten by hand. (0.4 to 0.6 Nm, (0.30 to 0.44 lbf)) ►...

- Page 14 M12 Waterproof connector wiring specifications 4 pin connector M12 plug 3 (COM) Solenoid Solenoid Coil Coil Solenoid valve side pin wiring diagram Circuit diagram Note: Solenoid valves have no polarity. Connection destination (female side) connector cable Connector Size Manufacturer Applicable series Correns Corporation VA-4D OMRON Corporation...

- Page 15 Specifications for vacuum sensor “MA” version Fluid Air/Non-corrosive gas/Non-flammable gas Rated pressure range 0 to –101 kPa Extension analogue output range -10.1 to 0 kPa Proof pressure 500 kPa 12 to 24 V DC ±10 %, Ripple (p-p) 10 % or less (with reverse connection Power supply voltage protection) Current consumption...

- Page 16 Pressure M8 3 poles male connector: MALE Connections: Blue (-) ►3 Black ►4 Brown (+) ►1 Page 16 of 30...

-

Page 17: Working Cycle Details

WORKING CYCLE DETAILS Working cycle details for Flow reduction and Bag cup version: The working cycle for a KCS gripping module follows the steps showed in the bellow: Positioning the module at the object to handle with the grip pad parallel to the grip surface. Lowering of module until contact with the grip surface. -

Page 18: Parts List

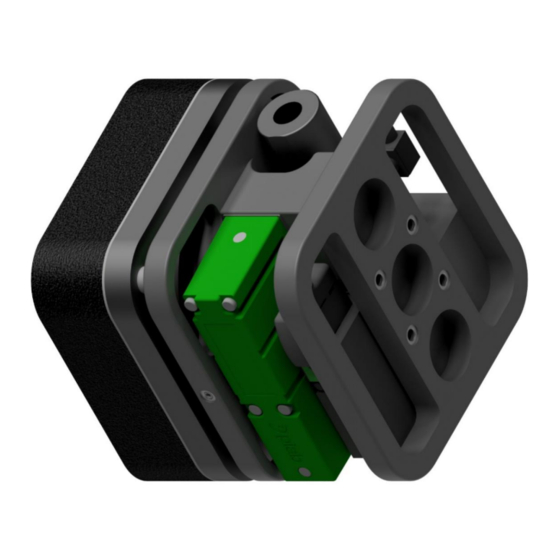

PARTS LIST Pump unit parts list Pos. Description Plastic basic body Ejector piCHIP SX42 or SX12 Solenoid valve Silencer Vacuum sensor M8 3 pin male connector Metal threaded insert for quick change system lock Page 18 of 30... - Page 19 b. Pump unit + Bag cup unit parts list Pos. Description Pump unit X-Ring Bag cup plastic body Screw for connection to pump unit Page 19 of 30...

- Page 20 Pump unit + Foam gripper unit parts list Pos. Description Pump unit X-Ring Foam gripper plastic body Screw for connection to pump unit Fixing Screws for technical foam with mounting plate Mounting plate Technical foam Page 20 of 30...

-

Page 21: Maintenance

MAINTENANCE Foam maintenance The foam that builds the gripping surface can be damaged during normal use. The medium lifetime depends on many factors: nature of the handled objects, quality of the gripping surface, work conditions, cycle times, etc. Remove the old foam. Clean the metal plate from any adhesive and dust residues (e.g. -

Page 22: Problems/Solutions

b. Maintenance plan Daily Weekly Monthly Every 6 months Every 12 months Check Max vacuum level of the ejector • Check the micro holes • Check the silencer • Check tightening’s • Check the foam • Check supply air pressure •... -

Page 23: Accessories

10. ACCESSORIES Standard cable Item n. PIAB Description 0108141 Cable M8 3-pin female L=2m 0121817 Cable M12 4-pin female L=5m b. Special cable Rethink Y cable RTH-KCS M12 8p V1/V3-MA 250mm Cable specification Item n. PIAB Description Cable color Function... - Page 24 Y cable RTH-KCS M12 8p V1/V3-MD 250mm Cable specification Item n. PIAB Description Cable color Function Yellow Monitoring connection 0212287 Y cable RTH-KCS M12 8p V1/V3-MD 250mm Black Solenoid valve connection Special cable UR Y cable UR-KCS M8 8p V1/V3-MA 250mm Item n.

-

Page 25: Technical Data

11. TECHNICAL DATA Air consumption Type Air consumption at 0.5 MPa (NI/s) KCS.XXXX.SX421.XX.XXX.XXXXXX.XX 2.21 (1 cartridge inside) KCS.XXXX.SX422.XX.XXX.XXXXXX.XX 4.42 (2 cartridges inside) Type Air consumption at 0.5 MPa (NI/s) KCS.XXXX.SX121.XX.XXX.XXXXXX.XX 0.72 (1 cartridge inside) KCS.XXXX.SX122.XX.XXX.XXXXXX.XX 1.44 (2 cartridges inside) b. Pneumatic technical documentation Descriprtion Unit SX42-ejector with (1-2 cartridge) -

Page 26: Pneumatic Diagram

12. PNEUMATIC DIAGRAM KCS.Q110.NXXX.FR SERIES PNEUMATIC DIAGRAM KCS.Q110.NXXX.FR.EJECTOR.BASE KCS.Q110.NXXX.FR.EJECTOR.V1 optional optional Only for Only for foam with foam with filter version filter version KCS.Q110.NXXX.FR.EJECTOR.V2 KCS.Q110.NXXX.FR.EJECTOR.V3 optional optional Only for Only for foam with foam with filter version filter version 1a = PRESSURE AIR SUPPLY FOR VACUUM 1b = PRESSURE AIR SUPPLY FOR BLOW OFF 2 = VACUUM 3 = EXHAUST... - Page 27 b. KCS.Q110.BCX SERIES PNEUMATIC DIAGRAM KCS.Q110.BC.EJECTOR.BASE KCS.Q110.BC.EJECTOR.V1 optional optional KCS.Q110.BC.EJECTOR.V2 KCS.Q110.BC.EJECTOR.V3 optional optional 1a = PRESSURE AIR SUPPLY FOR VACUUM 1b = PRESSURE AIR SUPPLY FOR BLOW OFF 2 = VACUUM 3 = EXHAUST Page 27 of 30...

-

Page 28: Spare Parts

13. SPARE PARTS Single spare parts list Item n. PIAB Descriprtion 0205575 COAX® cartridge SX12 0205724 COAX® cartridge SX42 0205356 KCS- Ejector gasket 0211613 Vacuum sensor analogue output 1 to 5 V connector Ø4 mm 0107731 Vacuum switch, adjustable, PNP NO LM8... -

Page 29: Warranties

14. WARRANTIES The Seller gives its Customers a one-year warranty from the receipt of the Products, accessories, control devices end • Kenos products included. It is a duty of the Buyer to check the goods at the time of delivery at the agreed destination. Complaints relating to •... - Page 30 BRAZIL – Sao Paulo GERMANY – Schmallenberg POLAND – Gdansk Email: info-sweden@piab.com Phone: +55 11 4492 9050 Robotic gripping Phone: +48 58 785 08 50 Email: info-brasil@piab.com Phone: +49 (0) 29 72/962 17-11 Email: info-poland@piab.com UNITED KINGDOM – Email: info- Loughborough CANADA –...

Need help?

Do you have a question about the KCS Series and is the answer not in the manual?

Questions and answers