Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for TierTime UP600

-

Page 1: Tiertime

Tiertime UP600/UP600D User Manual... -

Page 2: Table Of Contents

3.3 Connect Power ......................10 3.4 Install Software UP Studio 3.0 ................... 10 3.5 Update the Touchscreen Firmware ................11 Chapter 4. Prepare UP600/UP600D for Printing ..............12 4.1 Printer Calibration From Touch Screen ..............12 4.2 Load Filaments ......................14 4.3 Update the Touchscreen Firmware ................ - Page 3 8.3 Print Layout Tools ...................... 37 8.4 Support Editor ......................39 Support List ........................41 Support Filter ........................41 8.5 Print Settings ......................42 8.5.1 User Modes ......................43 8.6 Introduction to print parameters ................44 8.6.2 Path ......................... 48 8.6.3.Special ........................

- Page 4 15.4.2 Completely Blockage ..................... 83 15.4.3 Remove blockage at heater module ..............83 15.4Dual Filtration System ....................84 Chapter 16. Specification ......................86 Chapter 17. Customer Service and Community ..............87...

-

Page 5: Chaper 1. Safety And Printing Environment

Chaper 1. Safety and Printing Environment 1.1 Safety Precautions 1. The UP600/UP600D 3D printer uses 220V or 110V AC (depends on the geographical location) as power input. Internally the high voltage AC will be converted to 24V DC to power its extrusion and motion control system. The build platform however use 110V or 220V AC directly. -

Page 6: Printing Environment

Tiertime and its authorized resellers warrant to the original purchaser that this product is free from defects in material and workmanship. Tiertime or its resellers will for one year, at its option, repair or replace at no charge for parts and labor from the date you purchased the product from Tiertime or a reseller. -

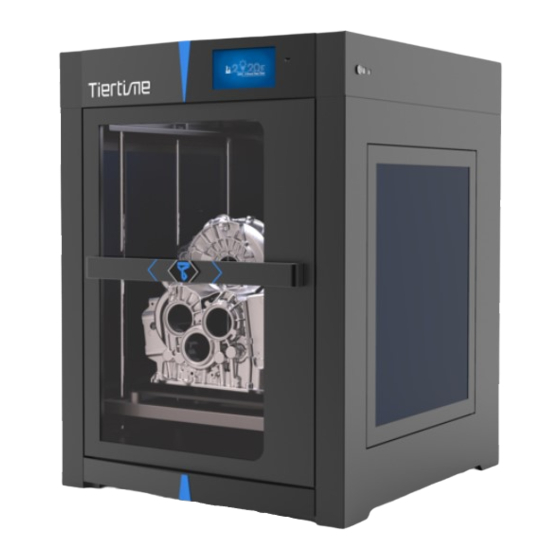

Page 7: Chapter 2. Introduction

Chapter 2. Introduction 2.1 Main Parts of UP600/600D 1. Top Lid 6. Filament Spool Racks 2. Touchscreen and Front USB port 7. Filament Entrance 3. Front Door 8. Side Door 4. Platform 9. USB and Ethernet 5. Door Check Sensor... - Page 8 1. Power Input Socket 2. Circuit Breaker 3. Power Switch 4. Back Cover (Air Filtration Unit inside) 5. Caster (FOOTMASTER Type) 6. Y-Axis (Left/Right) 7. X-Axis (Back/Forth) 8. Z-Axis (UP/Down) Print Head...

-

Page 9: Accessories

Packing List Power Supply 300W Push Pin The LT SingleExtruder is installed on the UP600 / The Convergence Due Extruder is installed on the UP600D Notice: All accessories may subject to change without prior notice. If anything is missing, please contactyour local distributor, or Tiertime’s global technical support... -

Page 10: Chapter 3. Printer Installation

Turn on the power switch. 3.4 Install Software UP Studio 3.0 To operate the UP600/UP600D, you need to install the UP Studio 3.0 software on your computer. Although UP Studio 2.X can also work with UP600, it does not support dual extrusion function and will be obsoleted once UP Studio 3.0 is... -

Page 11: Update The Touchscreen Firmware

1. Download the UP600 Touchscreen Upgrade Program from https://www.tiertime.com/touchscreen-upgrade-program/ 2. Save the file to the root directory of the USBdrive which comes with the UP600, and make sure the file is named as “UP600_x.x.x_update.tt” (Case sensitive), x.x.x being the version number. -

Page 12: Chapter 4. Prepare Up600/Up600D For Printing

Chapter 4. Prepare UP600/UP600D for Printing UP600/UP600D supports USB and various networking communications protocols. 4.1 Printer Calibration From Touch Screen 1. Switch on printer then go to touchscreen, press “Initialize” button to initialize the printer. 2.Install the auto-leveling probe, a magnetic gadget which can hold itself on the metal extruder mount. - Page 13 3.Initiate Auto-leveling. 2. Press “Calibrate” on touchscreen. 3. Press “AUTO” The printer will start the process of calibration. Make sure the nozzle is clean, plastic debris will add errors to the Nozzle Height. 4. Touch the probe’s sensor against the nozzle, which will inform the machine that the probe is installed properly and it is ready for the calibration process.

-

Page 14: Load Filaments

4.2 Load Filaments You will find one spool of500g Tiertime PLA for UP600 In order to archive good consistency and print quality, we recommend use Tiertime filaments. The default print settings of UP Studio are optimized using Tiertime materials, so you can start printing confidently without adjusting any parameters. -

Page 15: Prepare Up300D For Printing

5. Prepare UP300D for Printing 5.1Connectivity UP300D supports USB and other networking communications. For Wi-Fi, and Ethernet connection please refer to page 53-54, 66-68. 5.2 Auto Calibration Auto Calibration can be triggered from the touchscreen, or from Wand software when the printer is connected to a computer (refer to page 64). The calibration process consists of leveling of the build plate,and measurement of nozzle height. -

Page 16: Load The Filaments

1. 500g Tiertime PLA 2. 500g TiertimePVA In order to achieve good consistency and print quality, we recommend use Tiertime filaments. The default print settings of UP Studio are optimized using Tiertime materials, so you can start printing confidently without adjusting any parameters. - Page 17 5. Go to touchscreen 1. Press Material 2. Press “Filament 1”Material 3. Press “ ” to extrude Button until it shows “PLA”, material. The machine will heat then press “+” button to up and buzz when start to increase material weight to extrude.

- Page 18 Filament 2 entry from the filament bay and the extruder head. On touchscreen, user should choose the correct support material that matches the main material. For PLA, the matching support material could be Tiertime PVA; for ABS, it should be the Tiertime Breakaway.

- Page 19 To install the filament, please following the instruction below: 1. Remove the vacuumed bag of PLA filament. 2. Find the end of the filament, and use pliers to make a clean cut of the end. 3. Open the filamentbay,and the BLUE colored (for main material) filament entrance of the feeding tube.Insert PLA filament into the guiding tube, you should able to feel the filament triggered mechanical switch (filament sensor) at the entrance.

- Page 20 5. Go to touchscreen 5.1 Press Material Press Material Button until it shows “PLA”, then press “+” button to increase material weight to 500g. 5.3 Press “ ” to extrude material. The machine will heat up and buzz when start to extrude.

-

Page 21: Chapter 5. First Print

U600 supports USB, Wi-Fi, and Ethernet connection. For Connecting with WiFi or Ethernet, please refer to page xxx. USB Connection Use the USB cable included, connect to one of your computers USB port and UP600’s back side USB port (Type-B). Open UP Studio 3 on the computer, click the “... -

Page 22: Remove The Printed Model

Clean the print board from plastic residues, put back into the build chamber for the next print.6. Setup for Dual Extrusion UP600 has the ability to use Convergence Dual Extruder to print in dual material mode. The extruder mount for Single extruders and Convergence Dual are different,... -

Page 23: Chapter 6. Dual Extrusion

Chapter 6. Dual Extrusion 6.1 Switch Print head 1. Remove Single Extruder. Withdraw filament from the extruder and turn off the machine before removing the extruder, then remove the single extruder. 1.1. Unplug extruder cable 1.2. Remove M4 screw to remove the extruder from the mount. 链... - Page 24 3. Install the extruder mount for Dual Extruder. Install the extruder mount for dual extruder, install the 7x M3 screws indicated below. 链 链 链 链 接 接 接 接 链 接 链 链 接 接 4. Install the Convergence Dual Extruder. After swapping the print head, switch on power and printer will able to recognize the Convergence Dual Extruder automatically.

-

Page 25: Load Main And Support Material

Filament 1 is the main material and filament 2 by default is the support material. For dual extrusion version of UP600, you will find two spools of filaments in the package. 1. 500g Tiertime PLA 2. 500g TiertimePVA In order to archive good consistency and print quality, we recommend use Tiertime filaments. -

Page 26: Slicing

On touchscreen user should choose the correct support material that match the main material. For PLA, the matching support could be Tiertime PVA or breakaway. For more info refer to chaper xxx. ---Important!!!--- For Convergence Dual Extruder, both main and support materials must be loaded into the extruder. -

Page 27: Load A Stl File By Click The "+" Button On The Vertical Menu

The left side material is filament 1(main material) select PLA, the right side material (support) select Tiertime PVA. 6.3.2 Load a STL file by click the “+” button on the vertical menu. -

Page 28: Auxiliary Support (A.s.)

Auxiliary Support STL loaded Please note an Auxiliary support pillar is auto loaded with the file. This is due to the activation of second extruder. On the left object list, two new entries appear, one is the STL model loaded and the other is the Auxiliary support. 6.4 Auxiliary Support (A.S.) It is a special preset object for material switching during a print. - Page 29 Move the Auxiliary support pillar to a suitable location. 1. First left click on the Auxiliary support to select it, then click the “ ” move button. 2. Right-click-drag the Axuiliary support to an area not overlapping with the STL model. 3.

-

Page 30: Chapter 7. Printer Calibration

Chapter 7. Printer Calibration Printer calibration in Tiertime system involve of followings: 1. Nozzle Height Measurement 2. Platform Matrix Leveling (9-Point Compensation) 3. Vertical Calibration 4. Dimensional Calibration All the above calibration are made in terms of SOFTWARE. Nozzle Height and Leveling Compensation are routine procedures that are done by users. -

Page 31: Set Nozzle Height Through Touchscreen, Please Refer To

7.2 Set Nozzle Height through Touchscreen, please refer to page xxx. 7.3 Setup Nozzle Height Value through Wand (computer hosted) 1. Connect printer to computer, open UP Studio 3.0 and click the “Print” button to open “Wand”. Click “Nozzle Height” button, the print head will move the position that is near the platform. - Page 32 It is recommend to print a small test object after the measurement, check the following for recommended first layer adhesion.

-

Page 33: Matrix Leveling (9-Point Compensation)

7.3 Matrix Leveling (9-Point Compensation) Tiertime Matrix Leveling can effectively reduce the adverse effects of tilting and uneven surface of build platform. The leveling will not affect the print's dimensional accuracy in contrary to other leveling methods. Its leveling mechanism is to first measure the platform heights at 9 different points and then use the values to generate a compensating raft that provides a flat and leveled build surface. -

Page 34: Auto Matrix Leveling Through Touchscreen, Refer To

Find a USB cable, and connect one end to the computer and the other end to the UP600 back USB port (type-B). Open the UP Studio on the computer, you will find the connected UP600 listed in the available printer list of Wand. -

Page 35: Manual Calibration

Theleveling probe retracts automatically when the process is done. 7.4 Manual calibration Although the Auto Calibration is always the easiest way to calibrate the UP600, some advanced users may prefer to level manually to have full control of result. 1. At plate leveling interface, click the Manual Leveling button 2. - Page 36 A pop up message will hint user to adjust the platform level. Use the green up and down arrows (single) to increase or decrease platform height. Click “Next” button to Use the nozzle height detector (or a piece paper as feel gauge) to determine the platform height at the measurement point.

-

Page 37: Chapter 8. Introduction To Up Studio 3

Chapter 8. Introduction to UP Studio 3 8.1 Interface Quick Set Bar Program Log Model Layout Buttons Print Preview View Slider Print Setting Switcher Command Field Model list 8.2 Quick Setting Bar Printer Model Layer Thickness Nozzle Diameter Extruder 2 Material Print Quality Extruder 1 Material Support Material (2) - Page 38 Preview Slice Result. The 3D file will be sliced but not saved, the sliced result will appear on file list of right column. The “Print” button. clicking this button will call out the “Wand” hosting module. This button does not initiate printing.

-

Page 39: Support Editor

The support editing result will be shown on the model at real time. Support Types: There are three types of supports in Tiertime’s support generating algorithm. They treated differently and can be edited separately. Support Generated 1. - Page 40 Support the “Tip” features 3. Point support Support Parameters Support List Support Preview View Options Support Angle The overhang angle threshold for support, overhangs less than this angle will not have support generated. Top Layer This determine number of interface layers between the support structure and the surface being supported.

-

Page 41: Support List

Draft Angle = 0 Draft Angle = 50 Min. Area Area threshold of the support structure, overhang surface with area less then the threshold will not be supported. Min. Length Length threshold for the edge support. Edges shorter than the threshold will not be supported. -

Page 42: Print Settings

8.5 Print Settings - Click Gear button to edit current print setting. - Click the “Profile Name” to switch to profile management. The default profile cannot be deleted. User can created new profiles by copying existing profiles and edit upon the copy. Current Print Saved Print Profiles Profile... -

Page 43: User Modes

8.5.1 User Modes Print Setting Mode: Click the button to switch between Basic, Advanced,Expert mode. Basic Mode, the print setting is similar to UP Studio 2. The basic mode although limited but the print settings are highly optimized, with quick selection of basic print parameters, users will able to get excellent print quality. -

Page 44: Introduction To Print Parameters

Please refer to extruder setting for more info on this topic. For most up-to-date details of print settings, please go to Tiertime knowledge base: https://support.tiertime.com/xxxxxxxxx... - Page 45 Inner Outter Perimeter (Blue) Top Layers Perimeter (Green) Infill Support Top Layers Bottom Layers Support 8.6.1. Slicer Settings Unit Term Description Quality Layer Thickness Layer thickness of print, the bigger the thickness the faster the print speed and lower the print quality. Max.

- Page 46 Height: 25-35mm Layer: 1.0 mm Height: 0-10mm Layer: 1.0 mm For regions that are not defined by custom layer thickness, default layer thickness setting will be used. Custom layer thickness will override the adaptive layer function. Path Width Outer Perimeter Line width of the outter most Perimeter Inner Perimeter...

- Page 47 Layer Bottom Layers Set the number of bottom layers Min. Area Threshold area for top and bottom Expand Expand the area of top and bottom. Support Angle Angle Threshold for support, the larger this angle the more support will be generated Layer Layer...

-

Page 48: Path

How much to expand from the perimeter of the bottom layer for the raft layer Mode Raft infill mode, Profile is for Tiertime printer only, the raft is generated by printer. The pattern is not visible at this stage. The hatch and offset are for non-Tiertime printer, Tiertime machines cannot use these 2 types. - Page 49 stable to support but also use more material and more difficult to remove. Full Fill Area Area threshold that override density to full/solid Infill. Area smaller than this value will be printed 100% infill. Infill Path Top/Bottom Fill Infill pattern for Top/Bottom Offset/Zigzag/Line Inner Fill Infill pattern for Inner Fill...

- Page 50 Angle Increase = 30 Layer 1 Layer 2 Layer 3 Final Pattern Angle Increase = 45 Layer 1 Layer 2 Layer 3 Final Pattern Angle Increase = 90 Layer 1 Layer 2 Layer 3 Final Pattern Support Angle 1 Angle of support infill Support Angle 2 Angle of sparse support infill...

-

Page 51: Special

Profile/Fill Overlap Overlap ratio between Perimeter and Infill Bottom Overlap Overlap ratio between Perimeter and infill for the bottom layer 8.6.3.Special Special Options Fill Mode Fill = Perimeter+infill+top/bottom Shell = Perimeter+top/bottom (no infill) Vase = Perimeter only (no infill, no top/bottom) Perimeter Gap Tolerance +0.1 = X and Y plane both increase 0.1mm in size... -

Page 52: Speed

Max. Radius Threshold for applying shrink compensation, holes larger than this diameter value will be ignored. Ratio The bigger this value the more compensation for small holes Max Shrink Set max. Shrink ratio for compensation Entity ID Profile different regions of a print, are marked with an entity ID, so that they can be assign Inner Profile to different extruders to print. - Page 53 8.6.6 Seams Settings Start Optimize Layer Start Preference for layer start point Fixed Start X Define start point on X coordinate. Fixed Start Y Define start point on Y coordinate. Profile Start Preference of Start base perimeter features Join Size Size of join Join Extend How much the join extend and reach into infill area.

- Page 54 Extruder 1 Filament Choose material profiles, from Mat Lib Nozzle Diameter Select the nozzle diameter Scale Factor Extrusion Scale for the extruder (Result similar to E steps) Entity ID Input the entites assigned for this extruder X Offset Offset value for X axis, use for nozzle alignment for multiple extruders Y Offset Offset value for Y axis, use for nozzle alignment for multiple extruders Z Offset...

-

Page 55: Chapter 9. Material Library (Mat Lib) And Custom Materials

Chapter 9. Material Library (Mat Lib) and Custom Materials Filament Select material profile Type Material Type: can only choose from preset types A unique number for matching materials. E.g..Tsk file’s material Material ID ID must match printer’s material ID in order to print. Manufacturer Name of Material manufacturer Fila. -

Page 56: Chapter 10. Part Sub-Setting

Chapter 10. Part Sub-setting Save Mesh Model Print Profile Add Child Model Delete Model Add Child Profile Link to Main Setting Save Mesh Save the model to .UP3 format Delete Model Delete the model from the part list Add a child model, please refer to “Part Optimization” Add Child Model Model Print Profile Click to edit the print profile for the model, settings changed only... - Page 57 Height point range Click the gear button to modify print profile for the height range. chain button to link or unlink from the part profile. Start cross button to delete the child profile. point Setting child profile is same setting of main profile. However some settings are not available in child profiles, eg.

- Page 58 100% ( child (main model) model Support and Raft generation do not apply to child models.

-

Page 59: Chapter 11. "Wand" - The Printer Hosting Software

Chapter 11. “Wand” - the Printer Hosting Software UP Studio 3.0 is a package that includes two softwares; UP Studio now become an independent slicer and the printer hosting functions were spin off into a new software called “Wand” UP Studio 3.0 only handle modeling slicing and all printer communication, operation and maintenance functions are moved to Wand. - Page 60 corresponding X-Y location on the platform. Red square( indicate current location 4. Z-axis Control Z axis indicator: black dot indicate current Z location of print head. click to move print head long Z axis for a small distance click to move the print head long Z axis continuous until reach the end 5.

-

Page 61: Wi-Fi Connection

7.4 Wi-Fi Connection 1, Connect your UP300D with a USB cable to your computer, 2. Open Wand module on your computer and connect to printer. 3. Double click the name of the printer on the printer list on top. This will bring up a network setting window. -

Page 63: Chapter 12. Touchscreen Introduction

Chapter 12. Touchscreen Introduction Tiertime UP600Touchscreen consists of two sections, the Printer Status Bar and theMain Menu. 12.1 Printer Status Bar The Printer Status Bar is at the top of the UP600Touchscreen, which is easy for you to monitor the printer’s status regularly. -

Page 64: Main Menu

12.2 Main Menu There are six buttons in the Main Menu: Material, Print, Calibrate, Information, Config, and Initialize. The following table lists all the information of icons in the Main Menu and summarizes the actions associated with each icon. The printer must be initialize first before printing. Initialize The Material, Calibration and Print buttons on the Main menu of the touchscreen will be greyed out before the printer is properly... -

Page 65: Material

12.3 Material In the material section, there are Extrude, Withdraw, Change Material Type and Set Total Weight buttons functions. To change the material type, click the Material Type button, and then input your filament’s weight by press +/- button. Make sure the material settings properly reflect real situations, because wrong setting could result in print failure or compromised print quality. -

Page 66: Print

12.4 Print In the Print section, you can start a print job or manage the print jobs that currently in the print queue or have finished. H i story Entering the history list of the print jobs which has previously been printed on the printer, or ended with errors. -

Page 67: Calibrate

Pause the on-going print job. Pause Resume the paused print job. Resume The printer will stop the print job completely. Stop To extrude the inserted filament. Extrude To withdraw the inserted filament. Withdraw 12.5 Calibrate The nozzle height of a printer is a key parameter that needs properly set before any print jobs. -

Page 68: Information

12.6 Information In this section, it displays all the information of your printer, which is not editable. Model: The ModelName of your printer’s model. S.N.: Your printer’s ID, which will be required if you look for customer service. ... -

Page 69: Config

12.7 Config Config section contains five parameters, and the Network Settings . Name: it’s the printer’s name, you can change it on the Wand moduel. The default name is the printer’s S.N number. Sound: Toggle the click sound while using touchscreen. Preheat: Toggle the build plate preheating option. -

Page 70: Network Connection

3. Tap the name to connect the Wi-Fi Network. If the WiFi is protected by password, the keypad page will appear to allow password input. 4. The UP600 is connect to the Wi-Fi Network successfully, when the red exclamation mark disappeared, a interlock and Information icon appears. - Page 71 5/20 Ethernet Network Settings: 1. Plug an Ethernet cable to the LAN socket at the back of UP600. 2. The Ethernet connection Status icon should be appear in the Printer Status Bar. 3. You now can go to Network Settings section.

-

Page 72: Chapter 13. Print Boards

Chapter 13. Print Boards There are two build plates in the UP600 package. 13.1 Perf Glass Boards The one with many small holes on one side of the board. Perforated surface has the strongest surface adhesion when used with raft setting. It is made for printing material with high shrinkage ratio that tend to warp during printing and frequently used in conjunction with the HT extruder. -

Page 73: Chapter 13. Extruders

Chapter 13. Extruders UP600 has following extruder options: 1. LT Single Extruder (Included) 2. Convergence Dual Extruder (Optional) 3. HT Single Extruder (Optional) *HT=high temperture, LT=low temperature 14.1 Single Extrusion Print Heads HT Single Extruder There are 2 types of single extruders available: HT type and LT type. -

Page 74: Convergence Dual Extruder

Heater Block Part Cooling Nozzle Convergence Dual is a patented technology by Tiertime. The Convergence hotend has two channels “converge” at one nozzle opening, the two channels can extrude different materials alternately. Since the two extrusions share a single nozzle, there is no need for nozzle alignment calibration. The two... -

Page 75: Chapter 15. Maintenance

Chapter 15. Maintenance 15.1 Replacing Nozzle: 1. Wear heat resistance gloves and use the included nozzle wrench. 2. The nozzle must be removed while the extruder is heated up to near printing temperature. When extruder heated up, use the nozzle wrench to unscrew the nozzle. -

Page 76: Extruder Maintenace

15.3 Extruder Maintenace 15.3.1 Single Extruder 1. Withdraw any filament currently load into the extruder. 2. Remove the cover for CFC cable. 3. Unplug the extruder CFC cable. 4. Usethe include M4 Allen key to unscrew the screw on the left side of the extruder, remove the extruder, and then position the replacement extruder in the right place, tighten the screw, and plug in the extruder cable. - Page 77 Heater Extrusion Module Gear cable Heat Sink Extruder Motor cable Heater Module 6. Remove heater module and heat sink. 1. Remove the 2xM3 screws holding the heat sink to 2. Remove 2xM2.5 screws, remove the printed PCB extruder motor. mount and release the PCB and unplug the heater cable.

-

Page 78: Convergence Dual

15.3.2 Convergence Dual Replacing heater module. Unplug the CFC cable on the extruder. Remove the M4 screw on the right side of the extruder. Unplug the 2 cables of the fans. Pull off the extruder cover. -

Page 79: Releasing The Heater Block

Remove 2xM2.5 hex screws to remove the smaller fan. Remove 4xM3 hex screws above the hotend module. Unplug the 2x cables of heater modules and cut the ziptide to separate the heater module. 15.3.3 Releasing the heater block Remove the mounting block from heater module. - Page 80 Remove the 2xM3 hex screws that press hold the heater block onto the heatsinks. Remove the 4xM2.5 hex screws to release the PEEK filament entrance (brownish part). This will expose the PTFE tube inside the heater block. Remove the 2xM2.5 hex screws from the wind shield so that the heatsink separate into two parts.

-

Page 81: Remove/Replace Stepper Motor

15.3.4 Remove/Replace Stepper Motor The stepper motor’s gearbox may worn out over time. The stepper motor can be replaced invdividually. User may also use this method to clean the extrusion gear, as overtime the gear may be covered with debris of plastics. Remove the 2xM3 hex screws and unplug the correspeonding motor cable from extruder PCB. -

Page 82: Remove The Extrude Block

15.3.5 Remove the extrude block. The extruder block can be remove without disassembling other parts. This Method could be useful for cleaning or fixing a clog. Remove the 2xM2.5 hex screws. Pull out the extruder block, then turn it for so that is it is vertical and remove it from the extrusion mechanism. -

Page 83: Partial Blockage

15.4.1 Partial Blockage A partially blocked extruder will under-extrude and has following symptoms: 1. Spaghetti or spiral like extrusion when use the manual extrude function of Wand. Normally the extrusion should be straight. 2. Extrusion line is thinner and the part produce become very weak and sponge like. 3. -

Page 84: Dual Filtration System

15.4Dual Filtration System UP600 hasHEPA Filter and the Activated Carbon Filter. Both of the filters are located inside the build chamber, circulating the air internally to reduce the toxic particles generated during the 3D printing process. - Page 85 Use a screwdriver to unscrew the 4x screws on the lower panel, remove the cover. Remove the slot cover by loosening 3x screws. The filters casettes will slide down from the filter unit, replace filters and put back the panels.

-

Page 86: Chapter 16. Specification

Supported Materials UP Fila ABS, ABS+, PLA , TPU and more Filament Diameter 1.75mm Filament Spool Compatibility 500 - 1000g Tiertime Print Queue Pause to Change Filament Type Out of Filament Detection Compatible with 3 party Materials Physical dimensions Machine Dimensions 500x523x460 mm (19.6″... -

Page 87: Chapter 17. Customer Service And Community

Chapter 17. Customer Service and Community Support Ticket Email to support@tiertime.com Knowledge Base: https://support.tiertime.com User forum: https://forum.tiertime.com Facebook Group https://www.facebook.com/grou ps/205337203341609/ Facebook Page facebook.com/tiertime Youtube Channel youtube.com/tiertime... - Page 88 Twitter twitter.com/tiertimecorp Instagram instagram.com/tiertime...

- Page 89 FCC warning statements: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

Need help?

Do you have a question about the UP600 and is the answer not in the manual?

Questions and answers