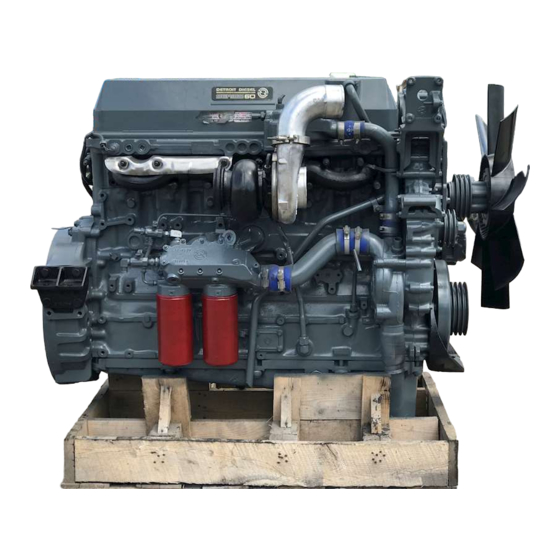

Detroit Diesel 60 Series Operator's Manual

Hide thumbs

Also See for 60 Series:

- Service manual (1669 pages) ,

- Operator's manual (172 pages) ,

- Owner's manual (24 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Detroit Diesel 60 Series

- Page 1 Series 60 Engine Operator's Guide...

- Page 2 Gates Rubber Company. Biobor ® is a registered trademark of U.S. Borax and Chemical Corporation. Tectyl ® is a registered trademark of Ashland Oil Corporation. 6SE484 0007 © Copyright 2000. Detroit Diesel Corporation. All rights reserved. Printed in U.S.A.

-

Page 3: Table Of Contents

Table of Contents Subject Page INTRODUCTION ....................ii NON-GENUINE AND REBUILT COMPONENT QUALITY ALERT......ii CAUTION SUMMARY ...................iv-viii ENGINE MODEL AND SERIAL NUMBER DESIGNATION........1-2 Option and Certification Labels................1 OPERATING INSTRUCTIONS .................3-9 Preparations for Starting the Engine the First Time ..........3 Starting the Engine .....................5 Running the Engine ....................7 Stopping the Engine...................8 Emergency Jump Starting ..................8... -

Page 4: Introduction

INTRODUCTION NON-GENUINE AND REBUILT COMPONENT This guide is intended for use by the QUALITY ALERT operator of a Detroit Diesel Series 60 ® engine used in the following applications: In recent years, electronic engine con- On-Highway Vehicles trols have been instrumental in aiding... - Page 5 Detroit Diesel The use of inadequately engineered, Corporation has built over 500,000 manufactured or tested components in engines with electronic unit injectors –...

-

Page 6: Caution Summary

CAUTION SUMMARY CAUTION: To avoid injury from loss of vehi- The following cautions must be cle/vessel control, the operator of observed by the operator of the a DDEC equipped engine must not vehicle or equipment in which this attempt to use or read the engine is installed and/or by those Diagnostic Data Reader when the performing basic engine preventive... - Page 7 CAUTION: CAUTION: To avoid injury from fire, contain To avoid injury from slipping and and eliminate leaks of flammable falling, immediately clean up any fluids as they occur. Failure to spilled liquids. eliminate leaks could result in fire. CAUTION: CAUTION: To avoid injury from the expulsion To avoid injury from contact with of hot coolant, never remove the...

- Page 8 4. Observe the following caution CAUTION: when using starting aids: To avoid injury from contact with CAUTION: rotating parts when an engine is operating with the air inlet piping To avoid personal injury when using removed, install an air inlet screen ether during an engine startup, shield over the turbocharger air ensure to follow these precautions:...

- Page 9 5. Observe the following cautions 6. Observe the following cautions when jump starting an engine, when fueling the vehicle, replac- charging a battery, or working ing fuel filters or working with the with the vehicle electrical system: engine fuel system: CAUTION: CAUTION: To avoid injury from accidental...

- Page 10 CAUTION: CAUTION: To avoid injury from fire, contain To avoid injury from contact with and eliminate leaks of flammable rotating parts when an engine is fluids as they occur. Failure to operating with the air inlet piping eliminate leaks could result in fire. removed, install an air inlet screen shield over the turbocharger air 7.

-

Page 11: Engine Model And Serial Number Designation

ENGINE MODEL AND With any order for parts, the engine model and serial number must be given. SERIAL NUMBER If a type number is shown on the option DESIGNATION label covering the equipment required, this number should also be included on The engine serial number and model the parts order. - Page 12 0262 FUEL PUMP 2261 GEN MOUNT 0688 INJ CONT ELEC 0409 INJECTOR 1405 OIL COOLER 0594 OIL DIST 0638 OIL FILTER 0919 OIL PAN 0169 OILFILSHPGONL U.S.A. 0444 PWR STR ADAP 0445 PWR STR ADAPT 0583 ROCKER COVER 0358 THERMOSTAT 1743 TURBOCHARGER 0650 VALVE MECH 0893 VENT SYSTEM...

-

Page 13: Operating Instructions

INSTRUCTIONS 2. Remove the radiator pressure control Preparations for Starting cap and fill with genuine Detroit Diesel the Engine Power Cool antifreeze or an equiva- lent quality ethylene glycol or propy- the First Time... - Page 14 For this rea- when installed and the manifolds are not son, Detroit Diesel recommends drained of fuel. replacing the engine lube oil and filter(s) after extended storage.

-

Page 15: Starting The Engine

If the engine is equipped with a Starting the Engine fuel/water separator, drain off any water Before starting the engine the first time, that has accumulated. Water in fuel can perform the operations listed under seriously affect engine performance and Preparations for Starting the Engine may cause engine damage. - Page 16 Initial Engine Start CAUTION: To start a Series 60 DDEC engine be To avoid personal injury when using sure the transmission is in neutral or ether during an engine startup, park and turn the ignition key on. ensure to follow these precautions: You will notice that both the “Check Engine”...

-

Page 17: Running The Engine

If pressure does not the engine until the cause of the con- fall within these guidelines, it should be cern has been investigated and cor- checked with a manual gauge. rected. Authorized Detroit Diesel service outlets are properly equipped to perform this service. -

Page 18: Stopping The Engine

Avoid Unnecessary Idling Stopping the Engine Normal Stopping CAUTION: 1. Decrease engine speed back to normal Diesel engine exhaust and some idle and put all shift levers in the neutral of its constituents are known to position. the state of California to cause 2. -

Page 19: Ddec Iii/Iv Options

Before attempting to jump start the DDEC III/IV OPTIONS engine, make sure jumper cables are Detroit Diesel Series 60 engines connected properly (positive to positive, equipped with DDEC III or DDEC IV negative to negative) and in the proper electronic control systems are identified sequence (negative to negative last). - Page 20 are no control racks or mechanical link- CAUTION: age to adjust. This system not only helps to improve fuel economy and vehi- To avoid injury from engine shut- cle performance, it also helps to reduce down in an unsafe situation, cold starting time and increase initial idle ensure the operator knows how to speed for fast engine warm-up and vir-...

- Page 21 Cruise Control engine braking effort is exceeded, nor can it maintain speed on upgrades if power requirements exceed engine power capability. When the cruise enable switch is in the on position cruise control is engaged momentarily contacting “Set/Coast” switch to the on position. Holding the switch in the on position allows the vehicle to slow to a lower speed.

- Page 22 Corporation at the request of the cus- tomer. The information in both DDEC III and IV can be extracted with Detroit Diesel The engine can be configured to give a Diagnostic Link 2.0 (DDDL 2.0) software.

- Page 23 In this situation the operator may elect It is important to point out that whenever to “override” the automatic stop engine the “Check Engine” light (CEL) or the sequence by pressing the “Stop Engine “Stop Engine” light (SEL) comes on, the Override”...

- Page 24 occurrence based on engine hours. If The malfunction code can also be there are no inactive codes, a code “25” obtained by the operator. A “Diagnostic will be flashed. Request” switch is provided which, Note that only one light will be flashing when pressed, will cause the “Check codes at any time.

- Page 25 Flash Flash Code DDEC III/IV Description Code DDEC III/IV Description ECM A/D conversion fail VSG sensor input voltage low ECM non volatile memory fault VSG sensor input voltage high Vehicle speed sensor fault Coolant level sensor input voltage low J1939 data link fault Oil or coolant temp.

- Page 26 Welding Precaution CAUTION: NOTICE: To avoid injury from loss of vehi- To prevent damage to the DDEC elec- cle/vessel control, the operator of tronic control module and other DDEC a DDEC equipped engine must not components, disconnect battery power attempt to use or read the and ground cables and the 5-pin power Diagnostic Data Reader when the connector at the ECM (electronic control...

-

Page 27: Ddec Iii/Iv Engine Driving Tips

DDEC III/IV ENGINE DRIVING TIPS Accelerating the Vehicle switch to activate cruise control. The cruise light will come on. To increase Engine response versus pedal move- road speed in one MPH increments, ment may feel different from the press the resume/accel switch. To mechanical governed engine you were reduce road speed, press and hold the driving. - Page 28 Jake Brakes If you decide to drive at lower RPM's for improved fuel economy, don’t let dif- If your engine is equipped with both ferent engine noises throw you off cruise control and Jake Brake ® guard. The Series 60 sounds quiet at retarders, the Jakes can operate auto- 1400 RPM, almost as if it had quit matically while you are in cruise control.

-

Page 29: Engine Systems

ENGINE SYSTEMS Cooling System A radiator/thermo-modulated fan cool- Fuel System ing system is used on Series 60 The fuel system consists of the DDEC engines. This system has a centrifugal electronic fuel system controls, fuel type fresh water pump to circulate injectors, fuel manifolds (integral with the coolant within the engine. - Page 30 Maintenance Interval NOTICE: Schedules Coolant must be inhibited with the rec- Recommended maintenance intervals ommended SCA’s (supplemental for Series 60 on-highway truck and par- coolant additives) listed in the “How to lor coach engines are listed in Table 2. Select Coolant” section of this engine Recommended maintenance intervals operator’s guide.

-

Page 31: Engine Maintenance Schedules

ITEM DAILY 1—Lubricating Oil* MAINTENANCE 2—Fuel Tank* 3—Fuel Lines and Flexible Hoses* 4—Cooling System* 5—Turbocharger* ITEM 7500 MILE (12,000 KM) INTERVAL SERVICE 6—Battery* RECOMMENDATIONS 8—Drive Belts* 9—Air Compressor* ON-HIGHWAY TRUCK ITEM 15,000 MILE (24,000 KM) INTERVAL OR PARLOR COACH 1—Lubricating Oil* 7—Tachometer Drive* 10—Air Cleaner* 11—Lubricating Oil Filter*... - Page 32 ITEM DAILY 1—Lubricating Oil* MAINTENANCE 2—Fuel Tank* 3—Fuel Lines and Flexible Hoses* 4—Cooling System* 5—Turbocharger* ITEM 6000 MILE (9,600 KM) INTERVAL SERVICE 1—Lubricating Oil* RECOMMENDATIONS 11—Lubricating Oil Filter* ITEM 7500 MILE (12,000 KM) INTERVAL TRANSIT COACH 6—Battery* 8—Drive Belts* 9—Air Compressor* ITEM 15,000 MILE (24,000 KM) INTERVAL 7—Tachometer Drive*...

- Page 33 ITEM DAILY 1—Lubricating Oil* MAINTENANCE 2—Fuel Tank* 3—Fuel Lines and Flexible Hoses* 4—Cooling System* 5—Turbocharger* ITEM 100 HOURS 3,000 MILES SERVICE 6—Battery* RECOMMENDATIONS 8—Drive Belts* ITEM 150 HOURS 4,500 MILES STATIONARY OR 1—Lubricating Oil* CONSTRUCTION/ 7—Tachometer Drive* INDUSTRIAL ENGINES 9—Air Compressor* 10—Air Cleaner* 11—Lubricating Oil Filter* 12—Fuel Filters*...

- Page 34 ITEM DAILY 1—Lubricating Oil* MAINTENANCE 2—Fuel Tank* 3—Fuel Lines and Flexible Hoses* 4—Cooling System* 5—Turbocharger* ITEM 100 HOURS 3,000 MILES SERVICE 6—Battery* RECOMMENDATIONS 8—Drive Belts* ITEM 300 HOURS 6,000 MILES FIRE FIGHTING, 1—Lubricating Oil* CRASH/RESCUE, AND 7—Tachometer Drive* EMERGENCY VEHICLES 9—Air Compressor* 10—Air Cleaner* 11—Lubricating Oil Filter*...

- Page 35 HOURS ITEM Prime, Standby, Daily Monthly STANDBY Replace every 150 hours or one year, 1. Lubricating Oil* whichever comes first PRIME POWER Replace every 250 hours or three months, whichever comes first 2. Fuel & Fuel Tank* 3. Fuel Lines, Flexible Hoses* 4.

-

Page 36: Lubrication And Preventive Maintenance Intervals

RECOMMENDED 1500 MILES QUART Kilometers = miles x 1.6 . For off-highway applications 1 hour = 33 miles. * Have your engine serviced by an authorized Detroit Diesel service facility at the earliest opportunity. Figure 12. Engine Oil Consumption Guidelines... - Page 37 How to Select Fuel Oil in to the crankcase, consult with an autho- the How To section of this guide. rized Detroit Diesel service outlet for the cause. Fuel or coolant dilution of lube oil can result in serious engine damage.

- Page 38 ings and brackets. At the same time, CAUTION: check the seal in the fuel tank cap, the breather hole in the cap and the condi- To avoid injury from fire, contain tion of the flexible fuel lines. Repair or and eliminate leaks of flammable replace the parts, as necessary.

- Page 39 Check the coolant level daily and main- Refer to How to Select Coolant for tain it near the bottom of the filler neck on required test intervals and inhibitor levels. the radiator. On some installations this is Coolant Drain Interval—Detroit done by checking an overflow bottle or Diesel recommends replacing cool- sight glass.

- Page 41 slip and may cause damage to acces- Maintain the electrolyte level accord- sory components. ing to the battery manufacturer’s recom- mendations, but do not overfill. Overfilling can cause poor performance CAUTION: or early failure. Keep the terminal side of the battery To avoid injury from rotating belts clean.

- Page 42 If a belt tension gage is not available, alternator and bracket mounting adjust the belt tension so that a firm bolts and retighten, as required. push with the thumb, at a point midway Item 9 — Air Compressor between the two pulleys, will depress the belt 12.70-19.05 mm (.500”-.750”).

- Page 43 in increased fuel consumption, inefficient Check for oil leaks after starting the engine operation and reduced engine engine. life. Dry-type air cleaner elements Item 12 — Fuel Filters should be replaced after one year of ® Fuel Pro 380— Install new Fuel Pro service or when the maximum allow- 380 primary filter element when the fuel able air intake restriction has been...

- Page 44 A method of determining when filters are plugged to the extent that they should be changed is based on the fuel pressure at the cylinder head fuel inlet fit- ting and the inlet restriction at the fuel pump. In a clean system, the maximum pump inlet restriction should not exceed 6 inches of mercury (20.3 kPa) and must not exceed 12 inches of mercury (41...

- Page 45 NOTICE: every 12 months or 100,000 miles (160,000 km), whichever comes first. Do not apply steam or solvent directly Authorized Detroit Diesel distributors on the battery-charging alternator, are properly equipped to perform this starting motor, DDEC components, service.

- Page 46 1. Avoid grounding the output terminal. 5. Never use a fast charger with the bat- Grounding an alternator’s output wire teries connected or as a booster for or terminal (which is always hot, battery output. regardless of whether or not the engine is running) and accidentally For information on the alternator assem- reversing the battery polarity will result...

- Page 47 Item 25 — Crankcase Breather Once the initial measurements/adjust- ments have been made, any adjustment The internally mounted (in the engine beyond this point should be made only rocker cover) crankcase breather as required to maintain satisfactory assembly should be removed every engine performance.

-

Page 48: How To" Section

Welding Precaution proper lubricating oil for all Detroit Diesel engines is selected based on SAE vis- cosity grade and API (American NOTICE: Petroleum Institute) service designation. To prevent damage to the DDEC Only oils licensed to display the electronic control system, discon-... -

Page 49: When To Change Oil

Detroit Diesel engines. Engine damage Stop the engine immediately if resulting from the use of such materials is an oil leak is detected. -

Page 50: How To Replace The Lube Oil Filters

Refer to publication, “Engine Requirements – Lubricating Oil, Fuel, and Filters” (7SE270), available from authorized Detroit Diesel Distributors. Table 11. Maximum Oil Drain and Filter Change Interval (Fuel Sulfur 0.5 Weight Percent or Less) Figure 19. -

Page 51: How To Select Fuel Oil

Tighten filters an additional two- acceptable exhaust emission levels. thirds turn by hand. Detroit Diesel engines are designed to operate on most diesel fuels marketed today. NOTICE: In general, fuels meeting the proper-... - Page 52 These products should be accompanied by performance data supporting their merit. It is not the policy of Detroit Diesel Corporation to test, evaluate, approve, or endorse such products.

-

Page 53: How To Replace The Fuel Filters

Keep those people who are not soon as possible. directly involved in servicing away Detroit Diesel Corporation will not be from the engine. responsible for any detrimental effects Stop the engine immediately if a which it determines resulted from fuel leak is detected. - Page 54 If the engine fails to start after filter replacement, the fuel system will require priming with tool J 5956 (or equivalent). Authorized Detroit Diesel service outlets are properly equipped to perform this service. NOTICE: Under no circumstances should the starting motor and fuel pump be used to prime the fuel filters.

- Page 55 Replace Fuel/Water Separator filter element and sealing grommet assembly, a filter spring, a see-thru cover If an optional primary filter/water separa- and seal, a cover collar, and a vent cap tor is installed, replace the element as and seal. The Fuel Pro 380E system also follows: includes a fuel heater element, thermo- static switch, and wiring harness.

- Page 56 3. Open the drain valve at the base of NOTICE: the fuel processor, and drain the fuel Do not use a wrench of any kind to until it is below the level of the filter. tighten the collar, since this may lead Close the drain valve.

-

Page 57: Engine Out Of Fuel-How To Restart

3. Open the fuel shutoff valve (if NOTICE: installed). Start engine, and check fil- Do not use a wrench of any kind to ters for leaks. tighten the collar, since this may lead to overtightening which can damage 4. If a Fuel Pro 380 filter is installed, the collar and/or the cover. -

Page 58: How To Select Coolant

J 5956 (or Fully Formulated Antifreeze — equivalent). Authorized Detroit Diesel Contains all the necessary inhibitors to service outlets are properly equipped protect a diesel engine, and does not, to perform this service. - Page 59 Ethylene Glycol/Water + APPROVED COOLANTS SCA Inhibitor/Propylene The approved and preferred coolants Glycol/Water + SCA Inhibitor for Series 60 engines are listed in Table These products are available as fully 12. Once installed, these coolants formulated, Phosphate-Free, Extended should be maintained according to the Service Interval (ESI) coolants.

- Page 60 (50% the Power Cool (see next paragraph). antifreeze, 50% water) is recommended. Detroit Diesel does not market a propy- An antifreeze concentration over 67% lene glycol coolant. If a propylene glycol (67% antifreeze, 33% water) is not rec-...

- Page 61 COOLANT FREEZING AND BOILING TEMPERATURES PROPYLENE GLYCOL VS. IEG CONCENTRATION (SEA LEVEL) IPG Boiling Point PG in Liquid, wt. % BOILING POINTS IPG Freezing Point FREEZING POINTS (°F) (°C) RECOMMENDED CONCENTRATION RANGE 30-67% - 18 - 20 - 29 Wt. % PG in Water - 40 - 40 - 60...

- Page 62 30. Traditional SCA (Power Cool OAT coolant. 3000) can also be used to protect the Detroit Diesel markets a NOAT inhib- engine. Power Cool 3000 coolant con- ited ethylene glycol coolant, DDC centration limits are listed in Table 14.

- Page 63 Table 15. silicate, offer no liner pitting protec- tion, and are not suitable for use in Maximum Allowable Detroit Diesel engines. Parts Grains 3. Methyl alcohol-based antifreeze per Million per Gallon...

- Page 64 Series 60 engines: Fully Formulated Coolant 1. Soluble oil additives are not The concentrations of some inhibitors approved for use in Detroit Diesel will gradually deplete during normal engine cooling systems. A small engine operation. SCAs replenish the...

- Page 65 centration of 800 PPM or less. If the Check the nitrite concentration at the regular intervals listed in Table 17 with a nitrite concentration is greater than 800 PPM, do not add additional SCA. If the PowerTrac 3-Way Test Strip. Nitrite lev- els must be within the ranges listed in nitrite concentration is above 2400 PPM, the system is over-inhibited and should...

- Page 66 Spin-on coolant filters are available for concentration. Freeze/boil-over protec- Detroit Diesel engines. Membranes in tion is determined by glycol concentra- the filters release SCAs before the tion. Use the test strips as follows:...

- Page 67 (alkali) type heavy-duty cleaner NOAT Coolant Drain Interval such as Detroit Diesel Power Cool On- A properly maintained NOAT-inhibited Line Cleaner (sodium nitrite/sodium coolant will last 4 years, 600,000 miles, tetraborate).

- Page 68 The need for maintenance elements is must be included in the coolant at determined by the results of the nitrite initial fill for all Detroit Diesel engines. concentration test performed at each This dosage is usually included in cooling system service interval. Do not...

- Page 69 Test the Glycol Coolant. A properly main- nitrite concentration by using a titra- tained cooling system, filled with tion kit or Detroit Diesel PowerTrac phosphate-free coolant consisting 3-Way Coolant Test Strips. Add of a 50/50 mix of antifreeze and SCA only if the nitrite concentration water per TMC RP-329 “Type A”...

-

Page 70: How To Drain And Flush The Cooling System

NOAT Coolant. A properly main- H. How to Drain and Flush tained NOAT coolant may be oper- the Cooling System ated 4 years, 600,000 miles (960,000 km), or until overhaul, whichever comes first. At this time, CAUTION: the system must be completely drained, thoroughly cleaned, and To avoid injury from the expulsion refilled. -

Page 71: When To Service The Dry Type Air Cleaner

8. With the engine cool, drain the NOTE: cleaner residue from the cooling If Detroit Diesel Power Cool antifreeze/ system. coolant (or equivalent fully formulated, precharged antifreeze) is used, a 9. Refill the system with the required precharge element is not required. -

Page 72: Basic Troubleshooting

BASIC TROUBLESHOOTING HARD STARTING Engine Will Not Rotate Probable Causes: Low Cranking Speed Engine Cranks But Will Not Start Low battery voltage Loose cranking motor connections Faulty cranking motor Faulty cranking motor switch Internal seizure Improper lube oil Circuit breaker/electronic control malfunction Fuse blown or missing Insufficient Fuel Supply... - Page 73 OBJECTIONABLE EXHAUST CAUTION: Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects and other reproductive harm. Always start and operate the engine in a well-ventilated area. If operating the engine in an enclosed area, vent the exhaust to the outside.

- Page 74 ABNORMAL ENGINE OPERATION Rough Running or Frequent Stalling Probable Causes: Low Power Detonation Misfiring cylinder Insufficient fuel High return fuel temperature Low compression DDEC malfunction High air inlet restriction/exhaust back pressure Engine application High air inlet temperature High altitude operation Incorrect engine gear train timing Low coolant temperature Oil picked up by inlet airstream...

- Page 75 ABNORMAL OPERATING CONDITIONS High Lubricating Oil Consumption Probable Causes: Low Oil Pressure Loose connections Cracked lines Damaged gaskets or seal rings *Lube oil loss at breather tube *Lube oil loss at dipstick tube *Indicates high crankcase pressure Leaking oil cooler Leaking valve stem seals Worn/broken oil control rings Scored liner and/or piston...

- Page 76 ABNORMAL COOLANT TEMPERATURES Above Normal Probable Causes: Below Normal Restricted cooling system passages Restricted radiator core passages Slipping fan drive belts Faulty temperature-controlled fan Obstruction in front of radiator or intercooler Low coolant level Damaged hoses Faulty thermostats Faulty water pump Faulty radiator pressure cap Air in coolant Thermostats not fully closed...

-

Page 77: Engine Storage

ENGINE STORAGE 5. If freezing weather is expected during the storage period, check the Preparing Engine for Storage antifreeze/coolant for required freeze and inhibitor protection. Add When an engine is to be stored or antifreeze solution to the cooling sys- removed from operation for a period of tem in accordance with the manufac- time, special precautions should be... - Page 78 Extended Storage NOTE: (More than 30 Days) If engines are stored where condensa- tion of water in the fuel tank may be a To prepare an engine for extended stor- problem, additives containing Methyl age (more than 30 days), follow this Carbitol or Butyl Cellusolve may be procedure: added to the fuel.

- Page 79 11. Power Take-Off— (If equipped)— 15. Drain the preservative oil from the Follow the manufacturer's recom- engine crankcase. Reinstall and mendations for prolonged storage. tighten the 3/4"-14 square, magnet- ic drain plug to 45-50 N•m (33-37 12. Turbocharger—Since turbocharg- lb-ft) torque. er bearings are pressure lubricated through the external oil line leading 16.

- Page 80 The stored engine should be inspect- ing temperatures, install genuine ed periodically. If there are any indica- ® Detroit Diesel Power Cool tions of rust or corrosion, corrective antifreeze or an equivalent ethylene steps must be taken to prevent damage glycol-base or propylene glycol- to the engine parts.

- Page 81 12. Power Take-Off (If equipped) — NOTE: Follow the manufacturer's recom- Before subjecting the engine to a load mendations covering the return of or high speed, allow it to reach normal the power take-off to service. operating temperature. Then, monitor the DDEC Diagnostic Data Link for trou- 13.

-

Page 82: Service Publications

To purchase a copy of any of these publications, contact an authorized The service manual covering Detroit Detroit Diesel distributor in the U.S. or Diesel Series 60 engines is listed in Canada. Check the Yellow Pages under Table 18. Also listed are reference “Engines, Diesel”... -

Page 83: Customer Assistance

CUSTOMER ASSISTANCE organizations. As the owner of a Detroit Diesel prod- uct you have a complete network of over The satisfaction and goodwill of the 2,000 Detroit Diesel service outlets in the owners of Detroit Diesel engines are of U.S. and Canada, plus many outlets... - Page 84 • Chronological summary of engine’s area (in the U.S. and Canada check the history. Yellow Pages for the Detroit Diesel ser- vice outlet nearest you). *Important: Your engine serial number To further assure your complete satis- should be written on the line provided.

-

Page 85: Limited New Engine Warranty

Detroit Diesel Corporation and/or sup- business hours. plied by Detroit Diesel Corporation, Warranty Period Detroit Diesel of Canada Limited or The WARRANTY PERIOD begins on the Detroit Diesel Overseas Distribution date the engine is delivered to the first Corporation (all which are collectively... - Page 86 Like Replacement Engine THIS WARRANTY DOES NOT Engine(s) supplied by DDC as a replace- COVER: ment for an engine still under warranty will assume the identity of the engine Repairs Due to Accidents, Misuse, being replaced and be entitled to the Storage Damage, Negligence or remaining warranty coverage.

- Page 87 Incidental or Consequential MAKES NO OTHER WARRANTIES Damages EXPRESS OR IMPLIED, INCLUDING Detroit Diesel Corporation is not respon- ANY IMPLIED WARRANTY OF MER- sible for incidental or consequential costs CHANTABILITY OR FITNESS FOR A or expenses which the owner may incur PARTICULAR PURPOSE.

- Page 88 Diesel Series 60 ® Engines (referred to as after taking the engine to the authorized Engine) manufactured by Detroit Diesel service outlet. Repairs will be performed Corporation and/or supplied by Detroit during normal business hours. Diesel Corporation, Detroit Diesel of...

- Page 89 Service Supplies Fuel Injectors and Starting Motors The cost of service supplies such as After 100,000 Miles/ coolant, oil and filters which are not 160 000 Kilometers reusable due to warranted repairs is The repair or replacement of fuel injec- covered by this warranty.

- Page 90 ARE THE ONLY WARRANTIES APPLI- CABLE TO THESE ENGINES POWER- ING URBAN BUS, MOTOR COACH OR MOTOR HOME APPLICATIONS. DETROIT DIESEL CORPORATION MAKES NO OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MER- CHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. DETROIT...

- Page 91 Diesel Series 60 ® Engines (referred to as allowed to perform the warranty repair Engine) manufactured by Detroit Diesel after taking the engine to the authorized Corporation and/or supplied by Detroit service outlet. Repairs will be performed Diesel Corporation, Detroit Diesel of during normal business hours.

- Page 92 Warranty Period THIS WARRANTY DOES NOT The WARRANTY PERIOD begins on the COVER: date the Engine is delivered to the first retail purchaser or put in use prior to sale Repairs Due to Accidents, Misuse, at retail, whichever date occurs first, and Storage Damage, Negligence or ends at the time or hour limits shown in Certain Modifications...

- Page 93 AS USED IN CONSTRUCTION/INDUS- Operator’s Guide for details. TRIAL, AGRICULTURAL MACHINERY AND STAND-BY PUMP APPLICATIONS. Incidental or Consequential DETROIT DIESEL CORPORATION Damages MAKES NO OTHER WARRANTIES DDC is not responsible for incidental or EXPRESS OR IMPLIED, INCLUDING consequential costs or expenses which...

- Page 94 Detroit Diesel Corporation and/or sup- sale at retail, whichever date occurs first, plied by Detroit Diesel Corporation, and ends at the time or mileage/kilome- Detroit Diesel of Canada Limited or ter limits shown in the WARRANTY Detroit Diesel Overseas Distribution PERIOD chart.

- Page 95 COVER: Incidental or Consequential Repairs Due to Accidents, Damages Misuse, Storage Damage, Detroit Diesel Corporation is not respon- Negligence or Certain sible for incidental or consequential costs Modifications or expenses which the owner may incur Repairs due to an accident, misuse,...

- Page 96 BLE TO THE ENGINE AS USED IN FIRE purchaser and subsequent owners TRUCK OR CRASH RESCUE VEHICLE during the WARRANTY PERIOD of APPLICATIONS. DETROIT DIESEL new Detroit Diesel Series 60 ® Engines (referred to as Engine) manufactured CORPORATION MAKES NO OTHER...

- Page 97 Warranty Period Engine Removal and The WARRANTY PERIOD begins on the Reinstallation date the engine is delivered to the first Labor costs for Engine removal and retail purchaser or put in use prior to reinstallation, when necessary to make a sale at retail, whichever date occurs first, warranty repair, are not covered by this and ends at the time or limits shown in...

- Page 98 Detroit Diesel Corporation and/or sup- MAKES NO OTHER WARRANTIES plied by Detroit Diesel Corporation, EXPRESS OR IMPLIED, INCLUDING Detroit Diesel of Canada Limited or ANY IMPLIED WARRANTY OF MER- Detroit Diesel Overseas Distribution Corporation (all which are collectively CHANTABILITY OR FITNESS FOR A referred to as DDC) which are used in PARTICULAR PURPOSE.

- Page 99 Warranty Period THIS WARRANTY DOES NOT The WARRANTY PERIOD begins on the COVER: date the engine is delivered to the first retail purchaser or put in use prior to Repairs Due to Accidents, sale at retail, whichever date occurs first, Misuse, Storage Damage, and ends at the time limits shown in the Negligence or Certain...

- Page 100 RANTY APPLICABLE TO THE ENGINE performance of required maintenance AS USED IN PRIME POWER GENERA- services as recommended by DDC, or TORS. DETROIT DIESEL CORPORA- the failure to use fuel, oil, lubricants, TION MAKES NO OTHER WAR- cooling air and ventilation meeting DDC-...

- Page 101 WARRANTY PERIOD of new Detroit Diesel Series 60 ® Engines (referred to as Service Supplies Engine) manufactured by Detroit Diesel The cost of service supplies such as Corporation and/or supplied by Detroit coolant, oil and filters which are not Diesel Corporation, Detroit Diesel of...

- Page 102 RANTY APPLICABLE TO THE ENGINE Such items may be covered by war- AS USED IN STAND-BY GENERA- ranties issued by the manufacturer or TORS. DETROIT DIESEL CORPORA- supplier. TION MAKES NO OTHER WAR- RANTIES EXPRESS OR IMPLIED, Maintenance...

-

Page 103: Specifications

SPECIFICATIONS FILTERS Table 19. FUEL FILTER REQUIREMENTS — Series 60 Regular Service Filter Type Detroit Diesel Part No. Primary Spin—On 23518481 Primary Water/Separator, Spin—On 23512317 Secondary Spin—On 23518482 Fuel Pro 380/382 Primary Element 23521528 LUBRICATING OIL FILTER ELEMENT REQUIREMENT Filter Type Detroit Diesel Part No. - Page 104 POWER COOL ENGINE PRODUCTS (Cont.) Table 22. Power Cool 2000 Supplemental Coolant Additive Coolant Type Part Number Description For Power Cool 23507858 Pint Bottle — 12 Per Case IEG Coolant 23507859 Half Gallon Jug — 6 Per Case 23507860 5 Gallon Pail 23507861 55 Gallon Drum Table 23.

- Page 105 POWER COOL ENGINE PRODUCTS Table 26 Power Cool Plus Extended Life NOAT Coolant Coolant Type Part Number Description Concentrated 23519394 55 Gallon Drum 23519395 Bulk Delivery — 1,000 Gallon Min. Pre-Blended 50:50 23519396 One Gallon Jug — 6 Per Case 23519398 55 Gallon Drum 23519399...

- Page 106 POWER COOL ENGINE PRODUCTS Table 29. Power Cool Cooling System Cleaners Cleaner Type Part Number Description On-Line Cleaner 23507862 One-Half Gallon Jug — 6 Per Case 23507863 5 Gallon Pail 23507864 55 Gallon Drum Twin Pack 23507867 Twin Pack — 2 Per Case Table 30.

- Page 107 NOTES...

- Page 108 NOTES...

- Page 109 NOTES...

- Page 110 NOTES...

- Page 111 Gates Rubber Company. Biobor ® is a registered trademark of U.S. Borax and Chemical Corporation. Tectyl ® is a registered trademark of Ashland Oil Corporation. 6SE484 0007 © Copyright 2000. Detroit Diesel Corporation. All rights reserved. Printed in U.S.A.

Need help?

Do you have a question about the 60 Series and is the answer not in the manual?

Questions and answers