Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Keysight Technologies 90000 A Series

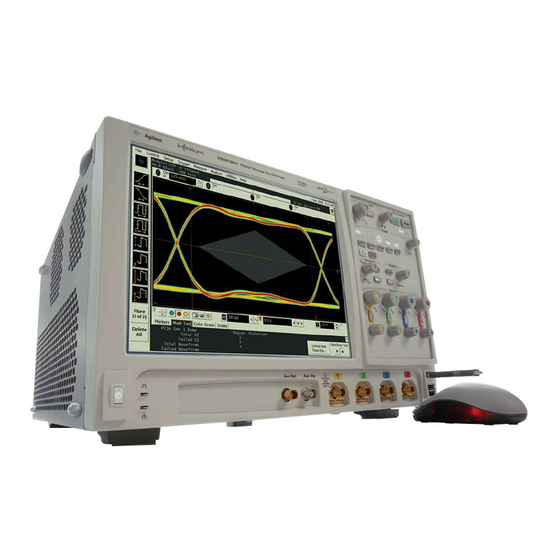

- Page 1 Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide...

- Page 2 Notices U.S. Government Rights Safety Notices © Keysight Technologies 2007, 2008, 2013, 2015 The Software is “commercial computer soft- No part of this manual may be reproduced in ware,” as defined by Federal Acquisition CAUTION any form or by any means (including elec- Regulation (“FAR”) 2.101.

-

Page 3: Table Of Contents

Contents 1 General Information Instruments Covered by this Service Guide / 8 Performance-Enhanced Versus Standard Models / 9 Accessories Supplied / 9 Specifications and Characteristics / 10 Oscilloscope Dimensions / 11 2 Calibration What Is a Calibration? / 14 Running a User Calibration / 15 Equipment required / 15 Procedure / 16 3 Testing Performance... - Page 4 5 Replacing Assemblies Replacing Assemblies / 80 Returning the oscilloscope to Keysight Technologies for service / 81 Removing and replacing the cover, top plate, and bottom plate / 82 Removing and replacing the front panel bezel and front panel circuit assembly / 87...

- Page 5 Removing and replacing the USB or GPIB port / 115 6 Replaceable Parts Ordering Replaceable Parts / 118 Exploded Views / 119 Replaceable Parts List / 123 7 Theory of Operation Block-Level Theory / 129 90000 A-Series Oscilloscopes Service Guide...

- Page 6 90000 A-Series Oscilloscopes Service Guide...

- Page 7 Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 1 General Information Instruments Covered by this Service Guide / 8 Performance-Enhanced Versus Standard Models / 9 Accessories Supplied / 9 Specifications and Characteristics / 10 Oscilloscope Dimensions / 11...

-

Page 8: General Information

The release date of this manual is shown on the back of the title page. This manual will be revised when necessary. If you have an oscilloscope that was manufactured after the release of this manual, please check the Keysight Technologies website at www.keysight.com to see whether a newer version of this manual is available. -

Page 9: Performance-Enhanced Versus Standard Models

General Information Performance-Enhanced Versus Standard Models In the fall of 2000, keysight started shipping performance-enhanced models of the 90000 A-Series oscilloscope. This service guide covers both the standard and performance-enhanced versions. Any differences between the two versions are noted. To tell whether the oscilloscope you have is a standard one or a performance-enhanced version, check whether it has one handle or two handles. -

Page 10: Specifications And Characteristics

General Information Specifications and Characteristics The following table contains a partial list of specifications and characteristics for the Keysight Infiniium 90000 A-Series oscilloscopes. For a complete list, see the data sheet at www.keysight.com/find/90000. Specifications that are pertinent to each test are in Chapter 3, “Testing Performance”. -

Page 11: Oscilloscope Dimensions

General Information Oscilloscope Dimensions The following pictures show the dimensions of the 90000 A-Series oscilloscope. 90000 A-Series Service Guide... - Page 12 General Information 90000 A-Series Service Guide...

-

Page 13: Calibration

Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 2 Calibration What Is a Calibration? / 14 Running a User Calibration / 15... -

Page 14: What Is A Calibration

Calibration What Is a Calibration? A calibration is simply an oscilloscope self-adjustment. The purpose of a calibration is performance optimization. There are two ways to calibrate an Infiniium A-Series oscilloscope: • A user calibration, also known as a self calibration. A user calibration includes the minimum set of calibrations and is intended to be run by oscilloscope users. -

Page 15: Running A User Calibration

Calibration Running a User Calibration The oscilloscope must be warmed up (with the oscilloscope application running) for at least NOTE 30 minutes at ambient temperature before starting the calibration procedure. Failure to allow warm up may result in inaccurate calibration. The user calibration uses signals generated in the oscilloscope to calibrate channel scale, offsets, and trigger parameters. -

Page 16: Procedure

Calibration Procedure Let the oscilloscope warm up before running the self calibration. The self calibration should be done only after the oscilloscope has run for 30 minutes at ambient temperature. Calibration of an oscilloscope that has not warmed up may result in inaccurate calibration. Click Utilities >... - Page 17 Calibration • Standard calibration and Default Time Scale—Factory time scale calibration factors will be used. The 10 MHz reference signal will not be required. The remaining calibration procedure will continue. Connect the calibration cable from Aux Out to channel 1. You must use the 54855-61620 cable assembly with two connector saver adapters for all oscilloscopes except the DSO90254A, which can use a good-quality BNC cable.

- Page 18 Calibration 90000 A-Series Service Guide...

-

Page 19: Testing Performance

Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 3 Testing Performance Verifying System Performance / 20 Vertical Performance Verification / 21 Offset Accuracy Test / 22 DC Gain Accuracy Test / 28 Analog Bandwidth—Maximum Frequency Test / 32 Time Scale Accuracy (TSA) Test / 39 Performance Test Record / 42 Full performance verification for 90000 A-Series oscilloscopes consists of three main procedures:... -

Page 20: Verifying System Performance

However, other equipment, cables, and accessories that satisfy the critical specifications in these lists may be substituted for the recommended models with some modification to the test procedures. Contact Keysight Technologies for more information about the Keysight products in these lists. 90000 A-Series Service Guide... -

Page 21: Vertical Performance Verification

Testing Performance Vertical Performance Verification This section describes the following vertical performance verification tests: • Offset Accuracy Test • DC Gain Accuracy Test • Analog Bandwidth Test • Time Scale Accuracy Test 90000 A-Series Service Guide... -

Page 22: Offset Accuracy Test

Testing Performance Offset Accuracy Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V. CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for NOTE at least 30 minutes prior to the start of any performance test. Specifications ≤... - Page 23 Testing Performance Configure the oscilloscope to measure the average voltage (V avg) on channel 1 as follows: Change the vertical scale of channel 1 to 5 mV/div. Click the Vertical Meas tab on the left side of the waveform window, then drag and drop the Average measurement icon onto the channel 1 waveform.

- Page 24 Testing Performance Press [Clear Display] on the oscilloscope and wait for the number of averages display (top right area of the screen) to return to 256. Record the oscilloscope’s mean V avg reading in the Offset Accuracy—Zero Error Test section of the Performance Test Record.

- Page 25 Testing Performance Offset Gain Test Procedure Make the connections to oscilloscope channel 1 as shown below. • Where the BNC Tee adapter is used, it is important to connect it directly to the oscilloscope NOTE channel input to minimize ground potential differences and to ensure that the DMM measures the input voltage to the oscilloscope channel as accurately as possible.

- Page 26 Testing Performance Configure the oscilloscope to measure the average voltage on the channel under test as follows: Make sure the channel under test is enabled. Click Setup > Acquisition..In the Acquisition dialog box, enable averaging and set # of Averages to 256. Change the vertical scale to 5 mV/div.

- Page 27 Testing Performance Calculate the offset gain error using the following expressions and record the value in the Offset Accuracy—Offset Gain Test section of the Performance Test Record. The offset gain error is the greater (maximum magnitude) of either: – V ...

-

Page 28: Dc Gain Accuracy Test

Testing Performance DC Gain Accuracy Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for NOTE at least 30 minutes prior to the start of any performance test. Specifications DC Gain Accuracy ±2% of full scale at full resolution channel scale. - Page 29 Testing Performance Procedure Make the connections to oscilloscope channel 1 as shown below. • Where the BNC Tee adapter is used, it is important to connect it directly to the oscilloscope NOTE channel input using the BNC (f) to SMA (m) adapter and the connector saver to minimize ground potential differences and to ensure that the DMM measures the input voltage to the oscilloscope channel as accurately as possible.

- Page 30 Testing Performance Press [Defaul t Setup], then configure the oscilloscope as follows: Click Setup > Acquisition..In the Acquisition dialog box, enable averaging and set # of Averages to 256. Set the Aux Out voltage (V ) to +15 mV as follows: Aux Out Click Utilities >...

- Page 31 Testing Performance Press [Clear Display] on the oscilloscope, wait for the number of averages to return to 256, and then record the DMM voltage reading as V and the DMM- scope V avg reading as V in the DC Gain Accuracy Test section of the Scope- Performance Test Record.

-

Page 32: Analog Bandwidth-Maximum Frequency Test

Testing Performance Analog Bandwidth—Maximum Frequency Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for NOTE at least 30 minutes prior to the start of any performance test. Specifications Analog Band wid th (-3 dB) DSO/DSA91304A... - Page 33 Testing Performance Connections • Connect output 1 of the 11667B splitter to the scope channel N input directly using the NOTE 54855-67604 adapter, without any additional cabling or adapters. • Connect the power sensor directly to output 2 of the power splitter without any additional cabling or adapters.

- Page 34 Testing Performance Press [Defaul t Setup], then configure the oscilloscope as follows: Ensure the channel under test is displayed and all other channels are turned off. Set the vertical scale of the channel under test to 5 mV/div. Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform).

- Page 35 Testing Performance Set the generator to apply a 50 MHz sine wave with a peak-to-peak amplitude of about four divisions. Use the following table to determine the approximate required signal amplitude. The amplitude values in the table is not absolutely required. If your generator is unable to produce the recommended amplitude, then set the generator to the highest value that does not produce a vertically clipped signal on the oscilloscope.

- Page 36 Testing Performance out @50 MHz Gain --------------------------------- - 50 MHz in @50 MHz Record this value in the Calculated Gain @50 MHz column in the Analog Bandwidth—Maximum Frequency Check section of the Performance Test Record. Change the generator frequency to the maximum value for the model being tested as shown in the table below.

- Page 37 Testing Performance For example, if (Vout @ Max Frequency) = 13.825 mV, (Vin @ Max Frequency) = 13.461 mV and Gain @ 50MHz = 1.0023, then: ⁄ 13.825 mV 13.461 mV ------------------------------------------------------------- Gain 20 log 0.212 dB Max Freq 1.0023 Record this value in the Calculated Gain @Max Freq column in the Analog Bandwidth—Maximum Frequency Check section of the Performance Test Record.

- Page 38 Testing Performance Move the splitter to channel 3 and change the oscilloscope configuration as follows: Press [Defaul t Setup]. Ensure channel 3 is displayed and all other channels are turned off. Set the vertical scale of channel 3 to 5 mV/div. Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform).

-

Page 39: Time Scale Accuracy (Tsa) Test

Testing Performance Time Scale Accuracy (TSA) Test This procedure verifies the maximum TSA specification for the oscilloscope. Description TSA refers to the absolute accuracy of an oscilloscope’s time scale. Because TSA depends directly on frequency of a crystal oscillator, it is comprised of two components: an initial accuracy component and an aging component. - Page 40 Testing Performance Connections Connect the equipment as shown here. Procedure Configure the sine wave source to output a 0 dBm (600 mVpp) sine wave into 50 ohms with a frequency of 10.00002000 MHz. Adjust the source amplitude such that the displayed sine wave is 600 mVpp. Press [Defaul t Setup] on the oscilloscope.

- Page 41 Testing Performance Convert the average frequency value to time scale error by subtracting 20 Hz and dividing by 10 Hz/ppm. Record the result in the Measured Time Scale Error (ppm) column of the Time Scale Accuracy table. Record the time since calibration (in years) in the table. The calibration date can be found in the Calibration window (Utilities >...

-

Page 42: Performance Test Record

Testing Performance Performance Test Record Keysight Technologies Keysight 90000 V-Series Oscilloscopes Model Number _____________________ Tested by________________________ Serial Number ___________________________ Work Order No.___________________ Recommended Test Interval—1 Year/2000 hours Date_____________________________ Recommended next test date ___________________ Ambient temperature ______________ Offset Accuracy—Zero Error Test... - Page 43 Testing Performance Offset Accuracy—Offset Gain Test Vertical Scale Calc. Offset Offset Gain Error Aux Out DMM+ Scope+ DMM- Scope- DMM0 Scope0 Setting Gain Error Test Limits Channel 1 5 mV/div ±400 mV 10 mV/div ±400 mV ±2% 20 mV/div ±400 mV ±2% 50 mV/div ±900 mV...

- Page 44 Testing Performance DC Gain Accuracy Test Vertical Scale Calc. DC DC Gain Error Aux Out DMM+ Scope+ DMM- Scope- Setting Gain Error Test Limits Channel 1 5 mV/div ±15 mV ±4.5% 10 mV/div ±30 mV ±2% 20 mV/div ±60 mV ±2% 50 mV/div ±150 mV...

- Page 45 Testing Performance Max frequency: DSO/DSA90254A = 2.5 GHz, DSO/DSA90404A = 4.0 GHz, DSO/DSA90604A = 6.0 GHz, DSO/DSA90804A = 8.0 GHz, DSO/DSA91204A = 12 GHz (11.8 GHz at 5 mV/div), DSO/DSA91304A = 12 GHz (11.8 GHz at 5 mV/div), Analog Bandwidth—Maximum Frequency Check Measurement Vout Calculated Gain...

- Page 46 Testing Performance Time Scale Accuracy Measured Time Scale Years Since Calibration Low Test Limit High Test Limit Pass/Fail (years) (ppm) (ppm) Error (ppm) ___________ ___________ ___________ ___________ ___________ 90000 A-Series Service Guide...

-

Page 47: Troubleshooting

Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 4 Troubleshooting Troubleshooting Overview / 48 Verifying Basic Operation / 49 Power Supply Troubleshooting / 53 Display Troubleshooting / 64 Checking the Backlight Inverter Voltages / 65 Checking the Display Board Video Signals / 66 Front Panel Display Troubleshooting / 67 Motherboard Verification / 69 Setting Up the BIOS / 71... -

Page 48: Troubleshooting Overview

Troubleshooting Troubleshooting Overview The service strategy for troubleshooting Infiniium 90000 A-Series oscilloscopes is to isolate problems to a faulty assembly, then use the disassembly and assembly procedures in Chapter 5, “Replacing Assemblies, to replace the defective assembly. Read the For Your Safety booklet before servicing the oscilloscope. Before performing any procedure, review it for any cautions and warnings. -

Page 49: Verifying Basic Operation

Troubleshooting Verifying Basic Operation Follow the procedures in this section to verify the basic operation of the oscilloscope. Where problems occur, you are directed to the section that provides detailed troubleshooting help. Power Up the oscilloscope Connect the power cord to the oscilloscope, then to a suitable AC voltage source. -

Page 50: Run The Oscilloscope Self Tests

Troubleshooting Run the oscilloscope self tests Running the oscilloscope self tests performs a series of internal procedures to verify that the oscilloscope is working properly. Click Utilities > Sel f Test..Select Scope Sel fTest from the Available Self Tests drop-down list box. Click Start and follow the instructions on the screen. - Page 51 Troubleshooting Turn each knob in both directions until you have turned all knobs. When you turn a knob in one direction, half the rotation arrow under the corresponding knob symbol should turn green. When you then turn the knob in the other direction, the entire rotation arrow under the knob symbol should turn green.

-

Page 52: Run A User Calibration

Troubleshooting Pressing [Mul ti Purpose] on the front panel illuminates all the LEDs, and pressing [Clear Display] turns off all the LEDs. When you are finished, click Close. If any of the LEDS do not work, go to “LED Troubleshooting” later in this chapter. To verify correct touch screen operation: Click Utilities >... -

Page 53: Power Supply Troubleshooting

Troubleshooting Power Supply Troubleshooting SHOCK HAZARD! Maintenance should be performed by trained service personnel. WARNING Lack of training and awareness could resul t in electrical shock or other injury. When maintenance can be performed without power applied, the power cord should be removed from the oscilloscope. -

Page 54: Under-Voltage Fault

Troubleshooting Under-Voltage Fault If the oscilloscope takes about 2 seconds to lose power as just described, the problem is either an under-voltage fault on the backplane assembly or one of the two acquisition assemblies, or a defective bulk 12 V power supply. To determine which problem it is, first remove the handle, the outer oscilloscope cover, and the inner top cover to expose the motherboard cavity and the top edges of the backplane assembly. - Page 55 Troubleshooting If the FP SUPPLY FAIL LED is lit If the FP SUPPLY FAIL LED is the only one lit, there might be a problem with one of the supplies that goes to the front panel assembly, or a problem on the front panel assembly.

- Page 56 Troubleshooting It is also possible that there is a short circuit on the bulk +12 V supply trace somewhere in the system, which would also cause the oscilloscope to not power on. If so, you need to isolate the assembly that is shorted. You do not need to remove the acquisition or backplane assemblies to perform the following steps.

- Page 57 Troubleshooting If there is a short, disconnect the power cable to the front panel and redo the resistance measurement. If the short is gone, replace the front panel assembly and verify that the oscilloscope now powers on. If there is still a short circuit, disconnect the two large connectors that provide power to the motherboard (J1201 and J1202) from the backplane assembly as shown below and redo the resistance measurements across the FET (Q1409) or the bulk supply input pins on the backplane assembly.

- Page 58 Troubleshooting reading you will get will be very low (near 0 ohms). Replace either assembly if needed. Measuring the acquisition assembly resistance between +12 V and ground If no shorts are found on the bulk +12 V supply trace or if you have fixed all the shorts and the oscilloscope still will not turn on, follow these steps, which include replacing parts with known good parts until you discover the problem.

-

Page 59: Over-Temperature Fault

Troubleshooting Over-Temperature Fault If the oscilloscope takes 4 seconds or more to lose power as described earlier, then the problem is a cooling system failure. Four case fans are located on the left side of the oscilloscope to cool it. In addition, a single fan is attached to the backplane assembly to cool the trigger ICs. - Page 60 Troubleshooting If any of the fans are turning then they are probably not the cause of your shutdown problem. (You should still replace any fans that are not turning, however.) If this is the case, the next step is to see if the FAN FAIL indicator LED on the upper right corner of the backplane assembly is lit.

- Page 61 Troubleshooting • If the oscilloscope stays on after you reset the shutdown logic (by removing AC power for 30 seconds) and powered it back on, then you have fixed the shutdown problem. • If the oscilloscope shuts down again after you have replaced the trigger ICs fan, then the problem could be that the rotation sensor for all the fans located on the backplane assembly failed, so replace the backplane assembly and redo this part of the diagnostic test.

-

Page 62: Over-Voltage Fault

Troubleshooting Over-Voltage Fault If the oscilloscope loses power almost immediately as described earlier, it is probably an over-voltage fault. Three groups of LEDs indicate over-voltage faults. One group is located near the center of the top edge of the backplane assembly just above the blue and red SATA cables. - Page 63 Troubleshooting The second and third groups of over-voltage LEDs are located behind this fan The acquisition assembly nearest the bottom of the instrument is the channels 1 and 2 acquisition assembly and the one above it is the channels 3 and 4 acquisition assembly.

-

Page 64: Display Troubleshooting

Troubleshooting Display Troubleshooting 90000 A-Series Service Guide... -

Page 65: Checking The Backlight Inverter Voltages

Troubleshooting Checking the Backlight Inverter Voltages The backlight inverter board MP13 is located in the front-left corner of the oscilloscope. • There is an input connector at one side of the board. • Two output connectors are on the other end of the board to power the two backlights, which are inserted into the flat panel display. -

Page 66: Checking The Display Board Video Signals

Troubleshooting Checking the Display Board Video Signals The video signals are checked on the 32-pin connector J2 on the display board MP12. You can use an oscilloscope with a bandwidth of at least 100 MHz to verify the signals. Even-numbered pins are closest to the PC board. If the signals are not present, suspect the display card. -

Page 67: Front Panel Display Troubleshooting

Troubleshooting Front Panel Display Troubleshooting Front Panel Display Trouble Isolation Connect external monitor to VGA port. Turn unit on. Does display appear Replace on ext monitor? motherboard Check display cable connection to display card front panel and LCD black? Does Check inverter board control front panel cable... - Page 68 Troubleshooting SHOCK HAZARD! The backlight inverter assembly, which is mounted at the front WARNING corner of the oscilloscope near the flat-panel d isplay, operates at 1.65 kV at turn on. DO NOT handle this assembly while it is in operation. An LED on the inverter board illuminates to ind icate the presence of high vol tage.

-

Page 69: Motherboard Verification

Troubleshooting Motherboard Verification If you have been through the Power Supply Troubleshooting section of this chapter and the oscilloscope still does not stay powered up, the problem may be with the motherboard. To diagnose this problem, follow these steps. Remove the handle, outer case, and top shield. Turn the oscilloscope on. - Page 70 Troubleshooting Be aware that there could be a fault on the motherboard that caused the backplane assembly to fail so before you plug the motherboard cables back into the new backplane assembly, measure the resistance to the chassis from the pin 9 contact in the connector that plugs into J1201. If you measure a very low resistance or a short circuit to the chassis, replace the motherboard and then assemble the instrument and confirm the unit beeps and boots up properly.

-

Page 71: Setting Up The Bios

Troubleshooting Setting Up the BIOS If the BIOS settings become corrupt, the Infiniium oscilloscope PC motherboard will not recognize the hard drive and the oscilloscope may not start. To configure the motherboard BIOS parameters to the default settings, follow these steps: Connect the power cable to the oscilloscope. -

Page 72: Acquisition/Backplane Assembly Troubleshooting

Troubleshooting Acquisition/Backplane Assembly Troubleshooting This section describes which board assembly to replace if any of the scope self tests fail. A self-test error message file is generated and is sent to this location: C:\ProgramData\Infiniium\selftest\SelfTestLog.txt The error message usually indicates the channel with the error. When identifying which acquisition assembly to replace, remember that the acquisition assembly nearest the bottom of the oscilloscope is for channels 1 and 2. -

Page 73: Autoprobe Board Troubleshooting

Troubleshooting AutoProbe Board Troubleshooting AutoProbe Board Trouble Isolation Inspect the cable between the AutoProbe assembly and the power board Cable Replace bad cable Turn unit on Does Replace unit turn AutoProbe assembly Go to “Verifying Basic Operation” 90000 A-Series Service Guide... -

Page 74: Keyboard Troubleshooting

Troubleshooting Keyboard Troubleshooting Use this procedure only if you encounter key failures in the keyboard self test procedure. If any knobs fail, replace the keyboard assembly. Disconnect the power cord and remove the cover. Remove the front panel assembly. Remove the keyboard assembly from the front panel assembly. Partially re-assemble the front panel assembly, including the flat-panel display and lens, but omitting the keyboard. -

Page 75: Led Troubleshooting

Troubleshooting LED Troubleshooting If you see a failure with the on/off switch backlight LED, replace the On/Off board. If the LED will still not illuminate, replace the motherboard and see if this fixes the problem. If the LED still does not work, check the on/off cable connecting the On/Off board to the motherboard. -

Page 76: Touch Screen Troubleshooting

Troubleshooting Touch Screen Troubleshooting 90000 A-Series Service Guide... -

Page 77: Checking Probe Power Outputs

Troubleshooting Checking Probe Power Outputs Probe power outputs are on the front panel, under each BNC input. Refer to the following figure to check the power output at the connectors. Measure the +3 V, -3 V, +12 V, and -12 V voltages with respect to the ground terminal on the front panel, located near the Aux Out BNC. -

Page 78: Before You Contact Keysight

This information will be useful when you contact Keysight Technologies. To find and save system information, follow these steps: Click Help > About Infiniium.. -

Page 79: Replacing Assemblies

Service Guide 5 Replacing Assemblies Returning the oscilloscope to Keysight Technologies for service / 81 Removing and replacing the cover, top plate, and bottom plate / 82 Removing and replacing the front panel bezel and front panel circuit assembly / 87... -

Page 80: Replacing Assemblies

Replacing Assemblies Replacing Assemblies Use the procedures in this chapter when removing and replacing assemblies and parts in the Infiniium 90000 A-Series oscilloscopes. The pictures in this chapter are representative of the oscilloscope at the time of this printing. Your unit may look different. Tools required The following tools are required for these procedures. -

Page 81: Returning The Oscilloscope To Keysight Technologies For Service

Replacing Assemblies Returning the oscilloscope to Keysight Technologies for service Before shipping the oscilloscope, contact Keysight Technologies for more details. Write the following information on a tag and attach it to the oscilloscope. • name and address of owner •... -

Page 82: Removing And Replacing The Cover, Top Plate, And Bottom Plate

Replacing Assemblies Removing and replacing the cover, top plate, and bottom plate Disconnect the power cable, all probes and BNC input cables, the accessory pouch if it is attached, and any other cables including those for a mouse, keyboard, printer, USB, and LAN. Remove the two Torx T20 screws securing each side handle. - Page 83 Replacing Assemblies Remove the three Torx T20 screws from the rear panel of the oscilloscope, then turn the instrument on its side and remove the ten Torx T10 screws from the underside of the oscilloscope that attach the cover to the chassis. Carefully slide the cover toward the rear of the instrument and off the chassis.

- Page 84 Replacing Assemblies Once the cover is removed, you can remove the top plate by removing the 12 Torx T10 screws from its edges. Then pull back on the top plate and lift it off. 90000 A-Series Service Guide...

- Page 85 Replacing Assemblies To remove the bottom plate, flip the oscilloscope upside down and remove the three Torx T20 screws from the bottom panel. Then remove the 3 Torx T20 screws from the bottom edge of the rear panel. Slide the bottom panel up and out.

- Page 86 Replacing Assemblies To replace the cover, top plate, and bottom plate, reverse this procedure. Note that all sheet metal holes that are supposed to have screws placed in them are marked by lines on four sides of the hole. PROPERLY TIGHTEN HANDLE AND SCREWS! Tighten the side handle screws to 2.4 Nm CAUTION (21 in-lbs).

-

Page 87: Removing And Replacing The Front Panel Bezel And Front Panel Circuit Assembly

Replacing Assemblies Removing and replacing the front panel bezel and front panel circuit assembly Disconnect the power cable and remove the cover, top plate, and bottom plate as described in the previous section. Disconnect front panel cables. Grasp and pull on all 13 knobs located on the front panel to remove them. Use a screwdriver to disengage the locking tabs located along the edges of the front panel bezel. - Page 88 Replacing Assemblies Remove two Torx T10 screws from the front panel assembly. 90000 A-Series Service Guide...

- Page 89 Replacing Assemblies Disengage the tabs located along the edges of the control panel faceplate. Three tabs are located along the right side (first photo below) and two more tabs are on the top and bottom of the left edge (following two photos). You need to look inside the instrument to see the left side tabs.

- Page 90 Replacing Assemblies Pull off both the control panel faceplate and front panel circuit assembly together after all the tabs are disengaged. The faceplate and the circuit assembly will not come all the way off the instrument until you disconnect all the cables connected to the front panel circuit assembly.

-

Page 91: Removing And Replacing The On/Off Board

Replacing Assemblies Removing and replacing the on/off board Remove the front panel bezel as described earlier. Remove the Torx T10 screw from the on/off board. Pull the board out a little so you can see the cables connected behind it. Disconnect these cables and then take the board off. -

Page 92: Removing And Replacing The Backlight Inverter Board

Replacing Assemblies Removing and replacing the backlight inverter board SHOCK HAZARD! The backlight inverter assembly, which is mounted at the front WARNING corner of the oscilloscope near the flat-panel d isplay, operates at high vol tages from 300-1 kVACrms. DO NOT handle this assembly while it is in operation. Disconnect the power cable and remove the cover and top plate. -

Page 93: Removing And Replacing The Touch Screen, Front Deck, And Controller Assembly

Replacing Assemblies Removing and replacing the touch screen, front deck, and controller assembly Disconnect the power cable and remove the cover, top plate, and bottom plate. Remove the front panel bezel and front panel circuit assembly from the chassis. Remove the two Torx T20 screws attaching the touch screen to the front deck of the chassis, located along the left side of the screen. - Page 94 Replacing Assemblies To remove the front deck off the chassis, remove four Torx T10 screws from the front deck (two on the right side and two on the left side). Turn the oscilloscope upside down or on its side and look through the bottom cavity to see the SMA connectors attached to the front deck.

- Page 95 Replacing Assemblies Feed the cables through any openings that are required and remove the front deck from the frame. Remove the controller board and backlight inverter board from the back of the front deck if these need to be replaced, by removing the Torx T20 screws attached to them.

- Page 96 Replacing Assemblies PREVENT GLASS BREAKAGE! Use care when handling the touch screen and the CAUTION flat-panel display to prevent glass breakage. Inspect the inside surfaces of the touch screen and the flat-panel display closely for dust, smudges, and fingerprints. Viewing these with line-of-sight 45 degrees to the surface is the best method for seeing subtle flaws.

-

Page 97: Removing And Replacing The Motherboard

Replacing Assemblies Removing and replacing the motherboard Disconnect the power cable and remove the cover and top plate. Disconnect all the cables from the motherboard. Remove the Torx T10 screws attaching the motherboard to the frame. The motherboard shown below is the one in the standard 90000A-Series models. If you have a performance-enhanced model it will look different, but you still remove the screws from it to lift it out. -

Page 98: Removing And Replacing The Acquisition Boards/Backplane Assembly

Replacing Assemblies Removing and replacing the acquisition boards/backplane assembly Disconnect the power cable and remove the cover, top plate, and bottom plate. Remove the motherboard and bulk +12 V power supply. Turn the oscilloscope on its side and remove the SMAs connected to the bottom of the backplane board. - Page 99 Replacing Assemblies Turn the oscilloscope over so it is positioned upright. Remove the Torx T20 locking screws from the top (underneath where the motherboard used to be). Remove the Torx T20 screws from the top of the backplane assembly. Flip the instrument so it is upside down or on its side. 90000 A-Series Service Guide...

- Page 100 Replacing Assemblies Remove the Torx T20 screws from lower side of the rear of the instrument. Remove the two Torx T20 screws from the underside of the backplane assembly. 90000 A-Series Service Guide...

- Page 101 Replacing Assemblies If unit is not already upside down, flip it upside down now. Then lift the entire acquisition boards/backplane assembly out of the instrument using the handles on the bottom. 90000 A-Series Service Guide...

-

Page 102: Removing The Backplane Assembly From The Acquisition Assemblies

Replacing Assemblies Removing the backplane assembly from the acquisition assemblies Remove the entire acquisition/backplane assembly as described in the previous section. Remove the four Torx T20 screws (two per acquisition assembly) on the side of the backplane assembly. Gently pry on the sheet metal portions to separate the backplane assembly from each of the acquisition assemblies. -

Page 103: Setting The Calibration Factors After Replacing The Acquisition Board

Replacing Assemblies Setting the calibration factors after replacing the acquisition board The following procedure must be performed after replacing an acquisition board. Only trained Keysight service personnel should perform this level of calibration. Let the oscilloscope warm up before running the calibration. NOTE The service calibration should be done only after the oscilloscope has run for 30 minutes at ambient temperature. - Page 104 Replacing Assemblies Perform a service calibration after the warm-up period: Connect the RS-232 cable to the Digital Multimeter RS-232 port and to the RS-232 port on the oscilloscope. Set the Digital Multimeter as follows: Interface: RS-232 Baud Rate: 9600 Baud Parity: None: 8 bits Language: SCPI Click Utilities >...

-

Page 105: Removing And Replacing The Hard Disk And Hard Disk Control Board

Replacing Assemblies Removing and replacing the hard disk and hard disk control board Disconnect the power cable and remove the cover and top plate. Disconnect the two cables connected to the hard disk. Remove the two latch screws located on the rear panel of the oscilloscope. Pull the hard disk out. - Page 106 Replacing Assemblies To remove the hard disk control board, first locate it by looking in the cavity where the hard disk used to be. Remove the two Torx T10 screws holding the board to the frame. To replace the hard disk and hard disk control board, reverse this procedure. 90000 A-Series Service Guide...

-

Page 107: Removing Cables (For Replacing The Motherboard)

Replacing Assemblies Removing cables (for replacing the motherboard) Disconnect the power cable and remove the top cover. Disconnect all cables from the motherboard. The following figure shows an overview of the cables that need to be removed from the standard 90000 A-Series motherboard. The subsequent figures show close-ups of each cable. - Page 108 Replacing Assemblies S A T A ca ble betwe en m otherboard a nd ha rd drive F ront pa ne l U S B ca ble S A T A ca bles between ba ckplane a nd m otherboard 90000 A-Series Service Guide...

- Page 109 Replacing Assemblies D ispla y ca ble between m otherboard a nd front pa nel P ower harness between ba ckplane a nd m otherboard P ower cab le for C P U fa n 90000 A-Series Service Guide...

- Page 110 Replacing Assemblies P ower harness between backplane and m otherboard O n/ O ff ca ble 90000 A-Series Service Guide...

- Page 111 Replacing Assemblies Motherboard and cables in performance-enhanced 90000 A-Series models 90000 A-Series Service Guide...

-

Page 112: Removing And Replacing The Power Supply

Replacing Assemblies Removing and replacing the power supply SHOCK HAZARD! If the power supply is defective it could have a dangerous charge WARNING on some capacitors. This charge could remain for many days after removing power from the supply. SHOCK HAZARD! When the power supply is removed, two AC leads are exposed. Be WARNING careful not to come into contact with these leads. -

Page 113: Removing And Replacing The Fans

Replacing Assemblies Removing and replacing the fans AVOID INJURY! The fan blades are exposed both inside and outside the chassis. WARNING Disconnect the power cable before working around the fan. Use extreme caution when working with the oscilloscope. Disconnect the power cable and remove the cover and top plate. Disconnect the fan harness cables. -

Page 114: Removing And Replacing The Power Cord

Replacing Assemblies Removing and replacing the power cord Disconnect the power cable and remove the cover and top plate. Unplug the power cable from the +12 V power supply. Unscrew the power cord connector from the rear panel (Torx T10 screws). Remove the ground screw (Torx T10) on right side of hard drive. -

Page 115: Removing And Replacing The Usb Or Gpib Port

Replacing Assemblies Removing and replacing the USB or GPIB port Use this procedure to remove and replace the USB or GPIB port. The GPIB is an option and may not be on your oscilloscope. The procedure is exactly the same for both of these ports so only one is shown here. - Page 116 Replacing Assemblies 90000 A-Series Service Guide...

- Page 117 Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 6 Replaceable Parts Ordering Replaceable Parts / 118 Exploded Views / 119 Replaceable Parts List / 123 This chapter describes how to order replaceable assemblies and parts for the Infiniium 90000 A-Series oscilloscopes. Service support for this oscilloscope is replacement of parts to the assembly level.

- Page 118 Replaceable Parts Ordering Replaceable Parts Listed Parts To order a part in the parts list, quote the Keysight Technologies part number, indicate the quantity desired, and address the order to the nearest Keysight Technologies Sales Office. Unlisted Parts To order a part not listed in the parts list, include the oscilloscope part number, oscilloscope serial number, a description of the part (including its function), and the number of parts required.

- Page 119 Replaceable Parts Exploded Views Front Frame and Front Panel 90000 A-Series Service Guide...

- Page 120 Replaceable Parts Fan and Acquisition Assembly 90000 A-Series Service Guide...

- Page 121 Replaceable Parts Power Supply and PC Motherboard 90000 A-Series Service Guide...

- Page 122 Replaceable Parts Sleeve and Accessory Pouch 90000 A-Series Service Guide...

- Page 123 The following table is a list of replaceable parts. Information given for each part includes: • reference designation in exploded views • Keysight Technologies part number • total quantity (QTY) in the oscilloscope or an assembly • description of the part...

- Page 124 Replaceable Parts Ref des Part number Description A18* 0960-2653* Motherboard Printed Circuit Assembly for M880 (standard models) A18** 0960-2869** Motherboard Printed Circuit Assembly for M890 (performance-enhanced models) 3160-4243 Motherboard Fan w/heatsink 54916-04112** CPU Adapter Plate (Required if upgrading to new performance-enhanced motherboard from a standard model.

- Page 125 Replaceable Parts Ref des Part number Description MP1** 54913-94333** Label - DSO 90804A (performance-enhanced models) MP1** 54913-94334** Label - DSO 90604A (performance-enhanced models) MP1** 54913-94335** Label - DSO 90404A (performance-enhanced models) MP1** 54913-94336** Label - DSO 90254A (performance-enhanced models) MP1** 54913-94346** Label - DSA 90254A (performance-enhanced models) MP1**...

- Page 126 Replaceable Parts Ref des Part number Description MP25** 54916-64901** Handle - Strap Assembly (performance-enhanced models -- order twice if you want to replace both handles) MP26* 54913-94309* Label - PC i/o (standard models) MP26** 54916-94309** Label - PC i/e (performance-enhanced models) MP27 54855-67601 Female Connector Assembly coaxial adapter...

- Page 127 Keysight Infiniium 90000 A-Series Oscilloscopes Service Guide 7 Theory of Operation Block-Level Theory / 129 Motherboard / 129 Acquisition Assembly / 129 Backplane Assembly / 130 Front panel / 131 Rear panel / 132 Display Board / 133 On/Off Board / 133 Main FPGA / 133 Power Supply Assembly / 134 Monitor Assembly / 134Disk Drive / 134...

- Page 128 Theory of Operation Oscilloscope block diagram 90000 A-Series Service Guide...

-

Page 129: Theory Of Operation

Theory of Operation Block-Level Theory The main components of the Infiniium 90000 A-Series oscilloscopes are described here. Motherboard The motherboard provides all system control and interface functions for the oscilloscope. It contains a CPU, ROM, and RAM; keyboard and mouse interfaces, serial and parallel interfaces, CDROM, hard disk drive interface, PCI buses, etc. -

Page 130: Backplane Assembly

Theory of Operation The upper acquisition assembly circuitry samples, digitizes, and stores the signals for channels 3 and 4 while the lower acquisition assembly does the same for channels 1 and 2. The acquisition boards contain the TUT modules, Onboard ADC, clock distribution, data management ASICs, external acquisition memory, ADCs, communication and programming FPGA, and supporting power supply circuitry. -

Page 131: Front Panel

Theory of Operation downstream FPGAs each communicate with the BFPGA using their 8-bit data bus along with a 62.5 MHz communication clock, a 2-bit command bus, a ready signal to the BFPGA, a Data_valid signal from the BFPGA, and an Interrupt line, Backplane assembly block diagram Front panel The front panel board combines functions from the main keyboard and the... -

Page 132: Rear Panel

Theory of Operation A conductive element on the inside of each key shorts a gap on the underlying keyboard circuit board. The keyboard controller detects this short and sends the proper keypress information to the system controller on the motherboard. Keyboard block diagram The front panel provides: •... -

Page 133: Display Board

Theory of Operation • A GPIB connector, for connection to an oscilloscope controller (optional) • An RS-232 connection • A parallel printer connection • XGA monitor connection • Mouse and keyboard connections • LAN 10/1000 connection • Auxiliary Trigger Input BNC •... -

Page 134: Power Supply Assembly

Theory of Operation main connections to the FPGA. In addition, the FPGA generates PCI interrupts for special events such as front-end overload, the timer done, and a stopped cooling fan. Main FPGA connections block diagram Config PROM Memory Memory Controller Controller JTAG Conn... - Page 136 This information is subject to change without notice. © Keysight Technologies 2015 7th edition, June 2015 *54913-97025* 54913-97025 www.keysight.com...

Need help?

Do you have a question about the 90000 A Series and is the answer not in the manual?

Questions and answers