Summary of Contents for Viessmann VITOTRANS 222

- Page 1 VIESMANN Service instructions for contractors Vitotrans 222 Heat exchanger set for cylinder loading system For applicability, see the last page VITOTRANS 222 Please keep safe. 5549 892 GB 4/2014...

- Page 2 Note For replacements, use only original spare parts Details identified by the word "Note" contain additional supplied or approved by Viessmann. information. Target group These instructions are exclusively intended for quali- fied contractors.

-

Page 3: Table Of Contents

Index Index Product information Intended use ..................Commissioning, inspec- Steps - commissioning, inspection and maintenance ......tion, maintenance Display and troubleshoot- LED at the HE circulation pump ............. 14 Parts lists Parts list ....................15 Commissioning/service ........................17 reports Specification ........................ -

Page 4: Product Information Intended Use

Product information Intended use The appliance is only intended to be installed and operated in sealed unvented systems that comply with EN 12828 / DIN 1988, or solar thermal systems that comply with EN 12977, with due attention paid to the associated installation, service and operating instruc- tions. -

Page 5: Commissioning, Inspec-Steps - Commissioning, Inspection And Maintenance

Commissioning, inspection, maintenance Steps - commissioning, inspection and maintenance Commissioning steps Inspection steps Maintenance steps Page • 1. Filling the system on the heating water and DHW side..........• • • 2. Checking connections....................... • • 3. System start-up........................• •... -

Page 6: Filling The System On The Heating Water And Dhw Side

System start-up 1. Set the pressure reducer (if installed) to the 3. Monitor initial heat-up of the Vitotrans 222. required operating pressure. Max. operating pressure: 10 bar (1 MPa) Note For the adjustment of the DHW temperature, see 2. - Page 7 Commissioning, inspection, maintenance Setting the heating output (cont.) Fig.1 1. Set sliding marker on scale to the flow rate 5. Only if indicator band is still above sliding determined from the diagram below. marker : Turn adjusting disc clockwise until the bottom edge of indicator band drops down to 2.

-

Page 8: Setting The Pumps

80 100 120 140 160 180 200 220 240 HE output in kW Fig.2 Setting the pumps Vitotrans 222 (up to 80 kW and up to 120 kW) - circulation pump, DHW side Min. 80 kW setting 120 kW setting Variable differential pressure... - Page 9 DHW volume at 10/60 °C and max. transferable heating output up to 120 kW = 2064 l/h, p = 150 mbar (15 kPa) Δ Vitotrans 222 (up to 240 kW) - circulation pump, DHW side Variable differential pressure Constant differential pressure 240 kW setting...

- Page 10 Commissioning, inspection, maintenance Setting the pumps (cont.) Vitotrans 222 (up to 80 kW and up to 120 kW) - circulation pump, heating water side 80 kW setting Variable differential pressure Constant speed I, II, III 120 kW setting Vitotrans 222 up to 80 kW and up to 120 kW Flow rate in m³/h...

-

Page 11: Setting The Cylinder Temperature

Commissioning, inspection, maintenance Setting the pumps (cont.) Vitotrans 222 (up to 240 kW) - circulation pump, heating water side Variable differential pressure Constant differential pressure 240 kW setting Vitotrans 222, up to 240 kW 1000 1.0 2.0 4.0 5.0 7.0 8.0 Flow rate in m³/h... -

Page 12: Shutting Down The System

"General" "4E:2" Connection on plug "DHW" "55:3" Cylinder temperature controller, cylinder loading system In addition for the Vitotrans 222 with 240 kW: "DHW" "6A:113" Set runtime 113 s. 2. Set the cylinder temperature (DHW temperature) on the Vitotronic. Vitotronic operating instructions... -

Page 13: Restarting The System

Commissioning, inspection, maintenance Inspection and maintenance of the cylinder… (cont.) Dirt trap or filter in the cold water supply: Backwash Service documents from the manufacturers ■ or replace and maintain regularly. ■ Drinking water filter: Replace filter element on non- backwashing filters every 6 months (visual inspection every 2 months). -

Page 14: Display And Troubleshoot-Led At The He Circulation Pump

Display and troubleshooting LED at the HE circulation pump Meaning Cause Action Illuminates green Circulation pump in opera- — — tion Flashes green in short in- RKA version — — tervals Pump runs for 10 min in the venting function. Then set the required out- put. -

Page 15: Parts Lists Parts List

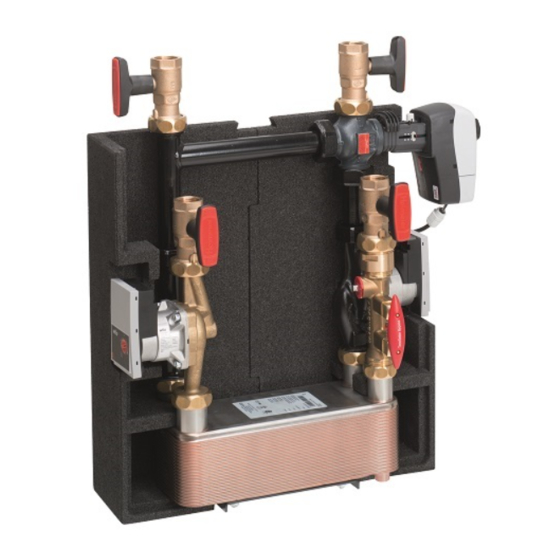

0002 Plate heat exchanger WP4-60 7843370 0002 Plate heat exchanger WP7-M30 7820387 0003 Vitotrans 222 gasket set sizes 1 + 2 7840893 7840893 0003 Vitotrans 222 gasket set size 3 7840894 0004 Vitotrans 222 insulating parts sizes 1 + 2... - Page 16 Parts lists Parts list (cont.) 0011 0011 0013 0017 0003 0010 0017 0014 0018 0012 0008 0012 0003 0017 0003 0009 0006 0007 0004 0015 0003 0003 0017 0002 0003 0005 0016 0024 0020 0019 0001 0022 0023 0021 Fig.7...

-

Page 17: Commissioning/Service

Commissioning/service reports Commissioning/service reports Commissioning Service Service date: Service Service Service date: Service Service Service date: Service Service Service date: Service Service Service date:... -

Page 18: Specification

Specification Specification Serial no. 7537 157 7537 158 7537 159 Transferable heating output at up to 80 up to 120 up to 240 75 °C heating water flow temperature/ 35 °C heating water return temperature and 10 °C cold water inlet temperature/ 60 °C DHW outlet temperature Content Heating water... -

Page 19: Certificates Declaration Of Conformity

Certificates Declaration of conformity We, Viessmann Werke GmbH & Co KG, D-35107 Allendorf, confirm as sole responsible body that the product Vitotrans 222 complies with the following standards: EN 60 335–1 EN 60 335-2-51 EN 61 000-6-3 EN 61 000-6-1... - Page 20 Applicability Serial no. (see type plate): 7537157 7537158 7537159 Viessmann Werke GmbH&Co KG Viessmann Limited D-35107 Allendorf Hortonwood 30, Telford Telephone: +49 6452 70-0 Shropshire, TF1 7YP, GB Fax: +49 6452 70-2780 Telephone: +44 1952 675000 www.viessmann.com Fax: +44 1952 675040...

Need help?

Do you have a question about the VITOTRANS 222 and is the answer not in the manual?

Questions and answers