Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for THORLABS LD2000

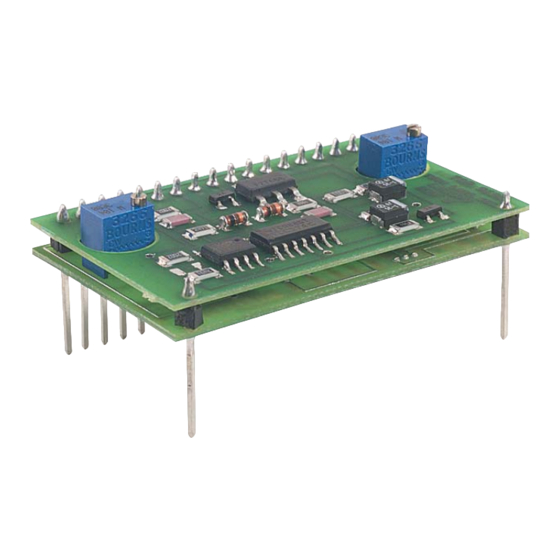

- Page 1 LD2000, LD2000R OEM Laser Diode Driver with Analog Modulation Operating Manual...

-

Page 2: Table Of Contents

Limit Current Circuit ..................4 2.3. Constant Power Feedback Loop ..............4 2.4. Theory of Operation ..................5 Part 3. Operating the LD2000 ................. 7 3.1. Setup ......................... 7 Setting the Feedback Resistor ....................9 3.2. Operating Modes ................... 10 CW Operation ........................ -

Page 3: Part 1. Description

The LD2000 supports a wide range of laser diodes with drive currents up to 100 mA and photodiode currents from 20 µA to 2 mA. The LD2000 also has an external modulation input to support applications that require modulating the laser output. -

Page 4: Part 2. Ld2000 Overview

The comparator input (pin 17, ON/OFF) has an input impedance of 20 kΩ. This resistance is used with an external resistor to form a voltage divider that sets the LD2000 dropout voltage. For most applications a 15 kΩ resistor tied from the 12 V power supply to the ON/OFF pin which disables the laser when the power supply drops below 4.5 V is... -

Page 5: Theory Of Operation

2.4. Theory of Operation The LD2000 uses the internal monitor photodiode provided on most low power diode lasers for feedback when operating in the Constant Power Mode. The following figure is a block diagram of the LD2000 laser driver. - Page 6 Since all analog signal levels are based on a 2.5 V internal reference, we will use this to derive the feedback gain setting resistor value: The LD2000 has an internal transimpedance gain of 20 kΩ. Without a user installed feedback resistor, the transimpedance gain is: = 20 kΩ...

-

Page 7: Part 3. Operating The Ld2000

The pinouts for the LD2000 are provided in Figure 1 and described below. The LD2000 can be used with A, D, or F style diodes. The D and F style diodes will need to be configured like an A style diode (see page 3 for diagrams). - Page 8 LD2000(R) Name Description These pins are provided for connecting an external capacitor to the control loop integrator to extend the integrator time constant. This may be necessary to get maximum bandwidth when using TTL modulation. Connect the positive terminal of the cap to CX2.

-

Page 9: Setting The Feedback Resistor

LD2000(R) Setting the Feedback Resistor The LD2000 is configured at the factory for a maximum feedback gain. This gain setting is appropriate for lasers that have low monitor currents in the range of 20 to 120 μA. For most lasers, the photodiode current is greater than 120 μA and the feedback gain will have to be reduced to drive the laser at full drive current. -

Page 10: Operating Modes

Connect your laser diode to the appropriate pins (11, 12, 13) Attach a suitable DC voltage supply to pins 9 and 10. The power supply should be bypassed near the LD2000 with a 10 µF tantalum capacitor and a 0.1 µF ceramic capacitor. -

Page 11: External Modulation Operation

The laser output will now be controlled by the external modulation voltage. The graph above describes the characteristic of the modulation voltage. If the LD2000 is set up to match a particular laser, the solid curve would represent the output power of the laser as a function of the modulation voltage. - Page 12 LD2000(R) Clipping due to Current Limit being set too low. The turn-off voltage is dependent on matching R to the laser. If the fext feedback gain is too high, the laser will turn off at a lower voltage where RF=R...

-

Page 13: Part 4. Specifications

LD2000(R) Part 4. Specifications Specification Value Current Output Trimpot or external analog voltage Limit Current Control 0 to 100 mA Limit Current Range ±1% Limit Accuracy Compliance Voltage Power Output Trimpot or external analog voltage Photodiode Current Control 20 to 125 μA (Factory configured - see note 1). -

Page 14: Part 5. Regulatory

Waste Treatment is Your Own Responsibility If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized in waste recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site. -

Page 15: Part 6. Thorlabs Worldwide Contacts

LD2000(R) Part 6. Thorlabs Worldwide Contacts USA, Canada, and South America Thorlabs, Inc. 435 Route 206 Newton, NJ 07860 Tel: 973-579-7227 Fax: 973-300-3600 www.thorlabs.com email: feedback@thorlabs.com Europe UK and Ireland Thorlabs GmbH Thorlabs LTD. Hans-Böckler-Str. 6 1 Saint Thomas Place, Ely... - Page 16 Thorlabs, Inc. 435 Route 206N Newton, NJ 07860 USA Phone: (973) 579-7227 ♦ Fax: (973) 300-3600 www.thorlabs.com...

Need help?

Do you have a question about the LD2000 and is the answer not in the manual?

Questions and answers