Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Emerson MultiFlex Series

- Page 1 026-1704 Rev 6 06-APR-10 MultiFlex I/O Board Installation and Operation Manual...

- Page 3 3240 Town Point Drive NW Suite 100 Kennesaw, GA 30144, USA Phone: 770-425-2724 Fax: 770-425-9319 ALL RIGHTS RESERVED. The information contained in this manual has been carefully checked and is believed to be accurate. However, Com- puter Process Controls, Inc. assumes no responsibility for any inaccuracies that may be contained herein. In no event will Computer Process Controls, Inc.

-

Page 5: Table Of Contents

Table of Contents 1 OVERVIEW OF THE MULTIFLEX PRODUCT LINE ..................1 1.1. M 16 I ............................1 ULTI NPUT OARD 1.2. M ....................2 ULTI OMBINATION NPUT UTPUT OARDS 1.3. O ......................3 THER OARDS IN THE ULTI AMILY 1.3.1. - Page 6 5 BOARD STATUS LEDS ............................. 19 5.1. S LED................................19 TATUS 5.2. T ............................... 19 X AND 5.3. C B LED ............................19 5.4. R ..............................20 ELAY UTPUT 6 THE MULTIFLEX HAND-HELD TERMINAL INTERFACE ................21 6.1. M I/O B ..................

-

Page 7: Overview Of The Multiflex Product Line

Overview of the Multi- Like the 16AI, the MultiFlex 16 communi- Flex Product Line cates with the site controller via an RS485 con- nection to a REFLECS COM A&D network or an Einstein I/O network. Dip switches on the board set the network ID (board number) and The MultiFlex line of control system boards baud rate. -

Page 8: Multi Flex Combination Input /Output Boards

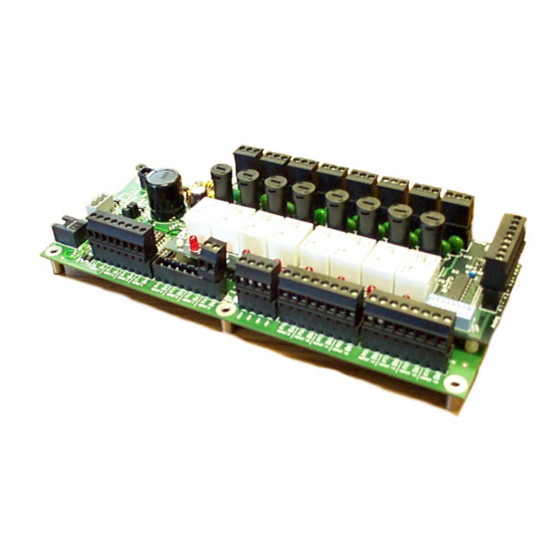

The MultiFlex combination I/O boards con- 1.2. MultiFlex Combination In- sist of two circuit boards: a bottom layer with up to 16 combination digital/analog inputs, and a put/Output Boards plug-in top layer which contains a combination of relay outputs, digital outputs, and analog out- puts. -

Page 9: Other Boards In The Multi Flex Family

The MultiFlex RTU board has 16 analog 810-3066 MultiFlex 168 16 analog/digital in- puts, 8 relay outputs. inputs, 8 relay outputs and 4 analog outputs. Most of these I/O points are reserved for sensors 810-3067 MultiFlex 168DO 16 analog/digital in- puts, 8 relay outputs, and input devices required to read environmental and 4 pulse-width... -

Page 10: The Multiflex Pak

denser fan control. The MultiFlex CUB-TD is a scaled-down version of the CUB-II that controls condenser fans using a temperature differential strategy. The MultiFlex CUB uses the same general hardware configuration as a MultiFlex 168AO. It is equipped with a processor and extra mem- ory to allow it to control compressors, condens- ers, refrigeration, and defrost for a single condensing unit using on-board I/O and control... -

Page 11: Mounting And Powering

Mounting and Power- 2.1. Snap-Track Installation MultiFlex boards not supplied in a custom panel or other enclosure are supplied with a The MultiFlex boards are usually installed snap-track for easy installation. The insulation by the refrigeration or building equipment man- sheet and I/O board must be removed from the ufacturer. -

Page 12: The Plug-In Output Board

The additional board makes the MultiFlex 2.2. The Plug-In Output Board combination I/O boards considerably taller than the MultiFlex 16 and all previous-generation CPC I/O boards. If you will be mounting these boards in an enclosure, the board will need at least 2.5"... -

Page 13: Choosing Transformer Sizes

2.3.1. Choosing Transformer Sizes 2.3.3. MultiFlex Combination Input/ Output Board Power Wiring In most site installations, a single trans- former will power multiple devices. Choose a The MultiFlex 88, 88AO, 168, 168AO, and transformer with a VA rating large enough to 168DO boards do not use a center tap. -

Page 14: New-Style Multiflex Combination I/O Boards (With Isolated Power Supply)

If there is a power LED next to the connec- In addition, the MultiFlex combination tor, your MultiFlex is a new-style MultiFlex -- boards can be powered by one of the 50VA or refer to Section 2.3.3.1., New-Style MultiFlex 75VA non-center-tapped transformers listed in Combination I/O Boards (with Isolated Power Table 2-1 on page 6. -

Page 15: Wire Types And Maximum Distances

Rule 2: Do not power an old-style MultiFlex The wire length from the transformer and the non-center-tapped board with a transformer number of boards connected to the same wire that is also powering a center-tapped device. determines the type wire gauge used. In most cases, the distance between the I/O boards and This means you cannot connect an old-style the transformer that supplies power to them is... -

Page 16: The I/O Network

The I/O Network A diagram of this network arrangement is shown in Figure 3-1. All MultiFlex boards and controllers use an RS485 network connection to communicate with Einstein and REFLECS site controllers. Techni- cians who are familiar with CPC’s previous gen- eration 16AI, 8IO, and ARTC boards will find the network setup procedure for the MultiFlex boards to be very much the same. -

Page 17: Network Id Numbers

3.3.2. Numbering for MultiFlex 3.3. Network ID Numbers Combination I/O Boards The "+", which appears on all MultiFlex Each device on an RS485 segment has a net- boards manufactured after May 2004, means the work dip switch that must be used to assign the board is equipped with a low-power network board a unique network ID number. -

Page 18: Addressing The 168Do

3.3.3. Addressing the 168DO Figure 3-4 provides a graphic representation of input and relay output board numbering for Setting up the network ID numbers for the two MultiFlex 16s, three 8ROs, two MultiFlex 168DO is the same as setting up a 168AO (see 88 boards, and a 1616LAO. - Page 19 nate a MultiFlex, these jumpers must be set to the IN (toward the center of the board) position. Figure 3-6 shows the termination jumper set- tings for all MultiFlex boards. TERMINATION JUMPERS NO TERMINATION - IN (toward center) TERMINATION - OUT (toward left edge) Figure 3-6 - I/O Network Termination Jumper Settings Setting the Terminating Resistance Jumpers The I/O Network •...

-

Page 20: O Board Input And Output Setup

I/O Board Input and 4.1.1.1. Wiring Output Setup An input point on a MultiFlex board consists of two terminals, as shown in Figure 4-1. One of these terminals, labeled “SIG,” reads the signal from the sensor, while the other, labeled “0v” is 4.1. -

Page 21: Sensor Wiring Types

unplug the connector from the old board and The input type dip switch tells the input plug it into the female end of the adapter. Plug board whether or not the sensor connected to the the male end into the appropriate MultiFlex point is a resistive type sensor. -

Page 22: Power Connection

1. Connect the input to the point labeled This can only be done with sensors that keep INPUT #1. This is the only point on the the 24VAC signal isolated from its DC output board that may accept this type of input. signal (such as CPC’s Dew Point Probe). -

Page 23: Relay Output Ratings And Fuse Protection

position of the fail-safe switch. The fail-safe Note: There are not many cases where you switches for the outputs are on a switch bank at would want a relay to be OPEN when called to the bottom right corner the plug-in output mod- be ON. -

Page 24: The Digital Outputs

The analog outputs have no hardware-based The 168DO has no hardware-based fail-safe fail-safe settings (fail-safes are set in the board settings (fail-safes are set up in the board firm- firmware; see Section 6.1.9., Analog Fail- ware). All that is required is to connect the “+” Safes). -

Page 25: Board Status Leds

Board Status LEDs When a MultiFlex board is powered up, you will be able to determine the operating status of the board by observing its status LEDs. Figure 5-1 shows the location of the MultiFlex’s status LEDs. Figure 5-1 - MultiFlex Status LED Locations If the MultiFlex is connected to the network 5.1. -

Page 26: Relay Output Leds

ther the I/O network is down or it has not yet been commissioned in the Einstein or REFLECS Net- work Configuration screen. Code B Failure Conditions • Blinking 2 times/second - This indicates the board has lost its configuration. For the MultiFlex I/O boards, a board is considered “configured”... -

Page 27: The Multiflex Hand-Held Terminal Interface

The MultiFlex Hand- and analog outputs (both in volts and in percentage) Held Terminal Interface • Override relay outputs to a fixed ON or OFF state, or override analog outputs to a fixed percentage • Configure set points Plugging In the Hand-Held Terminal All MultiFlex boards have a Hand-Held Ter- The Hand-Held Terminal plugs into the RJ11 minal interface, which can be used to view status... -

Page 28: Opening Screen

Configuration Mode cycle through the options. To record your On any menu or configuration screen, to change, simply press the UP ARROW or make a selection or enter a value you must press DOWN ARROW key to move the cursor to the RIGHT ARROW key to begin Configuration another field. -

Page 29: Board Address

6.1.3. Board Address 6.1.4. Settings Settings: 168AO Screen Baud: 9600 Board Address: In 1 Pulse? NO 16AI: 1 8RO: 1 4AO: 1 This screen shows the baud rate dip switch setting for the board, and the position of S3 168DO Screen switch #8, which is required to be UP for all Board Address: RMCC (all versions), BEC (all versions), and... -

Page 30: Input Screens

6.1.6. Input Screens 6.1.6.3. Status-Eng Units I01: 74.500 6.1.6.1. Input Status/Config Menu I02: 111.200 PSI SELECT: 1 I03: 75.200 1= STATUS-VOLTS I04: 65.04 2= STATUS-ENG UN 3= INPUT CONFIG The Status-Eng Units screen shows the same information as the Status-Volts screen, except it The Input Status/Config Menu offers three displays it in the engineering units designated choices:... -

Page 31: Relay Output Screens

the POINT (.) and DASH (-) keys to scroll Field Value Sensor Type Units through the sensor types and units supported by REF LEVEL Refrigerant Liquid PCT (%) CPC controllers. Table 6-1 lists all the possible Level Probe (Hansen) engineering unit settings. LIQ LEVEL Analog Liquid Level PCT (%) -

Page 32: Analog Output Screens

To begin an override, press the RIGHT Overriding an Analog Output ARROW key to enter Configuration Mode, and use the DOWN ARROW key to move the cursor WARNING! Point overrides performed by HHT are not visible to or recognized by the MultiFlex’s parent to the output you wish to override. -

Page 33: Analog Fail-Safes

6.1.9. Analog Fail-Safes Overriding a DO point from the HHT A01: 100% A02: 100% WARNING! Point overrides performed by HHT are not visible to or recognized by the MultiFlex’s parent A03: 100% controller. In some cases, this may cause unnecessary A04: 100% proof failure alarms and other erroneous conditions. -

Page 34: Config Fail % Screen

6.1.12.Config Fail % Screen D01: 100% D02: 100% line D03: 100% (Fail) D04: 100% This screen sets the default percentage at which the digital outputs on the 168DO will pulse if communication is lost with the site con- troller. When the board recognizes it is off-line, it will immediately switch to its fail-safe per- centage, and will remain at this rate until the board returns to on-line status. -

Page 35: Relay Output Test Mode

Relay Output Test In Relay Output Test Mode, fail-safe dip Mode switches 1-8 (located on the output board layer of MultiFlex I/O boards, and next to switch bank S1 on the 8ROSMT) can be used to change the state of the relays. Newly released versions of the MultiFlex I/O board family and the 8ROSMT have a new A fail-safe switch in the ON position will... - Page 36 Figure 7-1 - Relay Output Test Modes 30 • MultiFlex I/O Board Operator’s Guide 026-1704 Rev 6 06-APR-10...

Need help?

Do you have a question about the MultiFlex Series and is the answer not in the manual?

Questions and answers