Summary of Contents for SystemAir Sysloop EVO

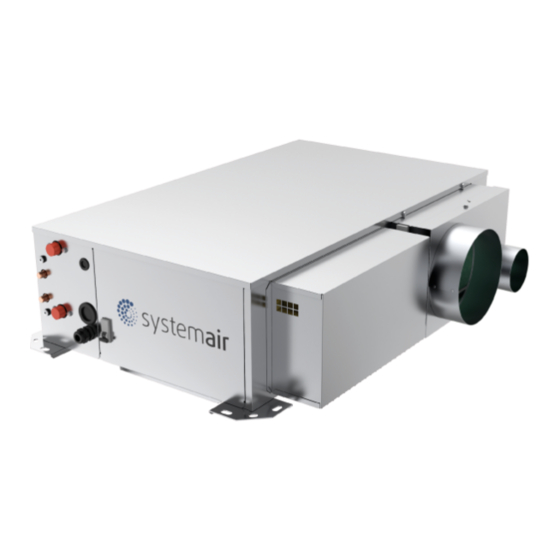

- Page 1 Installation and maintenance manual SYSLOOP EVO Water source heat pump Compressor of variable speed 2.00 â 3.77kW 1.69 â 2.95kW 290 â 525 m...

- Page 3 INSTALLATION INSTRUCTION English NOTICE D’INSTALLATION Français INSTALLATIONSHANDBUCH Deutsch ISTRUZIONI INSTALLAZIONE Italiano INSTRUCCIONES DE INSTALACIÓN Español...

-

Page 4: Table Of Contents

11.3. AIR DISCHARGE MODIFICATION ........................................12 11.4. FILTER ACCESS .............................................12 11.5. VENTILATION ...............................................12 11.6. AERAULIC ADJUSTEMENT ...........................................13 11.6.1. MODEL SYSLOOP EVO ................................................13 12. UNCLAMPING THE COMPRESSOR ..............................14 13. HYDRAULIC LINKS ..................................15 13.1. WATER QUALITY ............................................15 13.2. RECOMMENDATIONS FOR HYDRAULIC CONNECTIONS ................................16 13.3. -

Page 5: General Recommendations

SYSLOOP EVO POWER SUPPLY MUST BE SWITCHED OFF BEFORE STARTING WORK IN THE ELECTRIC CONTROL BOX 1. GENERAL RECOMMENDATIONS The purpose of this Manual is to provide users with instructions for installing, commissioning, using and maintaining the units. It also contains instructions on starting up the machine as well as recommendations to avoid bodily injury and risks of damage to the device during its operation. -

Page 6: Equipment Safety Data

4 SYSLOOP EVO 1.3. EQUIPMENT SAFETY DATA Safety data R513A Toxicity level Low. Dermal contact with the rapidly evaporating liquid can cause frostbite to the tissue. In the event In contact with the skin of contact with the liquid, warm the frozen tissue with water and notify a physician. Remove contaminated clothing and shoes. -

Page 7: Inspection And Storage

SYSLOOP EVO 2. INSPECTION AND STORAGE At the time of receiving the equipment carefully cross check all the elements against the shipping documents in order to ensure that all the crates and boxes have been received. Inspect all the units for any visible or hidden damage. -

Page 8: Refrigeration Specifications

Refrigerating fluids must be handled by skilled personnel. Caution SYSLOOP EVO units use the R513A fluoro-carbonated fluid, belonging to group 2 as defined in directive 2014/68/UE. Considering the maximum operating pressure of these units (18 bar g), they integrate category 2 (or lower) components as defined in directive 2014/68/UE. -

Page 9: Technical Specifications

SYSLOOP EVO 8. TECHNICAL SPECIFICATIONS 8.1. OPERATING LIMITS 8.1.1. ENVIRONMENT This equipment is designed EXCLUSIVELY for INDOOR installation. In general, sheltered locations such as garages, roof space, etc, do not provide sufficient protection against extreme temperatures and/or humidity and may be harmful to the unit’s performance, reliability and service life. -

Page 10: Electric Specifications

8 SYSLOOP EVO 9. ELECTRIC SPECIFICATIONS 9.1. ELECTRICAL POWER SUPPLY A variance of ±10% is acceptable in relation to the operating voltage marked on the appliance’s Maker’s Plate. Operating voltages: 230V / 1 ph / 50 Hz (207 Volts minimum; 253 Volts maximum.) ²... -

Page 11: Clearance

SYSLOOP EVO 10.2. CLEARANCE 600mm 600mm 600mm 600mm 200mm 10.3. UNIT LOCATION Caution The unit base shall be arranged as indicated in the manual. There could be a risk of personal injury or damage to property in the event of the unit being incorrectly supported. -

Page 12: Ducting And Noise Level Reduction

10 SYSLOOP EVO 11. DUCTING AND NOISE LEVEL REDUCTION Water circuit heat pumps are usually installed in conjunction with an air blowing duct. A return air duct may also be required. All ductwork shall be compliant with best air conditioning engineering practices. -

Page 13: Air Blowing Frame And Return Air Intake Frame

SYSLOOP EVO 11.1. AIR BLOWING FRAME AND RETURN AIR INTAKE FRAME RETURN AIR INTAKE (IN LINE) AIR FILTER 225X366X23 RETURN AIR INTAKE (REAR) IN LINE BLOWING (STANDARD CONFIGURATION) 11.2. AIR BLOWING PLENUM AND RETURN AIR INTAKE PLENUM RETURN AIR INTAKE... -

Page 14: Air Discharge Modification

12 SYSLOOP EVO 11.3. AIR DISCHARGE MODIFICATION The units can be delivered configured either for frontal air return, known as "In LINE" or for side air return. It is also possible to modify the return air configuration onsite by proceeding as follows: 1. -

Page 15: Aeraulic Adjustement

: External static pressure at blowing EXTERNAL STATIC PRESSURE = P2-P1 Caution External static pressure at the air intake above -100Pa External static pressure at blowing less than 100Pa 11.6.1. MODEL SYSLOOP EVO BASIC FILTER - WITHOUT PLENUN BASIC FILTER - WITH PLENUM Ductwork Ductwork... -

Page 16: Unclamping The Compressor

14 SYSLOOP EVO 12. UNCLAMPING THE COMPRESSOR Caution Before the first start-up the compressor transport clamping be removed. Failure to do this could result in vibrations, high noise and could lead to the refrigerant tubes breaking. It is not necessary to open the panels to unlock the compressor. This can be achieved by removing the... -

Page 17: Hydraulic Links

Caution The SYSLOOP EVO must not run on a network with open loops, likely to cause incidents related to oxygenation, or with non treated table water. Using improperly treated or non treated water in the SYSLOOP EVO may cause scaling, erosion, corrosion or algae or sludge deposits in the exchangers. -

Page 18: Recommendations For Hydraulic Connections

16 SYSLOOP EVO 13.2. RECOMMENDATIONS FOR HYDRAULIC CONNECTIONS 1. It is recommended that all units are connected to a water supply and return pipe system of the Tickelman Loop type. The Tickelman Loop system is self-balancing and thus only requires manual balancing if a large number of units with different flow and pressure loss characteristics are connected to a single hydraulic loop. - Page 19 SYSLOOP EVO 6. Certain flexible hose threaded connectors are supplied with sealing paste. If this is not the case, use Teflon tape to create a tight seal. 7. Each unit must be equipped with isolation valves on the water inlet and outlet pipes. The return isolation valve is used for both cutting off the water supply and balancing the installation’s water...

-

Page 20: Recommendations For Cleaning And Flushing Out The System

18 SYSLOOP EVO 13.3. RECOMMENDATIONS FOR CLEANING AND FLUSHING OUT THE SYSTEM 1. Before commissioning an appliance for the first time, the water loop must be cleaned and rinsed out to remove any dirt and manufacturing debris. If the appliances are equipped with isolation valves (either electric or pressostatic), the water... -

Page 21: Wiring Diagram And Legend

SYSLOOP EVO 14. WIRING DIAGRAM AND LEGEND 14.1. WIRING DIAGRAM SEE APPENDIX SE4809 model SYSLOOP EVO EC motor Control Siemens 230V 50Hz +/- 10% 14.2. LEGEND N 823 SEE APPENDIX 14.2.1. POWER SUPPLY The power supply must be protected by an FFG mains circuit breaker. -

Page 22: Generalities

20 SYSLOOP EVO 15.1. GENERALITIES Ensure that the available electrical power supply and the network frequency are matched to the required operating current, taking account of the appliance’s specific location and the current required to supply any other appliances connected to the same circuit. -

Page 23: Electrical Connections

The control return must be connected as per the following diagrams. For the connection, use a KNX TP1 type cable (Twisted pair with insulation) with a 0.8mm² cross-section. SYSLOOP EVO - AUTONOMOUS Lmax = 700 M SYSLOOP EVO - MASTER/SLAVES... -

Page 24: Regulation

22 SYSLOOP EVO 16. REGULATION SYSLOOP EVO units are fitted with an electronic control system. It provides the command, control and alarm functions. 16.1. ORDER OF PRIORITY FOR CONTROL SYSTEMS The integrated regulator in the SYSLOOP EVO can be controlled by various interfaces and systems. The order... -

Page 25: Screen

SYSLOOP EVO 16.2.2. SCREEN Icons Meanings AUTO 23.5 SYSLOOP EVO off °C Hourly programming active 05:30 AUTO month year Operation in Eco mode Operation in Comfort mode COOL mode HEAT Mode Auto-changeover mode. The control displays the active heat control mode. -

Page 26: Scheduling

24 SYSLOOP EVO 16.2.4. SCHEDULING Scheduling is used to select the unit activation and shutdown times. Each day is broken down into 6 time slots set by Selected time slot mode A start time ² A state: ON or OFF ²... -

Page 27: Final Tasks

Place the plugs back on the valves and check that they are properly tightened. If needed, fix the cables and the pipes on the wall with clamping collars. Operate the SYSLOOP EVO in the presence of the user and explain all functions. Show him how to remove, clean and place back the filters. -

Page 28: Commissioning

26 SYSLOOP EVO 18.1. COMMISSIONING After performing all the above-mentioned checks, proceed with creating a demand for Cooling and Heating or vice versa. 18.1.1. DEMAND FOR COOLING 1. With the key on the control module, select COOL mode and then set the minimum temperature with the UP and DOWN arrows. -

Page 29: Maintenance And Servicing

SYSLOOP EVO 19. MAINTENANCE AND SERVICING 1. Normal maintenance of the appliances is generally limited to replacing filters. 2. The filters must be changed at regular intervals. The frequency is dependent on the specific application conditions. Certain installations, for example in hotels where there large amounts of fluff due to the frequent bedding changes and the presence of fitted carpets, require more frequent filter changes. -

Page 30: Insufficient Cooling Or Heating Production

28 SYSLOOP EVO 19.1.3. INSUFFICIENT COOLING OR HEATING PRODUCTION 1. Check that the thermostat is properly located in the zone to be heated or cooled and that it is not near to a source of cold or heat that may influence the reading. -

Page 31: Alarm Codes

SYSLOOP EVO 19.2. ALARM CODES Code Type Message HP pressure switch LP pressure switch water min. temperature cool mode alarm water max. temperature cool mode water min. temperature heat mode water max. temperature heat mode alarm RAT sensor defective alarm... - Page 32 30 SYSLOOP EVO...

- Page 33 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO APPENDIX ANNEXE ANLAGE ALLEGATO ANEXO...

- Page 34 CONFIGURACIÓN R1.AI RECT/S4.AO 1Ø200 O R2.AI 1Ø200 FAØ100/S3.AO 1Ø200 O R1.AI RECT/S3.AO 1Ø200 ................VII R2.AI 1Ø200 FAØ125/S3.AO 1Ø200 ............X CONFIGURACIÓN R2.AI RECT/S4.AO 1Ø200 O CONFIGURACIÓN AO XLN ................XI R2.AI RECT/S3.AO 1Ø200 ................VIII ESQUEMA ELECTRICO ..............XII LEYENDA ......................XIII II SYSLOOP EVO...

- Page 35 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO DIMENSIONS DIMENSIONS ABMESSUNGEN DIMENSIONI DIMENSIONES CONFIGURATION R1.AI RECT/S4.AO RECT Ø 1/2“ Gas male 917.5 R1.AI RECT S4.AO RECT SYSLOOP EVO...

- Page 36 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION R2.AI RECT/S4.AO RECT Ø 1/2“ Gas male 917.5 1030 S4.AO RECT R2.AI RECT IV SYSLOOP EVO...

- Page 37 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION R1.AI 1Ø200/S4.AO RECT OR R1.AI 1Ø200 FAØ100/S4.AO RECT OR R1.AI 1Ø200 FAØ125/S4.AO RECT Ø 1/2“ Gas male 917.5 R1.AI 1Ø200 FAØ100 R1.AI 1Ø200 FAØ125 R1.AI 1Ø200 S4.AO RECT SYSLOOP EVO...

- Page 38 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION R2.AI 1Ø200/S4.AO RECT OR R2.AI 1Ø200 FAØ100/S4.AO RECT OR R2.AI 1Ø200 FAØ125/S4.AO RECT Ø 1/2“ Gas male 917.5 1095 S4.AO RECT R2.AI 1Ø200 R2.AI 1Ø200 FAØ100 R2.AI 1Ø200 FAØ125 VI SYSLOOP EVO...

- Page 39 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION R1.AI RECT/S4.AO 1Ø200 OR R1.AI RECT/S3.AO 1Ø200 Ø 1/2“ Gas male 917.5 R1.AI RECT S4.AO 1Ø200 R1.AI RECT 1004 S3.AO 1Ø200 SYSLOOP EVO...

- Page 40 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION R2.AI RECT/S4.AO 1Ø200 OR R2.AI RECT/S3.AO 1Ø200 Ø 1/2“ Gas male 917.5 R2.AI RECT S4.AO 1Ø200 1030 R2.AI RECT S3.AO 1Ø200 VIII SYSLOOP EVO...

- Page 41 FAØ125/S4.AO 1Ø200 OR R1.AI 1Ø200/S3.AO 1Ø200 OR R1.AI 1Ø200 FAØ100/S3.AO 1Ø200 OR R1.AI 1Ø200 FAØ125/S3.AO 1Ø200 Ø 1/2“ Gas male 917.5 R1.AI 1Ø200 FAØ100 R1.AI 1Ø200 FAØ125 R1.AI 1Ø200 S4.AO 1Ø200 R1.AI 1Ø200 FAØ100 R1.AI 1Ø200 FAØ125 1004 R1.AI 1Ø200 S3.AO 1Ø200 SYSLOOP EVO...

- Page 42 FAØ125/S4.AO 1Ø200 OR R2.AI 1Ø200/S3.AO 1Ø200 OR R2.AI 1Ø200 FAØ100/S3.AO 1Ø200 OR R2.AI 1Ø200 FAØ125/S3.AO 1Ø200 Ø 1/2“ Gas male 917.5 R2.AI 1Ø200 R2.AI 1Ø200 FAØ100 S4.AO 1Ø200 R2.AI 1Ø200 FAØ125 1095 R2.AI 1Ø200 R2.AI 1Ø200 FAØ100 R2.AI 1Ø200 FAØ125 S3.AO 1Ø200 X SYSLOOP EVO...

- Page 43 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO CONFIGURATION AO XLN R1.AI RECT R1.AI 1Ø200 1 055 SYSLOOP EVO...

- Page 44 MISE HORS TENSION OBLIGATOIRE AVANT TOUTE INTERVENTION DANS LES BOITIERS ELECTRIQUES. VOR JEDEM EINGRIFF AN DEN ANSCHLUßKÄSTEN UNBEDINGT DAS GERÄT ABSCHALTEN! PRIMA DI OGNI INTERVENTO SULLE CASSETTE ELETTRICHE ESCLUDERE TASSATIVAMENTE L’ALIMENTAZIONE ! PUESTA FUERA DE TNESIÓN OBLIGATORIA ANTES DE CUALQUIER INTERVENCIÓN EN LAS CAJAS ELÉCTRICAS! XII SYSLOOP EVO...

- Page 45 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO LEGEND SYSLOOP EVO XIII...

- Page 46 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO XIV SYSLOOP EVO...

- Page 47 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO SYSLOOP EVO...

- Page 48 APPENDIX / ANNEXE / ANLAGE / ALLEGATO / ANEXO XVI SYSLOOP EVO...

- Page 49 Ground cable is wired Condensate connection Main electrical protection suits the unit Presence of a regulating valve All electrical connections are correctly tightened Presence of air filters OBSERVATIONS: ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SYSLOOP EVO XVII...

- Page 50 Air outlet temperature °C °C REMARKS: ............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................DATE: DATE: TECNICIAN: CLIENT Name: Name: Sign-in: Sign-in: XVIII SYSLOOP EVO...

- Page 52 As part of our ongoing product improvement programme, our products are subject to change without prior notice. Non contractual photos. Systemair AC SAS Route de Verneuil 27570 Tillières-sur-Avre FRANCE & : +33 (0)2 32 60 61 00 6 : +33 (0)2 32 32 55 13...

Need help?

Do you have a question about the Sysloop EVO and is the answer not in the manual?

Questions and answers