Table of Contents

Advertisement

Installation and maintenance manual

Manuel d'installation et de maintenance

Installations- und Wartungshandbuch

Manuale di installazione e di manutenzione

Manual de instalación y de mantenimiento

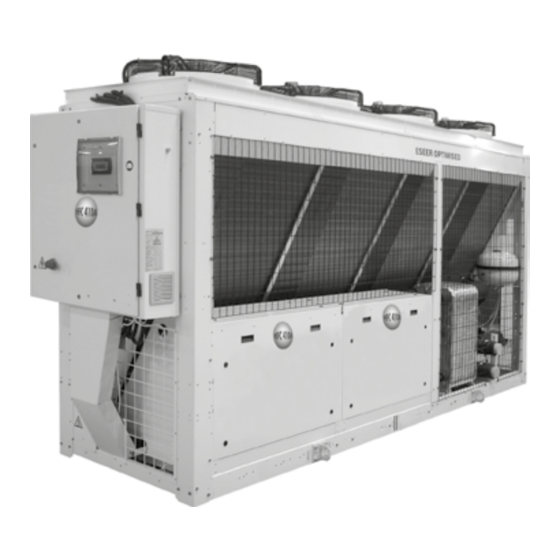

VLS/VLC/VLH/VLR

English

Air Cooled Water Chillers and Heat Pump

137

Refrigerateurs à Eau et Pompes de Chaleur Refroidies à Air

308 kW

Luftgekühlte Wasserkühler und Wärmepumpen

Refrigeratori d'Acqua e Pompe di Calore Raffreddati ad Aria

150

Refrigeradores de Agua y Bombas de Calor Refrigerados por Aire

336 kW

Part number / Code / Code / Codice / Código: 342603/J

Supersedes / Annule et remplace / Annulliert und ersetzt / Annulla e sostituisce /

Anula y sustituye: 342603/I

Notified Body / Organisme Notifié / Benannte Zertifizierungsstelle / Organismo

Notificato / Organismo Notificado N°. 0425

Français

Deutsch

Italiano

Español

ISO 9001:2015 certified management system

Advertisement

Table of Contents

Summary of Contents for SystemAir VLS Series

- Page 1 Installation and maintenance manual Manuel d’installation et de maintenance Installations- und Wartungshandbuch Manuale di installazione e di manutenzione Manual de instalación y de mantenimiento VLS/VLC/VLH/VLR English Français Deutsch Italiano Español Air Cooled Water Chillers and Heat Pump Refrigerateurs à Eau et Pompes de Chaleur Refroidies à Air 308 kW Luftgekühlte Wasserkühler und Wärmepumpen Refrigeratori d’Acqua e Pompe di Calore Raffreddati ad Aria...

-

Page 2: Table Of Contents

Table of contents 1 FOREWORD 7 7 GENERAL DESCRIPTION 1.1 Introduction 7.1 Introduction 1.2 Warranty 7.2 General specifications 1.3 Emergency stop/Normal stop 7.3 Compressors 1.4 An introduction to this manual 7.4 Refrigeration circuits 7.5 Water heat exchanger 2 SAFETY 7.6 Air heat exchanger 2.1 Foreword 7.7 Fans 2.2 Definitions... -

Page 3: Foreword

Foreword FOREWORD 1.3 Emergency stop / Normal stop The emergency stop of the unit can be enabled using 1.1 Introduction the master switch on the control panel (move down the lever). Units manufactured to state-of-the-art design and im- plementation standards, ensure top performance, For a normal stop, press the relevant push-buttons. -

Page 4: Safety

Safety SAFETY The guards of the fans (only for units provi- ded with air heat exchangers) must be al- ways mounted and must never be removed Foreword before de-energising the appliance. DANGER These units must be installed in conformity with It is the User’s responsibility to ensure that provisions Machinery... -

Page 5: Access To The Unit

Safety ENGINEER: means a person authorised directly 2.5 Precautions against residual risks by manufacturer or, in all EC countries, excluding Italy, under his full responsibility, by the distributor Prevention of residual risks caused by the of product, to perform any routine and extraordinary control system maintenance operations, as well as any regulation, be sure to have perfectly understood the operating... -

Page 6: Precautions During Maintenance Operations

Safety to the instructions provided in this manual and on The following precautions must be always adopted: the unit’s panelling do not scatter the fluids of the refrigeration circuit in the surrounding environment if you have to disassemble a piece, make sure that it has been properly mounted again before restar- when replacing an eprom or electronic cards, use ting the unit... -

Page 7: Safety Labels

(max) Kw POWER INPUT PRESS. MAX ESERCIZIO ACQUA MAX WATER OPERATING PRESSURE MASSA MASS ATTENZIONE ! ATTENTION ! SYSTEMAIR S.r.l. Via XXV Aprile 29 20825 BARLASSINA MB ITALIA MADE IN ITALY COD.NO: P35952 MODELLO: MODEL Prima di Enlever MATRICOLA: aprire togliere l’alimentation... - Page 8 Safety EIN - INLET ENTRÉE - ENTRATA AUS - OUTLET SORTIE - USCITA Fitting identification - Adjacent to fittings Grounding connection - On the electrical Start up warning - board, adjacent to the connection Outside the door of the electrical board Warning - safety valves’...

-

Page 9: Safety Regulations

Safety Safety regulations Safety data: R410A Refrigerant data Toxicity Contact with skin If sprayed, the refrigerant is likely to cause frost burns. If absorbed by the skin, the danger is very limited; it may cause a slight irritation, and the liquid is degreasing. Unfreeze the affected skin with water. Remove the contaminated clothes with great care - in the presence of frost burns, the clothes may stick to the skin. - Page 10 Safety General precautions Do not inhale concentrated vapours. Their concentration in the atmo- sphere should not exceed the minimum preset values and should be maintained below the professional threshold. Being more weighty than the air, the vapour concentrates on the bottom, in narrow areas. There- fore, the exhaust system must work at low level.

- Page 11 Safety Safety data: Polyester oil (POE) Lubricant oil data ClasHPFication Not harmful May cause slight irritation. Does not require first aid measures. It is Contact with skin recommended to follow usual personal hygiene measures, including washing the exposed skin with soap and water several times a day. It is also recommended to wash your overalls at least once a week.

-

Page 12: Transport, Lifting And Positioning

Transport, Lifting and Positioning It is recommended to use a spacer to prevent cables TRANSPORT, LIFTING AND from damaging the unit (see the figure). POSITIONING Refrigerators are supplied assembled (apart from standard antivibrating rubber supports, that will be installed on site). The equipment are full of refrig- erant and oil, in the quantity required for a proper operation. -

Page 13: Anchoring

Transport, Lifting and Positioning For lifting operations, use only tools and material fit for this purpose, in accordance with accident-prevention regulations. WARNING During the lifting and handling of the unit, be careful not to damage the finned pack of the coils positioned on the sides of the unit. The sides of the unit must be protected by WARNING cardboard or plywood sheets. -

Page 14: Installation

Installation INSTALLATION 4.2 Spring Isolator Installation 4.1 Positioning of the unit Prepare the base, that must be flat and plane. Lift the appliance and insert shock absorbers as Before installing the unit, make sure that the follows: structure of the building and/or the suppor- ting surface can withstand the weight of the appliance. -

Page 15: External Hydraulic Circuit

Installation External hydraulic circuit The flow switch and the filter water, although not included in the supply, must always be fitted such as plant components. Their installation is mandatory for warranty. The external hydraulic circuit must ensure the water flow to the evaporator under any working or adjustment conditions. -

Page 16: Hydraulic Connection

Installation Then: Provide the evaporator with a by-pass circuit equipped with a valve to wash the plant. Insulate the piping, to prevent the risk of heat loss. Position a filter on the suction side of the evapora- tor of the heat recovery condenser. Installation Flow Switch External Hydraulic Circuit Unit... -

Page 17: Power Supply

Installation 4.6 Power supply 4.7 Electrical connections The unit must be installed on site according Before carrying out any operations on the to the Machinery Directive (2006/42/EC), the electrical system, make sure that the unit is Electromagnetic Compatibility deenergised. Directive (2014/30/EU) usual DANGER... - Page 18 Installation VLS/VLH/VLC Version – Electrical Connections Page 17...

- Page 19 Installation VLR Version – Electrical Connections QG - Y1 (SRS) REMOTE START/STOP SWITCH (COMMON) FLOW SWITCH (SF) EXTERNAL INTERLOCK (OPTIONAL) CIRC PUMP ETC EXTERNAL INTERLOCK HEAT RECOVERY QG - Y2 (NO) REMOTE INDICATION VOLTAGE ON (COMMON) (NO) (COMMON) GENERAL ALARM SYSTEM 1 (NC) (NO) (COMMON)

-

Page 20: Connecting Plate-Type Evaporator

Installation Connecting plate-type evaporator temperature sensors VLS and VLH units are provided with fittings for hydraulic connections between heat exchangers and plant. Each fittings is complete with sensor well to fasten temperature sensor (BT-IN and BT-OUT). Fittings are supplied separate and must be mounted during the installation of the unit, as explained in the instruction below. -

Page 21: Start-Up

Start-up START-UP 5.2 Start-up The unit must be started for the first time by Start-up sequence: personnel suitably trained by one of Authorised Service Centre. Fail Turn on the master switch (at least 12 hours befo- to meet this requirement will immediately re). -

Page 22: Checking The Operation

Start-up 5.3 Checking the operation Check the following: The temperature of the water entering the evapo- rator. The temperature of the water leaving the evapora- tor. The level of the water flow rate in the evaporator, if possible. The current absorption upon the start of the com- pressor and in case of stabilised operation. -

Page 23: Control

Control The control system consists of: GENERAL INFORMATION Keyboard & Display Terminal Introduction General information This document contains the information and the ope- rating instructions for 4 compressors & electronic The figure shows the terminal with the front door control. open. -

Page 24: Display

Control Display Esc key: allows you to move from one mask to another. Alarm key: used to display the alarms, to reset them in manual. Press it one to display the mask of the activated alarm, press it again to reset the alarm signal. - Page 25 Control Alarms Alarm code Description Notes Main board - EPROM Failure Main board - Clock card Failure Main board - External air temperature sensor fault Main board - Return Water temperature sensor fault Main board - Leaving Water temperature sys 1 sensor fault Main board - Leaving Water temperature sys 2 sensor fault Main board - Low pressure sys 1 sensor fault Main board - Low pressure sys 2 sensor fault...

- Page 26 Control Alarm code Description Notes EPROM Error Driver 2 Driver 1 S1 Sensor fault Driver 1 S3 Sensor fault Driver 1 S2 Sensor fault Driver 1 S4 Sensor fault Driver 2 S1 Sensor fault Driver 2 S2 Sensor fault EEV motor Error (Check viring) Sys 1 EEV motor Error (Check viring) Sys 2 Driver 1 Battery alarm Driver 2 Battery alarm...

-

Page 27: Protection And Safety Equipment

Control 6.4 Protection and Safety Compressor protection Equipment Compressors are equipped with a heating element to prevent oil dilution, which may result in remarkable Defrosting System risks of failure of compressors. (only for VLH models) The windings of the compressors’ motors are provi- The VLH units are provided with an automatic defro- ded with a thermal protection. -

Page 28: Hpf Version Configuration

Control 6.5 HPF version configuration Units equipped with High pressure fan (HPF) can be The table below shows the correspondance between set-up on the field to give the unit a specific static chiller model, fan RPM, high static pressure. pressure. By entering parameter in service level - Max Speed (Vdc) - it is possible to modify high static pressure. -

Page 29: 7 General Description

General Description GENERAL DESCRIPTION 7.1 Introduction te fluids (glycoled water), for air-conditioning appli- cations in industrial processes. The VLS/VLH units are water chillers /air-water heat These units can be installed outdoor on the roof of a pumps provided with hermetic scroll compressors building or at ground level. -

Page 30: Air Heat Exchanger

General Description The hydraulic connections to the evaporator are of 2” Fans Victaulic type on 504 – 804 units and 3” Victaulic type on 904 – 1204 units. Fans are of directly coupling propeller type, provi- ded with aluminium blade with wing profile. 7.6 Air heat exchanger Each fan is provided with galvanised steel accident- prevention guard. - Page 31 General Description VLC refrigeration diagram OIL EQUAL. OIL EQUAL. Components: Safety /control devices: 1) Compressor Tandem Scroll Type A - High Pressure switch (42 bar) 2) Air cooled condenser AT - High Pressure transducer 3) Globe valve BT - Low Pressure transducer D - Air temperature sensor G - PED pressure relief valve (46 bar) S - 5/16”...

-

Page 32: Electric Power Supply And Control System

General Description 7.8 Electric power supply and RS-485 serial card (for MODBUS or control system LONWORK or BACNET ) A communication interface makes it possible to con- The control compartment contains and electronic trol and manage the unit from a local station, with card with keyboard and a display for working para- RS485 connection, up to a distance of 1,000m. -

Page 33: Pressure Drop

Technical data TECHNICAL DATA 8.1 Pressure drops PRESSURE DROP IN THE EVAPORATOR VLS 524 VLS 604 VLS 704 VLS 804 VLS 904 VLS 1004 VLS 1104 VLS 1204 kPa/(l/s)^2 0,66 0,66 0,66 0,54 0,19 0,19 0,19 0,19 Min. water flow rate Nominal flow rate 10,9 12,0... -

Page 34: Technical Data

Technical data Technical data VLS BLN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 7,8/7,8 8,2/8,2 15/15 15/15 Charge 1/2 16,3/16,3 17,1/17,1 31,3/31,3 31,3/31,3 Compressor Type... - Page 35 Technical data VLS BLN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 15/15 17/17 18/18 18/18 Charge 1/2 31,3/31,3 35,5/35,5 37,6/37,6 37,6/37,6 Compressor...

- Page 36 Technical data VLS LN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 7,8/7,8 8,2/8,2 15/15 15/15 Charge 1/2 16,3/16,3 17,1/17,1 31,3/31,3 31,3/31,3 Compressor Type Scroll Number...

- Page 37 Technical data VLS LN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 15/15 17/17 18/18 18/18 Charge 1/2 31,3/31,3 35,5/35,5 37,6/37,6 37,6/37,6 Compressor...

- Page 38 Technical data VLS ELN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 7,8/7,8 8,2/8,2 15/15 15/15 Charge 1/2 16,3/16,3 17,1/17,1 31,3/31,3 31,3/31,3 Compressor Type Scroll Number...

- Page 39 Technical data VLS ELN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 15/15 17/17 18/18 18/18 Charge 1/2 31,3/31,3 35,5/35,5 37,6/37,6 37,6/37,6 Compressor...

- Page 40 Technical data VLS HT Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 7,8/7,8 8,2/8,2 15/15 15/15 Charge 1/2 16,3/16,3 17,1/17,1 31,3/31,3 31,3/31,3 Compressor Type Scroll Number...

- Page 41 Technical data VLS HT 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 15/15 17/17 18/18 18/18 Charge 1/2 31,3/31,3 35,5/35,5 37,6/37,6 37,6/37,6 Compressor...

- Page 42 Technical data VLH BLN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 43 Technical data VLH BLN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 44 Technical data VLH LN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 45 Technical data VLH LN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 46 Technical data VLH ELN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 47 Technical data VLH ELN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 48 Technical data VLH HT Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 49 Technical data VLH HT 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 50 Technical data VLC BLN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 51 Technical data VLC BLN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 52 Technical data VLC LN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 53 Technical data VLC LN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 54 Technical data VLC ELN Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 55 Technical data VLC ELN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 56 Technical data VLC HT Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 16,5/16,5 18,5/18,5 21,5/21,5 24,5/24,5 Charge 1/2 34,5/34,5 38,6/38,6 44,9/44,9 51,2/51,2 Compressor Type Scroll Number...

- Page 57 Technical data VLC HT 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 27/27 30,5/30,5 34/34 37,5/37,5 Charge 1/2 56,4/56,4 63,7/63,7 71,0/71,0 78,3/78,3 Compressor...

- Page 58 Technical data Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 25-50-75-100 28-57-78-100 20-50-70-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 7,8/7,8 8,2/8,2 15/15 15/15 Charge 1/2 16,3/16,3 17,1/17,1 31,3/31,3 31,3/31,3 Compressor Type Scroll Number Start-up type Direct...

- Page 59 Technical data 1004 1104 1204 Power supply V/ph/Hz 400 (±10%) / 3 / 50 Number of circuits Capacity steps 28-50-78-100 25-50-75-100 23-50-73-100 25-50-75-100 Refrigerant Type / GWP R410A / 2.088 15/15 17/17 18/18 18/18 Charge 1/2 31,3/31,3 35,5/35,5 37,6/37,6 37,6/37,6 Compressor Type Scroll...

-

Page 60: Unit Electrical Data

Technical data 8.3 Unit Electrical Data VLS/VLH/VLC/VLR BLN 1004 1104 1204 Rated voltage V/ph/Hz 400 (±10%) /3/50 Max. absorbed power 60,0 69,6 80,8 96,4 105,2 112,0 130,0 148,0 Rated current 88,0 100,0 112,0 120,0 142,0 160,0 172,0 184,0 156,0 186,0 172,0 Max. - Page 61 Technical data VLS/VLH/VLC/VLR HSE BLN 1004 1104 1204 Rated voltage V/ph/Hz 400 (±10%) /1/50 Max absorbed power 61,2 71,4 82,6 98,2 107,6 114,4 132,4 150,4 Rated current 88,2 100,3 112,3 120,3 142,4 160,4 172,4 184,4 Max current FLA 148,2 156,3 186,3 172,3 193,4...

- Page 62 Technical data VLS/VLH/VLC/VLR HPF 1004 1104 1204 Rated voltage V/ph/Hz 400 (±10%) /3/50 Max absorbed power 60,4 70,2 81,4 97,0 106,0 112,8 130,8 148,8 Rated current 87,4 99,1 111,1 119,1 140,8 158,8 170,8 182,8 Max current FLA 147,4 155,1 185,1 171,1 191,8 208,8...

- Page 63 Technical data Fans Electrical Data VLS/VLH/VLC/VLR BLN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%)/3/50 Number Rated power Absorbed rated current FLA VLS/VLH/VLC/VLR LN/ELN 1004 1104 1204 Power supply V/ph/Hz 400 (±10%)/3/50 Number Rated power 1,25 1,25 1,25 1,25 1,25 1,25 1,25 1,25...

-

Page 64: Position Of Shock Absorbers And Weight Distribution On Supports

Technical data 8.4 Position of shock absorbers and weight distribution on supports VLS/VLH/VLC 524-604 BLN/LN/ELN/HT Version Electrical board Compressor Side C.G. P1 - P4 Unit positions VLS 524 - 604 MCHX BLN/LN Version Weight distribution (kg) Operating Shipping P1-P4 Weight Weight coordinates* coordinates... - Page 65 Technical data VLS 524 - 604 Cu/Cu BLN/LN/ELN/HT Version Weight distribution (kg) Operating Shipping P1-P4 Weight Weight coordinates* coordinates Cu/Cu ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) a (mm)* b (mm) c (mm) x (mm)

- Page 66 Technical data VLS/VLH/VLC 704-1204 BLN/LN/ELN/HT Version Electrical board C.G. Compressor side P1 - P6 Unit positions VLS 704 - 1204 Al/Cu BLN/LN Version Weight distribution (kg) Operating Shipping P1-P6 Weights Weights coordinates* coordinates Al/Cu ( kg ) ( kg ) ( kg ) ( kg ) ( kg )

- Page 67 Technical data VLR 704 - 1204 Al/Cu BLN/LN Version Weight distribution (kg) Operating Shipping P1-P6 Weights Weights coordinates* coordinates Al/Cu ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) ( kg ) a (mm)* b (mm) c (mm)

-

Page 68: Overall Dimensions

Technical data 8.5 Overall dimensions VLS/VLH 524-604 BLN/LN/ELN/HT 2 FANS size 524 3 FANS size 604 1761 LIFT 3300 2200 1100 (*) Only with 2 pumps WATER CONNECTIONS WATER OUTLET “A” 2” 1/2 M WATER INLET (with pump) “B” 2” 1/2 M WATER INLET (without pump) “C”... - Page 69 Technical data VLS/VLH 704-1204 BLN/LN/ELN/HT 3 FANS for 704-804 4 FANS for 904-1204 1985 LIFT 4300 1985 1629 1629 1985 1100 704-804 904-1204 100** (*) Only with 2 pumps (**) Max with Desuperheather WATER CONNECTIONS 704-804 904-1204 WATER OUTLET “A” 2”...

- Page 70 Technical data VLC 524-604 BLN/LN/ELN/HT 2 FANS size 524 3 FANS size 604 1761 LIFT 3300 circ.2 liquid line : 7/8" ODS suction line : 1"5/8 ODS circ.1 2200 1100 1179 LIFT 1249 Page 69...

- Page 71 Technical data VLC 704-1204 BLN/LN/ELN/HT 3 FANS for 704-804 4 FANS for 904-1204 1985 LIFT 4300 1985 1629 circ.2 circ.1 1629 1985 1100 704-804 904-1204 1179 LIFT 1249 1” 5/8 2” 1/8 7/8” 1” 1/8 Page 70...

- Page 72 Technical data VLR 524-604 BLN/LN/ELN/HT 2 FANS size 524 3 FANS size 604 1761 LIFT 3300 2200 1100 WATER CONNECTIONS WATER OUTLET “A” 2” 1/2 M WATER OUTLET (recover) “B” 2” 1/2 M WATER INLET “C” 2” 1/2 M WATER INLET (recover) “D” 2”...

- Page 73 Technical data VLR 704-1204 BLN/LN/ELN/HT 3 FANS for 704-804 4 FANS for 904-1204 1985 LIFT 4300 1985 1629 1629 1985 1100 704-804 904-1204 WATER CONNECTIONS 704-804 904-1204 WATER OUTLET “A” 2” 1/2 M 3” M WATER OUTLET (recover) “B” 2” 1/2 M 3”...

- Page 74 Technical data VLS/VLH 524-604 with hydrokit 2 FANS size 524 3 FANS size 604 1614 1320 2208 LIFT 4260 2200 1100 WATER CONNECTIONS 1179 LIFT WATER OUTLET “A” 2” 1/2 M 1249 WATER INLET (with pump) “B” 2” 1/2 M DESUPERHEATER IN/OUT “D”...

- Page 75 Technical data VLS/VLH 704-1204 with hidrokit 3 FANS for 704-804 4 FANS for 904-1204 1958 2578 LIFT 5255 1985 1629 1629 1985 1100 704-804 904-1204 100 ** 1186 1208 (**) Max with Desuperheather WATER CONNECTIONS 704-804 904-1204 WATER OUTLET “A” 2”...

-

Page 76: Services Spaces

Technical data 8.6 Service spaces VLS/VLC/VLH/VLR All models Installation of Single Units Installation of several Units ARRANGEMENT 1 ARRANGEMENT 1 A and C GRILLE A and B FULL A and C FULL A and B GRILLE A and D GRILLE B and D FULL C and D FULL B and D GRILLE... -

Page 77: General Requirements

Maintenance MAINTENANCE Planned maintenance Carefully read the “Safety” section of this manual before carrying out any maintenance operations. Do not discharge the refrigerant into the at- Operations mosphere while the refrigeration circuits are being drained. Use appropriate recov- ery equipment. DANGER When the recovered refrigerant cannot be Check the temperature... -

Page 78: Refrigerant Charge

Maintenance 9.3 Refrigerant charge Compressors use polyester oil. During main- tenance operations on the compressor, or if you have to open the refrigerant circuit Do not inject refrigerant liquid into the LP in any point, remember that this type of side of the circuit. -

Page 79: Dehydrating Filter

Maintenance 9.7 Dehydrating filter If the expansion valve cannot be regulated, it is prob- ably broken, and shall be replaced. The replacement must be carried out by a Service Centre. The refrigeration circuits are provided with dehydrat- ing filters. 9.10 Evaporator The filter clogging is marked by the presence of air bubbles in the sight glass, or by the difference be- Check at regular intervals that the water side of the... -

Page 80: Troubleshooting

Troubleshooting 10 TROUBLESHOOTING The table below lists the anomalies of operation of the unit, the relevant causes and the corrective measures. For anomalies of any other type or not listed, contact one of Service Centre for technical as- authorised sistance. Anomaly Cause Operation... - Page 81 Troubleshooting Anomaly Cause Operation One or both compressors Breaking of the electric circuit. Check the electric circuit and detect are not working. any ground dispersions and short cir- cuits. Check fuses. Intervention of the HP pressure Reset the pressure switch and the con- switch.

-

Page 82: Spare Parts

Spare parts SPARE PARTS 11.1 Spare part list The table below shows the list of spare parts recom- mended during the first two years of operation. Component Number HP pressure switch LP pressure switch Gas filter Electronic expansion valve Auxiliary relays Fan’s fuses Compressor’s fuses Auxiliary fuses... -

Page 83: Raee Directive

Systemair srl Via XXV Aprile, 29 20825 Barlassina (MB) Italy Tel. +39 0362 680 1 Fax +39 0362 680 693 www.systemair.com As part of our ongoing product improvement programme, our products are subject to change without prior notice. Non contractual photos. - Page 84 Systemair srl Via XXV Aprile, 29 20825 Barlassina (MB) Italy Tel. +39 0362 680 1 Fax +39 0362 680 693 www.systemair.com As part of our ongoing product improvement programme, our products are subject to change without prior notice. Non contractual photos.

Need help?

Do you have a question about the VLS Series and is the answer not in the manual?

Questions and answers