Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Paton ADI 160 STANDARD

- Page 1 0 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

-

Page 2: Table Of Contents

OPERATIONAL CYCLE OF THE WELDING PROCESS WITH TIG-4T ....4.3.3 TIG-4T CONTACTLESS ARC STARTING FUNCTION .......... PRE-WELDING GAS PURGING ................INITIAL CURRENT (PILOT ARC CURRENT) SETTING ........LINEAR INCREASE OF WELDING CURRENT ............22 1 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... - Page 3 DELIVERY SET ......................WARRANTY ........................ SAFETY REGULATIONS ................... WASTE ELECTRICAL & ELECTRONIC EQUIPMENT ..........ELECTRICAL SCHEMATIC DIAGRAM ..............40 ACCEPTANCE CERTIFICATE ................... 41 WARRANTY CARD ....................2 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

- Page 4 PRODUCT: DIGITAL ARGON-ARC INVERTER PATON ADI 200 STANDARD DC TIG/MMA MIG/MAG The statement is based on a single evaluation of one sample of above mentioned products. It does not imply an assessment of the whole production. The manufacturer should ensure that all product in series production are in conformity with the product sample detailed in this report.

- Page 5 MMA welding welding processes MIG/MAG welding conductor process (mm) process (mm) PATON ADI 160 STANDARD Ф 2 mm Not more than Ф 0.6 Not more than 80 A Ф 3 mm Not more than Ф 0.8 Not more than 120 A Ф...

-

Page 6: General Information

The basic advantages of the PATON™ welding units are the following: The possibility to adjust welding parameters in wide ranges... -

Page 7: Technical Characteristics

315 110 255 Overall dimensions (length width height) 315 110 255 mm Weight without accessories, 5.7 kg 5.8 kg Protection class* IP 21 IP 21 6 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

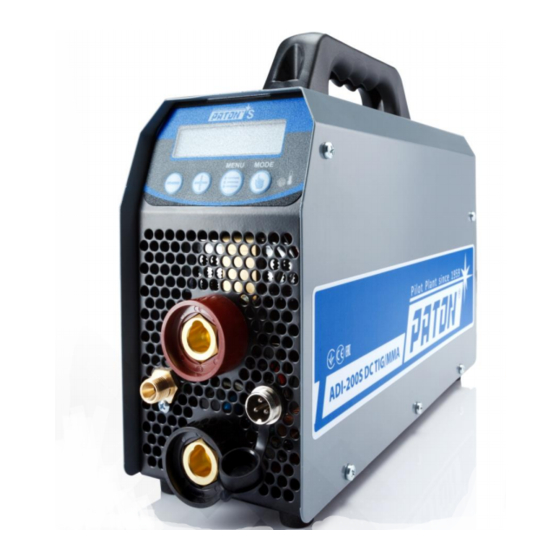

Page 8: Controls And Connectors

* These Standard Series welding units are protected against ingress of foreign particles more than 12.5 mm in size and against vertically falling water drops. 1.2. CONTROLS AND CONNECTORS 7 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... - Page 9 8. A connector for transmitting signals from the source to the wire feed mechanism 9. Push-button switch for switching on and off the welding unit 10. Fitting for connecting a cylinder with protective gas 8 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

-

Page 10: Setting The Welding Unit Into Operation

5 minutes of time required for the electronic elements of the unit to be cooled. 9 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 11: Connection To A Power Supply System

(see Section 1.1, "Technical characteristics"). Connect the welding unit to an electrical outlet that is rated for a three-wire plug with a grounding conductor. 10 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 12: Manual Covered-Electrode Arc Welding Process (Mma)

11 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 13: Operational Cycle Of The Manual Arc Welding Process

The procedure for changing the values of the operational parameters of the welding unit for the current welding process is described in Section 6.1. 12 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 14: Reduced-Voltage Welding Mode "Arc-Force

3.2 mm in diameter, electrode sticking is possible (see Section 3.5). The procedure for changing the values of the operational parameters of the welding unit for the current welding process is described in Section 6.1. 13 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 15: Protection Against Electrode Sticking "Anti-Stick

The procedure for changing the values of the operational parameters of the welding unit for the current welding process is described in Section 6.1 14 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 16: Welding At Pulse Welding Current

[DUTY CYCLE OF PULSE] [DUTY CYCLE OF PULSE] t, s t, s t, s Operations required to set these parameters for the current welding process are described in Section 6.1. 15 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 17: Argon Arc Welding Process (Tig)

12. Using the buttons (1) set the current basic parameter - welding current or parameter of the selected function; 13. The device is ready for use. Enjoy Your work. 16 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 18: Operational Cycle Of The Welding Process Tig - Lift

To prevent surface melting of the electrode tip, the rate of lifting the electrode should correspond to the set welding current value. The period of linear current rise is [TIME UP ARC] discussed in Section 4.6. 17 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 19: Argon Arc Welding Process With Tig-2T Function

15. The device is ready for use. Enjoy Your work. If required, perform the additional functions specified for the argon arc welding process (see Section 6.1). 18 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 20: Operational Cycle Of The Welding Process With Tig-2T

When the button is released, the welding current will decrease linearly, the welding unit will be switched off, and the weld area will be purged with gas. After these operations, the gas supply valve will be closed with delay. 19 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 21: Argon Arc Welding Process With Tig-4T Function

15. The device is ready for use. Enjoy Your work. The procedure for changing the values of the operational parameters of the welding unit is described in Section 6.1. 20 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 22: Operational Cycle Of The Welding Process With Tig-4T

After these operations, the gas supply valve will be closed with delay. 21 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 23: Pre-Welding Gas Purging

By default, the crater welding [Finish Current] current is 20 A and can be varied by the operator at his option. The procedure for changing the values of the operational parameters of the welding unit is described in Section 6.1. 22 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 24: Post Welding Gas Purging

100 A. As a result, the average heat input to the weld will not change. 23 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 25: Semiautomatic Arc Welding Process (Mig/Mag)

This variant is not recommended, as in this case, the electrode wire feeding unit cannot provide uniform and stable wire feed. 24 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 26: Preparing The Welding Unit For Operation

WELDING TORCH GROUNDING CLAMP WORKPIECE The order of preparing the device for MIG/MAG welding with the PATON™ production wire feeder 1. Install the source on the base of the wire feed mechanism, for better stability, fasten and tighten the belt with the source and the base (through the holes in the form of slits on the sides of the source), the strap is included in the set;... - Page 27 (3) in wire feeder unit. 23. The device is ready for use. Enjoy Your work. If required, perform the additional functions specified for the semiautomatic arc welding process (see Section 6.1). 26 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

- Page 28 Remember that the parameters to be set are different for different welding processes. If required, perform the additional functions specified for the semiautomatic arc welding process (see Section 6.1). 27 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

-

Page 29: Operational Cycle Of The Welding Process - Mig / Mag

By default, the linear welding voltage reduction period [TIME ] is 1.0 s and can be varied by the operator at his option (see Section 6 .1). DOWN VOLTAGE 28 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 30: Welding At Pulse Welding Voltage

18 V. As a result, the average heat input to the weld will not change. 29 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 31: Setting The Welding Unit

(1). In the situation of fast pressing and releasing the button (3), you can switch over to the next welding machine functions. 30 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 32: Switching To The Required Welding Process

Reduction of voltage: = OFF (default value) VOLT REDUCTION a) ON DEVICE b) OFF Current pulse amplitude: = OFF (default value) POWER PULSE a) 0 [OFF] … 80% (adjustment 1%) 31 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 33: Argon Shielded Tungsten-Arc Welding Process (Tig)

Duty cycle (the ratio of the pulse length to the pulse repetition period): DUTY CYCLE PULSE 50 % (default value) a) 20 … 80 % (positive or negative increment 1 %) 32 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 34: Semiautomatic Arc Welding Process (Mig/Mag)

After completion of works with the welding unit, apply to the unit a plate with a warning text prohibiting switching on the unit. 33 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 35: Storage

10 – 200 A for ADI – 200S 160 А for ADI – 160S Welding current at a load factor of 45 %, for 5 minutes 200 A for ADI – 200S 34 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 36: Delivery Set

5. Operation manual 14. WARRANTY The Pilot Plant of Welding Equipment of the Institute of Electric Welding named after E. O. Paton guarantees the correct operation of the power supply if the costumers provided service conditions, storage and transportation. ATTENTION!!! Warranty commitments are cancelled in case of mechanical damage. -

Page 37: Safety Regulations

Failure to follow the instructions in this manual may result in serious personal injury, death and damage to the unit itself. Incorrect installation, maintenance and operation resulting in damage to the device - the manufacturer is not liable. 36 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... - Page 38 Welding hoses should be arranged in parallel, as close as possible to each other. 37 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

- Page 39 It is recommended that the power line be provided with a separate protection against the shock absorber. 38 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

-

Page 40: Waste Electrical & Electronic Equipment

All rights reserved. This document is protected by copyright. Copying or distributing the User Manual in whole or in excerpts without MasterWeld permission is prohibited. 39 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 41: Electrical Schematic Diagram

17. ELECTRICAL SCHEMATIC DIAGRAM BUV-0400 CURRENT ~ 230 V 40 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... -

Page 42: Acceptance Certificate

ATTENTION!!! The delivery of the device to the Paton Service Center is carried out at the expense of the manufacturer for the entire warranty period from the date of purchase exclusively in Poland! 41 | P a g e ®... -

Page 43: Warranty Card

_______________ (Signature) (Signature) FAULTS DETECTED AND FAULTY-CONDITION CAUSE: Tel. Technical support: +48 22 290 86 96 Address of the service center: 35105, Poland, Rzeszów, 14 Przemysłowa Street, 42 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG... - Page 44 _______________ (Signature) (Signature) FAULTS DETECTED AND FAULTY-CONDITION CAUSE: Tel. Technical support: +48 22 290 86 96 Address of the service center: 35105, Poland, Rzeszów, 14 Przemysłowa Street, 43 | P a g e ® PATON ADI 200 STANDARD TIG/MMA MIG/MAG...

Need help?

Do you have a question about the ADI 160 STANDARD and is the answer not in the manual?

Questions and answers