Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for PIAB KCS Series

- Page 1 Art. No. 0209961 Rev.00 Piab AB, 2017-07...

-

Page 2: Table Of Contents

It is intended exclusively for use by persons authorized in your company. The transfer to third parties can only take place with the prior written consent of Piab AB. All documentation is protected under the copyright law. -

Page 3: Safety Instructions

KCS Series Safety instructions General safety instructions The correct use of pneumatic equipment within a system is the responsibility of the system designer or the person who determines its technical specifications. The use of safety guards is recommended to minimize the risk of injury to persons; pay close attention to the fact that compressed air may lead to the explosion of closed containers, and vacuum may lead to the implosion of closed containers. - Page 4 KCS Series Assembly Compressed air may be dangerous if used by unskilled personnel. Assembling, using and maintaining systems should solely be carried out by experienced and specially trained per- sonnel. Both for fastening and supplying, solely use the bores and methods provided by the manufacturer.

- Page 5 KCS Series machine is concerned, the division between the steel parts and those in other metals or alloys is sufficient for a correct sending to recycling by casting. Failure to comply with the above rules may cause malfunctions, damage, injury, including with serious consequences.

-

Page 6: Overview

KCS Series Overview Part list with flow reduction version Pos. Description Pneumatic supply G 1/8” connection Blow-off G 1/8” connection Pump unit Flow reduction module with technical foam Specifications subject to change without notice... - Page 7 KCS Series Part list with bag cup version Pos. Description Pneumatic supply G 1/8” connection Blow-off G 1/8” connection Pump unit Bag cup module Specifications subject to change without notice...

-

Page 8: Work Cycle Details For Flow Reduction And Bag Cup Version

KCS Series Work cycle details for Flow reduction and Bag cup version The working cycle for a KCS gripping module follows the steps showed in the bellow: 1. Positioning the module at the object to handle with the grip pad parallel to the grip surface. -

Page 9: Installation

KCS Series Installation Mounting on the adapter system The pump unit is mounted on the special adapter system. Pos. Description Special adapter system Pump unit Hole for ISO 4762 M5x12mm screw Adapter ISO9409-1-50-4-M6 Adapter ISO9409-1-40-4-M6 Specifications subject to change without notice... - Page 10 KCS Series Quick change system The pump unit and the gripper modules are connected by a quick change system. Attention: the point 1 need to be aligned with the indication B. Pos. Description Quick change system Metal threaded insert for quick change system locking...

- Page 11 KCS Series Connecting integrated solenoid valve (EV) Pos. Description Connection G 1/8” compressed air for pneumatic supply Connection G 1/8” compressed air for blow off Solenoid valve, vacuum, N.C. Vacuum sensor Connector M8 3 pole male Specifications for solenoid valves...

- Page 12 KCS Series Push-turn slotted locking type (Type D) While pressing, turn in the direction of the Round head combination screw arrow. If it is not turned, it can be opened in M3x31, Matt nickel plated the same way as the non-locking type.

- Page 13 KCS Series ► 1. M8 connector has an indication of IP65 (enclosure) that give protection to dust and water. Take note, however, that the product is not designed to be used in contact with water. ► 2. Do not use a tool to mount the connector, as this may cause damage.

- Page 14 KCS Series A = Ø 4 mm B = 18 mm Specifications for vacuum sensor pipping Port size Ø 4 reducer Case Pressure sensing section Silicon, O-ring: NBR Max. curvature ray for flexing use 10 x external diameter Case PUR (UL/CSA)

-

Page 15: Parts Diagram

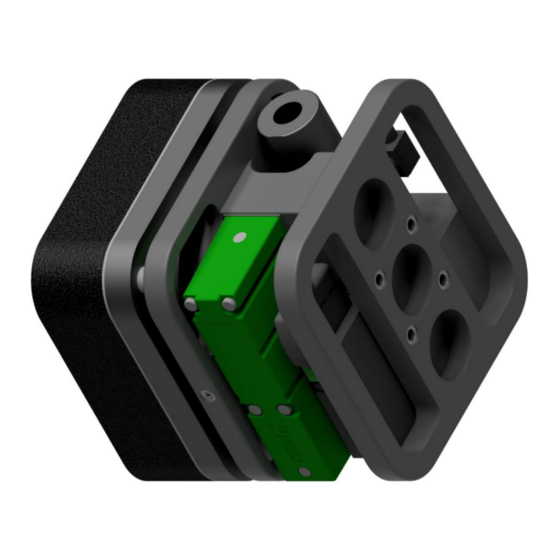

KCS Series Parts diagram Part diagram for pump unit Pos. Description Plastic basic body Ejector piCHIP SX422 Solenoid valve EV 3/2 N.C Silencer Vacuum sensor, analogue output 1 to 5 V connector Ø4 mm M8 3 pole male connector Metal threaded insert for quick change system lock... - Page 16 KCS Series Part diagram for pump unit + Bag cup module Pos. Description Pump unit X-RING Bag cup plastic body Screw for connection to pump unit Specifications subject to change without notice...

- Page 17 KCS Series Part diagram for pump unit + Flow reduction module Pos. Description Pump unit X-RING Flow reduction module plastic body Screw for connection to pump unit Fixing Screws for technical foam with mounting plate Technical foam with mounting plate...

-

Page 18: Maintenance

KCS Series Maintenance Remove the old foam. Clean the metal plate from any adhesive and dust residues (e.g. with solvent) Attention: Be careful that the holes are not blocked by any kind of residue, if they are, clean them. Remove the silicon paper from the foam. - Page 19 KCS Series Press the new foam To store the foam: Temperature (5 ° C to 25 ° C) Not under the light Be free of tension No dust chemical protected Maintenance plan Every 12 Every 6 Daily Weekly Monthly months...

-

Page 20: Problems/Solutions

KCS Series Problems/solutions Problem Possible reason Solutions Operating pressure too low Increase the pressure Internal diameter of pressure Use hoses with larger internal hose too small diameter Insufficient vacuum level Check and replace if Damaged sealing or vacuum achieved too... -

Page 21: Technical Data

KCS Series Technical data Type Air consumption at 0.5 MPa (NI/s) KCS.XXXX.SX421.XX.XXX.XXXXXX.XX 2.21 (1 cartridge inside) KCS.XXXX.SX422.XX.XXX.XXXXXX.XX 4.42 (2 cartridge inside) Type Air consumption at 0.5 MPa (NI/s) KCS.XXXX.SX121.XX.XXX.XXXXXX.XX 0.72 (1 cartridge inside) KCS.XXXX.SX122.XX.XXX.XXXXXX.XX 1.44 (2 cartridge inside) Pneumatic technical information... -

Page 22: Pneumatic Diagram

KCS Series Pneumatic diagram KCS.Q110.NXXX.FR SERIES PNEUMATIC SCHEME KCS.Q110.NXXX.FR.EJECTOR.BASE KCS.Q110.NXXX.FR.EJECTOR.V1 KCS.Q110.NXXX.FR.EJECTOR.V2 KCS.Q110.NXXX.FR.EJECTOR.V3 1a = PRESSURE AIR SUPPLY FOR VACUUM 1b = PRESSURE AIR SUPPLY FOR BLOW OFF 2 = VACUUM 3 = EXHAUST Specifications subject to change without notice... - Page 23 KCS Series KCS.Q110.BC SERIES PNEUMATIC SCHEME KCS.Q110.BC.EJECTOR.BASE KCS.Q110.BC.EJECTOR.V1 KCS.Q110.BC.EJECTOR.V2 KCS.Q110.BC.EJECTOR.V3 1a = PRESSURE AIR SUPPLY FOR VACUUM 1b = PRESSURE AIR SUPPLY FOR BLOW OFF 2 = VACUUM 3 = EXHAUST Specifications subject to change without notice...

- Page 24 KCS Series Spare parts Art. No Description 0211607 Ejector piCHIP SX121 0211608 Ejector piCHIP SX122 0211610 Ejector piCHIP SX421 0211612 Ejector piCHIP SX422 0211613 Vacuum sensor analogue output 1 to 5 V connector Ø4 mm 0107731 Vacuum switch, adjustable, PNP NO LM8...

- Page 25 KCS Series Piab gives you service all over the world. To find your local distributor, please visit www.piab.com No need to compromis Specifications subject to change without notice...

Need help?

Do you have a question about the KCS Series and is the answer not in the manual?

Questions and answers