Detroit Diesel 60 Series Service Manual

Diesel and natural gas-fueled engines

Hide thumbs

Also See for 60 Series:

- Operator's manual (172 pages) ,

- Owner's manual (24 pages) ,

- Service manual (23 pages)

Table of Contents

Advertisement

Quick Links

6SE483 JULY 2005

~~~□~~150®

Service

Manual

Detroit Diesel®

Series 60 Diesel and

Natural Gas-Fueled

Engines

NOTE:

D_ET_R_D_I_T_~-a~-~-~-!-~-@®

Detroit Diesel Corporation

13400 Outer Drive, West / Detroit, Michigan 48239-4001

Telephone: 313-592-5000

Fax: 313-592-3878

Additional copies of this service manual may be

purchased from Detroit Diesel Corporation

Distributors. See your yellow pages- under

Engines, Diesel.

http:l/www.detroltdiesel.com

Detroit Diesel®, DDC® and the spinning arrows design are registered trademarks of Detroit Diesel Corporation.

Series 60®is a registered trademark of Detroit Diesel Corporation.

All information subject to change without notice.

6SE483 0507 Copyright@2005 DETROIT DIESEL CORPORATION. All rights reserved.

Printed

in

U.S.A.

Advertisement

Table of Contents

Summary of Contents for Detroit Diesel 60 Series

- Page 3 SERIES 60 SERVICE MANUAL ABSTRACT This manual provides instruction for servicing on-highway applications of the Detroit Diesel Series 60 Diesel and Natural Gas-Fueled Engines. Specifically a basic overview of each major component and system along with recommendations for removal, cleaning, inspection, criteria for replacement, repair and installation and mechanical troubleshooting are contained in this manual.

-

Page 4: Engine Exhaust

□ If operating an engine in an enclosed area, vent the exhaust to the outside. □ Do not modify or tamper with the exhaust system or emission control system. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 5 Revisions to this manual will be sent marked with a revision bar (see Example 2). Sections containing revisions will have a third line in the page footer (compare Examples 1 and 2). All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 6 SERIES 60 SERVICE MANUAL (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 7: Table Of Contents

CRANKSHAFT PULLEY ................1-252 1.16 FLYWHEEL ..................... 1-266 1.17 RING GEAR ..................... 1-275 1.18 FLYWHEEL HOUSING ................1-277 1.19 PISTON AND PISTON RING ..............1-285 All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 8 TURBO SPEED SENSOR (TSS) ............. 2-173 2.23 TURBO BOOST PRESSURE SENSOR ..........2-177 2.24 AIR INTAKE PRESSURE SENSOR ............2-179 2.25 OIL PRESSURE SENSOR ..............2-181 (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 9 VENTING AND LEAK CHECKING PROCEDURES FOR NATURAL GAS ENGINE (LOW PRESSURE SYSTEM) ..........2-255 ADDITIONAL INFORMATION ..............2-257 LUBRICATION SYSTEM OVERVIEW OF LUBRICATING SYSTEM ..........OIL PUMP ....................All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 10 THREE-PIECE EXHAUST MANIFOLD WITH FEY RINGS ..... THREE-PIECE EXHAUST MANIFOLD WITHOUT FEY RINGS ..... 7-16 THREE-PIECE EXHAUST MANIFOLD WITH HEAT SHIELD ....7-23 (Rev. 2005) All information subject to change without notice. viii 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 11 ENGINE TUNE-UP PROCEDURES FOR THE SERIES 60G ENGINE .. 13-24 13.4 VALVE LASH FOR THE SERIES 60G ENGINE ........13-26 PREVENTIVE MAINTENANCE 14.1 MAINTENANCE OVERVIEW ..............14-3 All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 12 IGNITER MODULE ................. 16-10 16.6 IGNITER MODULE BRACKET ..............16-11 16.7 IGNITION COIL HARNESS ..............16-12 16.8 SPARK PLUGS ..................16-15 INDEX ....................Index-1 (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 13: General Information

GENERAL INFORMATION Section Page SCOPE AND USE OF THIS MANUAL ............CLEARANCE OF NEW PARTS AND WEAR LIMITS ......... THE FOUR CYCLE PRINCIPLE FOR DIESEL ENGINES ......FOUR CYCLE PRINCIPLE FOR NATURAL GAS ENGINES ..... GENERAL DESCRIPTION ................. GENERAL SPECIFICATIONS ..............GENERAL SPECIFICATIONS FOR THE SERIES 60G ENGINE .... - Page 14 SERIES 60 SERVICE MANUAL (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 15: Scope And Use Of This Manual

Refer to section ADDITIONAL INFORMATION, "Table of Specifications, New Clearances, and Wear Limits" under "Specifications", for a listing of clearances of new parts and wear limits on used parts. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 16: The Four Cycle Principle For Diesel Engines

The intake charge consists of air only with no fuel mixture. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 17 first, compression for ignition, and second, that fuel be measured and injected into the compressed air in the cylinder in the proper quantity and at the proper time. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 18: Four Cycle Principle For Natural Gas Engines

See Figure 2 for the four stroke cycle utilized on the natural gas engine. Figure 2 The Four Stroke Cycle (Series 60G Engine) (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 19 The burning gases are forced out of the combustion chamber through the open exhaust valve port by the upward travel of the piston. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 20: General Description

A battery charging alternator, with a suitable voltage regulator, serves to keep the battery charged. The Series 60 diesel engine was designed to be electronically controlled. The Detroit Diesel Electronic Control (DDEC) system has evolved with the product. - Page 21 (depending on option selection) in the case of damaging engine conditions, such as low oil pressure, low coolant level, or high oil temperature. Figure 3 Schematic Diagram of DDEC I All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 22 (depending on option selection) in the case of damaging engine conditions, such as low oil pressure, low coolant level, or high oil temperature. Figure 4 Schematic Diagram of DDEC II (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 23 Data Reader (DDR) requests and receives engine data and diagnostic codes. This equipment provides many unique capabilities including cylinder cutout, printer output, and data snapshot. The DDR also provides limited programming capability. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 24 Data Reader (DDR) requests and receives engine data and diagnostic codes. This equipment provides many unique capabilities including cylinder cutout, printer output, and data snapshot. The DDR also provides limited programming capability. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 25 Schematic Diagram of DDEC V Any faults that occur are stored as codes in the ECU's memory. A DDDL® can be used to read the codes. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 26: General Specifications

15.0:1 or 16.5:1 15.0:1 or 16.5:1 Number of Main Bearings Table 1 Specifications for the Series 60 Engine Figure 8 Cylinder Designation and Firing Order (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 27: General Specifications For The Series 60G Engine

Number of Main Bearings Table 2 General Specifications for the Series 60G Engine Figure 9 Cylinder Designation and Firing Order for the Series 60G Engine All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 28: Engine Model, Serial Number And Option Label (Series 60G Engine)

Table 3. Figure 10 Location of Engine Serial and Model Number on Block (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 29 All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 30 All groups or parts used on a unit are standard for the engine model unless otherwise listed on the option plate. Figure 11 Rocker Cover with Option Label (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 31: Engine Model, Serial Number And Option Label (Series 60G Engine)

DDEC III / DDEC IV DDEC V Alternate Fuel Engine 5 / 8 Customer Designation Table 4 Model Number Description for Series 60G Engine All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 32: Replacing And Repairing

Those items having machined faces, which might be easily damaged by steel or concrete, should be stored on suitable wooden racks or blocks, or a parts dolly. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 33: Cleaning

[e] Neutralize the acid that may cling to the casting by immersing the block in an alkaline bath. [f] Wash the block in clean water or steam clean it. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 34: Steam Cleaning

Protection Agency) as possessing ozone-depleting properties. Special procedures have been developed for the handling and proper disposal of these chemicals. For environmental considerations, Detroit Diesel has replaced 1,1,1 trichloroethane with Tech Solv 340 branded solvent. (Rev. 2005) All information subject to change without notice. - Page 35 Detroit Diesel believes that a prudent environmental approach to the use of 1,1,1 trichloroethane should be taken. Therefore, Detroit Diesel recommends replacing 1,1,1 trichloroethane with Tech Solv 340 branded solvent wherever the former solvent was used.

- Page 36 (with a speed of 15,000-18,000 r/min), have proven successful in removing the gasket eliminator without damaging the mating surfaces of engine parts. See Figure 13. Scotch-Brite® is a registered trademark of the 3M Corporation. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 37 A coarse pad, is suitable for steel surfaces. A medium pad is recommended for aluminum surfaces. The pads are easily interchangeable. See Figure 14. Figure 14 Scotch-Brite Surface Conditioning Disc Installation All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 38 In addition to measuring the used parts after cleaning, the parts should be carefully inspected for cracks, scoring, chipping and other detrimental conditions. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 39: Safety Precautions

Select appropriate safety glasses for the job. It is especially important to wear safety glasses when using tools such as hammers, chisels, pullers or punches. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 40 To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 41 Use proper shielding around hydraulic lines when welding to prevent hydraulic line damage. Ensure that a metal shield separates the acetylene and oxygen that must be chained to a cart. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 42: Work Place

Check for frayed cords prior to using the tool. Be sure all electric tools are grounded. Defective electrical equipment can cause severe injury. Improper use of electrical equipment can cause severe injury. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 43: Fuel Lines

If injured by escaping fluid, see a doctor at once. Serious infection or reaction can result without immediate medical treatment. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 44 This will reduce the likelihood of a dangerous spark. The following cautions should be followed when filling a fuel tank: (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 45: Personal Injury

To avoid injury from fire, keep all potential ignition sources away from diesel fuel, including open flames, sparks, and electrical resistance heating elements. Do not smoke when refueling. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 46 To avoid injury from electrical shock, use care when connecting battery cables. The magnetic switch studs are at battery voltage. Use care when connecting battery cables to avoid electrical shock. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 47: Cleaning Agent

PERSONAL INJURY To avoid injury, use care when working around moving belts and rotating parts on the engine. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 48 (freezing). □ Vent systems on the equipment should be ducted to a safe area whenever equipment is in an enclosed area. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 49 Follow the manufacturer's instructions on proper product use. Follow the instructions on the container or by the manufacturer of the starting aid. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 50 Use of this shield does NOT preclude any other safety practices contained in this manual. Figure 15 Turbocharger Compressor Inlet Shield (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 51 SERIES 60 SERVICE MANUAL Figure 16 Turbocharger Compressor Inlet Shield, Series 60G Engine All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 52: Fluoroelastomer (Viton) Caution

This is extremely corrosive and, if touched by bare skin, may cause severe burns, sometimes with symptoms delayed for several hours. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

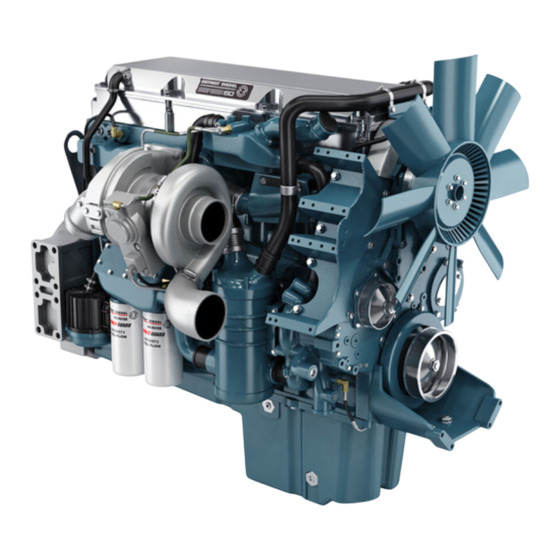

Page 53: Engine Views

DDEC III/IV. See Figure 17. For Series 60G engine views, see Figure 18. For Series 60 2002 Exhaust Gas Recirculation (EGR) engine views see Figure 19. For Series 60 2004 Exhaust Gas Recirculation (EGR) engine views see Figure 20. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 54 SERIES 60 SERVICE MANUAL Figure 17 Engine Views (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 55 SERIES 60 SERVICE MANUAL Figure 18 Engine Views (60G Automotive Engine) All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 56 SERIES 60 SERVICE MANUAL Figure 19 Engine Views for 2002 Series 60 Exhaust Gas Recirculation (EGR) Engine (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 57 SERIES 60 SERVICE MANUAL Figure 20 Engine View for 2004 Series 60 Exhaust Gas Recirculation (EGR) Engine All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 58: English To Metric Conversion

To get equivalent number of: Pound-inch (lb·in.) 0.11298 Newton-meters (N·m) Pound-foot (lb·ft) 1.3558 Newton-meters (N·m) Multiply Power To get equivalent number of: Horsepower (hp) 0.746 Kilowatts (kW) (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 59: Decimal And Metric Equivalents

Kilometers/hour (km/hr) Table 5 English to Metric Conversion Table DECIMAL AND METRIC EQUIVALENTS Listed in Table 6 are the decimal and metric equivalents: All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 60: Specifications

0.500 12.70000 1.00 25.40000 Table 6 Conversion Chart-Customary and Metric Units SPECIFICATIONS This section contains fastener torque specifications and pipe plug torque specifications. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 61 M14 X 2.0 160-200 118-148 M16 X 2.0 245-306 181-226 M20 X 2.5 478-598 353-441 Table 8 Class 10.9 Torque Specifications for Metric Fasteners All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 62 *Use sealant such as Pipe Plug Sealant with Teflon®, PT-7271 (Loctite® 592), or equivalent on all uncoated pipe plugs. Table 9 Standard Pipe Plug Torque Specifications (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 63: Engine

ENGINE Section Page CYLINDER BLOCK AND CYLINDER LINER .......... CYLINDER HEAD ..................1-30 VALVE AND INJECTOR OPERATING MECHANISM ......1-60 VALVES, SPRINGS, GUIDES, INSERTS, SEALS AND ROTATORS ..1-79 ENGINE LIFTER BRACKETS ..............1-106 ROCKER COVER ..................1-111 CRANKSHAFT ..................1-129 CRANKSHAFT OIL SEALS .............. - Page 64 1.34 CRANKSHAFT TIMING GEAR AND TIMING WHEEL ......1-538 1.35 ACCESSORY DRIVE ................1-557 1.36 JAKE BRAKE ................... 1-585 ADDITIONAL INFORMATION ..............1-639 (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 65: Cylinder Block And Cylinder Liner

Oil galleries are machined into the cooler side of the block. See Figure 1-1. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 66 First usage of the drilled block was on May 2, 1998, effective with engine serial number 6R408505. (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 67 Refer to section 11.1.3, of this manual for information on installing the adaptorless air compressor. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 68 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-4. Figure 1-4 Flowchart for Repair or Replacement of Cylinder Block (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 69 14. Remove the charge air cooler, radiator, fan guard and other cooling system related parts as necessary to remove the engine. Refer to section 6.8.2. All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 70 18. Lift the engine from its mounts using a suitable lifting device. See Figure 1-5. Figure 1-5 Lifting Engine (Rev. 2005) All information subject to change without notice. 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 71 20. Bolt cylinder block adaptor (J–35635–2, part of tool set J–35635–A) to the cylinder block and mate it with the stand adaptor (J–35635–1, part of tool set J–35635–A). See Figure 1-7. Figure 1-7 Cylinder Block Adaptor All information subject to change without notice. (Rev. 2005) 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 72 No. 6 x 37.92 in. (963 mm) long hose assembly (23504785) is now routed from the fuel pump discharge fitting to the inlet of the secondary fuel filter. (Rev. 2005) All information subject to change without notice. 1-10 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 73 [w] Remove the oil pan, refer to section 3.11.2. [x] Remove the piston and connecting rod assembly, refer to section 1.21.2. [y] Remove the crankshaft, refer to section 1.7.2. All information subject to change without notice. (Rev. 2005) 1-11 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 74 See Figure 1-8. Figure 1-8 Cylinder Liner Removal Tool (J-45876) (Rev. 2005) All information subject to change without notice. 1-12 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 75 [e] Neutralize the acid that may cling to the casting by immersing the block in an alkaline bath. [f] Wash the block in clean water or steam clean it. All information subject to change without notice. (Rev. 2005) 1-13 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 76 7. Pressure test the cylinder block. Two methods of cylinder block pressure testing may be used depending on the test facilities available: [a] Immersion method; refer to section 1.1.3.1. [b] Leak-marker method; refer to section 1.1.3.2. (Rev. 2005) All information subject to change without notice. 1-14 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 77 4. Install the bolts through the strips and into the cylinder block. Torque the bolts on the ring strips to 230-237 N·m (170-175 lb·ft). Torque the bolts on the outside strips to 14 N·m (10 lb·ft). All information subject to change without notice. (Rev. 2005) 1-15 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 78 9. Install the cylinder block to the engine overhaul stand (J–29109). See Figure 1-6. (Rev. 2005) All information subject to change without notice. 1-16 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 79 Any coolant leakage past the upper seal is drained to the outside rather than into the crankcase, and is easily detected by a visual inspection. All information subject to change without notice. (Rev. 2005) 1-17 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 80 Drain the water jacket. Then blow out all of the passages in the cylinder block with compressed air. 10. Install the cylinder block to the engine overhaul stand (J–29109). See Figure 1-6. (Rev. 2005) All information subject to change without notice. 1-18 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 81 2. Measure the bore of each cylinder with cylinder bore gage (J–5347–B) which has a dial indicator calibrated in 0.0001 in. increments. See Figure 1-12. Figure 1-12 Gaging Cylinder Bores All information subject to change without notice. (Rev. 2005) 1-19 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 82 149.050 - 149.120 5.868 - 5.871 146.050 - 146.120 5.750 - 5.753 146.050 - 146.120 5.750 - 5.753 Table 1-1 Acceptable Cylinder Bore Diameters (Rev. 2005) All information subject to change without notice. 1-20 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 83: Feeler Gauge

flatness between the liner flanges. The deck must be flat within 0.127 mm (0.005 in.) front-to-rear, and flat within 0.0762 mm (0.003 in.) side-to-side. If not, the deck must be resurfaced. All information subject to change without notice. (Rev. 2005) 1-21 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 84 Record the amount of stock removed from the cylinder block by stamping the amount removed on the cylinder block pad. See Figure 1-15. Figure 1-15 Recording Stock Removal on Cylinder Block Pad (Rev. 2005) All information subject to change without notice. 1-22 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 85 Refer to section ADDITIONAL INFORMATION1.A, for line bore specifications which are listed in Table 1-16. NOTE: Dial bore master setting fixture should be used to zero the cylinder bore gage. All information subject to change without notice. (Rev. 2005) 1-23 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 86: General Inspection

If the block is to be stored for an extended period of time, spray or dip it in a polar-type rust preventive such as "Tectyl® 502-C" from Valvoline Oil Company (or equivalent). Tectyl® is a registered trademark of Ashland Oil, Inc. (Rev. 2005) All information subject to change without notice. 1-24 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 87 flange of the block. 4. Install the main bearing caps in their original positions; refer to section 1.9.3. All information subject to change without notice. (Rev. 2005) 1-25 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 88 See Figure 1-18 for location of nozzle. Torque plate nozzle retaining bolts to 30–38 N·m (22–28 lb·ft). Figure 1-18 Oil Spray Nozzle Location (Rev. 2005) All information subject to change without notice. 1-26 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 89 (J–35653). See Figure 1-19. Figure 1-19 Cup Plug Installation Tool Set All information subject to change without notice. (Rev. 2005) 1-27 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 90 [u] To install the crankshaft vibration damper, refer to section 1.14.3. [v] To install the crankshaft pulley, refer to section 1.15.3. [w] To install the engine lifter brackets, refer to section 1.5.3. (Rev. 2005) All information subject to change without notice. 1-28 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 91 Transfer the engine to a suitable engine dynamometer test stand. Operate the engine on a dynamometer following the Run-in procedure; refer to section 12.7.3.2. Install the engine in the equipment from which it was removed. All information subject to change without notice. (Rev. 2005) 1-29 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 92: Cylinder Head

With the overhead camshaft design, the cylinder head assembly includes: □ Cylinder head □ Valve and injector operating mechanism □ Injector, valve guide and related parts □ Camshaft and camshaft bearings (Rev. 2005) All information subject to change without notice. 1-30 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 93: Cylinder Head Assembly

1. Roller Follower 4. Exhaust Valve Rocker Arm 2. Injector Rocker Arm 5. Camshaft 3. Intake Valve Rocker Arm Figure 1-21 Cylinder Head Assembly All information subject to change without notice. (Rev. 2005) 1-31 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 94 3. Exhaust Valve Rocker Arm 2. Intake Valve Rocker Arm 4. Camshaft 5. Spacer Figure 1-22 Cylinder Head Assembly (Series 60G Engine) (Rev. 2005) All information subject to change without notice. 1-32 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 95 6. Valve Spring 3. Valve Seat Insert 7. Valve Rotator 4. Valve 8. Valve Keepers Figure 1-24 Valve Guides and Related Parts All information subject to change without notice. (Rev. 2005) 1-33 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 96: Mounting Flange

The fuel gallery outlet (restricted) fitting is installed in the rear of the cylinder head. See Figure 1-25. Figure 1-25 Fuel Gallery Inlet and Outlet Fittings (Rev. 2005) All information subject to change without notice. 1-34 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 97 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-26. Figure 1-26 Flowchart for Repair or Replacement of Cylinder Head All information subject to change without notice. (Rev. 2005) 1-35 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 98 3. Remove the air cleaner and charge air cooler ducting from turbocharger and intake manifold. Refer to section 6.2.2and refer to section 6.3.2. (Rev. 2005) All information subject to change without notice. 1-36 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 99 17. Bracket, Oil Drain Tube Clip Mounting 8. Washer, Turbo Mounting 9. Turbocharger Assembly 18. Nut, Oil Drain Tube Clip Figure 1-27 Turbocharger Oil Lines All information subject to change without notice. (Rev. 2005) 1-37 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 100 6. Remove and inspect the exhaust manifold if necessary. Refer to section 7.2.2 and refer to section 7.2.2.1. See Figure 1-28. 1. Exhaust Manifold 2. Heat Shield Figure 1-28 Exhaust Manifold (Series 60G Engine) (Rev. 2005) All information subject to change without notice. 1-38 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 101 8. Turbo Boost Pressure Sensor 4. Cylinder Head 9. O-ring 5. Manifold Bolt (7) 10. Intake Manifold Figure 1-29 Intake Manifold and Related Parts All information subject to change without notice. (Rev. 2005) 1-39 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 102 3. Intake Manifold Gasket 7. Air Temperature Sensor 4. Cylinder Head 8. Turbo Boost Pressure Sensor Figure 1-30 Intake Manifold and Related Parts (Natural Gas) (Rev. 2005) All information subject to change without notice. 1-40 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 103: Thermostat Housing Removal

8. Drain Cock 4. Hose, Coolant 9. Seals, Thermostat Housing (2) 5. Hose Clamps (2) 10. Cylinder Head Figure 1-31 Thermostat Housing Removal All information subject to change without notice. (Rev. 2005) 1-41 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 104 Positioning Camshaft Thrust Plate 15. Inspect the rocker arm assemblies and camshaft lobes. Refer to section 1.3.2.2, and refer to section 1.28.3.1. (Rev. 2005) All information subject to change without notice. 1-42 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 105 19. Remove the harness mounting flange from the rear of the cylinder head and carefully remove the harness from the head by pulling the harness through the hole in the cylinder head. See Figure 1-25. All information subject to change without notice. (Rev. 2005) 1-43 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 106 No. 3 cam cap and two tapped Jake Brake® bolt holes. See Figure 1-34. Figure 1-34 Cylinder Head Lift Bracket Removal (Rev. 2005) All information subject to change without notice. 1-44 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 107: Cylinder Head Removal

24. Drain the engine lubricating oil, refer to section 14.6.1, to remove any coolant that may have drained into the oil pan when the water jacket was opened. Remove any coolant from the cylinder bores. All information subject to change without notice. (Rev. 2005) 1-45 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 108: Inspection Of Cylinder Head

4. Perform the following tests for cylinder head inspection. [a] Pressure test, refer to section 1.2.3.2. [b] Firedeck straightness test, refer to section 1.2.3.3. (Rev. 2005) All information subject to change without notice. 1-46 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 109 3. Install the thermostat opening cover plate, and gasket to the cylinder head using the bolts provided with the cover plate. See Figure 1-37. Figure 1-37 Thermostat Opening Cover Plate Installation All information subject to change without notice. (Rev. 2005) 1-47 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 110 2.4.6for installation of new injector tube. [b] If a cracked cylinder head is detected, replace the cylinder head. Refer to section 1.2.5. (Rev. 2005) All information subject to change without notice. 1-48 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 111 1. Use a heavy, accurate straight-edge and feeler gages to check for transverse and longitudinal warpage. See Figure 1-39. Figure 1-39 Checking Firedeck Straightness All information subject to change without notice. (Rev. 2005) 1-49 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 112 0.076 mm (0.003 in.) side-to-side. Cylinder head specifications are listed in Table 1-32. If the cylinder head flatness is outside of the specifications, Detroit Diesel Corporation recommends replacing the cylinder head. (Rev. 2005) All information subject to change without notice.

- Page 113 1-32. See Figure 1-41. If not, reduced-thickness valve seat inserts must be installed. Refer to section 1.4.6. Figure 1-41 Valve Head-to-Cylinder Head Measurement All information subject to change without notice. (Rev. 2005) 1-51 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 114 This is to eliminate surface marks. NOTE: The J–38189 tool pilot has a shoulder stop that will not allow the cutter to remove material in excess of the Detroit Diesel Corporation specifications. (Rev. 2005) All information subject to change without notice. 1-52...

-

Page 115: Assembly Of Cylinder Head

4. Install valve guides and seats, valves, valve stem seals, valve springs and rotators. Refer to section 1.4.8and refer to section 1.4.7. All information subject to change without notice. (Rev. 2005) 1-53 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 116: Installation Of Cylinder Head

2. Position the head gasket on the block and install cylinder head guide studs (J–35784) at front and rear of the block. See Figure 1-42. Figure 1-42 Cylinder Head Guide Studs (Rev. 2005) All information subject to change without notice. 1-54 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 117: Cylinder Head Installation

The new head bolt can be used with the former cylinder head gaskets, the former head bolts cannot be used with the new head gasket. Former and new bolts must not be mixed. All information subject to change without notice. (Rev. 2005) 1-55 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 118 7. Repeat the torque sequence to verify all of the head bolts are torqued to specification. (Rev. 2005) All information subject to change without notice. 1-56 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 119 All information subject to change without notice. (Rev. 2005) 1-57 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 120 23. Connect the exhaust and air-to-air cooler air ducting and install the air cleaner or air separator. 24. Install any other components that were removed and fill with the required fluids, as recommended. Refer to OEM guidelines. (Rev. 2005) All information subject to change without notice. 1-58 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 121 25. Start the engine and check for fuel, coolant or oil leaks. Keep the engine running while you check. 26. Shut down the engine. All information subject to change without notice. (Rev. 2005) 1-59 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 122: Valve And Injector Operating Mechanism

The center rocker operates the fuel injector follower. See Figure 1-48. Figure 1-48 Rocker Arm Identification (Rev. 2005) All information subject to change without notice. 1-60 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 123 7. Exhaust Rocker Arm Assembly 4. Fuel Injector Rocker Arm Assembly 8. Unitized Valve Adjusting Screw Assembly; Injector Figure 1-49 Rocker Arm and Related Parts All information subject to change without notice. (Rev. 2005) 1-61 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 124 3. Intake Rocker Arm Assembly 7. Exhaust Rocker Arm Assembly 4. Spacer Figure 1-50 Rocker Arm and Related Parts (Series 60G Engine) (Rev. 2005) All information subject to change without notice. 1-62 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 125 The oil passage within one rocker arm cylinder set is shown. See Figure 1-51 and see Figure 1-52. All information subject to change without notice. (Rev. 2005) 1-63 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 126 5. Cylinder Head 3. Camshaft Cap 6. Intake Rocker Arm Assembly Figure 1-51 Rocker Arm Assembly Lubrication Schematic with Former Valve Adjusting Screw Assembly (Rev. 2005) All information subject to change without notice. 1-64 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 127 5. Cylinder Head 3. Camshaft Cap 6. Intake Rocker Arm Assembly Figure 1-52 Rocker Arm Assembly Lubrication Schematic with Unitized Valve Adjusting Screw Assemblies All information subject to change without notice. (Rev. 2005) 1-65 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 128 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-53. Figure 1-53 Flowchart for Repair or Replacement of Valve and Injector Operating Mechanism and Camshaft (Rev. 2005) All information subject to change without notice. 1-66 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 129: Removal Of Rocker Arm Assembly

Whenever nuts No. 1 or 8 are loosened or removed, the torque on the corresponding rocker shaft stud must be checked. Torque to 126–146 N·m (93–108 lb·ft). All information subject to change without notice. (Rev. 2005) 1-67 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 130 Figure 1-54 Rocker Arm Shaft Bolts and Nut Identification Numbers Figure 1-55 Rocker Arm Shaft Bolts and Nut Identification Numbers (Series 60G Engine) (Rev. 2005) All information subject to change without notice. 1-68 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 131 Unitized Valve Adjusting Screws will not be serviced separately. NOTE: If removing a former valve adjusting screw with valve button and retainer clip, proceed to step 6. All information subject to change without notice. (Rev. 2005) 1-69 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 132 Front and rear rocker arm shaft sections look identical, but must not be reversed, and must be installed as removed, due to bolt hole center line distances. The DDC logo is (Rev. 2005) All information subject to change without notice. 1-70 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 133 See Figure 1-58. Figure 1-58 Rocker Arm Shaft Identification Mark All information subject to change without notice. (Rev. 2005) 1-71 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 134 5. Run a wire brush through the oil passage to remove any foreign material or sludge. 6. Clean the exterior of the shaft and blow out the passages and oil holes; and dry with compressed air. (Rev. 2005) All information subject to change without notice. 1-72 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 135 2. Remove all of the old gasket sealer from the joint face of the Number 1 and Number 7 camshaft bearing caps and the cylinder head. Refer to "Gasket Eliminator Removal" in the "General Information" section. All information subject to change without notice. (Rev. 2005) 1-73 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 136 Former style valve adjusting screw assemblies and the unitized valve adjusting screw assemblies are interchangeable and can be mixed in the same engine. (Rev. 2005) All information subject to change without notice. 1-74 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 137 2. Check the torque on the rocker shaft studs to ensure they were not loosened when the nuts were removed. Torque the studs to 101-116 N·m (75-86 lb·ft). All information subject to change without notice. (Rev. 2005) 1-75 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 138 If the rocker arm shaft does not have flats, decide on the position of the worn surfaces and rotate the rocker shaft accordingly. (Rev. 2005) All information subject to change without notice. 1-76 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 139 If new rocker arm components are installed, engine oil should be poured over the rocker arms, rocker shaft, and camshaft as a pre-lubricant. All information subject to change without notice. (Rev. 2005) 1-77 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 140: Personal Injury

□ Do not modify or tamper with the exhaust system or emission control system. 13. Start the engine and check for leaks. Shut down the engine when completed. (Rev. 2005) All information subject to change without notice. 1-78 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 141: Valves, Springs, Guides, Inserts, Seals And Rotators

Hard-alloy valve seat inserts, pressed into both intake and exhaust ports, can be replaced when worn to restore new engine performance. All information subject to change without notice. (Rev. 2005) 1-79 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 142 Replacement guides are reamed to close tolerances, and do not require reaming after installation. All valves are retained by valve rotator spring caps and two-piece tapered valve locks. (Rev. 2005) All information subject to change without notice. 1-80 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 143 When a reduced thickness valve seat insert is used, a correspondingly thicker valve spring seat must be used. See Figure 1-66, and see Figure 1-67. Figure 1-66 Standard Valve Seat Insert Thickness All information subject to change without notice. (Rev. 2005) 1-81 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 144 See Figure 1-68. The identification ring can be seen from the right side of the engine with rocker cover removed. (Rev. 2005) All information subject to change without notice. 1-82 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 145 See Figure 1-68and see Figure 1-69. Figure 1-69 Location of Dimples on Intake Valves All information subject to change without notice. (Rev. 2005) 1-83 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 146 2. If the engine has a Jake Brake®, remove the Jake Brake® housings that cover the rocker arm and shaft assembly for the valve to be serviced refer to section 1.36.2. (Rev. 2005) All information subject to change without notice. 1-84 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 147 All valve spring or seal removal and replacement must be completed for each cylinder being serviced while the piston is at top-dead-center, before turning the crankshaft to work on another cylinder. All information subject to change without notice. (Rev. 2005) 1-85 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 148 5. Remove the cylinder head lifting hardware. 6. Turn the crank of the engine overhaul stand to position the cylinder head in an upright position. (Rev. 2005) All information subject to change without notice. 1-86 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 149 10. Remove the valve spring seat. 11. As parts are removed, mark or segregate them according to their original position for possible reuse. All information subject to change without notice. (Rev. 2005) 1-87 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 150 [b] For natural gas engines; a cloth or soft nylon brush is recommended for this procedure. NOTE: Do not use bore brush (wire) on natural gas powdered metal guides. (Rev. 2005) All information subject to change without notice. 1-88 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 151 2. Position the cylinder head, firedeck side up, on a turn over stand or supported on 102 x 102 mm (4 x 4 in.) wooden blocks on a workbench. All information subject to change without notice. (Rev. 2005) 1-89 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 152: Valve Guide Removal

5. Clean the valve guide bore with bore brush (J–5437) (or equivalent), to remove all gum and carbon deposits. (Rev. 2005) All information subject to change without notice. 1-90 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 153: Inspection Of Valve

If leak paths exist, reface the valves or install new valves. If the valve heads are warped or the valve stem is bent, replace the valves. All information subject to change without notice. (Rev. 2005) 1-91 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 154 Table 1-37and listed in Table 1-39. See Figure 1-77. Figure 1-77 Intake and Exhaust Valve Face Refacing and Rim Width (Rev. 2005) All information subject to change without notice. 1-92 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 155: Inspection Of Valve Springs

Inspect valve seat inserts for wear, cracking or incorrect seat angle, which should be 31 degrees, standard valve seat insert thickness. See Figure 1-66. All information subject to change without notice. (Rev. 2005) 1-93 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 156 2. Use valve seat insert installers (J–33190) (intake) and (J–34983) (exhaust), to install new inserts. See Figure 1-79. Figure 1-79 Valve Seat Insert Installation Tools (Rev. 2005) All information subject to change without notice. 1-94 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 157: Valve Seat Insert Installation

Valve Seat Insert Insertion 4. Pilot the installer into the valve guide from the firedeck surface. See Figure 1-81. Figure 1-81 Valve Seat Insert Installation All information subject to change without notice. (Rev. 2005) 1-95 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 158: Cylinder Head

(J–35623–A). See Figure 1-83. Figure 1-83 Check Valve Seat Concentricity [a] If the concentricity is within 0.05 mm (0.002 in.), no grinding is required. (Rev. 2005) All information subject to change without notice. 1-96 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 159 fine adjustment. See Figure 1-84. Seats must be ground to a 31 degree angle. Figure 1-84 Grinding Valve Seat Insert All information subject to change without notice. (Rev. 2005) 1-97 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 160 A full 360° contact line should appear approximately centered on the valve face. (Rev. 2005) All information subject to change without notice. 1-98 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 161: Valve Guide Installation

(J–33191–A) and install this assembly over the valve guide. Drive the guide into the cylinder head until the driver bottoms in the limiting sleeve. See Figure 1-87. Figure 1-87 Valve Guide Installation All information subject to change without notice. (Rev. 2005) 1-99 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 162 2. Oil Seal Protector Cap 5. Valve 3. Valve Spring Seat 6. Valve Stem Oil Seal Figure 1-88 Valve Stem Oil Seal Installation Tools (Rev. 2005) All information subject to change without notice. 1-100 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 163 Oil Seal Protection Cap Sizing 4. Install the cap over the valve stem. See Figure 1-90. Figure 1-90 Oil Seal Protection Cap Installation All information subject to change without notice. (Rev. 2005) 1-101 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 164 6. Push the seal down on the valve stem using the seal installer (J–39109) while holding the valve head against the seal. See Figure 1-92. Figure 1-92 Valve Stem Oil Seal Installer (Rev. 2005) All information subject to change without notice. 1-102 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 165 Be sure the valve rotator is properly centered and aligned to avoid scoring the valve stem. Do not compress the spring any more than necessary to install the locks, to avoid damaging the oil seal. All information subject to change without notice. (Rev. 2005) 1-103 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 166 10. After all of the valves are installed, check the spring opening pressure on each valve using spring load gage. See Figure 1-94. Figure 1-94 Checking Valve Spring Load (Rev. 2005) All information subject to change without notice. 1-104 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 167 □ Do not modify or tamper with the exhaust system or emission control system. 20. Start the engine and check for leaks. All information subject to change without notice. (Rev. 2005) 1-105 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 168: Engine Lifter Brackets

A total of three engine lifter brackets are installed on each Series 60 engine and are utilized when removing and replacing the engine.See Figure 1-95. Figure 1-95 Lifting Engine (Rev. 2005) All information subject to change without notice. 1-106 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 169 A lifter bracket should always be reinstalled whenever removal is necessary see Figure 1-96. For engine models equipped with the compact gear train see Figure 1-97. Figure 1-96 Engine Lifter Brackets All information subject to change without notice. (Rev. 2005) 1-107 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 170 Engine Lifter Brackets Compact Gear Train Models 1. Front Lifter Bracket 3. Right Rear Lifter Bracket 2. Bolt 4. Left Rear Lifter Bracket (Rev. 2005) All information subject to change without notice. 1-108 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 171 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-99. Figure 1-99 Flowchart for Repair or Replacement of Lifter Bracket All information subject to change without notice. (Rev. 2005) 1-109 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 172 1. Install the bracket to the engine. Torque the mounting bolts to 101-126 N·m (75-93 lb·ft). 2. Install the fan support, heat exchanger support, or charge air cooler support bracket, refer to section 1.10.3. (Rev. 2005) All information subject to change without notice. 1-110 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 173: Rocker Cover

2. Rocker Cover 6. Bolt 3. Isolator 7. Element 4. Washer 8. Clip Figure 1-100 One-piece Rocker Cover - Series 60 Diesel Engine All information subject to change without notice. (Rev. 2005) 1-111 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 174 3. Washer 7. Rocker Cover Base 4. Bolt 8. Isolator Rim Seal Figure 1-101 Two-piece Rocker Cover - Series 60 Diesel Engine (Rev. 2005) All information subject to change without notice. 1-112 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 175 12. Rocker Cover Base 13. Gasket 6. Cover 7. Bolt Figure 1-102 Two Piece Rocker Cover - Series 60G Engine with Coil Over Plug Ignition All information subject to change without notice. (Rev. 2005) 1-113 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 176 2. Isolator 6. Diamond-Shaped Seal 3. Washer 7. Rocker Cover Base 4. Bolt 8. Isolator Rim Seal Figure 1-103 Two-piece Rocker Cover (Rev. 2005) All information subject to change without notice. 1-114 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 177 The three-piece design and the Series 60G cap incorporate a combination filler/breather at the camshaft cover (gear case cover) position. All information subject to change without notice. (Rev. 2005) 1-115 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 178 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-105. Figure 1-105 Flowchart for Repair or Replacement of Rocker Cover (Rev. 2005) All information subject to change without notice. 1-116 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 179 5. Clean the breather recess in the rocker cover. 6. Check for damage. Replace as necessary. 7. Reinstall the breather element and retainer clip. All information subject to change without notice. (Rev. 2005) 1-117 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 180 (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure. 4. Blow dry with compressed air. (Rev. 2005) All information subject to change without notice. 1-118 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 181 4. Pull the six extension tubes from the cylinder head. 5. Loosen and remove the ten bolt/isolator assemblies that attach the base to the cylinder head. All information subject to change without notice. (Rev. 2005) 1-119 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 182 Reuse gaskets with manufacturing date after May 28, 1999. 4. Inspect the lower rocker cover base-to-cylinder head gasket for damage replace if gasket is damaged. (Rev. 2005) All information subject to change without notice. 1-120 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 183 Then install each section at its halfway point. Seat the seal completely around the arch. Be sure the corners are still firmly seated after the arch is completed. All information subject to change without notice. (Rev. 2005) 1-121 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 184 Make sure the seal is completely seated all the way around the valve cover. NOTE: The corners must be cleaned prior to RTV installation for best results. (Rev. 2005) All information subject to change without notice. 1-122 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 185 4. Press the two protective plugs into the two center holes until they are firmly seated. 5. Install any other components that were removed for their procedure. All information subject to change without notice. (Rev. 2005) 1-123 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 186 4. Flat Washer Figure 1-109 Rocker Cover Base Hold Down Hardware 3. Install the hold-down bolts, with washers installed, to the limiting sleeves. (Rev. 2005) All information subject to change without notice. 1-124 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 187 See Figure 1-110. Figure 1-110 Rocker Cover Base Hold-down Bolt Installation All information subject to change without notice. (Rev. 2005) 1-125 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 188 The same procedure applies to the intermediate cover diamond seal installation. (Rev. 2005) All information subject to change without notice. 1-126 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 189 2. Install the rocker cover cap to the base. Install the eight bolts that attach the cap to the base, and torque to 22-25 N·m (16-18 lb·ft) using the torque sequence. See Figure 1-113. All information subject to change without notice. (Rev. 2005) 1-127 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 190 9. Install any other parts that were removed for this procedure. 10. Refer to section1.6.8 for the exhaust caution before preceeding. Start the engine and check for leaks. Refer to section 12.7. (Rev. 2005) All information subject to change without notice. 1-128 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 191: Crankshaft

Complete static and dynamic balance of the crankshaft has been achieved by counterweights incorporated in the crankshaft. Current crankshafts may have a six-bolt or twelve-bolt mounting pattern on the front. All information subject to change without notice. (Rev. 2005) 1-129 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 192 (The iron piston pin bolts interefere with the new lightweight crankshaft design.) See Figure 1-115 and see Figure 1-116. Figure 1-115 Current and Former Crankshafts (Rev. 2005) All information subject to change without notice. 1-130 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 193 SERIES 60 SERVICE MANUAL Figure 1-116 Varied Piston Dome-Crankshaft Clearances All information subject to change without notice. (Rev. 2005) 1-131 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 194 The current design makes use of thrust washers in the upper positions only. Oversize thrust washers are available to correct for excessive end play. (Rev. 2005) All information subject to change without notice. 1-132 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 195 Former No. 6 Main Bearing Cap The current design does not use the indexing dowels. See Figure 1-119. Figure 1-119 Current No. 6 Main Bearing Cap All information subject to change without notice. (Rev. 2005) 1-133 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 196 Each standard main bearing journal is 125.000-124.968 mm (4.921-4.920 in.) in diameter and each standard connecting rod journal is 85.000-84.975 mm (3.346-3.345 in.) in diameter. (Rev. 2005) All information subject to change without notice. 1-134 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 197 The new crankshafts, bearings, and connecting rods must be used together to ensure interchangeability. Former parts cannot be mixed with new parts in the same engine. The former crankshafts will no longer be available. All information subject to change without notice. (Rev. 2005) 1-135 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 198 To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 1-121. Figure 1-121 Flowchart for Repair or Replacement of Crankshaft (Rev. 2005) All information subject to change without notice. 1-136 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 199 180 degrees apart and install two flywheel guide studs (J–36235) in their place. Then loosen and remove the remaining four pulley retaining bolts and hardened washers. Refer to section 1.15.2. All information subject to change without notice. (Rev. 2005) 1-137 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 200: Inspection Of Crankshaft

1. Clean out the oil passages thoroughly with a stiff wire brush. Clean the crankshaft with fuel oil and dry it with compressed air. (Rev. 2005) All information subject to change without notice. 1-138 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 201 No. 3 and No. 5 0.127 mm (0.005 in.) No. 1 and No. 7 No. 4 0.152 mm (0.006 in.) Table 1-3 Crankshaft Bow All information subject to change without notice. (Rev. 2005) 1-139 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 202 0.0381 mm (0.0015 in.) or the out-of-round is greater than 0.0254 mm (0.001 in.) the crankshaft must be reground. Specifications for the crankshaft are listed in Table 1-22. (Rev. 2005) All information subject to change without notice. 1-140 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 203 1.7.2.6, for magnetic particle method, refer to section 1.7.2.7, for fluorescent magnetic particle method, or refer to section 1.7.2.8, for fluorescent penetrant method. All information subject to change without notice. (Rev. 2005) 1-141 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 204 Unless abnormal conditions are discovered and corrected, there will be a repetition of the failure. (Rev. 2005) All information subject to change without notice. 1-142 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 205 These cracks are most likely to occur on either side of the damaged bearing. All information subject to change without notice. (Rev. 2005) 1-143 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 206 Refer to section 1.7.3. 1.7.2.12 Crankshaft Grinding The use of properly remanufactured crankshafts is very important to maximize crankshaft main and connecting rod bearing life. (Rev. 2005) All information subject to change without notice. 1-144 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 207 If one or more main or connecting rod journals require grinding, grind all of the main journals or all of the connecting rod journals to the same required size. All information subject to change without notice. (Rev. 2005) 1-145 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 208: Installation Of Crankshaft

Refer to section 1.34.3. NOTE: It may be easier to remove the bull gear assembly and re-time the engine. (Rev. 2005) All information subject to change without notice. 1-146 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 209: Main Bearing Cap Installation

6. Install the main bearing caps together with lower bearing shells in place. Figure 1-126 Main Bearing Cap Installation All information subject to change without notice. (Rev. 2005) 1-147 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 210: Measuring Crankshaft End Play

Figure 1-127 Measuring Crankshaft End Play (Rev. 2005) All information subject to change without notice. 1-148 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 211 29. After replacing the main or connecting rod bearings or installing a new or reground crankshaft, operate the engine as outlined in the "Run-In Schedule." Refer to section 12.7.3.2. All information subject to change without notice. (Rev. 2005) 1-149 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 212: Crankshaft Oil Seals

Because of the spiral grooves on the sealing lip, a front crankshaft seal will leak if installed at the rear, and a rear crankshaft seal will leak if installed at the front. (Rev. 2005) All information subject to change without notice. 1-150 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 213: Front View

flywheel housing and block to direct additional oil to the seal for cooling. See Figures 1-130 and 1-131. 1. Rib Location Figure 1-130 Cast-in-Rib Front View All information subject to change without notice. (Rev. 2005) 1-151 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 214: Rear View

This sleeve must be installed with replacement seals to prevent seal damage or oil leakage. (Rev. 2005) All information subject to change without notice. 1-152 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 215: Replacement Of Oil Seal

To determine if replacement is necessary, perform the following procedure. See Figure 1-132. To determine whether flywheel housing runout is excessive, refer to section 1.18.3.1. Figure 1-132 Flowchart for Replacement of Crankshaft Oil Seal All information subject to change without notice. (Rev. 2005) 1-153 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 216 3. If the crankshaft oil seal wear sleeve remains installed on the hub of the crankshaft, reinstall the gear case cover or flywheel housing. (Rev. 2005) All information subject to change without notice. 1-154 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 217 4. Remove the wear sleeve using wear sleeve remover (J–37075–A). See Figure 1-134. Refer to section 1.8.4. Figure 1-134 Crankshaft Wear Sleeve Remover Tool All information subject to change without notice. (Rev. 2005) 1-155 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 218 4. Remove any metal chips from the face of the seal, the crankshaft and the bore surface. 5. Rotate the removal tool (J–41329) clockwise until the “B” holes align with drilled holes and install sheet metal screws. (Rev. 2005) All information subject to change without notice. 1-156 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 219 Crocus cloth may be used to remove dirt, rust and to clean up the high spots from the surface of the crankshaft and gear case cover bore. Thoroughly clean the contact surfaces. All information subject to change without notice. (Rev. 2005) 1-157 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 220 Crocus cloth may be used to clean up the high spots from the surface of the crankshaft. 3. Thoroughly clean the crankshaft contact surface. Figure 1-136 Rear Oil Seal Wear Sleeve Removal (Rev. 2005) All information subject to change without notice. 1-158 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 221 Rear, Dry Housing 23519651 J–35686–20 J–35686–6 and J–35686–11 Rear, Wet Housing 23513578 J–35686–10 J–35686–6 and J–35686–11 Table 1-4 Crankshaft Seal Tool Application All information subject to change without notice. (Rev. 2005) 1-159 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 222 Failure to lubricate the outside of the seal and the inside of the bore prior to installation may damage seal causing seal to leak. (Rev. 2005) All information subject to change without notice. 1-160 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 223: Spacer Installation

3. Install the spacers to the center screw of the base. Refer to Table 1-4 and Figure 1-138. Figure 1-138 Spacer Installation All information subject to change without notice. (Rev. 2005) 1-161 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 224: Thrust Bearing

8. Tighten the hex nut until the oil seal and wear sleeve are pressed into the flywheel housing or gear case cover. (Rev. 2005) All information subject to change without notice. 1-162 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 225 If the total indicator reading is more then 0.762 mm (0.030 in.) the seal must be removed and a new seal installed. All information subject to change without notice. (Rev. 2005) 1-163 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 226: Crankshaft Main Bearings

13. Upper No. 6 Thrust Bearing Shell 6. Bolt 7. No. 6 Main Cap Figure 1-141 Main Bearing Caps, Bearing Shells and Crankshaft Thrust Washers (Rev. 2005) All information subject to change without notice. 1-164 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 227 06R0762048 use the two-piece washers with locking tangs that register with locating notches in the bearing shell. See Figure 1-142. All information subject to change without notice. (Rev. 2005) 1-165 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 228 Figure 1-142 No. 6 Thrust Bearing Detail The condition of the lower bearing shells may be observed by removing the main bearing caps. (Rev. 2005) All information subject to change without notice. 1-166 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 229 3.11.2. 2. Remove the oil pump pickup and outlet pipes, and the oil pump. Refer to section 3.2.2. All information subject to change without notice. (Rev. 2005) 1-167 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 230 No. 6 and No. 7. Figure 1-144 Main Bearing Shell Remover and Installer Tool Set (Rev. 2005) All information subject to change without notice. 1-168 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 231 8. Using the main bearing cap bolts and washer removed from the engine, install the assembled main bearing cap remover and installer tool to the main bearing saddle being All information subject to change without notice. (Rev. 2005) 1-169 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 232 "Front" facing the front of the engine. If the No. 6 main bearing is being done, install the thrust washers to the bearing. Refer to step 7 in this procedure. (Rev. 2005) All information subject to change without notice. 1-170 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 233 22. After removal, clean the bearings. 1.9.2.1 Cleaning of Main Bearings Perform the following to clean the main bearing: 1. Immerse the bearing in cleaning agent. All information subject to change without notice. (Rev. 2005) 1-171 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 234 Measure the thickness of the bearing shells at a point, 90 degrees from the parting line. See Figure 1-148. Figure 1-148 Main Bearing Measurements (Rev. 2005) All information subject to change without notice. 1-172 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 235 Ensure the correct bearing to journal clearance is maintained when using these parts. NOTE: Bearing shells are NOT reworkable from one undersize to another undersize under any circumstances. All information subject to change without notice. (Rev. 2005) 1-173 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 236 6. Torque all of the main bearing cap bolts to 470-530 N·m (347-391 lb·ft). 7. Measure the main bearing bores with dial bore gage (J–5347–B). The minimum specifications are listed in Table 1-16. (Rev. 2005) All information subject to change without notice. 1-174 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 237: Gear Case Cover Pre-Exhaust Gas Recirculation (Egr)

The gear case cover also serves as a retainer for the crankshaft front oil seal. See Figure 1-150. Figure 1-150 Crankshaft Front Oil Seal All information subject to change without notice. (Rev. 2005) 1-175 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 238: Front Engine Support

The front engine support is bolted to the front of the gear case cover, directly behind the crankshaft pulley and vibration damper. See Figure 1-152 Figure 1-152 Typical Front Engine Support (Rev. 2005) All information subject to change without notice. 1-176 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 239 With the fan support bracket and the camshaft drive gear access cover removed, the gear lash between the adjustable idler gear and the camshaft drive gear can be measured and adjusted Refer to section 1.24.2.1. All information subject to change without notice. (Rev. 2005) 1-177 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 240 fits in the splined hole in the center of the air compressor drive gear. The pump is installed with a gasket. (Rev. 2005) All information subject to change without notice. 1-178 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 241 2. Loosen the fan hub mounting bolts. Loosen the fan adjusting bolt. Back the adjuster off far enough to remove the drive belts. Remove the fan and fan hub assembly. Refer to section 4.6.2. All information subject to change without notice. (Rev. 2005) 1-179 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 242 7. Remove the power steering pump (if so equipped). Refer to OEM guidelines. 8. Remove the crankshaft pulley. Refer to section 1.15.2. 9. Remove the vibration damper. Refer to section 1.14.2. (Rev. 2005) All information subject to change without notice. 1-180 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 243 12. Remove the accessory drive assembly by pulling it straight out of the gear case cover to avoid damaging the rubber O-ring. See Figure 1-159. All information subject to change without notice. (Rev. 2005) 1-181 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 244 Gear Case Cover Bolt Arrangement (Front) NOTE: Bolts 21 and 22 are rear bolts on pre-1991 engines. [a] Remove the SRS. Refer to section 2.30.2. (Rev. 2005) All information subject to change without notice. 1-182 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 245 Gear Case Cover Bolt Arrangement (Right Rear) 14. Support the gear case cover with a suitable lifting device, using the front engine lift bracket. See Figure 1-163. All information subject to change without notice. (Rev. 2005) 1-183 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 246 15. Tap the gear case cover with a fiber mallet or plastic hammer to loosen it from the gear case. Remove the engine gear case cover. (Rev. 2005) All information subject to change without notice. 1-184 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 247: Installation Of Gear Case Cover

All information subject to change without notice. (Rev. 2005) 1-185 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 248 5. There are 34 bolts that secure the gear case cover to the gear case (including five for the fan support bracket). Install them as follows: (Rev. 2005) All information subject to change without notice. 1-186 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 249 [e] Bolts F1 through F5 are fan support bracket bolts. Install the fan support bracket and torque bolts F1, F2 and F3 to 58-73 N·m (43-54 lb·ft). Torque bolts F4 and F5 to 160-200 N·m (118-148 lb·ft). All information subject to change without notice. (Rev. 2005) 1-187 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 250 (right) side of the engine. Torque the number 2 and 3 bolts to 58-73 N·m (43-54 lb·ft) torque. See Figure 1-168. Figure 1-168 Gear Case Cover Bolt Torque Sequence (Right Rear) (Rev. 2005) All information subject to change without notice. 1-188 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 251 Refer to section 14.6.9. 18. Install the engine oil pan. Refer to section 3.11.4. Fill the crankcase with recommended lubricating oil. Refer to section 14.6.1. All information subject to change without notice. (Rev. 2005) 1-189 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 252: Gear Case Cover Exhaust Gas Recirculation (Egr) Model

The gear case cover and gear case bolt together at the front of the engine to form a sealed compartment for the engine gear train. See Figure 1-170. Figure 1-170 Engine Gear Case and Cover Series 60 EGR Model (Rev. 2005) All information subject to change without notice. 1-190 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 253 The gear case cover also serves as a retainer for the crankshaft front oil seal. See Figure 1-171. 1. Oil Seal Figure 1-171 Crankshaft Front Oil Seal All information subject to change without notice. (Rev. 2005) 1-191 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 254 The front engine support is bolted to the front of the gear case cover, directly behind the crankshaft pulley and the vibration damper. See Figure 1-172. 1. Front Engine Mount 2. Bolt Figure 1-172 Front Engine Support (Rev. 2005) All information subject to change without notice. 1-192 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 255 1. Accessory Drive Assembly 3. (Optional) Power Steering Pump Location 2. Fan Support Bracket Figure 1-173 Gear Case Cover Mounted Components EGR Model All information subject to change without notice. (Rev. 2005) 1-193 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 256 Refer to section 1.25.2.2. See Figure 1-174. Figure 1-174 Gear Case Cover Fan Bracket and Camshaft Access Cover (Rev. 2005) All information subject to change without notice. 1-194 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 257 3. Loosen the fan hub mounting bolts. Loosen the fan adjusting bolt. Back the adjuster off far enough to remove the drive belts. Remove the fan and fan hub assembly. Refer to section 4.6.2. All information subject to change without notice. (Rev. 2005) 1-195 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 258 4. For engines equipped with a fan support bracket, remove nine fan support bolts and remove fan support. See Figure 1-176. Figure 1-176 Fan Support Bolt Locations (Rev. 2005) All information subject to change without notice. 1-196 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 259 6. Rotate engine until cylinder No.1 is at TDC; install timing pin (J–45947) into the slot in crankshaft. 1. Timing Pin Figure 1-178 Timing Pin Location All information subject to change without notice. (Rev. 2005) 1-197 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 260 See Figure 1-179. 1. Front Engine Support 2. Bolt Figure 1-179 Front Engine Support 18. Remove timing pin bracket. (Rev. 2005) All information subject to change without notice. 1-198 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 261 20. Remove accessory drive by pulling it straight out of the gear case cover to avoid damaging the rubber O-ring. 21. Remove fuel pump. Refer to section 2.8. All information subject to change without notice. (Rev. 2005) 1-199 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION...