Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

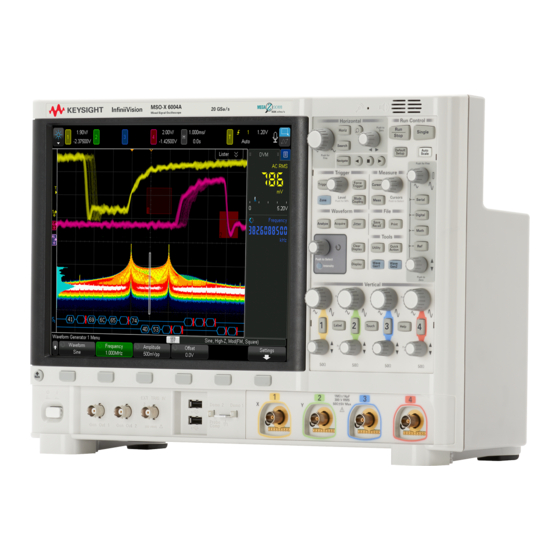

Summary of Contents for Keysight Technologies InfiniiVision 6000 X Series

- Page 1 Keysight InfiniiVision 6000 X-Series Oscilloscopes Service Guide...

-

Page 2: Figure 51. Exploded View 2 Of

Federal Acquisition This product has been designed and tested in Keysight Technologies, Inc. as governed by Regulation ("FAR") 2.101. Pursuant to FAR accordance with accepted industry United States and international copyright 12.212 and 27.405-3 and Department of... -

Page 3: In This Service Guide

In This Service Guide This book provides the service information for the Keysight 6000 X-Series oscilloscopes. This manual is divided into these chapters: Characteristics and Specifications This chapter contains a partial list of characteristics and specifications for the Keysight InfiniiVision 6000 X-Series oscilloscopes. Testing Performance This chapter explains how to verify correct oscilloscope operation and perform tests to ensure that the oscilloscope meets the performance specifications. - Page 4 Digital Channels Because all of the oscilloscopes in the Keysight 6000 X-Series have analog channels, the analog channel topics in this book apply to all instruments. Whenever a topic discusses the digital channels, that information applies only to Mixed-Signal Oscilloscope (MSO) models or DSO models that have been upgraded to an MSO.

-

Page 5: Table Of Contents

Contents In This Service Guide / 3 Figures / 9 Tables / 11 Characteristics and Specifications Power Requirements / 13 Measurement Category / 14 Measurement Category / 14 Measurement Category Definitions / 14 Maximum Input Voltages / 15 Environmental Conditions / 16 Specifications / 16 Contact us / 16 Testing Performance... - Page 6 Contents What to Test / 24 Verifying Test Results / 24 To verify DC vertical gain accuracy / 29 To verify dual cursor accuracy / 34 To verify bandwidth (-3 dB) / 38 To verify time base accuracy / 43 To verify trigger sensitivity / 45 Test Internal Trigger Sensitivity / 46 Test External Trigger Sensitivity (all models) / 49...

- Page 7 Contents Troubleshooting Internal Assemblies / 69 Equipment Required for Troubleshooting Internal Assemblies / 69 To prepare for internal assembly troubleshooting / 69 Flowchart for Internal Assembly Power Troubleshooting / 71 To check the line filter AC output / 72 To check the power supply DC output / 73 To check the fan power supply / 75 To check power to the acquisition board / 77 To check power to the front panel (AutoProbe) interfaces / 80...

- Page 8 Contents Replaceable Parts Ordering Replaceable Parts / 116 Listed Parts / 116 Unlisted Parts / 116 Direct Mail Order System / 116 Exchange Assemblies / 117 Exploded Views / 118 Replaceable Parts List / 120 Safety Information Index 6000 X-Series Oscilloscopes Service Guide...

-

Page 9: Figures

Figures Figure 1. Constructing the 8-by-2 Connector / 22 Figure 2. Setting Up Equipment for Digital Channel Threshold Accuracy Test / 26 Figure 3. Setting up Equipment for DC Vertical Gain Accuracy Test / 32 Figure 4. Using a Blocking Capacitor to Reduce Noise / 33 Figure 5. - Page 10 Figures Figure 28. Removing the analog channel BNC securing T6 screws / 95 Figure 29. Removing cables from power board to other boards / 96 Figure 30. Acquisition board TORX T10 mounting screw locations / 97 Figure 31. Lifting acquisition board off the front deck / 98 Figure 32.

-

Page 11: Tables

Tables Table 1. List of test equipment / 19 Table 2. Conventions / 20 Table 3. Materials required to construct the test connectors / 21 Table 4. Equipment Required to Test Digital Channel Threshold Accuracy / 25 Table 5. Threshold Accuracy Voltage Test Settings / 27 Table 6. - Page 12 Tables 6000 X-Series Oscilloscopes Service Guide...

-

Page 13: Characteristics And Specifications

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 1 Characteristics and Specifications Power Requirements / 13 Measurement Category / 14 Environmental Conditions / 16 Specifications / 16 Contact us / 16 This chapter contains a partial list of characteristics and specifications for the Keysight InfiniiVision 6000 X-Series oscilloscopes. -

Page 14: Measurement Category

Characteristics and Specifications Measurement Category Measurement Category The InfiniiVision 6000 X-Series oscilloscopes are not intended to be used for measurements in Measurement Category II, III, or IV. Use this instrument only for measurements within its specified measurement category WARNING (not rated for CAT II, III, IV). No transient overvoltages allowed. Measurement Category Definitions The "Not rated for CAT II, III, IV"... -

Page 15: Maximum Input Voltages

Characteristics and Specifications Maximum Input Voltages Maximum input voltage at analog inputs CAUTION Do not exceed the maximum input voltage rating. The maximum input voltage for the 50 Ω input impedance setting is ±5 V. Input protection is enabled in 50 mode and the 50 load will disconnect if greater Ω... -

Page 16: Environmental Conditions

Characteristics and Specifications Environmental Conditions Environment Indoor use only. ° ° ° ° Ambient Operating 0 C to +50 C; non-operating –30 C to +70 temperature Humidity Maximum Relative Humidity (non-condensing): 80% RH up to 40 °C, decreases linearly to 50% at 50 °C. From 40 °C to 50 °C, the maximum % Relative Humidity follows a line of constant dew point. -

Page 17: Testing Performance

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 2 Testing Performance Overview / 18 List of Test Equipment / 19 To construct the test connector (for use with MSO models only) / 21 To test digital channels (MSO models only) / 23 To verify digital channel threshold accuracy (MSO models only) / 24 To verify DC vertical gain accuracy / 29 To verify dual cursor accuracy / 34... -

Page 18: Overview

Testing Performance Overview To completely test and troubleshoot MSO models, create and use the test connector accessory as described in this chapter. • The test connector is only required for oscilloscopes that have the MSO option licensed (enabled). • The connector is used in the digital channel threshold accuracy test. •... -

Page 19: List Of Test Equipment

Testing Performance List of Test Equipment Below is a list of test equipment and accessories required to perform the performance test verification procedures. Table 1 List of test equipment Equipment Critical Specifications Recommended Model/ Part Number Test connector, 8-by-2* page 21 for instructions on building test connector. -

Page 20: Conventions

Testing Performance Conventions The following conventions will be used when referring to oscilloscope models throughout this chapter. Table 2 Conventions DSO-X 6002A, DSO-X 6004A, Referred to as: MSO-X 6002A, MSO-X 6004A Bandwidth Option (none) 1 GHz Models BW250 2.5 GHz Models BW400 4 GHz Models BW600... -

Page 21: To Construct The Test Connector (For Use With Mso Models Only)

Testing Performance To construct the test connector (for use with MSO models only) Keysight 6000 X-Series oscilloscopes that have digital channels enabled require the test connector described below. Follow the steps to build the test connector. Table 3 Materials required to construct the test connectors Description Recommended Part BNC (f) Connector... -

Page 22: Figure 1 Constructing The 8-By-2 Connector

Testing Performance Jumper (2) Ground Lead (from scope’s MSO cable) Signal Lead (from scope’s MSO cable) 8 x 2 Berg Strip BNC Panel Mount Connector Figure 1 Constructing the 8-by-2 Connector 6000 X-Series Oscilloscopes Service Guide... -

Page 23: To Test Digital Channels (Mso Models Only)

Testing Performance To test digital channels (MSO models only) The acquisition system testing provides confidence that the acquisition system is functioning correctly. It does not, however, check a particular specification. 1 Disconnect all probes from the circuit under test and from any other input source. -

Page 24: To Verify Digital Channel Threshold Accuracy (Mso Models Only)

Testing Performance To verify digital channel threshold accuracy (MSO models only) This test verifies the digital channel threshold accuracy specification of the Keysight 6000 X-Series oscilloscopes. Threshold accuracy test limits: ±(100 mV + 3% of threshold setting) When to Test You should perform this test every two years or after 4000 hours of operation, whichever comes first. -

Page 25: Table 4. Equipment Required To Test Digital Channel Threshold Accuracy

Testing Performance Table 4 Equipment Required to Test Digital Channel Threshold Accuracy Equipment Critical Specifications Recommended Model/Part Digital Multimeter 0.1 mV resolution, 0.005% accuracy Keysight 34401A/34461A Precision Source DC voltage of -5.5 V to 35.5 V, 0.1 mV resolution Keysight B2912A/B2962A Adapter (qty 2) BNC(f) to banana (m) Keysight 1251-2277... -

Page 26: Figure 2 Setting Up Equipment For Digital Channel Threshold Accuracy Test

Testing Performance Precision Source 6000 X-Series Oscilloscope Digital Multimeter Probe BNC Tee Cables Channels BNC-Bananna Test 8 - 15 Channels Cable Connector 0 - 7 Figure 2 Setting Up Equipment for Digital Channel Threshold Accuracy Test 4 Use a BNC-banana cable to connect the multimeter to the other side of the BNC Tee. -

Page 27: Table 5. Threshold Accuracy Voltage Test Settings

Testing Performance 7 Press the User softkey to the right of the D7 - D0 softkey, then turn the Entry knob ( ) on the front panel of the oscilloscope to set the threshold test settings as shown in Table Table 5 Threshold Accuracy Voltage Test Settings Threshold voltage setting (in... - Page 28 Testing Performance 9 When testing 6000 X-Series MSOs, use the 8-by-2 test connector to connect digital channels D15-D8 to the output of the precision source. Then connect the D15-D8 ground lead to the ground side of the 8-by-2 connector. 10 Repeat this procedure (steps 6 through 8) for digital channels D15-D8 to verify threshold accuracy and record the threshold levels in the Performance Test Record (see page...

-

Page 29: To Verify Dc Vertical Gain Accuracy

Testing Performance To verify DC vertical gain accuracy This test verifies the accuracy of the analog channel DC vertical gain for each channel. In this test, you will measure the dc voltage output of a precision source using the oscilloscope’s Average - Full Screen voltage measurement and compare the results with the multimeter reading. -

Page 30: Table 8. Settings Used To Verify Dc Vertical Gain Accuracy

Testing Performance 2 Set up the oscilloscope. a Adjust the horizontal scale to 200.0 us/div. b Set the Volts/Div setting to the value in the first line in Table 8 (depending on the oscilloscope model). c Adjust the channel’s vertical position knob to place the baseline (reference level) at 0.5 major division from the bottom of the display. - Page 31 Testing Performance 3 Add a measurement for the average voltage: a Press the [Meas] key. b Press Source; then, turn the Entry knob (labeled on the front panel) to select the channel you are testing. c Press Type:; then, turn the Entry knob to select Average - Full Screen, and press Add Measurement.

-

Page 32: Figure 3. Setting Up Equipment For Dc Vertical Gain Accuracy Test

Testing Performance Oscilloscope Precision Source BNC Tee Digital Multimeter BNC (f) to dual bananna adapter Figure 3 Setting up Equipment for DC Vertical Gain Accuracy Test 6 Adjust the output so that the multimeter reading displays the first Volts/div precision source setting value in Table 8 (depending on the oscilloscope model). -

Page 33: Figure 4 Using A Blocking Capacitor To Reduce Noise

Testing Performance The difference in average voltage readings should be within the test limits of Table 8 (depending on the oscilloscope model). If a result is not within the test limits, go to the “Troubleshooting” chapter. Then return here. 11 Disconnect the precision source from the oscilloscope. 12 Repeat this procedure to check the DC vertical gain accuracy with the remaining Volts/div setting values in Table 8... -

Page 34: To Verify Dual Cursor Accuracy

Testing Performance To verify dual cursor accuracy This test verifies the dual cursor accuracy for each analog channel. This test is similar to the test for verifying the DC vertical gain, except you will measure the dc voltage output of an precision source using dual cursors on the oscilloscope and compare the results with the multimeter reading. -

Page 35: Table 10. Settings Used To Verify Dual Cursor Accuracy

Testing Performance Table 10 Settings Used to Verify Dual Cursor Accuracy Volts/Div Setting Precision Source Setting Test Limits 5 V/Div 35 V 33.832 V 36.168 V 2 V/Div 14 V 13.533 V 14.467 V 1 V/Div 6.766 V 7.234 V 500 mV/Div 3.5 V 3.383 V... -

Page 36: Figure 5. Setting Up Equipment For Dual Cursor Accuracy Test

Testing Performance Note: Set the Low Force terminal of the Precision Source to its "Floating" state to prevent offset error caused by ground loop current from the Precision Source ground to the DUT ground. Oscilloscope Precision Source BNC Tee Digital Multimeter BNC (f) to dual bananna adapter... -

Page 37: Figure 6. Using A Blocking Capacitor To Reduce Noise

Testing Performance 8 Press the Y2 softkey, then position the Y2 cursor to the center of the voltage trace using the Entry knob. The ΔY value on the lower line of the display should be within the test limits of Table If a result is not within the test limits, go to the “Troubleshooting”... -

Page 38: To Verify Bandwidth (-3 Db)

Testing Performance To verify bandwidth (-3 dB) This test checks the bandwidth (-3 dB) of the oscilloscope. In this test you will use a signal generator and a power meter. Table 11 Bandwidth (-3 dB) Test Limits Models Test Limits 6 GHz Models All channels (-3 dB), dc to 6 GHz 4 GHz Models... -

Page 39: Figure 7. Setting Up Equipment For Bandwidth (-3 Db) Verification Test

Testing Performance Oscilloscope Signal Generator N to BNC Adapter Power Splitter Power Sensor N Cable Power Meter Figure 7 Setting Up Equipment for Bandwidth (-3 dB) Verification Test 2 Set up the power meter. Set the power meter to display measurements in units of watts. 6000 X-Series Oscilloscopes Service Guide... - Page 40 Testing Performance 3 Set up the oscilloscope. a Press the [Default Setup] key. b Set channel 1 Coupling to DC. c Set channel 1 Imped to 50 Ohm. d Set the time base to 500 ns/div. e Set the Volts/Div for channel 1 to 100 mV/div. f Press the [Trigger] key, then press the Source softkey.

- Page 41 Testing Performance 9 Change the signal generator output frequency according to the maximum frequency for the oscilloscope using the following: • 6 GHz Models: 6 GHz • 4 GHz Models: 4 GHz • 2.5 GHz Models: 2.5 GHz • 1 GHz Models: 1 GHz 10 Referencing the frequency from step 9, set the power meter Cal Factor % to the frequency value on the calibration chart on the power sensor.

- Page 42 Testing Performance 16 Move the power splitter from the channel 1 to the channel 2 input. 17 Turn off the current channel and turn on the next channel using the channel keys. 18 Repeat steps 3 through 17 for the remaining channels, setting the parameters of the channel being tested where appropriate.

-

Page 43: To Verify Time Base Accuracy

Testing Performance To verify time base accuracy This test verifies the accuracy of the time base. In this test you will measure the absolute error of the time base oscillator and compare the results to the specification. Table 13 Equipment Required to Verify Time Base Accuracy Equipment Critical Specifications Recommended Model/Part... - Page 44 Testing Performance 4 Make the measurement. a Set oscilloscope horizontal sweep speed control to 2 ms/div. b Set horizontal position control to +10 ms. c Set the oscilloscope horizontal sweep speed control to 5 ns/div or 10 ns/div. d Measure the number of nanoseconds from where the rising edge crosses the center horizontal grid line to the center vertical grid line.

-

Page 45: To Verify Trigger Sensitivity

Testing Performance To verify trigger sensitivity This test verifies the trigger sensitivity. In this test, you will apply a sine wave to the oscilloscope at the upper bandwidth limit. You will then decrease the amplitude of the signal to the specified levels, and check to see if the oscilloscope is still triggered. -

Page 46: Test Internal Trigger Sensitivity

Testing Performance Table 16 Equipment Required to Verify Trigger Sensitivity Equipment Critical Specifications Recommended Model/Part Signal Generator 100 kHz to 6 GHz sine waves Keysight N5171B with 6 GHz option Power splitter Outputs differ < 0.20 dB Keysight 11667A ± Power Meter 6 GHz 3% accuracy... -

Page 47: Figure 8 Setting Up Equipment For Internal Trigger Sensitivity Test

Testing Performance 3 Connect the equipment (see Figure a Connect the signal generator output to the oscilloscope channel 1 input. Oscilloscope Signal Generator N to BNC Adapter N Cable Figure 8 Setting Up Equipment for Internal Trigger Sensitivity Test b Set channel 1 Impedance to 50 Ohm. 6000 X-Series Oscilloscopes Service Guide... - Page 48 Testing Performance 4 To verify the trigger sensitivity, for each of the settings listed in the following table for your oscilloscope model, follow these steps: Oscilloscope BW Signal Generator Signal Generator Oscilloscope Vertical Division of Signal Model Frequency Amplitude V/div 1 GHz 1 GHz 10 mV...

-

Page 49: Test External Trigger Sensitivity (All Models)

Testing Performance Test External Trigger Sensitivity (all models) This test applies to all models. Verify the external trigger sensitivity at these settings: Table 17 External Trigger Sensitivity Test Settings Input Range 100 MHz 200 Mhz 1.6 V 40 mV 70 mV 200 mV 350 mV 1 Connect the equipment (see... -

Page 50: Figure 9. Setting Up Equipment For 4-Channel External Trigger Sensitivity

Testing Performance Oscilloscope Signal Generator 50 Ohm Feedthrough N to BNC Adapter Power Splitter Power Sensor N Cable Power Meter Figure 9 Setting Up Equipment for 4-Channel External Trigger Sensitivity Test 6000 X-Series Oscilloscopes Service Guide... - Page 51 Testing Performance 2 Set up the oscilloscope. a Press the [Default Setup] key. b Press the [Mode/Coupling] key; then, press the Mode softkey to select Normal. 3 Change the signal generator output frequency to 100 MHz or 200 MHz. 4 Set the power meter Cal Factor % to the appropriate value (100 MHz or 200 MHz) on the calibration chart on the power sensor.

-

Page 52: Keysight 6000 X-Series Oscilloscopes Performance Test Record

Testing Performance Keysight 6000 X-Series Oscilloscopes Performance Test Record Serial No. ______________________________________ Test by _____________________________ Test Interval ____________________________________ Work Order No. ______________________ Recommended Next Testing ________________________ Temperature ____________ Threshold Specification Limits Ch D7-D0 Ch D15-D8 Accuracy Test 5 V - 250 mV 4.750 V ________ ________... - Page 53 Testing Performance Dual Cursor Accuracy Range Power Supply Setting Test Limits Channel 1 Channel 2 Channel 3* Channel 4* 5 V/Div 35 V 33.832 V to 36.168 V ________ ________ ________ ________ 2 V/Div 14 V 13.533 V to 14.467 V ________ ________ ________...

- Page 54 Testing Performance Internal Trigger Sensitivity Generator Setting Test Limits Channel 1 Channel 2 Channel 3* Channel 4* 6 GHz models, 3.5 GHz < 10 mV/div: greater of ________ ________ ________ _______ 4 GHz models, 1.5 div or 5 mVpp 2.5 GHz models: >= 10 mV/div: 1 div ________ ________...

-

Page 55: Calibrating And Adjusting

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 3 Calibrating and Adjusting This chapter explains how to adjust the oscilloscope for optimum operating performance. You should perform self-calibration according to the following recommendations: • Every two years or after 4000 hours of operation •... - Page 56 Calibrating and Adjusting Read All Cautions and Warnings Read the following cautions and warning before making adjustments or performing self-calibration. HAZARDOUS VOLTAGES! WARNING Read the safety notice at the front of this book before proceeding. Maintenance is performed with power supplied to the oscilloscope and with the protective covers removed.

-

Page 57: User Calibration

Calibrating and Adjusting User Calibration Perform user-calibration: • Every two years or after 4000 hours of operation. • If the ambient temperature is >10° C from the calibration temperature. • If you want to maximize the measurement accuracy. The amount of use, environmental conditions, and experience with other instruments help determine if you need shorter User Calibration intervals. - Page 58 Calibrating and Adjusting 6000 X-Series Oscilloscopes Service Guide...

-

Page 59: Troubleshooting

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 4 Troubleshooting Solving General Problems with the Oscilloscope / 60 Verifying Basic Operation / 63 Troubleshooting Internal Assemblies / 69 Read All Cautions and Warnings Before you begin any troubleshooting, read all Warning and Cautions in the “Troubleshooting” section. This chapter begins with “Solving General Problems with the Oscilloscope. -

Page 60: Solving General Problems With The Oscilloscope

Check that the probe clips are securely connected to points in the circuit under test, and that the ground is connected. Check that the circuit under test is powered on. Press the [Auto Scale] key. Obtain service from Keysight Technologies, if necessary. 6000 X-Series Oscilloscopes Service Guide... -

Page 61: If The Trace Display Is Unusual Or Unexpected

Troubleshooting If the trace display is unusual or unexpected Check that the Horizontal time/division setting is correct for the expected frequency range of the input signals. The sampling speed of the oscilloscope depends on the time/division setting. It may be that when time/division is set to slower speeds, the oscilloscope is sampling too slowly to capture all of the transitions on the waveform. - Page 62 Troubleshooting Performing the checks listed here ensures that the signals from the circuit under test will be seen by the oscilloscope. Perform the remaining checks in this topic to make sure the oscilloscope channels are on, and to obtain an automatic setup.

-

Page 63: Verifying Basic Operation

Troubleshooting Verifying Basic Operation To power-on the oscilloscope 1 Connect the power cord to the rear of the oscilloscope, then to a suitable ac voltage source. The oscilloscope power supply automatically adjusts for input line voltages in the range of 100 to 240 VAC. Ensure that you have the correct line cord (see page 115). -

Page 64: To Perform Hardware Self Test

Troubleshooting To perform hardware self test Pressing [Utility] > Service > Hardware Self Test performs a series of internal procedures to verify that the oscilloscope is operating properly. It is recommended you run Hardware Self Test: • After experiencing abnormal operation. •... - Page 65 Troubleshooting • Channel 1 on. • 5 V/div scale. • dc coupling. • 0 V position. • probe factor to 1.0 if an AutoProbe probe is not connected to the channel. • Trigger: • Edge trigger. • Auto sweep mode. •...

-

Page 66: To Perform An Auto Scale On The Probe Comp Signal

Troubleshooting Figure 10 Default setup screen 2 If your screen looks substantially different, replace the acquisition board. To perform an Auto Scale on the Probe Comp signal 1 Press the [Default Setup] key. The oscilloscope is now configured to its default settings. -

Page 67: To Compensate Passive Probes

Troubleshooting 5 You should see a waveform on the oscilloscope’s display similar to this: If you see the waveform, but the square wave is not shaped correctly as shown above, perform the procedure “To compensate passive probes" on page 67. If you do not see the waveform, ensure your power source is adequate, the oscilloscope is properly powered-on, and the probe is connected securely to the front-panel analog channel input BNC and to the Demo 2 (Probe Comp) -

Page 68: Figure 11 Example Pulses

Troubleshooting 3 In the Channel Menu, press Probe. 4 In the Channel Probe Menu, press Probe Check; then, follow the instructions on-screen. If necessary, use a nonmetallic tool (supplied with the probe) to adjust the trimmer capacitor on the probe for the flattest pulse possible. On the N2862/63/90 probes, the trimmer capacitor is the yellow adjustment on the probe tip. -

Page 69: Troubleshooting Internal Assemblies

Then, you check that the assembly is supplied with the proper power. If cables are good and the power is good, but the assembly still does not function properly, it must be replaced. If you need parts or assistance from Keysight Technologies to repair your instrument, go to www.keysight.com and locate the service facility for your area. - Page 70 Troubleshooting REMOVE POWER TO AVOID DAMAGE ! CAUTION Do not disconnect any cables or remove any assemblies while power is applied to the oscilloscope, or damage to the oscilloscope can occur. AVOID ESD DAMAGE TO COMPONENTS ! CAUTION ELECTROSTATIC DISCHARGE (ESD) can damage electronic components. Use proper ESD precautions when doing any of the procedures in this chapter.

-

Page 71: Flowchart For Internal Assembly Power Troubleshooting

Troubleshooting Flowchart for Internal Assembly Power Troubleshooting The following flowchart is a simplified overview of troubleshooting power to the oscilloscope’s internal assemblies. Power Replace Power Start Supply Voltage Supply AC Input Board Okay? Okay? Replace Power Supply Replace Fan Voltage Power Supply Okay? Supplies... -

Page 72: To Check The Line Filter Ac Output

Troubleshooting To check the line filter AC output When the 13 V bulk power is not being properly supplied, this procedure tests the AC input to the power supply to determine whether there is a problem with the line filter. 1 Follow the instructions in “To prepare for internal assembly troubleshooting"... -

Page 73: To Check The Power Supply Dc Output

Troubleshooting • If there is no AC power at SK1 of the power supply, there is something wrong with the power switch or AC mains section of the line filter, and you need to replace the power board. • If there is AC power at SK1 of the power supply, but the instrument still will not power ON when the power switch (S100) is in the ON position, go to “To check the power supply DC output"... -

Page 74: Figure 13 Verify Power Supply Dc Output

Troubleshooting 8-10 J102 Figure 13 Verify power supply DC output Table 19 DC output from power supply Supply Test Point Expected Value If Good If Bad VP13V Connector J102: +13 V ±0.2V Indicates power supply is good. Indicates power supply is bad or pins 8, 9, 10 = +13V cable from power supply to power pins 3, 4, 5 = GND... -

Page 75: To Check The Fan Power Supply

Troubleshooting To check the fan power supply The +12 V fan power comes from the power supply. The fan speed is controlled by a circuit on the acquisition board. Signal FAN_PWM_DRIVE comes from the acquisition board and the FAN_TACH signal returns to the acquisition board. -

Page 76: Table 20 Fan Power

Troubleshooting Table 20 Fan power Supply Test Point Expected Value If Good If Bad VP12V_FAN Connector J104, pin 1 +12 V Indicates power Indicates power supply is bad or Connector J102, pin 1 supply is good. cable from power supply to power board connector J102 is bad. -

Page 77: To Check Power To The Acquisition Board

Troubleshooting To check power to the acquisition board This procedure checks the power supplies from the power board to the acquisition board. Values outside the expected range help identify bad assemblies. 1 Follow the instructions in “To prepare for internal assembly troubleshooting"... -

Page 78: Figure 16. J105 Connector Pinout

Troubleshooting Power Cable Header VM13V VP13VF VP5V VP5V VM6V5 VP2V5 VP2V5 VP3V3 VP3V3 VP1V3 VP1V3 VP1V8 VP1V8 J105 Figure 16 J105 connector pinout Table 21 Power supplies to acquisition board (from power board J105) Supply Test Point Expected Value If Good If Bad VP13VF J105, pin 20... - Page 79 Troubleshooting VP13VF VP13VF is a filtered +13V supply that is the source for other supplies on the acquisition board. When connected to an acquisition board, VP13VF should measure >+12.8 V using a DMM. If VP13VF is less than <+12V, it indicates that there may be abnormal current draw on acquisition board.

-

Page 80: To Check Power To The Front Panel (Autoprobe) Interfaces

Troubleshooting To check power to the front panel (AutoProbe) interfaces This procedure checks the power supplies from the power board to the front panel keyboard (for the AutoProbe interface. Values outside the expected range help identify bad assemblies. 1 Follow the instructions in “To prepare for internal assembly troubleshooting"... -

Page 81: Table 22. Power Supplies To Front Panel Board

Troubleshooting Table 22 Power supplies to front panel board (AutoProbe power, from power board J106) Supply Test Point Expected Value If Good If Bad VP13VF_PRB J106, pin 1 +13 V ±2% Supply is good. Replace the power board. VM13VF_PRB J106, pin 2 -13 V ±2% Supply is good. - Page 82 Troubleshooting 6000 X-Series Oscilloscopes Service Guide...

-

Page 83: Replacing Assemblies

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 5 Replacing Assemblies This chapter describes how to remove assemblies from an oscilloscope. To install a replacement assembly after you have removed an old one, follow the instructions in reverse order. The parts shown in the following figures are representative and may look different from what you have in your oscilloscope. - Page 84 Replacing Assemblies • Flat head screwdriver. See how the Oscilloscope Parts Fit Together An exploded view of the oscilloscope is included in the “Replaceable Parts” chapter. It shows the individual part numbers used in the assemblies, and shows you how the parts fit together. Read All Warnings and Cautions Read the following warnings and cautions before removing and replacing any assemblies in the oscilloscope.

-

Page 85: To Remove The Cabinet

Replacing Assemblies To remove the cabinet Removing the cabinet allows access to the rear deck, fan assembly, power supply cover, power supply assembly, and power switch assembly. 1 Using a TORX T20 driver, remove the five screws securing the cabinet to the rear deck assembly. -

Page 86: To Remove The Rear Deck Assembly

Replacing Assemblies To remove the rear deck assembly Removing the rear deck allows access to the front deck and acquisition board. 1 Remove the BNC securing nuts and washers. Figure 19 Removing the BNC securing nuts and washers 6000 X-Series Oscilloscopes Service Guide... -

Page 87: Figure 20 Removing Perimeter Screws Securing Rear Deck

Replacing Assemblies 2 Using a TORX T10 driver, locate and remove all the perimeter screws securing rear deck to front deck. Figure 20 Removing perimeter screws securing rear deck 6000 X-Series Oscilloscopes Service Guide... -

Page 88: Figure 21 Removing Rear-Facing Screws Securing Rear Deck

Replacing Assemblies 3 Locate and remove all rear-facing screws securing rear deck to front deck. You need to remove the AC input shield (see “To remove the AC input shield" on page 93) before you can remove the screw on the lower right. -

Page 89: Figure 22 Removing Cables From Power Board To Other Boards

Replacing Assemblies 4 Disconnect the acquisition board control cable, the acquisition board power cable, and the probe power cable. Note cable locations for re-assembly. Figure 22 Removing cables from power board to other boards 6000 X-Series Oscilloscopes Service Guide... -

Page 90: Figure 23 Separating Front And Rear Deck Assemblies

Replacing Assemblies 5 Carefully separate rear deck from front deck. Take care not damage extender switch. Sheet metal parts may have sharp edges. Handle with care to avoid injury. WARNING Figure 23 Separating front and rear deck assemblies 6000 X-Series Oscilloscopes Service Guide... -

Page 91: To Remove The Power Supply Shield

Replacing Assemblies To remove the power supply shield 1 To remove the power supply shield, locate and remove using a TORX T10 driver the two screws securing the shield to the rear deck. Figure 24 Removing the power supply shield Thin sheet metal parts may have sharp edges. -

Page 92: To Remove The Probe Power Shield

Replacing Assemblies To remove the probe power shield 1 To remove the probe power shield, locate and remove using a TORX T10 driver the one screw securing the shield to the rear deck. Figure 25 Removing the probe power shield Thin sheet metal parts may have sharp edges. -

Page 93: To Remove The Ac Input Shield

Replacing Assemblies To remove the AC input shield 1 To remove AC input shield, locate and remove using a TORX T10 driver the two screws securing the shield to the rear deck. Figure 26 Removing the AC input shield Thin sheet metal parts may have sharp edges. Handle with care to avoid injury. WARNING 2 Once the screws have been removed, carefully remove the shield by lifting it up and off retaining tabs on rear deck. -

Page 94: To Replace The Battery

Replacing Assemblies To replace the battery If the battery needs to be replaced, use a CR2032/1HG or CR2032/HGN 3V manganese dioxide lithium battery. Figure 27 Battery location 6000 X-Series Oscilloscopes Service Guide... -

Page 95: To Remove The Acquisition Board

Replacing Assemblies To remove the acquisition board These steps show how to remove the acquisition board. 1 Using a TORK T6 driver locate and remove the 4 screws on the front of the instrument (4 Channel version). Figure 28 Removing the analog channel BNC securing T6 screws 6000 X-Series Oscilloscopes Service Guide... -

Page 96: Figure 29 Removing Cables From Power Board To Other Boards

Replacing Assemblies 2 Disconnect display power, display video, and keyboard cables. Note locations for re-connection. The keyboard cable connector has a latch that must be flipped up before you can disconnect the cable. Figure 29 Removing cables from power board to other boards 6000 X-Series Oscilloscopes Service Guide... -

Page 97: Figure 30 Acquisition Board Torx T10 Mounting Screw Locations

Replacing Assemblies 3 Using a TORX T10 driver locate and remove 12 mounting screws. Figure 30 Acquisition board TORX T10 mounting screw locations 6000 X-Series Oscilloscopes Service Guide... -

Page 98: Figure 31 Lifting Acquisition Board Off The Front Deck

Replacing Assemblies 4 Carefully lift acquisition board off front deck. Figure 31 Lifting acquisition board off the front deck 6000 X-Series Oscilloscopes Service Guide... -

Page 99: To Remove The Front Panel Knobs

Replacing Assemblies To remove the front panel knobs The front panel knobs must be removed prior to localized front panel overlay installation or front panel disassembly. 1 Gently pull on the front panel knobs to remove them. Figure 32 Removing the front panel knobs 6000 X-Series Oscilloscopes Service Guide... -

Page 100: To Remove The Front Bezel Assembly

Replacing Assemblies To remove the front bezel assembly 1 Remove the bezel from the front deck. The bezel is secured to front deck by molded-in retaining clips located around the perimeter of the bezel. Gently pry these outward (either by hand or using a flat head screwdriver). -

Page 101: Figure 34 Disconnecting The Keyboard Cable

Replacing Assemblies 2 Before separating the bezel from the front deck, unlatch and disconnect the keyboard cable. Figure 34 Disconnecting the keyboard cable 6000 X-Series Oscilloscopes Service Guide... -

Page 102: To Remove The Display Assembly

Replacing Assemblies To remove the display assembly 1 Using a TORX T10 driver, remove the two screws that secure the display assembly to the front deck. Figure 35 Removing the display assembly 6000 X-Series Oscilloscopes Service Guide... -

Page 103: Figure 36 Display Assembly Removed

Replacing Assemblies 2 Take care while guiding display cables through front deck sheet metal openings. Figure 36 Display assembly removed 6000 X-Series Oscilloscopes Service Guide... -

Page 104: To Remove The Keyboard And Keypad

Replacing Assemblies To remove the keyboard and keypad 1 Remove the softkey board cable from the keyboard board. Slide the connector clamp toward the softkey board; then, slide the ribbon cable out. Figure 37 Disconnecting the softkey board cable 6000 X-Series Oscilloscopes Service Guide... -

Page 105: Figure 38 Disconnecting The Speaker/Microphone Cable

Replacing Assemblies 2 Remove the speaker/microphone cable from the keyboard board. Figure 38 Disconnecting the speaker/microphone cable 6000 X-Series Oscilloscopes Service Guide... -

Page 106: Figure 39 Removing The Keyboard

Replacing Assemblies 3 To separate the keyboard board from the bezel, carefully pull back locking tabs that secure it. Figure 39 Removing the keyboard Figure 40 Keyboard and keypad removed 6000 X-Series Oscilloscopes Service Guide... -

Page 107: Figure 41 Unclip The Softkey Board From The Bezel

Replacing Assemblies 4 To separate the softkey board from the bezel, carefully pull back locking tabs that secure it. Figure 41 Unclip the softkey board from the bezel Figure 42 Softkey board and keypad removed 6000 X-Series Oscilloscopes Service Guide... -

Page 108: To Remove The Fan Assembly

Replacing Assemblies To remove the fan assembly 1 Ensure that the fan power cable has been disconnected from the power board. Figure 43 Disconnecting the fan cable 6000 X-Series Oscilloscopes Service Guide... -

Page 109: Figure 44 Removing Fan Assembly

Replacing Assemblies 2 Carefully slide fan assembly (fan and fan mount) to the right, then lift away from rear deck. Note, fan mount is soft and can be damaged by sharp sheet metal edges. Take care that the fan power cable is not damaged when pulling across sheet metal edges. -

Page 110: To Remove The Power Supply

Replacing Assemblies To remove the power supply 1 Disconnect all cables between the power supply and the power board. Figure 45 Removing cables to/from power supply 6000 X-Series Oscilloscopes Service Guide... -

Page 111: Figure 46 Removing The Power Supply

Replacing Assemblies 2 Locate and remove using a TORX T10 driver the four screws securing the power supply assembly to the rear deck. Figure 46 Removing the power supply 6000 X-Series Oscilloscopes Service Guide... -

Page 112: To Remove The Power Board

Replacing Assemblies To remove the power board 1 Disconnect the ground wire from its chassis terminal. Figure 47 Disconnecting the ground wire 6000 X-Series Oscilloscopes Service Guide... -

Page 113: Figure 48 Removing The Power Board

Replacing Assemblies 2 Locate and remove using a TORX T10 driver the four screws securing the power board to the rear deck. Figure 48 Removing the power board 3 Slide assembly back and lift out of rear deck. 4 Take care that you do not damage the switch extender during removal. 6000 X-Series Oscilloscopes Service Guide... -

Page 114: Figure 49 Removing Power Switch Extender

Replacing Assemblies 5 To remove the switch extender, gently pry open the extender using a flat head screwdriver. Twisting the latch too much could cause it to break! CAUTION Figure 49 Removing power switch extender 6000 X-Series Oscilloscopes Service Guide... -

Page 115: Replaceable Parts

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 6 Replaceable Parts This chapter describes how to order replaceable assemblies and parts for the Keysight 6000 X-Series oscilloscopes. Diagrams and parts lists are included for assemblies and hardware that you can order. Before working on the oscilloscope, read the safety summary at the back of this book. -

Page 116: Ordering Replaceable Parts

Ordering Replaceable Parts Listed Parts To order a part in the parts list, quote the Keysight Technologies part number, indicate the quantity desired, and address the order to the nearest Keysight Technologies Sales Office. To find your nearest sales office go to www.keysight.com. -

Page 117: Exchange Assemblies

The exchange parts have a part number in the form XXXXX-695XX. After receiving the repaired exchange part from Keysight Technologies, a United States customer has 30 days to return the faulty assembly. For orders not originating in the United States, contact the local Keysight Technologies service organization. -

Page 118: Exploded Views

Replaceable Parts Exploded Views The following exploded views provide a graphical representation of the oscilloscope at the time this manual was released. Not all parts are shown. Your parts may be slightly different than those shown. These views provide reference designator numbers that map to those used in the parts list table in this chapter. - Page 119 Replaceable Parts MP12 MP18 MP13 MP14 MP16 MP17 MP15 MP19 Figure 51 Exploded View 2 of 2 6000 X-Series Oscilloscopes Service Guide...

-

Page 120: Replaceable Parts List

Replaceable Parts Replaceable Parts List The information given for each part consists of the following: • Reference designation. • Keysight Technologies part number. • Total quantity (Qty) in the instrument or on assembly. • Description of the part. Table 23... - Page 121 Replaceable Parts Table 23 Replaceable Parts (continued) Ref Des Keysight Part Description Number Not shown 0515-0380 Screw-Machine W/Crest-Cup-Con-Washer Pan-HD Torx-T20 M4X0.7 12mm-LG SST-300 Passivated Not shown 0515-0659 2, 4 Screw-Machine with CrestCup-Washer Pan-HD Torx-T6 M2X0.4 8mm-LG SST-300 passivated (qty=2 for 2 Ch, qty=4 for 4 Ch) Not shown 0515-1753 Screw-Machine with Patch-Lock Pan-HD Torx-T10 M3X0.5 8mm-LG...

- Page 122 Replaceable Parts Table 23 Replaceable Parts (continued) Ref Des Keysight Part Description Number 54609-41901 Keyboard Keypad 54709-41903 Softkey Keypad MP10 54609-44102 Cover Protective Front MP11 54609-00101 Front Deck MP12 54609-00102 Rear Deck MP13 54609-00602 Shield Power Supply MP14 54609-00604 Shield AC Input MP15 54609-00606 Shield Probe Power...

- Page 123 Replaceable Parts Table 23 Replaceable Parts (continued) Ref Des Keysight Part Description Number Not shown 54609-61601 Cable Line to Power Supply Not shown 54609-61602 Cable Power Supply Control and DC Out Not shown 54609-61603 Cable Acquisition Power Not shown 54609-61604 Cable Probe Power Not shown 54609-61605...

- Page 124 Replaceable Parts Table 23 Replaceable Parts (continued) Ref Des Keysight Part Description Number Not shown 54609-94311 Overlay - Traditional Chinese, 4 channel Not shown 54608-94311 Overlay - Traditional Chinese, 2 channel Not shown 54609-94317 Overlay - Japanese, 4 channel Not shown 54608-94317 Overlay - Japanese, 2 channel Not shown...

-

Page 125: Safety Information

Keysight InfiniiVision 6000 X-Series Oscilloscope Service Guide 7 Safety Information The following general safety precautions must be observed during all phases of operation of this instrument. Failure to comply with these precautions or with specific warnings or operating instructions in the product manuals violates safety standards of design, manufacture, and intended use of the instrument. -

Page 126: Table 24 Description Of Safety Related Symbols That May Appear On A Product

Safety Information Do Not Operate in Do not operate the instrument in the presence of flammable gases or fumes. an Explosive Atmosphere Do Not Remove Only qualified, service-trained personnel who are aware of the hazards involved the Instrument should remove instrument covers. Always disconnect the power cable and any Cover external circuits before removing the instrument cover. - Page 127 Safety Information Table 24 Description of Safety related symbols that may appear on a product (continued) Symbol Description Three phase alternating current Earth ground terminal Protective earth ground terminal Frame or chassis ground terminal Terminal is at earth potential Equipotentiality Neutral conductor on permanently installed equipment Line conductor on permanently installed equipment On (mains supply)

- Page 128 Safety Information Table 24 Description of Safety related symbols that may appear on a product (continued) Symbol Description Equipment protected throughout by DOUBLE INSULATION or REINFORCED INSULATION Caution, refer to accompanying documentation Caution, risk of electric shock Do not apply around or remove from HAZARDOUS LIVE conductors Application around and removal from HAZARDOUS LIVE conductors is permitted Caution, hot surface Ionizing radiation...

- Page 129 Index front panel, instrument, accuracy, DC vertical gain, ordering parts, accuracy, dual cursor, overvoltage category, assemblies exchange, fan assembly removal, replacing, front panel parts exploded view, list, removal, ordering, front panel self test, bandwidth passive probe, verification, perform user calibration, performance test record, hardware self test,...

- Page 130 Index safety information, warnings, 84, 91, 92, safety notice, 56, warranted specifications, safety symbols, self test, front panel, self test, hardware, self-alignment, user calibration, self-tests, specifications, startup sequence, status, User Calibration, status, user calibration, storage lid, removal, test connector, constructing, digital channels, equipment, record,...

Need help?

Do you have a question about the InfiniiVision 6000 X Series and is the answer not in the manual?

Questions and answers