Subscribe to Our Youtube Channel

Summary of Contents for Samlexpower Evolution EVO-4248SP

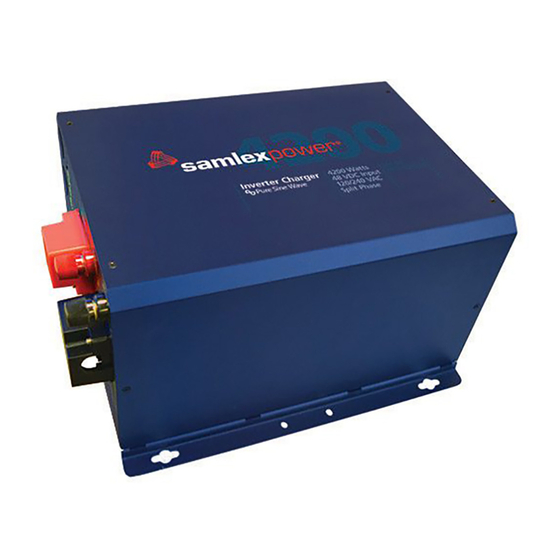

- Page 1 Evolution Series Owner's Please read this manual BEFORE Manual Inverter/Charger operating. Pure Sine Wave Model: EVO-4248SP Firmware: Rev 0.77...

-

Page 2: Table Of Contents

INVERTER/CHARGER MANUAL | Index ™ SECTION 1.1 Safety Instructions ..............3 SECTION 1.2 Definitions ................9 SECTION 1.3 General Information – Inverter Related ......12 SECTION 1.4 General Information – Battery Related ....... 16 SECTION 2 Components & Layout ............30 SECTION 3 Installation ................ -

Page 3: Safety Instructions

SECTION 1.1 | Safety Instructions 1.1 IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS. THIS MANUAL CONTAINS IMPORTANT INSTRUCTIONS FOR MODEL: EVO-4248SP THAT SHALL BE FOLLOWED DURING INSTALLATION & MAINTENANCE OF THE INVERTER/CHARGER. THE FOLLOWING SYMBOLS WILL BE USED IN THIS MANUAL TO HIGHLIGHT SAFETY AND IMPORTANT INFORMATION: WARNING! Indicates possibility of physical harm to the user in case of non-compliance. - Page 4 SECTION 1.1 | Safety Instructions CAUTION! For indoors use only. CAUTION! Hot Surface - To reduce the risk of burns - Do not touch! CAUTION! The AC input / output wiring terminals are intended for field connection using Copper conductors that are to be sized based on 75°C.

- Page 5 SECTION 1.1 | Safety Instructions Lead Acid Batteries Batteries contain very corrosive diluted Sulphuric Acid as electrolyte. Precautions should be taken to prevent – contact with skin, eyes or clothing. Wear eye protection. Batteries generate Hydrogen and Oxygen during charging resulting in evolution of explosive gas mixture. –...

- Page 6 SECTION 1.1 | Safety Instructions l'utilisateur. Voir les lignes directrices à tableau 1.1.1 pour le dimensionnement des disjoncteurs pour les circuits d’entrée CA et le tableau 1.1.2 pour le dimensionnement des disjoncteurs pour les circuits de sortie AC. Codes électriques nationaux et locaux remplaceront ces lignes directrices. ATTENTION! Les bornes de la batterie sont destinés pour le champ Connexion à...

- Page 7 SECTION 1.1 | Safety Instructions provoquer une explosion. Toujours utiliser des outils isolés. Retirer les objets métalliques tels que bagues, bracelets et montres lors de travaux avec des – batteries. Les batteries peuvent produire un courant de court-circuit suffisamment haut pour souder un anneau ou similaires à...

- Page 8 SECTION 1.1 | Safety Instructions Table 1.1.2 AC OUTPUT WIRING AND BREAKERS (Refer to Section 3.9) Rated Output Current in Size of External AC Conductor Size of AC Charging Mode Output Breaker Output Wiring (Column 3) (Column 1) (Column 2) 2-Pole, 120 / 240VAC AWG# 10 TABLE 1.1.3 SIZING OF BATTERY SIDE CABLES AND EXTERNAL BATTERY SIDE FUSES...

-

Page 9: Definitions

SECTION 1.2 | Definitions The following definitions are used in this manual for explaining various electrical concepts, specifications and operations: Peak Value: It is the maximum value of electrical parameter like voltage / current. RMS (Root Mean Square) Value: It is a statistical average value of a quantity that varies in value with respect to time. - Page 10 SECTION 1.2 | Definitions Impedance, Z: It is the vectorial sum of Resistance and Reactance vectors in a circuit. Active Power (P), Watts: It is denoted as “P” and the unit is “Watt”. It is the power that is consumed in the resistive elements of the load.

- Page 11 SECTION 1.2 | Definitions • Devices like (i) Infrared Quartz Halogen Heaters (also used in Laser Printers) / Quartz Halogen Lights / Incandescent Light Bulbs using Tungsten heating elements and (ii) PTC Ceramic Heaters: Tungsten and PTC Ceramic have a very high Positive Temperature Coefficient of Resistance i.e. it has lower resistance when cold and higher resistance when hot.

-

Page 12: General Information - Inverter Related

SECTION 1.3 | General Information – Inverter Related 1.3 GENERAL INFORMATION - INVERTER RELATED General information related to operation and sizing of inverters is given in succeeding sub-sections. 1.3.1 AC Voltage Waveforms = 169.68V (for 120 V ) or, 339.36V (for 240 V peak 240 V 120 V... - Page 13 SECTION 1.3 | General Information – Inverter Related 1.3.2 Advantages of Pure Sine Wave Inverters – The output waveform is a Sine Wave with very low harmonic distortion and cleaner power like Grid / Utility supplied electricity. – Inductive loads like microwaves, motors, transformers etc. run faster, quieter and cooler. –...

- Page 14 SECTION 1.3 | General Information – Inverter Related INFO The manufacturers’ specification for power rating of AC appliances and devices indicates only the Maximum Continuous Running Power Rating. The Starting Surge Power required by some specific types of devices as explained has to be determined by actual testing or by checking with the manufacturer.

- Page 15 SECTION 1.3 | General Information – Inverter Related used in accordance with the instruction manual, may cause harmful interference to radio communications. The effects of EMI will also depend upon a number of factors external to the inverter like proximity of the inverter to the EMI receptors, types and quality of connecting wires and cables etc.

-

Page 16: General Information - Battery Related

SECTION 1.3 | General Information – Inverter Related NOTE: Voltage and Current scales are di erent Input voltage Peak Inrush Current Rated Steady State Input RMS Current Inrush current Fig 1.3.2 Inrush current in an SMPS Peak Current NOTE: Voltage and Non-linear Current scales Input Current... - Page 17 SECTION 1.4 | General Information – Battery Related independent enclosed compartment that has Positive and Negative Plates (also called Electrodes) dipped in electrolyte that is composed of diluted Sulphuric Acid. Battery Packs are available with nominal voltages of 2V, 4V, 6V, 8V and 12V. 1.4.1.2 A fully charged Lead Acid Battery comprises of (i) Positive Plates: Lead Dioxide (PbO ), (ii) Negative Plates:...

- Page 18 SECTION 1.4 | General Information – Battery Related 1.4.3 BATTERY CHARGING STAGES: General descriptions of 4 stages of battery charging are given at Sections 1.4.3.1 to 1.4.3.4. Depending upon the type of battery and its application, different Charging Profiles can be created using appropriate charging stages. NOTE: 7 types of Charging Profiles are available in EVO Series through programming parameter "CHARGING PROFILE".

- Page 19 SECTION 1.4 | General Information – Battery Related c) Using Adaptive Charging Algorithm: This ensures that the battery is completely charged in a safe manner for longer battery life (Suitable for battery that does not have load connected to it). In this algorithm, the time the battery remains in Absorption and Equalization Stages is automatically made proportional to the time the battery remains in the Bulk Charge Stage.

- Page 20 SECTION 1.4 | General Information – Battery Related 1.4.4.1 Sulfation: Section 1.4.1.2 gives details of basic electrochemical reactions during charging and discharging. If the charging process is not complete due to the inability of the charger to provide the required voltage levels or if the battery is left uncharged for a long duration of time, the soft Lead Sulfate (PbSO ) crystals on the Positive and Negative plates that are formed during discharging / self discharge are not fully converted back to Lead Dioxide (PbO...

- Page 21 SECTION 1.4 | General Information – Battery Related 1.4.5.2 Rise / fall in the temperature of the electrolyte with respect to the Standard Room Temperature of 77º F / 25º C will require temperature compensation. Charging voltages will be required to be reduced at higher electrolyte temperature and increased at lower electrolyte temperature with respect to the Standard Room Temperature of 77º...

- Page 22 SECTION 1.4 | General Information – Battery Related corresponding to 20 Hour discharge period. The rated capacity “C” in Ah in this case will be the number of Amperes of current the battery can deliver for 20 Hours at 80ºF (26.7ºC) till the voltage drops to 1.75V / Cell. i.e. (i)10.5V for 12V Battery Pack/ Bank or (ii) 21V for 24V Battery Bank or, (iii) 42V for 48V Battery Bank.

- Page 23 SECTION 1.4 | General Information – Battery Related 1.4.10.3 Example for Determining C-rate of Discharge for Particular Value of Discharge Current: • Determine the Ah capacity (C) of the battery – say 100 Ah (C=100) • Determine the value of discharge current – say 20 Amperes •...

- Page 24 SECTION 1.4 | General Information – Battery Related Typical 12V/24V/48V Flooded Lead-Acid Battery Chart - 80˚F / 26.7˚C 24V 12V 66.0 33.0 16.5 C/10 64.0 32.0 16.0 CHARGE C/20 62.0 31.0 15.5 C/40 60.0 30.0 15.0 58.0 29.0 14.5 56.0 28.0 14.0 54.0...

- Page 25 SECTION 1.4 | General Information – Battery Related Table 1.4.3 shows that a 100 Ah capacity battery will deliver 100% (i.e. full 100 Ah) capacity if it is slowly discharged over 20 Hours at the rate of 5 Amperes (50W output for a 12V inverter, 50 and 100W output for a 24V inverter and 200W output for 48V inverter).

- Page 26 SECTION 1.4 | General Information – Battery Related Inverters are provided with a buzzer alarm to warn that the loaded battery has been deeply discharged to around 80% of the rated capacity. Normally, the buzzer alarm is triggered when the voltage at the DC input terminals of the inverter has dropped to around (i) 10.5V for a 12V battery pack/ battery bank or, (ii) 21V for 24V battery bank or, (iii) 42V for 48V battery bank at C-rate discharge current of C/5 Amps and electrolyte temp.

- Page 27 SECTION 1.4 | General Information – Battery Related In view of the above, it may be seen that a fixed Low DC Input Voltage Alarm is not useful. Temperature of the battery further complicates the situation. All the above analysis is based on battery electrolyte temperature of 80°F.

- Page 28 SECTION 1.4 | General Information – Battery Related INFO Series Inverter/ Chargers have a programmable Low DC Input Voltage Shutdown that can be set to specific operating conditions using programming parameter "BATT LOW VOLTAGE". (See Table 6.2 under Section 6.4.1 and Section 4.4.2.9 of Owner's Manual for Remote Control Model EVO-RC-PLUS) 1.4.15 DEPTH OF DISCHARGE OF BATTERY AND BATTERY LIFE The more deeply a battery is discharged on each cycle, the shorter the battery life.

- Page 29 SECTION 1.4 | General Information – Battery Related Next, the energy required by the load in Ampere Hours (Ah) is determined. For example, if the load is to operate for 3 hours then as per Formula 3, the energy to be delivered by the 48V batteries = 25 Amperes ×...

-

Page 30: Components & Layout

SECTION 2 | Components & Layout 2. LAYOUT 2.1 LAYOUT – FRONT VIEW 12 13 FAULT ON/OFF Status EXT. Charger + EXT. Charger - Common Relay + Remote - ON/OFF + 12V - Output Black + Battery Positive Comm1 Comm 2 Comm 3 Comm 4 - Battery Negative... - Page 31 SECTION 2 | Components & Layout 2.2 LAYOUT OF EVO-4248SP – BACK VIEW Fig 2.2 Layout - Back Legend for Fig 2.2 1. Air outlet vents for 2 variable speed, temperature controlled cooling fans (fans are not shown). 2.3 LAYOUT OF AC WIRING COMPARTMENT Removable Cover Plate Output Input...

- Page 32 SECTION 2 | Components & Layout 2.4 REMOTE CONTROL EVO-RC-PLUS Fault Fig 2.4(a) Optional Remote Control EVO-RC-PLUS LEGEND for Fig 2.3 1. LCD Screen: - 4 rows of 20 characters each - Blue screen with white characters 2. ON/OFF Key 3.

- Page 33 SECTION 2 | Components & Layout 2.5 BATTERY TEMPERATURE SENSOR EVO-BCTS [FIG 2.5(a)] Temperature Sensor [Negative Temperature Coefficient (NTC) resistor]: Mounting hole: 10mm/0.39” suitable for 3/8” or 5/16” battery studs 1. RJ-45 Plug: Pins 1 to 4 Ò + NTC ; Pins 5 to 8 Ò – NTC (See pinout of mating RJ-45 Jack Fig 3.12) 2.

-

Page 34: Installation

SECTION 3 | Installation 3.1 SAFETY OF INSTALLATION WARNING! Ensure safety instructions given under Section 1 are strictly followed. MISE EN GARDE Se il vous plaît assurer consignes de sécurité fournies à la section 1 sont strictement suivies. 3.2 OVERALL DIMENSIONS The overall dimensions and the location of the mounting holes are shown in Fig. - Page 35 SECTION 3 | Installation 3.3 MOUNTING OF THE UNIT In order to meet the regulatory safety requirements, the mounting has to satisfy the following requirements: • Mount on a non-combustible material • The mounting surface should be able to support a weight of 3 times the weight of the inverter for 1 minute. Use 4 pcs of 1/4"...

- Page 36 SECTION 3 | Installation • Mounting Arrangement No. 2: Mount horizontally on a vertical surface (like a wall). Fig 3.3 Mounting Arrangement 2: On Vertical Surface • Mounting Arrangement No. 3: Mount vertically on a vertical surface. Protect against possibility of small objects or water entering the ventila- tion openings on the top.

- Page 37 SECTION 3 | Installation 3.4 INSTALLING BATTERIES - SERIES AND PARALLEL CONNECTION Batteries are normally available in voltages of 2V, 6V and 12V and with different Ah capacities. A number of individual batteries can be connected in series and in parallel to form a bank of batteries with the desired increased voltage and capacity.

- Page 38 SECTION 3 | Installation 3.4.3 Series – Parallel Connection 24V String 1 24V String 2 Battery Bank 1 Battery Bank 2 Battery Bank 3 Battery Bank 4 Cable “A” 48V Inverter or 48V Charger Battery Bank Battery Bank Battery Bank Battery Bank Cable “B”...

- Page 39 SECTION 3 | Installation The resistances of the connecting cables will not be balanced. The individual batteries will see different series resistances. All the individual batteries will be charged/discharged at different charging/discharging current and thus, will reach fully charged/discharged state at different times. The battery with lower series resistance will take shorter time to charge/discharge as compared to the battery which sees higher series resistance and hence, will experience over charging/over discharging and its life will be reduced.

- Page 40 SECTION 3 | Installation 3.5 DC SIDE CONNECTIONS FAULT ON/OFF Status EXT. Charger + EXT. Charger - Common Relay + Remote - ON/OFF + 12V - Output + Battery Positive Comm1 Comm 2 Comm 3 Comm 4 Black - Battery Negative Battery Temp Remote Sensor...

- Page 41 SECTION 3 | Installation 3.5.0 Making DC Side Connections The following DC side connections are required to be made [See Figs 3.8(a) & 3.8(b)]: 48VDC battery bank is connected to the battery input terminals [1 & 2 in Figs 3.8(a) & 3.8(b)]. The terminals are –...

- Page 42 SECTION 3 | Installation 3.5.3 Connection From Batteries / External Charge Controller To The DC Input Side – Sizing of Cables And Fuses WARNING! The input section of the inverter has large value capacitors connected across the input terminals. As soon as the DC input connection loop (Battery (+) terminal → Fuse → Positive input terminal of EVO™...

- Page 43 SECTION 3 | Installation Effects of low voltage on common electrical loads are given below: • Lighting circuits - incandescent and Quartz Halogen: A 5% voltage drop causes an approximate 10% loss in light output. This is because the bulb not only receives less power, but the cooler filament drops from white-hot towards red-hot, emitting much less visible light.

- Page 44 SECTION 3 | Installation 3.5.6 DC Input Connection for External Solar Charge Controller External charger is connected to terminals consisting of M8 Stud with Thumb Nut [3, 4 in Fig. 3.8 (a)]. - Max current fed through these terminals should be < 100A - Use wire size given in Table 3.1.

- Page 45 SECTION 3 | Installation a) The Ampere rating of the fuse is not less than NEC Ampacity of 125% of the Rated Continuous DC Input Current (Column 3) - Refer to NEC-2014 (National Electrical Code) - Section 215.3 b) Standard Ampere Rating of Fuse equal to the above NEC Ampacity of 125% of the Rated DC Input Current has been used - Refer to NEC-2014 (National Electrical Code) - Section 240.6(A) c) Where Standard Fuse Rating does not match the required Ampacity of 125% of the Rated Continuous DC Input Current (Column 3), the next higher Standard Rating of the fuse has been used - Refer to NEC-2014...

- Page 46 SECTION 3 | Installation 2. Avant d'effectuer des connexions CA, assurez-vous que l'appareil est déconnecté du groupe de batteries et qu'aucune alimentation CA n'est connectée à l'appareil. 3. La sortie CA de l'unité ne doit jamais être connectée à une source d'alimentation CA. Cela pourrait endommager gravement l'appareil et ces dommages ne seront pas couverts par la garantie.

- Page 47 SECTION 3 | Installation 3.6.1.2 AC Input Connections for 120VAC Single Phase AC Input Source CAUTION! Please observe the following CAUTIONS! when the input voltage of the unit is 120VAC Single Phase (fed through 30A, 1-Pole 120V Breaker): 1. Please ensure that value of charging current set through programming parameter “BULK CURRENT” (Section 4.4.2.1 of Owner’s Manual for Remote Control Model EVO-RC-PLUS) is set to 30A or less.

- Page 48 SECTION 3 | Installation 3.6.3 System Grounding and Output Neutral to Chassis Ground Bond Switching WARNING! • In "Inverting Mode" (default condition), the Neutral of the AC output of the unit gets bonded to the metal chassis of the unit through the internal “Neutral to Chassis Switching Relay” [Relay RY-5 in Fig 4.1]. •...

- Page 49 SECTION 3 | Installation result in parallel operation of different power sources and AC power from the other AC source will be fed back into the unit which will instantly damage the output section of the unit and may also pose a fire and safety hazard.

- Page 50 SECTION 3 | Installation MISE EN GARDE! Veuillez vous assurer que l'entrée CA est connecté à l'entrée aux bornes et non pas à l'AC bornes de sortie et que cette connexion est effectuée uniquement lorsque l'appareil est en position d'arrêt. Lorsque l'unité...

- Page 51 SECTION 3 | Installation MISE EN GARDE! Pour EVO-4248SP, Breaker AC pour les circuits d’entrée AC ont pas été fournis en interne. Cela doit être fournie en externe par l’installateur / utilisateur en fonction des directives données ci-dessous. Se il vous plaît noter que les directives ci-dessous sur dimensionnement des câbles et protection contre les surintensités seront remplacées par les nationaux / codes électriques locaux applicables.

- Page 52 SECTION 3 | Installation Table 3.3 provides details of wire and breaker sizing for the AC output side for EVO-4248SP. TABLE 3.3 SIZING OF AC OUTPUT WIRING AND BREAKERS Rated AC Pass Through Current in Size of External AC Conductor Size of AC Charging Mode Output Breaker Output Wiring...

- Page 53 SECTION 3 | Installation 3.12 GROUNDING ARRANGEMENT Internally, EVO™ consists of DC and AC Section that are isolated through a transformer (See Transformer T-1 in Fig 3.13). Both these sections are required to be grounded appropriately. For wiring details for appropriate grounding, refer to Fig 3.13, and associated explanation under Sections 3.13 and 3.14. When using a generator instead of Grid, please ensure that the Neutral of the generator is bonded to the metal frame of the generator and the metal frame of the generator is bonded to Earth Ground through the Grounding Electrode (GE) i.e.

- Page 54 SECTION 3 | Installation Battery Negative, the chassis of the DC Electrical Panel and the metal chassis of the EVO™ will all be bonded to the Earth Ground. Connect the DC Grounding Terminal (Figs 2.1 and 3.8), to the Grounded Bus Bar (G-B) in the DC Electrical Panel using AWG #6 insulated stranded copper wire.

- Page 55 SECTION 3 | Installation • The “INPUT GND” Terminal (8A, Fig 3.9) of the AC Input / Output Terminal Block in EVO™ gets connected to the Grounded Bus Bar (G-B) in the Grid Electrical Panel (AC PANEL 1) through the grounding wire of AC input connection •...

- Page 56 SECTION 3 | Installation 3.15.2 Constructional Details and Installation The Temperature Sensor consists of 5 meters / 16.5 ft cable with Temperature Sensor Head for the battery end [1 in Fig 2.5(a)] and RJ-45 Plug [2 in Fig 2.5(a)] for EVO end.

- Page 57 SECTION 3 | Installation Charging voltages of Lithium Ion Battery are not affected by temperature and hence, Battery Temperature Sensor Model EVO-BCTS must NOT be used when Lithium Ion batteries are used. The RJ-45 Jack marked "Battery Temp Sensor" [6, Fig 2.1] can be used to feed control signals from certain Lithium Ion Battery Management Systems (BMS) that may have capability of enabling / disabling “Stop Charging”...

- Page 58 SECTION 3 | Installation 58 | SAMLEX AMERICA INC.

- Page 59 SECTION 3 | Installation LEGEND FOR FIG 3.13 NOTES: For sizing of wiring and fuses, refer to the following: a) DC side wiring: Table 3.1 b) AC side wiring: Table 3.2 for AC input and Table 3.3 for AC output c) For details regarding 120 VAC Single Phase Input, see Section 3.6.1.2 AC Panel 1.

-

Page 60: General Description & Principles Of Operation

SECTION 4 | General Description & Principles of Operation 4.1 GENERAL DESCRIPTION EVO-4248SP is a Low Frequency Type, Pure Sine Wave, 120 / 240 VAC Split Phase Inverter-Charger with built-in Transfer Relays (Section 4.4.2). It uses high performance, 100MHz DSP (Digital Signal Processing) type of micro- controller and Pulse Width Modulation (PWM) control. - Page 61 SECTION 4 | General Description & Principles of Operation 4.3.1 Principle of working of Inverter Section Low DC voltage from the DC Battery Source is inverted to AC voltage in two steps. Low DC voltage from the DC Battery Source is first converted to low frequency (60 Hz), low voltage synthesized sine wave AC using Mosfet based H-bridge configuration and high frequency (30 KHz) PWM (Pulse Width Modulation) technique.

- Page 62 SECTION 4 | General Description & Principles of Operation 4.5.2 Operation of Transfer Relays (RY-1 to RY-4) and Neutral to Ground Bond Switching Relay (RY-5) Refer to the connection diagram at Fig 4.1. Operation is explained in the succeeding Sections 4.5.2(A) to 4.5.2(E) 4.5.2(A) 240VAC Split Phase input from Grid / Utility is available (within the programmed limits of voltage and frequency) •...

- Page 63 SECTION 4 | General Description & Principles of Operation 4.5.2(D) Automatic Switching On /Off of Bonding Between the Output Neutral and Metal Chassis Ground of the Unit In EVO-4248SP Inverter Charger, both the Input / Output Neutral Terminals (4,5 in Fig 4.1) are connected to the same common Neutral of the Bi-directional Input / Output Transformer (Fig 4.1).

- Page 64 SECTION 4 | General Description & Principles of Operation LEGEND for Fig 4.1 RY-1, RY-2, RY-3, Transfer Relays for Lines L1 and L2 Specifications: RY-4 • SPDT (Single Pole, Double Throw), 277VAC, 40A o Contacts 3,4: Normally Open (NO) • Open when the relay is OFF •...

- Page 65 SECTION 4 | General Description & Principles of Operation 4.5.2.1 Synchronized Transfer of Power 4.5.2.1.1 General information When the frequency and phase of output voltages of two AC power sources are the same (in sync), the two AC sources are considered to be “synchronized”. Critical AC loads require un-interruptible AC input power.

- Page 66 SECTION 4 | General Description & Principles of Operation Transfer From Inverter Section to AC Input Source 4.5.2.1.3 When power from AC input source is made available, its voltage and frequency are monitored for 2 sec to check if these are within the programmed limits. If yes, the output voltage of the Inverter Section is synchronized with the AC input source.

- Page 67 SECTION 4 | General Description & Principles of Operation INFO It is recommended that “GSCM-Mini” Series of Generator Start / Stop Control Module, appropriate for the generator to be used, may ordered directly from Atkinson Electronics www.atkinsonelectronics.com Based on the Generator Start Logic contained in of one of the selected Options 2, 3 or 4 (under programming parameter "RELAY FUNCTION") [See Sections 4.8.2.5.2 in EVO-RC-PLUS Remote Control Manual], the Status Relay will be switched ON (energized), its “Common”...

- Page 68 SECTION 4 | General Description & Principles of Operation The “No Load Power Draw” of EVO-4248SP in the Normal Operating Mode is <30W. The EVO-4248SP has an optional programmable operating mode called “Power Saving Mode” that is designed to reduce this “No Load Power Draw” to less than 8W during conditions where the Inverter Section is ON but is not supplying any load [Applicable only when the unit is operating in “Inverting Mode”].

- Page 69 SECTION 4 | General Description & Principles of Operation INFO Power Saving Mode should be disabled for the following loads: • Low power loads that draw less than 5W e.g. digital clocks, satellite receivers, phones / answering machines etc. • Audio / video / computing devices that consume normal operating power >...

- Page 70 SECTION 4 | General Description & Principles of Operation Value of charging current produced by Programmed value of charging current set by pa- EVO™ Charging Section rameter “BULK CURRENT” [See Section 4.4.2.1 of EVO-RC-PLUS Remote Control Manual] minus the value of current fed from the external solar charge controller When AC input fails or, is not within the programmed values of voltage and frequency, the unit will change over to “Inverting Mode”...

- Page 71 SECTION 4 | General Description & Principles of Operation will switch back from "Charging Mode" to "Inverting Mode" when the batteries have charged to the voltage threshold set by parameter "RESET VOLTAGE"[See Section 4.4.2.7 in the EVO-RC-PLUS Remote Control Manual] and have remained at this threshold or higher for time period set by parameter "GEN OFF DELAY"...

- Page 72 SECTION 4 | General Description & Principles of Operation ATTENTION! 1. Le chargement au lithium-ion ne nécessite pas de compensation de température. Par conséquent, n'utilisez pas le capteur de température EVO-BCTS lors du chargement de batteries au lithium-ion. 2. La compensation automatique de température à l'aide du capteur de température EVO-BCTS est conçue pour les batteries au plomb selon le paramètre de programmation "COMPENSATE"...

- Page 73 SECTION 4 | General Description & Principles of Operation 4.12 OPTIONAL REMOTE CONTROL EVO-RC-PLUS FOR PROGRAMMING OF MODES OF OPERATION AND PARAMETERS Optional Remote Control Model EVO-RC-PLUS [Fig 2.4(a)] will be required for more advanced control and monitoring. Please see separate Owner’s Manual for EVO-RC-PLUS. The Remote Control comes with 10M / 33 ft., RJ-45 Data Cable. The Remote plugs into RJ-45 Jack on the front panel of the unit (7, Fig 2.1).

-

Page 74: Battery Charging In Evolution Series

SECTION 5 | Battery Charging in Evolution™ Series 5.1 PRINCIPLES OF OPERATION OF BATTERY CHARGING SECTION INFO For background information on batteries and charging process, please read Section 1.4, “General Information - Battery Related”. All battery charging voltages are specified at battery temperature of 25˚C / 77˚F. - Page 75 SECTION 5 | Battery Charging in Evolution™ Series two Low-Side Mosfet Switches are switched OFF, short circuit of the winding is removed resulting in collapse of the magnetic field and generation of induced voltage pulses at PWM frequency of 30 kHz with a value = - L di/dt where “L”...

- Page 76 SECTION 5 | Battery Charging in Evolution™ Series capacity. This situation is prevented by “Dynamic AC Input Current Diversion Control between AC Pass through Current and Battery Charging Current”. This is accomplished through appropriate setting of programmable parameters “GRID MAX CURRENT”. Optional Remote Control Model EVO-RC-PLUS will be required for the above setting [Please refer to Section 4.5.2.2 of the EVO-RC-PLUS Remote Control Manual].

- Page 77 SECTION 5 | Battery Charging in Evolution™ Series 4) If now, the AC pass-through Line Current is increased from 9A to 12A for more than 5 sec, the total AC input Line Current will be 13A (12A pass through Line Current + 1A AC side charging current corresponding to 3.42A DC side charging current).

- Page 78 SECTION 5 | Battery Charging in Evolution™ Series This is the default setting. Under this setting, the total charging current will be as follows: Total Charging Current = Charging current from External Charge Controller PLUS adjusted charging • current from the Internal AC Charger Adjusted Charging current from the Internal AC Charger = Programmed value of Parameter “BULK CURRENT”...

- Page 79 SECTION 5 | Battery Charging in Evolution™ Series ATTENTION! S'assurer que la charge de tension, les paramètres connexes d'EVO comme (i) La tension d'absorption, (ii) EQUALIZE VOLTAGE, (iii) Tension d'égaliser et (iv) La compensation de température (COMPENSATE) est réglée / programmée pour correspondre aux paramètres programmés du contrôleur de charge externe. [Veuillez consulter (i) le tableau 6.2, section 6 et (ii) les sections 4.4.2.2 à...

- Page 80 SECTION 5 | Battery Charging in Evolution™ Series Temperature Sensor Head [1 in Fig 2.5(a)]: The Temperature Sensor Head is installed on the Positive / Negative battery Stud [Fig 2.5(b)] to monitor the temperature of the battery electrolyte. The Sensor Head contains an embedded Negative Temperature Coefficient (NTC) Resistor with 2 internal terminals “NTC+”...

- Page 81 SECTION 5 | Battery Charging in Evolution™ Series 0 = 3 Stage Adaptive (Default) Refer to the following for more details: 1 = 3 Stage Type 1 • Section 5.7 for description and charging curves for 2 = 3 Stage Type 2 3-Stage Charging Profiles 3 = 2 Stage Type 1 •...

- Page 82 SECTION 5 | Battery Charging in Evolution™ Series TABLE 5.2 3 TYPES OF CHARGING PROFILE OPTIONS FOR 3-STAGE CHARGING Options under Programming Parameter “CHARGING PROFILE” Charging Stages Battery Type (See Section 4.4.2.21 in EVO-RC-PLIS Remote Control Manual) 1. Stage 1 – Bulk Stage (See Section 5.7.1.1 for details) 0 = 3 Stage Adaptive −...

- Page 83 SECTION 5 | Battery Charging in Evolution™ Series 3. Stage 3 - Float Stage (See Section 5.7.3 for details) • Charge at constant voltage (CV) = the programmed value of parameter “FLOAT VOLTAGE”. (Default value is 54.0V. For details of programming range & procedure, refer to Section 4.4.2.4 of EVO-RC-PLUS Remote Control Manual) •...

- Page 84 SECTION 5 | Battery Charging in Evolution™ Series This current is delivered to the batteries until the battery voltage approaches its Gassing Voltage i.e. Absorption Voltage which is typically around 57.6 volts for 48 volt batteries. The desired value can be programmed using the optional Remote Control EVO-RC-PLUS [Refer to parameter "ABSORP VOLTAGE"...

- Page 85 SECTION 5 | Battery Charging in Evolution™ Series The value of the "BULK CURRENT" (“Io”) depends upon the total Ampere Hour (Ah) capacity of the battery or bank of batteries. A battery should never be charged at very high charging current as very high rate of charging will not return the full 100 percent capacity as the Gassing Voltage rises with higher charging current.

- Page 86 SECTION 5 | Battery Charging in Evolution™ Series For 3-Stage Adaptive Charging Profile Option "0=3 Stage Adaptive" (See Srl. No. 1 in Table 5.2), T1 Timer (explained under Bulk Stage in Section 5.7.1.1 and Fig 5.1) computes the time of charging in this stage as follows: •...

- Page 87 SECTION 5 | Battery Charging in Evolution™ Series 5.8 4 STAGE ADAPTIVE CHARGING PROFILE - EQUALIZATION CAUTION! 4-Stage Adaptive Charging Profile - Equalization should be used only for vented, flooded (non-sealed or “wet”) batteries and not on sealed AGM / Gel Cell / Nickel-Zinc (Ni-Zn) / Lithium batteries and only as often as recommended by the battery manufacturer.

- Page 88 SECTION 5 | Battery Charging in Evolution™ Series BULK ABSORPTION EQUALIZATION STAGE 4 Displayed as: Displayed as: Displayed as: (Refer to Notes 3 & 4) “E-Bulk Stage” “E-Absorption Stage” “E-Equalization Stage” - 0.3V) Set value of Absorp Equalization Voltage FOR STAGE 4 DETAILS, REFER TO NOTES 3 &...

- Page 89 SECTION 5 | Battery Charging in Evolution™ Series 5.8.2.1 Stage 1 – Bulk Charge Stage under 4-Stage Adaptive Charging Profile - Equalization Refer to Section 1.4.3.1 for general information on Bulk Charge Stage and to Fig 5.2 for voltage and current curves during this stage.

- Page 90 SECTION 5 | Battery Charging in Evolution™ Series 5.8.2.2 Stage 2 – Adaptive Absorption Stage under 4-Stage Adaptive Charging Profile - Equalization Refer Section 1.4.3.2 for general information on Absorption Stage and to Fig 5.2 for voltage and current curves during this stage.

- Page 91 SECTION 5 | Battery Charging in Evolution™ Series EXAMPLE BASED ON TABLE 5.2.1 Assume that 4-Stage Charging Profile for Equalization was switched on when 3-Stage Adaptive Charging Profile option “0= 3 Stage Type 0” was active [Column (1), Table 5.2.1]. In this Charging Profile, the last i.e. the 3rd Stage is FLOAT [Column (2), Table 5.2.1].

- Page 92 SECTION 5 | Battery Charging in Evolution™ Series NOTE: Procedure described is to be used when the optional Remote Control EVO-RC-PLUS has NOT been plugged into the RJ-45 Remote Control Jack (7, Fig 2.1). Please note if the Remote Control has been plugged into the RJ-45 Jack, the above procedure cannot be activated and the ON/OFF of Equalization Profile will be controlled by the Remote Control EVO-RC-PLUS.

- Page 93 SECTION 5 | Battery Charging in Evolution™ Series BULK ABSORPTION CHARGER STAGE STAGE Displayed as: Displayed as: Displayed as: “3-Bulk Stage” “3-Absorption Stage” “3-Charger Off” V=”ABSORP VOLTAGE” BULK CURRENT, =” ” ” ” 100% “RESET TO BULK” “ABSORP TIME” TIME LEGEND for Fig 5.3 —————...

- Page 94 SECTION 5 | Battery Charging in Evolution™ Series BULK ABSORPTION STAGE (*See NOTE 4) STAGE Displayed as: Displayed as: “4-Bulk Stage” “4-Absorption Stage” V=”ABSORP VOLTAGE” BULK CURRENT, =” ” 100% ” ” TIME LEGEND for Fig 5.4 ————— Voltage (V) Curve •...

- Page 95 SECTION 5 | Battery Charging in Evolution™ Series ABSORPTION BULK CHARGER STAGE STAGE Displayed as: Displayed as: Displayed as: “5-Bulk Stage” “5-Absorption Stage” “5-Charger Off” V=”ABSORP VOLTAGE” BULK CURRENT, =” ” 100% ” ” “RESET TO BULK” “ABSORP EXIT AMPS” TIME LEGEND for Fig 5.5 —————...

- Page 96 SECTION 5 | Battery Charging in Evolution™ Series TABLE 5.3 3 TYPES OF CHARGING PROFILE OPTIONS FOR 2-STAGE CHARGING Options under Programming Parameter “CHARGING PROFILE” Charging Stages Battery Type (See Section 4.4.2.21 in EVO-RC-PLUS Remote Control Manual) 3=2Stage Type1 1. Stage 1 – Bulk Stage (See Section 5.7.1.1) −...

- Page 97 SECTION 5 | Battery Charging in Evolution™ Series 5=2Stage Type3 1. Stage 1 – Bulk Stage (See Section 5.7.1.1) − Lithium (See Section 5.11) • Charge at constant current = the programmed value of parameter “BULK CURRENT” (Default value is 20A. For details of REFER TO FIG 5.5 FOR VOLTAGE- −...

- Page 98 SECTION 5 | Battery Charging in Evolution™ Series 5.11.1 Charging Profiles for Lithium Batteries Programming parameter “CHARGING PROFILE” is used to select up to 5 programming options for 2/3-Stage charging profiles for Lithium Ion Batteries. Details are given in Table below: Srl.

- Page 99 SECTION 5 | Battery Charging in Evolution™ Series b) Wiring Connection: Output from the SSR Terminals on the Lithium Battery BMS should be wired to the RJ- 45 Jack marked “Battery Temp. Sensor” (6, Fig 2.1) as follows: • Connect terminal marked “+” on the SSR (Drain of Mosfet switch inside SSR) to any of pins 1/2/3/4 of RJ-45 Jack (Pinout shown at Fig 5.6) •...

- Page 100 SECTION 5 | Battery Charging in Evolution™ Series CAUTIONS! a) Please ensure that all safety instructions at Section 1 of this manual are read and understood before operating the unit b) Please ensure that the unit has been installed properly as per instructions at Section 3 of this manual ATTENTIONS! a) Veuillez vous assurer que toutes les instructions de sécurité...

-

Page 101: Operation, Protections & Troubleshooting

SECTION 6 | Operation, Protections and Troubleshooting 6.1 POWERING ON / POWERING OFF USING FRONT PANEL ON/OFF BUTTON (11, FIG 2.1) CAUTIONS! a) Please ensure that all safety instructions at Section 1 of this manual are read and understood before operating the unit b) Please ensure that the unit has been installed properly as per instructions at Section 3 of this manual ATTENTIONS! - Page 102 SECTION 6 | Operation, Protections and Troubleshooting 6.1.3 Power off Sequence: 6.1.3.1 Power off Sequence when AC Input is in Switched Off Condition / Not Connected: When the AC input is in switched Off condition / not connected and the unit is in ON condition, the unit will be operating in Inverting Mode and the Blue LED marked will be in steady ON condition.

- Page 103 SECTION 6 | Operation, Protections and Troubleshooting Manual for Remote Control EVO-RC-PLUS) • When the EVO is in Off condition, momentary feeding of +12V signal through the external Push Button for > 2 sec will turn the unit On. The EVO™ will remain ON even when the Push Button is released •...

- Page 104 SECTION 6 | Operation, Protections and Troubleshooting Optional Remote Control Model EVO-RC-PLUS will be required for more detailed messaging that is available through its LCD display and LEDs. This remote will also be required for programming of various parameters to suit specific requirements. TABLE 6.1 FRONT PANEL LED AND BUZZER INDICATIONS Blue LED...

- Page 105 SECTION 6 | Operation, Protections and Troubleshooting TABLE 6.2 PROGRAMMABLE AND DEFAULT PARAMETERS: PARAMETER GROUP NO.1 "CHARGING CURVE" (For detailed information on parameters in this Table, refer to Section 4.4.2 of the Owner's Manual for Remote Control EVO-RC-PLUS) Programming Range Parameter Default (Programming requires optional Remote Control...

- Page 106 SECTION 6 | Operation, Protections and Troubleshooting TABLE 6.2 PROGRAMMABLE AND DEFAULT PARAMETERS: PARAMETER GROUP NO.1 "CHARGING CURVE" (For detailed information on parameters in this Table, refer to Section 4.4.2 of the Owner's Manual for Remote Control EVO-RC-PLUS) Programming Range Parameter Default (Programming requires optional Remote Control...

- Page 107 SECTION 6 | Operation, Protections and Troubleshooting TABLE 6.4 PROGRAMMABLE AND DEFAULT PARAMETERS: PARAMETER GROUP NO.3 "INPUT LOW LIMIT" (For detailed information on parameters in this Table, refer to Section 4.6.2 of the Owner's Manual for Remote Control EVO-RC-PLUS) Group Parameter name Setting range Default value...

- Page 108 SECTION 6 | Operation, Protections and Troubleshooting TABLE 6.6 PROGRAMMABLE AND DEFAULT PARAMETERS: PARAMETER GROUP NO.5 "OTHER FUNCTIONS" (For detailed information on parameters in this Table, refer to Section 4.8.2 of the Owner's Manual for Remote Control EVO-RC-PLUS) Parameter name Setting range Default Value “POWER SAVING”...

- Page 109 SECTION 6 | Operation, Protections and Troubleshooting TABLE 6.6 PROGRAMMABLE AND DEFAULT PARAMETERS: PARAMETER GROUP NO.5 "OTHER FUNCTIONS" (Continued from previous page) (For detailed information on parameters in this Table, refer to Section 4.8.2 of the Owner's Manual for Remote Control EVO-RC-PLUS) Parameter name Setting range...

- Page 110 SECTION 6 | Operation, Protections and Troubleshooting 6.8 STANDBY MODE When the EVO™ is in Standby Mode, it will stop inverting or charging / pass through. 6.8.1 General Information INFO 1. Standby Mode may also be used to temporary halt normal operation of the Inverter Charger without switching Off the unit completely.

-

Page 111: Specifications

SECTION 7 | Specifications Model No. EVO-4248SP INVERTER SECTION Output Waveform Pure Sine Wave Input Battery Voltage Range 36 - 68 VDC Nominal AC Output Voltage 120 / 240 VAC ± 5% Split Phase Output Frequency 60 Hz ± 0.1 Hz Total Harmonic Distortion of Pure Sine Wave Form (THD) <... - Page 112 SECTION 7 | Specifications Model No. EVO-4248SP TRANSFER CHARACTERISTICS SPDT, 40A Transfer Relay Type and Capacity NOTE: In Charging Mode, input current will be limited to 30A by the 30A external input breaker Transfer Time – Inverter to Grid / <...

- Page 113 SECTION 7 | Specifications Model No. EVO-4248SP INPUT AND OUTPUT CONNECTIONS Battery Connection – Stud and Nut: M8 (Pitch1.25mm) External Charge Controller – Stud and Thumb Nut: M8 (Pitch 1.25mm) Connection Hard-wired through screw down terminals AC Input / Output Connection –...

-

Page 114: Warranty

SECTION 8 | Warranty 3 YEAR LIMITED WARRANTY EVO-4248SP Inverter/Charger manufactured by Samlex America Inc. (the “Warrantor“) is warranted to be free from defects in workmanship and materials under normal use and service. The warranty period is 3 years for the United States and Canada, and is in effect from the date of purchase by the user (the “Purchaser“). - Page 115 NOTES: SAMLEX AMERICA INC. | 115...

- Page 116 Contact Information Toll Free Numbers Ph: 1 800 561 5885 Fax: 1 888 814 5210 Local Numbers Ph: 604 525 3836 Fax: 604 525 5221 Website www.samlexamerica.com USA Shipping Warehouses Kent, WA Plymouth, MI Canadian Shipping Warehouse Delta, BC Email purchase orders to orders@samlexamerica.com 11027-EVO-4248SP-1221...

Need help?

Do you have a question about the Evolution EVO-4248SP and is the answer not in the manual?

Questions and answers