Summary of Contents for Samlexpower Pure Sine PST-60S-12E

- Page 1 DC-AC Power Inverter owner's Please read this manual bEforE Manual Pure Sine Wave installing your inverter PST-60S-12E / PST-60S-24E PST-100S-12E / PST-100S-24E PST-150S-12E / PST-150S-24E PST-200S-12E / PST-200S-24E...

-

Page 2: Table Of Contents

Owner's MAnuAl | Index Section 1 Safety Instructions ..............3 Section 2 General Information ............. 6 Section 3 Limiting Electromagnetic Interference (EMI) ....... 11 Section 4 Powering Direct / Embedded Switch Mode Power Supplies (SMPS) ............12 Section 5 Principle of Operation ............14 Section 6 Layout ................. -

Page 3: Safety Instructions

seCtIOn 1 | safety Instructions The following safety symbols will be used in this manual to highlight safety and information: WARninG! Indicates possibility of physical harm to the user in case of non-compliance. cAUtion! Indicates possibility of damage to the equipment in case of non-compliance. inFo Indicates useful supplemental information. -

Page 4: Precautions When Working With Batteries

seCtIOn 1 | safety Instructions Preventing fire and explosion hazards • Working with the unit may produce arcs or sparks. Thus, the unit should not be used in areas where there are flammable materials or gases requiring ignition protected equipment. These areas may include spaces containing gasoline-powered machinery, fuel tanks, and battery compartments. Precautions when working with batteries • Batteries contain very corrosive diluted sulphuric acid as electrolyte. Precautions should be taken to prevent contact with skin, eyes or clothing. • Batteries generate Hydrogen and oxygen during charging resulting in evolution of explosive gas mixture. Care should be taken to ventilate the battery area and follow the battery manufacturer’s recommendations. • Never smoke or allow a spark or flame near the batteries. - Page 5 seCtIOn 1 | safety Instructions the 12V battery version and 33.0 VDC for the 24V battery version to prevent permanent damage to the unit. Please observe the following precautions: • Ensure that the maximum charging voltage of the external battery charger / alterna- tor / solar charge controller does not exceed 16.5 VDC for the 12V battery version and 33.0 VDC for the 24V battery version • Do not use unregulated solar panels to charge the battery connected to this unit. Under cold ambient temperatures, the output of the solar panel may reach > 22 VDC for 12V Battery System and > 44 VDC for the 24V Battery system. Always use a charge controller between the solar panel and the battery. • Do not connect this unit to a battery system with a voltage higher than the rated bat- tery input voltage of the unit (e.g. do not connect the 12V version of the unit to 24V battery system or the 24V version to the 48V Battery System) Preventing Reverse Polarity on the input Side When making battery connections on the input side, make sure that the polarity of bat-...

-

Page 6: General Information

seCtIOn 2 | General Information The following definitions are used in this manual for explaining various electrical concepts, specifications and operations: Peak Value: It is the maximum value of electrical parameter like voltage / current. RMS (Root Mean Square) Value: It is a statistical average value of a quantity that varies in value with respect to time. for example, a pure sine wave that alternates between peak values of Positive 325V and Negative 325V has an RMS value of 230 VAC. Also, for a pure sine wave, the RMS value = Peak value ÷ 1.414. Voltage (V), Volts: It is denoted by “V” and the unit is “Volts”. It is the electrical force that drives electrical current (I) when connected to a load. It can be DC (Direct Current – flow in one direction only) or AC (Alternating Current – direction of flow changes peri- odically). The AC value shown in the specifications is the RMS (Root Mean Square) value. - Page 7 seCtIOn 2 | General Information the net effect is a tendency to cancel each other. Hence, in a circuit containing both inductances and capacitances, the net Reactance (X) will be equal to the difference be- tween the values of the inductive and capacitive reactances. The net Reactance (X) will be inductive if X > X and capacitive if X > X impedance, Z: It is the vectorial sum of resistance and reactance vectors in a circuit. Active Power (P), Watts: It is denoted as “P”...

- Page 8 seCtIOn 2 | General Information the inverter. The inverter can be sized based on the Active Power rating (Watts) without creating overload. Reactive Load: A device or appliance that consists of a combination of resistive, induc- tive and capacitive elements (like motor driven tools, refrigeration compressors, micro- waves, computers, audio/ video etc.). These devices require Apparent Power (VA) from the inverter to operate. The Apparent Power is a vectorial sum of Active Power (Watts) and Reactive Power (VAR). The inverter has to be sized based on the higher Apparent Power (VA). output Voltage Waveforms Sine Wave Modi ed Sine Modi ed Sine Wave Wave sits at ZERO for some time and then rises or falls...

- Page 9 seCtIOn 2 | General Information frequency harmonic content in a modified sine wave produces enhanced radio interfer- ence, higher heating effect in inductive loads like microwaves and motor driven devices like hand tools, refrigeration / air-conditioning compressors, pumps etc. The higher frequency harmonics also produce overloading effect in low frequency capacitors due to lowering of their capacitive reactance by the higher harmonic frequencies. These capaci- tors are used in ballasts for fluorescent lighting for Power factor improvement and in single-phase induction motors as start and run capacitors. Thus, modified and square wave inverters may shut down due to overload when powering these devices.

- Page 10 seCtIOn 2 | General Information Power Rating of the inverters The continuous output power rating of the inverter is specified in Active Power in Watts for resistive types of loads like heating elements, incandescent lamps etc. where Power factor (Pf) = 1. The Surge Power rating is for < 1 sec. Non resistive / reactive loads with Power factor < 1 like motors (Pf = 0.4 to 0.8), non Power factor corrected electronics (Pf = 0.5 to 0.6) etc, will draw higher Apparent Power in Volt Amps (VA). This Apparent Power is the sum of Active Power in Watts plus Reac- tive Power in VAR and is = Active Power in Watts ÷ Power factor. Thus, for such reactive loads, higher sized inverter is required based on the Apparent Power. further, all reac- tive types of loads require higher inrush / starting surge power that may last for > 1 to 5 sec and subsequent lower running power. If the inverter is not sized adequately based on the type of AC load, it is likely to shut down or fail prematurely due to repeated overloading. inFo The manufacturers’ specification for power rating of the appliances and devices indicates only the running power required.

-

Page 11: Limiting Electromagnetic Interference (Emi)

seCtIOn 2 | General Information tABLe 2.1: inVeRteR SiZinG FActoR inverter type of Device or Appliance Sizing Factor* Laser Printer / other Devices using Quartz Lamps for heating Switch Mode Power Supplies (SMPS): no Power factor correction Photographic Strobe / flash Lights 4 (Note 1) Multiply the Running Active Power Rating {Watts} of the appliance by this Factor to arrive at the Continuous Power Rating of the inverter for powering this appliance. tABLe 2.1: noteS 1. for photographic strobe / flash unit, the surge power of the inverter should be > 4 times the Watt Sec rating of photographic strobe / flash unit. -

Page 12: Powering Direct / Embedded Switch Mode Power Supplies (Smps)

seCtIOn 4 | Powering Direct / embedded switch Mode Power supplies (sMPs) Switch Mode Power Supplies (SMPS) are extensively used to convert the incoming AC power into various voltages like 3.3V, 5V, 12V, 24V etc. that are used to power various devices and circuits used in electronic equipment like battery chargers, computers, audio and video devices, radios etc. These power supplies use large capacitors in their input section for filtration. When the power supply is first turned on, there is a very large inrush current drawn by the power supply as the input capacitors are charged (The ca- pacitors act almost like a short circuit at the instant the power is turned on). The inrush current at turn-on is several to tens of times larger than the rated rMS input current and lasts for a few milliseconds. An example of the input voltage versus input current waveforms is given in fig. -

Page 13: Input Voltage

seCtIOn 4 | Powering Direct / embedded switch Mode Power supplies (sMPs) Input voltage RMS Current Inrush current Fig 4.1: Inrush current in an SMPS Peak Current Non-linear Input Current RMS Current Input Sine Wave Voltage TIME Fig. 4.2: High Crest Factor of current drawn by SMPS SAMLEX AMERICA INC. -

Page 14: Principle Of Operation

seCtIOn 5 | Principle of Operation These inverters convert DC battery voltage to AC voltage with an RMS (Root Mean Square) value of 230 VAC, 50 Hz RMS. The waveform of the AC voltage is a pure sine wave form that is same as the waveform of grid power (Supplementary information on pure sine waveform and its advantages are discussed on pages 8 & 9). fig. 5.1 below specifies the characteristics of 230 VAC, 50 Hz pure sine waveform. The instantaneous value and polarity of the voltage varies cyclically with respect to time. for example, in one cycle in a 230 VAC, 50 Hz system, it slowly rises in the positive direction from 0V to a peak positive value “Vpeak” = + 325V, slowly drops to 0V, changes the polarity to negative direction and slowly increases in the negative direction to a peak... -

Page 15: Layout

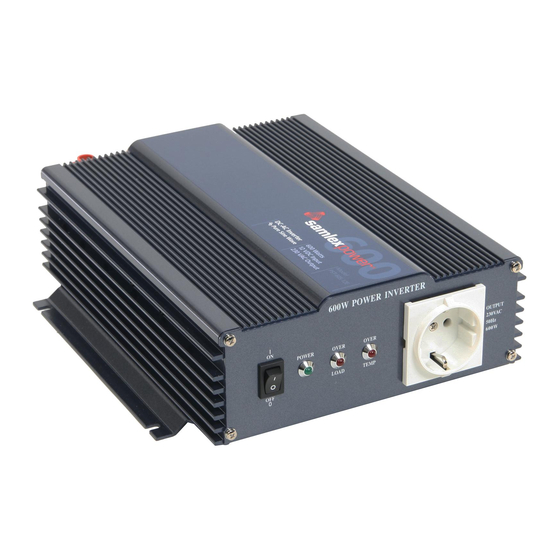

Positive (+) DC Input Terminal NEG - POS + 10. Modular Jack for RC-15 Remote Control (Bottom of Unit) PST-60S: Back Fig. 6.1: Layout of PST-60S-12E, PST--60S-24E 1000W POWER INVERTER Power ON/OFF Switch Green LED - Power PST-60S-230-Layout Output Status... -

Page 16: Section 7

seCtIOn 6 | layout Power ON/OFF Switch Green LED - Power Output Status OVER OVER POWER OUTPUT Red LED - Over Load 230V 50Hz TEMP LOAD Red LED - Over Temperature “Schuko” Type AC Outlets Cooling Fans Pure Sine Wave Inverter Remote Grounding Terminal PST-150S, PST-200S: Front... -

Page 17: General Information On Batteries For Powering Inverters

seCtIOn 7 | General Information on Batteries for Powering Inverters an electrical conductor in one second. The Capacity “C” in Ah relates to the ability of the battery to provide a constant specified value of discharge current (also called “C-Rate”) over a specified time in hours before the battery reaches a specified discharged terminal voltage (Also called “End Point Voltage”) at a specified temperature of the electrolyte. As a bench- mark, the automotive battery industry rates batteries at a “Discharge Rate” C/20 Amperes corresponding to 20 Hour discharge period. The rated capacity “C” in Ah in this case will be the number of Amperes of current the battery can deliver for 20 Hours at 80ºf (26.7ºC) till the voltage drops to 1.75V / Cell i.e. 10.5V for 12V battery, 21V for 24V battery and 42V for a 48V battery. for example, a 100 Ah battery will deliver 5A for 20 Hours. Rated capacity in Reserve capacity (Rc) Battery capacity may also be expressed as Reserve Capacity (RC) in minutes typically for automotive SLI (Starting, Lighting and Ignition) batteries. It is the time in minutes a vehicle can be driven after the charging system fails. - Page 18 seCtIOn 7 | General Information on Batteries for Powering Inverters as the “C-Rate”. If the battery delivers a very high discharge current, the battery will be discharged to the “End Point Voltage” in a shorter period of time. on the other hand, if the battery delivers a lower discharge current, the battery will be discharged to the “End Point Voltage” after a longer period of time. Mathematically: eQUAtion 1: Discharge current “C-Rate” = Capacity “C” in Ah ÷ Discharge Time “T” Table 7.2 below gives some examples of C-Rate specifications and applications: tABLe 7.2: DiScHARGe cURRent RAteS - “c-RAteS” Hours of discharge time C-Rate Discharge Current in Amps Example of C-Rate “T” till the “End Point Discharge Currents for fraction Decimal...

- Page 19 seCtIOn 7 | General Information on Batteries for Powering Inverters 12 Volt Lead-Acid Battery Chart - 80˚F 16.5 C/10 16.0 CHARGE C/20 15.5 C/40 15.0 14.5 14.0 13.5 13.0 C/100 C/20 12.5 C/10 DISCHARGE 12.0 11.5 11.0 10.5 Please note that X-axis shows % State of Charge.

- Page 20 seCtIOn 7 | General Information on Batteries for Powering Inverters Table 7.3 (page 19) will show that a 100 Ah capacity battery will deliver 100% (i.e. full 100 Ah) capacity if it is slowly discharged over 20 hours at the rate of 5 Amperes (50W output for a 12V inverter and 100W output for a 24V inverter). However, if it is dis- charged at a rate of 50 Amperes (500W output for a 12V inverter and 1000W output for a 24V inverter) then theoretically, it should provide 100 AH ÷ 50 = 2 hours. However, the Table above shows that for 2 hours discharge rate, the capacity is reduced to 50% i.e. 50 Ah. Therefore, at 50 Ampere discharge rate (500W output for a 12V inverter and 1000W output for a 24V inverter) the battery will actually last for 50 Ah ÷ 50 Amperes = 1 Hour. State of charge (Soc) of a Battery – Based on “Standing Voltage” The “Standing Voltage” of a battery under open circuit conditions (no load connected to it) can approximately indicate the State of Charge (SoC) of the battery. The “Standing Voltage” is measured after disconnecting any charging device(s) and the battery load(s) and letting the battery “stand”...

- Page 21 seCtIOn 7 | General Information on Batteries for Powering Inverters the DC input cables are thick enough to allow a negligible voltage drop between the battery and the inverter) . Inverters are normally provided with a buzzer alarm to warn that the loaded battery has been deeply discharged to around 80% of the rated capacity. Normally, the buzzer alarm is triggered when the voltage at the DC input terminals of the inverter has dropped to around 10.7V for a 12V battery or 21.4V for 24V battery at C-Rate dis- charge current of C/5 Amps and electrolyte temp.

- Page 22 seCtIOn 7 | General Information on Batteries for Powering Inverters In the example given above, the 10.7V Low Battery / DC Input Alarm would trigger at around 80% discharged state (20% SoC) when the C-Rate discharge current is C/5 Amps. However, for lower C-Rate discharge current of C/10 Amps and lower, the battery will be almost completely discharged when the alarm is sounded. Hence, if the C-Rate discharge current is lower than C/5 Amps, the battery may have completely discharged by the time the Low DC Input Alarm is sounded. Low Dc input Voltage Shut-down in inverters: As explained above, at around 80% State of Discharge of the battery at C-Rate discharge current of around C/5 Amps, the Low DC Input Voltage Alarm is sounded at around 10.7V for a 12V battery (at around 21.4V for 24V battery) to warn the user to disconnect the battery to prevent further draining of the battery. If the load is not disconnected at this stage, the batteries will be drained further to a lower voltage and to a completely discharged condition that is harmful for the battery and for the inverter.

- Page 23 seCtIOn 7 | General Information on Batteries for Powering Inverters based on the actual application requirements. Please consider using the following Programmable Low Battery Cut-off / “Battery Guard” Models manufactured by Samlex America, Inc. www.samlexamerica.com - BG-40 (40A) – for up to 400W, 12V inverter or 800W , 24V inverter - BG-60 (60A) - for up to 600W, 12V inverter or 1200W , 24V inverter - BG-200 (200A) - for up to 2000W, 12V inverter or 4000W , 24V inverter Depth of Discharge of Battery and Battery Life The more deeply a battery is discharged on each cycle, the shorter the battery life. Using more batteries than the minimum required will result in longer life for the battery bank. A typical cycle life chart is given in the Table 7.5 below: tABLe 7.5: tYPicAL cYcLe LiFe cHARt Depth of Discharge cycle Life of Group cycle Life of Group...

- Page 24 seCtIOn 7 | General Information on Batteries for Powering Inverters terminal of Battery 4 is connected to the Positive terminal of Battery 3. The Negative terminal of Battery 3 is connected to the Positive terminal of Battery 2. The Negative terminal of Battery 2 is connected to the Positive terminal of Battery 1. The Negative ter- minal of Battery 1 becomes the Negative terminal of the 24V battery bank. Cable “A” Battery 1 Battery 2 Battery 3 Battery 4 Parallel connection 12V Inverter or 12V Charger Cable “B” Fig 7.3: Parallel Connection When two or more batteries are connected in parallel, their voltage remains the same but their Ah capacities add up. fig. 7.3 above shows 4 pieces of 12V, 100 Ah batteries connected in parallel to form a battery bank of 12V with a capacity of 400 Ah. The four Positive terminals of Batteries 1 to 4 are paralleled (connected together) and this com- mon Positive connection becomes the Positive terminal of the 12V bank. Similarly, the four Negative terminals of Batteries 1 to 4 are paralleled (connected together) and this...

- Page 25 seCtIOn 7 | General Information on Batteries for Powering Inverters teries to form a 12V, 400 Ah battery bank. Two 6V, 200 Ah batteries, Batteries 1 and 2 are connected in series to form a 12V, 200 Ah battery (String 1). Similarly, two 6V, 200 Ah batteries, Batteries 3 and 4 are connected in series to form a 12V, 200 Ah battery (String 2). These two 12V, 200 Ah Strings 1 and 2 are connected in parallel to form a 12V, 400 Ah bank. cAUtion! When 2 or more batteries / battery strings are connected in parallel and are then connected to an inverter or charger (See figs 7.3 and 7.4 given above), attention should be paid to the manner in which the charger / inverter is con- nected to the battery bank. Please ensure that if the Positive output cable of the battery charger / inverter (Cable “A”) is connected to the Positive battery post of the first battery (Battery 1 in fig 7.3) or to the Positive battery post of...

- Page 26 seCtIOn 7 | General Information on Batteries for Powering Inverters The first step is to estimate the total AC watts (W) of load(s) and for how long the load(s) will operate in hours (H). The AC watts are normally indicated in the electrical nameplate for each appliance or equipment. In case AC watts (W) are not indicated, formula 1 given above may be used to calculate the AC watts by multiplying 120 VAC / 230 VAC by the AC current in Amperes. The next step is to estimate the DC current in Amperes (A) from the AC watts as per formula 2 above. An example of this calculation for a 12V inverter is given below: Let us say that the total Ac Watts delivered by the 12V inverter = 1000W. Then, using formula 2 above, the DC current to be delivered by the 12V batteries = 1000W ÷10 = 100 Amperes. next, the energy required by the load in Ampere Hours (Ah) is determined.

-

Page 27: Installation

seCtIOn 8 | Installation WARninG! 1. Before commencing installation, please read the safety instructions explained in the Section titled “Safety Instructions” on page 3. 2. It is recommended that the installation should be undertaken by a qualified, licensed / certified electrician. 3. Various recommendations made in this manual on installation will be super- seded by the National / Local Electrical Codes related to the location of the unit and the specific application. Location of installation Please ensure that the following requirements are met: cool: Heat is the worst enemy of electronic equipment. Hence, please ensure that the unit is installed in a cool area that is also protected against heating effects of direct... - Page 28 The overall dimensions and the location of the mounting slots are shown in fig. 8.1 to 8.3 below: 16.5 Height: 82 mm 16.5 PST-60S Dimensions (mm): 281 x 241 x 82 Fig. 8.1: PST-60S-12E, PST-60S-24E Dimensions and Mounting Slots / Dimensions (mm): 281 x 241 x 82 28 | SAMLEX AMERICA INC.

- Page 29 seCtIOn 8 | Installation 16.5 Height: 82 mm 16.5 PST-100S Dimensions (mm): 400 x 241 x 82 Fig. 8.2: PST-100S-12E, PST-100S-24E Dimensions and Mounting Slots / Dimensions (mm): 400 x 241 x 82 80.5 Height: 101 mm Fig. 8.3: Dimensions and Mounting Slots for PST-150S-12E, PST-150S-24E and PST-200S-12E, PST-200S-24E / Dimensions (mm): 415 x 282 x 101 PST-150S &...

- Page 30 seCtIOn 8 | Installation Mounting orientation The unit has air intake and exhaust openings for the cooling fan(s). It has to be mounted in such a manner so that small objects should not be able to fall easily into the unit from these openings and cause electrical / mechanical damage. Also, the mounting orienta- tion should be such that if the internal components overheat and melt / dislodge due to a catastrophic failure, the melted / hot dislodged portions should not be able to fall out of the unit on to a combustible material and cause a fire hazard.

- Page 31 seCtIOn 8 | Installation into the diversion load if there are no other loads. The charge controller will discon- nect the diversion load if the current rating of the controller is exceeded. Disconnec- tion of the diversion load may damage the battery as well as the inverter or other DC loads connected to the battery due to high voltages generated during conditions of high winds (for wind generators), high water flow rates (for hydro generators). It is, therefore, to be ensured that the diversion load is sized correctly to prevent the above over voltage conditions. - Do not connect this unit to a battery system with a voltage higher than the rated bat- tery input voltage of the unit (e.g.

- Page 32 seCtIOn 8 | Installation The size (thickness / cross-section) of the conductors is designated by AWG (American Wire Gauge). Please note that a smaller AWG # denotes a thicker size of the conductor up to AWG #1. Wires thicker than AWG #1 are designated AWG 1/0, AWG 2/0, AWG 3/0 and so on. In this case, increasing AWG # denotes thicker wire. The DC input circuit is required to handle very large DC currents and hence, the size of the wires and connectors should be selected to ensure minimum voltage drop between the battery and the inverter. Thinner wires and loose connections will result in poor inverter performance and will produce abnormal heating leading to risk of insulation melt down and fire. Normally, the thickness of the wire should be such that the voltage drop due to the current & the resistance of the length of the wire should be less than 2%. Use oil resistant, multi- stranded copper wire wires rated at 90ºC minimum. Do not use aluminum wire as it has higher resistance per unit length.

- Page 33 AWG #2/0 AWG #4/0 200A DC-2000-KIT PST-150S-24E 100A AWG #8 AWG #4 AWG #2 100A DC-1000-KIT PST-100S-12E 160A AWG #3 AWG #1/0 AWG #3/0 160A DC-2000-KIT PST-100S-24E AWG #8 AWG #6 AWG #4 DC-1000-KIT PST-60S-12E AWG #6 AWG #3 AWG #1 DC-1000-KIT PST-60S-24E AWG #12 AWG #10 AWG #6 40 A DC-1000-KIT Manufactured by Samlex America, Inc. (contains 2 wires and fuse) SAMLEX AMERICA INC. | 33...

- Page 34 seCtIOn 8 | Installation inFo 4 standard Models of Samlex America, Inc. DC Installation Kits are available to cover installation requirements of 600 to 3500W inverters. Voltage drop of 2% or less will be applicable for 3 ft. distance. In some cases, the kits may contain thicker cables and higher rated fuses than the minimum sizes recommended. Thicker cables will produce lower voltage drop and hence, will further improve the overall efficiency. Also, voltage drop may be > 2% in some cases for distances > 3 ft. Dc input terminals for Battery connection The DC input terminals for battery connection (8, 9) have cylindrical hole with set screw as follows: Model PST-60S has an 8 mm cylindrical hole diameter with M-8 set screw and Models PST-100S-150S and 200S have an 11 mm cylindrical hole diameter with M-8 set screw.

- Page 35 seCtIOn 8 | Installation center which is also fed from the utility power/ generator. Such a connection will result in parallel operation and AC power from the utility / generator will be fed back into the inverter which will instantly damage the output section of the inverter and may also pose a fire and safety hazard. If an electrical breaker panel / load center is being fed from the utility power / generator and the inverter is required to feed this panel as backup power source, the AC power from the utility power/ generator and the inverter should first be fed to a manual selector switch / Automatic Transfer Switch and the output of the manual selector switch / Automatic Transfer Switch should be con- nected to the electrical breaker panel / load center. 2. To prevent possibility of paralleling and severe damage to the inverter, never use a simple jumper cable with a male plug on both ends to connect the AC output of the inverter to a handy wall receptacle in the home / rV.

- Page 36 seCtIOn 8 | Installation tion and are internally connected to the metal chassis of the inverter. The metal chassis of the inverter is connected to the designated Ground. When the “Schuko” plug (1) of the power cord of the AC device is plugged into the corresponding “Schuko” receptacle on the inverter (2 in fig. 8.4 or 5 in figs. 6.1, 6.2 and 6.3), the chassis of the AC device is automatically connected to the designated Ground through the equipment grounding conductor that is connected to the spring contacts (2.2, fig 8.4) of the “Schuko” recepta- cle on the inverter (5 in figs. 6.1, 6.2 and 6.3) WARninG! Because the “Schuko” plug (1) can be inserted in either direction into the Schuko receptacle (2), the “Schuko” connection system is not polarized (i.e. Line and Neutral could get reversed). Hence, both the current carrying conductors are isolated from the chassis of the inverter and there is No NEUTRAL. Each of the 2 female contacts (2.1) of the “Schuko” receptacle will be at an elevated voltage with respect to the chassis of the inverter as follows and should not be touched: - PST-60S: 15 VAC to 214 VAC - PST-100S: 74 VAC to 151 VAC...

-

Page 37: Operation

seCtIOn 9 | Operation Powering on the Loads After the inverter is switched on, it takes a finite time to become ready to deliver full power. Hence, always switch on the load(s) after a few seconds of switching on the inverter. Avoid switching on the inverter with the load already switched on. This may prematurely trigger the overload protection. When a load is switched on, it may require initial higher power surge to start. Hence, if multiple loads are being powered, they should be switched on one by one so that the inverter is not overloaded by the higher starting surge if all the loads are switched on at once. Switching the inverter on/oFF Before switching on the inverter, check that all the AC loads have been switched off. The oN/off switch (1) on the front panel of the inverter is used to switch on and switch off the inverter. This switch operates a low power control circuitry, which in turn controls all... - Page 38 seCtIOn 9 | Operation indications For normal operation When the inverter is operating normally and supplying AC load(s), the LED (2) will be GREEN. In case of abnormal operation, other displays and alarms will be activated. Please see under “Protections Against Abnormal Conditions” . optional Wired Remote on/oFF control – Model Rc-15 An optional wired Remote Control Model, No. RC-15, is available to enable switching on and off from a distance of 15 ft. The remote on / off control comes with 15 ft. cable. one end of the Remote Control is plugged into the 6 Position Modular Jack (10) provided on the inverter.

-

Page 39: Protections

seCtIOn 10 | Protections The inverter has been provided with protections detailed below: overload / Short circuit Shut Down The inverter can provide a higher than normal instantaneous power (< 1 second) limited to the surge power rating of the inverter. Also, the inverter can provide continuous power limited to the continuous power rating of the inverter. If there is an overload beyond these specified limits, the AC output of the unit will be shut down permanently. RED LED marked “oVER LoAD” (3) will be lighted and GREEN LED marked “PoWER” (2) will be switched off. The unit will be latched in this shutdown condition and will require manual reset. To reset, switch off the power oN/off switch, wait for 3 minutes and then switch oN again. Before switching on again, remove the cause of the shutdown. - Page 40 seCtIOn 10 | Protections The unit will automatically reset after the hot spot has cooled down to 70°C. Reverse Polarity at the Dc input terminals The Positive of the battery should be connected to the Positive DC input terminal of the inverter (9) and the Negative of the battery should be connected to the Negative DC input terminal of the inverter (8). A reversal of polarity (the Positive of the battery wrongly connected to the Negative DC input terminal of the inverter and the Negative of the battery wrongly connected to the Positive DC input terminal of the inverter) will blow the external / internal DC side fuses. If the DC side fuse is blown, the inverter will be dead. The GREEN LED marked “PoWER” (2) will be switched off and there will be no AC output. inFo Reverse polarity connection is likely to damage the DC input circuitry. The internal fuse(s) should be replaced with the correct size of fuse shown under specifications. If the unit does not work after replacing the fuse(s), it has been permanently damaged and will require repair / replacement (Please read Sec- tion 11 - “Troubleshooting Guide” for more details). cAUtion! Damage caused by reverse polarity is not covered by warranty! When making battery connections on the input side, make sure that the polarity of battery...

-

Page 41: Trouble Shooting Guide

seCtIOn 11 | trouble shooting Guide iSSUe PoSSiBLe cAUSe ReMeDY When switched ON, GREEN There is no voltage at the Check the continuity of the battery LED “Power” (2) does not DC input terminals. input circuit. light. Buzzer is Off. There is Check that the external battery fuse is intact. - Page 42 seCtIOn 11 | trouble shooting Guide iSSUe PoSSiBLe cAUSe ReMeDY AC output shuts down com- Permanent shut-down of Reduce the load. pletely. RED LED “Overload” the AC output due to con- The load is not suitable as it requires higher (3) is lighted.

-

Page 43: Specifications

12 | specifications MoDeL no. PSt-60S-12e PSt-60S-24e oUtPUt PoWeR, continUoUS 600 Watts 600 Watts PoWeR, SURGe (FoR <1 Sec) 1000 Watts 1000 Watts oUtPUt VoLtAGe 230 VAC +/- 3% 230 VAC +/- 3% oUtPUt FReQUencY 50 Hz 50 Hz oUtPUt VoLtAGe WAVeFoRM Pure Sine Wave Pure Sine Wave totAL HARMonic DiStoRtion < 3%... - Page 44 seCtIOn 12 | specifications MoDeL no. PSt-100S-12e PSt-100S-24e oUtPUt PoWeR, continUoUS 1000 Watts 1000 Watts PoWeR, SURGe (FoR <1 Sec) 2000 Watts 2000 Watts oUtPUt VoLtAGe 230 VAC +/- 3% 230 VAC +/- 3% oUtPUt FReQUencY 50 Hz 50 Hz oUtPUt VoLtAGe WAVeFoRM Pure Sine Wave Pure Sine Wave totAL HARMonic DiStoRtion < 3% < 3%...

- Page 45 seCtIOn 12 | specifications MoDeL no. PSt-150S-12e PSt-150S-24e oUtPUt PoWeR, continUoUS 1500 Watts 1500 Watts PoWeR, SURGe (FoR <1 Sec) 3000 Watts 3000 Watts oUtPUt VoLtAGe 230 VAC +/- 3% 230 VAC +/- 3% oUtPUt FReQUencY 50 Hz 50 Hz oUtPUt VoLtAGe WAVeFoRM Pure Sine Wave Pure Sine Wave totAL HARMonic DiStoRtion < 3% < 3%...

- Page 46 seCtIOn 12 | specifications MoDeL no. PSt-200S-12e PSt-200S-24e oUtPUt PoWeR, continUoUS 2000 Watts 2000 Watts PoWeR, SURGe (FoR <1 Sec) 4000 Watts 4000 Watts oUtPUt VoLtAGe 230 VAC +/- 3% 230 VAC +/- 3% oUtPUt FReQUencY 50 Hz 50 Hz oUtPUt VoLtAGe WAVeFoRM Pure Sine Wave Pure Sine Wave totAL HARMonic DiStoRtion < 3% < 3%...

-

Page 47: Warranty

13 | warranty 2 YeAR LiMiteD WARRAntY The PST-60S-12E / PST-60S-24E; PST-100S-12E / PST-100S-24E; PST-150S-12E / PST-150S-24E; and PST-200S-12E / PST-200S-24E Series Inverters are manufactured by Samlex America, Inc. (the “Warrantor“) is warranted to be free from defects in workmanship and materi- als under normal use and service. The warranty period is 2 years for the United States and Canada, and is in effect from the date of purchase by the user (the “Purchaser“). Warranty outside of the United States and Canada is limited to 6 months. for a warranty claim, the Purchaser should contact the place of purchase to obtain a Return Authoriza- tion Number. The defective part or unit should be returned at the Purchaser’s expense to the author- ized location. A written statement describing the nature of the defect, the date of pur- chase, the place of purchase, and the Purchaser’s name, address and telephone number should also be included. If upon the Warrantor’s examination, the defect proves to be the result of defective material or workmanship, the equipment will be repaired or replaced at the Warran- tor’s option without charge, and returned to the Purchaser at the Warrantor’s expense. (Contiguous US and Canada only) No refund of the purchase price will be granted to the Purchaser, unless the Warrantor is unable to remedy the defect after having a reasonable number of opportunities to do so. Warranty service shall be performed only by the Warrantor. Any attempt to remedy... - Page 48 Contact Information Toll Free Numbers Ph: 800 561 5885 Fax: 888 814 5210 Local Numbers Ph: 604 525 3836 Fax: 604 525 5221 Website www.samlexamerica.com USA Shipping Warehouse Kent WA Canadian Shipping Warehouse Delta BC Email purchase orders to orders@samlexamerica.com 11001-PST-60-100-150-200S-12-24E-0412...

Need help?

Do you have a question about the Pure Sine PST-60S-12E and is the answer not in the manual?

Questions and answers