Table of Contents

Advertisement

Quick Links

Instructions - Parts

ProBell®

ProBell® Cart

ProBell®

Cart Systems

Cart

ProBell Rotary

Rotary Applicator

Applicator System

ProBell

ProBell

Rotary

Applicator

or or or waterborne

waterborne spray

waterborne

spray materials.

spray

materials. Not

materials.

For

For

For professional

professional use

professional

use

use only.

only.

only.

Important

Important Safety

Important

Safety Instructions

Safety

This equipment could present hazards if not operated according to

the information in the manuals. Read all warnings and instructions

in this manual and in all ProBell™ component manuals. Save

instructions.

instructions.

instructions.

100 psi (0.7 MPa, 7.0 bar) Maximum Air

Inlet Pressure

See page 3 for approval information.

Systems

Systems

System for

for electrostatic

electrostatic finishing

System

for

electrostatic

Not approved

Not

approved for

approved

Instructions

Instructions

PROVEN QUALITY. LEADING TECHNOLOGY.

finishing and

and coating

coating applications

finishing

and

coating

for use

for

use in in in explosive

use

explosive atmospheres

explosive

atmospheres or or or hazardous

atmospheres

Save all all all

Save

3A4232D

applications using

using solventborne

solventborne

applications

using

solventborne

hazardous locations.

hazardous

EN

locations.

locations.

Advertisement

Table of Contents

Summary of Contents for Graco ProBell

- Page 1 Instructions Instructions This equipment could present hazards if not operated according to the information in the manuals. Read all warnings and instructions Save all all all in this manual and in all ProBell™ component manuals. Save Save instructions. instructions. instructions.

-

Page 2: Table Of Contents

Complete the Installation ......14 Models............... 3 Connect Air Supply ........14 Warnings ............6 Parts..............15 ProBell System Information ......... 9 ProBell System ..........15 Cart Kit 24Z225 ........... 17 System Connections and Features ...... 10 Dimensions ............19 Installation............ -

Page 3: Models

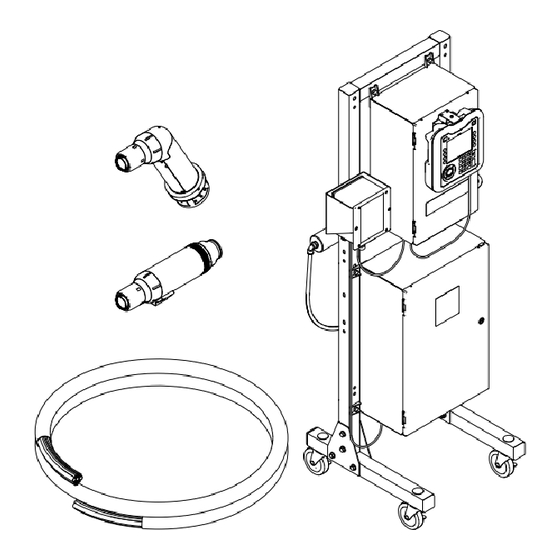

Models Models ProBell Cart Systems include applicator, 20 meter (65 ft.) hose bundle, Electrostatic Controller, Speed Controller, Electronic Air Controller, and System Logic Controller. The systems differ by the applicator, hose bundle, and electrostatic controller included. See the tables below for a description of the models available. - Page 4 HOLLOW WRIST 1.25 P5A268 R5A268 HOLLOW WRIST System for waterborne applicators. This model does not contain the ProBell ® Rotary 24Z717 Applicator or the hose bundle. * All applicators ship with a serrated aluminum bell cup. See the Cup Selection Charts in the Applicator manual to see all available cups.

- Page 5 DESCRIPTION MODEL MODEL MODEL Cart-only system for use with non-electrostatic bells. Includes the cart, speed controller, electronic air controller, and system logic controller. Control cart for 25T742 non-electrostatic bells The non-electrostatic ProBell and hose bundle must be purchased separately. 3A4232D...

-

Page 6: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable. - Page 7 Warnings WARNING WARNING WARNING ELECTRIC ELECTRIC ELECTRIC SHOCK SHOCK HAZARD SHOCK HAZARD HAZARD This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock. • Turn off and disconnect power at main switch before disconnecting any cables and before servicing or installing equipment.

- Page 8 Warnings WARNING WARNING WARNING PLASTIC PLASTIC PLASTIC PARTS PARTS CLEANING PARTS CLEANING SOLVENT CLEANING SOLVENT SOLVENT HAZARD HAZARD HAZARD Many cleaning solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property damage. • Use only compatible water-based solvents to clean plastic structural or pressure-containing parts.

-

Page 9: Probell System Information

The controller uses a 24W462 Modbus TCP 334183 fiber optic signal from the ProBell applicator to provide precise closed-loop control of the bell cup rotation speed. The Speed Controller must be mounted in the non-hazardous area, as close to... -

Page 10: System Connections And Features

System Connections and Features System Connections Connections and and Features Features System System Connections Features The following air connections are included within the ProBell system. Electronic Electronic Electronic Speed Speed Speed Controller Controller Controller Air Controller Controller Controller Air Line... -

Page 11: Installation

Installation Installation Installation Installation System Components Components System System Components KEY: KEY: KEY: Cart Electrostatic Controller Speed Controller Air Filter Electronic Air Controller Ground Wire Dryaire Membrane Filter CAN cable (1 m, 3.3 ft) Filter Coalescer CAN cable (0.5 m, 1.6 ft) System Logic Controller CAN cable (1.5 m,4.9 ft) Power Supply... -

Page 12: Install Optional Wheels

Installation Install Optional Optional Wheels Wheels Install the the System System Logic Logic Controller Controller Install Install Optional Wheels Install Install System Logic Controller To protect it from damage during shipping, the System Logic Controller is packaged separately. It is already loaded with the necessary software. -

Page 13: Connect The Electrostatic Controller

Installation Connect the the Electrostatic Electrostatic Controller Controller Connect Connect Electrostatic Controller As much as possible, cables and tubing are connected at the factory. Two additional connections are needed for the Electrostatic Controller (21). 1. For any installation that involves discrete integration, connect the discrete I/O cable (49) from the I/O cable connection on the Electrostatic Controller to a PLC or other device. -

Page 14: Ground The System

All cart components are system, follow the instructions in the ProBell Rotary connected together for grounding. Connect a ground Applicator manuals. -

Page 15: Parts

Parts Parts Parts Parts ProBell System System ProBell ProBell System Parts surrounded by dashed lines are not included for non-electrostatic carts. 3A4232D... - Page 16 Parts ProBell System System ProBell ProBell System Part Part Part Description Description Description Part Part Part Description Description Description — — — 24Z225 CART KIT TUBE, nylon, 1/2 OD x 3/8 ID SPEED CONTROLLER, CORD SET with North 24Z220 includes Ref. 60...

-

Page 17: Cart Kit 24Z225

Parts Cart Kit Kit 24Z225 24Z225 Cart Cart 24Z225 3A4232D... - Page 18 SCREW, cap, hex, 3/8–16 x 100454 3 inch 100086 WASHER 101566 NUT, lock 100321 114575 PLUG, button 100018 WASHER 16F207 CASTER, swivel 100639 WASHER, Lock BRACKET, mounting, system 17† 277853 † Not shown, see ProBell System, page 15 logic controller 3A4232D...

-

Page 19: Dimensions

Dimensions Dimensions Dimensions Dimensions A A A B B B C C C D D D E E E F F F G G G 19.26 in. 28.4 in. 64.7 in. 22.0 in. 2.0 in. 18.0 in. 17.26 in. (48.9 cm) (72.1 cm) (164.3 cm) (55.9 cm) -

Page 20: Technical Specifications

Technical Specifications Technical Specifications Specifications Technical Technical Specifications For ProBell Rotary Applicator information, see Manual 334452 or 334626. For Electrostatic Controller information, see Manual 3A3657. ProBell Cart System Metric Metric Metric Maximum working air pressure 100 psi 0.69 MPa, 6.9 bar Ambient temperature range 41°F to 104°F... - Page 21 3A4232D...

-

Page 22: Graco Standard Warranty

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations. This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Need help?

Do you have a question about the ProBell and is the answer not in the manual?

Questions and answers