Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for KSB Etanorm FXV

- Page 1 Sprinkler Pump Etanorm FXV Installation/Operating Manual...

- Page 2 All rights reserved. The contents provided herein must neither be distributed, copied, reproduced, edited or processed for any other purpose, nor otherwise transmitted, published or made available to a third party without the manufacturer's express written consent. Subject to technical modification without prior notice. © KSB SE & Co. KGaA, Frankenthal 09/08/2021...

-

Page 3: Table Of Contents

Aligning the pump and motor ........................ 24 5.7.1 Levelling the pump set with adjusting screws ................. 24 5.7.2 Levelling the pump set without adjusting screws ................ 25 Electrical connection ............................ 26 Checking the direction of rotation........................ 26 Commissioning/Start-up/Shutdown.................... 28 Commissioning/Start-up .......................... 28 Etanorm FXV 3 of 62... - Page 4 Recommended spare parts stock ...................... 49 Trouble-shooting.......................... 51 Related Documents .......................... 53 General assembly drawing with list of components .................. 53 9.1.1 Etanorm FXV ............................ 53 EU Declaration of Conformity ...................... 57 Certificate of Decontamination...................... 58 Index .............................. 59 Etanorm FXV 4 of 62...

-

Page 5: Glossary

Pump Machine without drive, additional components or accessories Pump set Complete pump set consisting of pump, drive, additional components and accessories Suction lift line/suction head line The pipeline which is connected to the suction nozzle Etanorm FXV 5 of 62... -

Page 6: General

In the event of damage, immediately contact your nearest KSB service facility to maintain the right to claim under warranty. 1.2 Installation of partly completed machinery To install partly completed machinery supplied by KSB refer to the sub-sections under Servicing/Maintenance. -

Page 7: Key To Safety Symbols/Markings

In conjunction with one of the signal words this symbol indicates a hazard involving electrical voltage and identifies information about protection against electrical voltage. Machine damage In conjunction with the signal word CAUTION this symbol indicates a hazard for the machine and its functions. Etanorm FXV 7 of 62... -

Page 8: Safety

Deficits in knowledge must be rectified by means of training and instruction provided by sufficiently trained specialist personnel. If required, the operator can commission the manufacturer/supplier to train the personnel. Training on the pump (set) must always be supervised by technical specialist personnel. Etanorm FXV 8 of 62... -

Page 9: Consequences And Risks Caused By Non-Compliance With This Manual

▪ Only perform work on the pump set when it has been disconnected from the power supply (de-energised). ▪ The pump (set) must have cooled down to ambient temperature. ▪ Pump pressure must have been released and the pump must have been drained. Etanorm FXV 9 of 62... -

Page 10: Unauthorised Modes Of Operation

Never operate the pump (set) outside the limits stated in the data sheet and in this manual. The warranty relating to the operating reliability and safety of the supplied pump (set) is only valid if the equipment is used in accordance with its intended use. (ð Section 2.2, Page 8) Etanorm FXV 10 of 62... -

Page 11: Transport/Storage/Disposal

1. On transfer of goods, check each packaging unit for damage. 2. In the event of in-transit damage, assess the exact damage, document it and notify KSB or the supplying dealer and the insurer about the damage in writing immediately. -

Page 12: Storage/Preservation

4. Always complete and enclose a certificate of decontamination when returning the pump. Indicate any safety measures and decontamination measures taken. (ð Section 11, Page 58) NOTE If required, a blank certificate of decontamination can be downloaded from the following web site: www.ksb.com/certificate_of_decontamination Etanorm FXV 12 of 62... -

Page 13: Disposal

2. Separate and sort the pump materials, e.g. by: - Metals - Plastics - Electronic waste - Greases and other lubricants 3. Dispose of materials in accordance with local regulations or in another controlled manner. Etanorm FXV 13 of 62... -

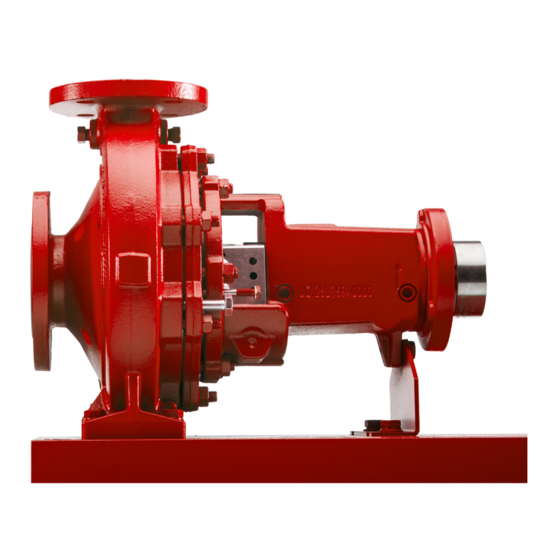

Page 14: Description Of The Pump (Set)

▪ Volute casing pump for sprinkler installations to VdS CEA 4001 4.2 Product information as per Regulation No. 1907/2006 (REACH) For information as per chemicals Regulation (EC) No. 1907/2006 (REACH), see https:// www.ksb.com/ksb-en/About-KSB/Corporate-responsibility/reach/ 4.3 Designation Example: Etanorm FXV 065-040-250 GB 10 Table 4: Designation key Code Description Etanorm Type series... -

Page 15: Design Details

Shaft seal ▪ Gland packing ▪ Single mechanical seal to EN 12756 ▪ Shaft equipped with replaceable shaft sleeve in the shaft seal area Bearings ▪ Grease-packed deep groove ball bearings Only for submersible borehole pumps Etanorm FXV 15 of 62... -

Page 16: Configuration And Function

Surface sound pressure level as per ISO 3744 and DIN EN ISO 20361 ; valid for a pump operating range of Q/ QBEP = 0.8 - 1.1 and non-cavitating operation. If noise levels are to be guaranteed: Add +3 dB for measuring and constructional tolerance. Etanorm FXV 16 of 62... -

Page 17: Scope Of Supply

▪ Baseplate ▪ Coupling ▪ Coupling guard ▪ Drive ▪ Supply system for double mechanical seal 4.9 Dimensions and weights For dimensions and weights please refer to the general arrangement drawing/outline drawing of the pump/pump set. Etanorm FXV 17 of 62... -

Page 18: Installation At Site

Permissible deviation: 0.2 mm/m 2. Use shims (1) for height compensation, if necessary. Always fit shims, if any, immediately to the left and right of the foundation bolts (3) between the baseplate/foundation frame and the foundation. Etanorm FXV 18 of 62... -

Page 19: Piping

▷ Prevent current flowing through the rolling element bearings. NOTE Installing check and shut-off elements in the system is recommended, depending on the type of plant and pump. However, such elements must not obstruct proper drainage or hinder disassembly of the pump. Etanorm FXV 19 of 62... - Page 20 Use a filter with laid-in wire mesh (mesh width 0.5 mm, wire diameter 0.25 mm) of corrosion-resistant material. Use a filter with a filter area three times the cross-section of the piping. Conical filters have proved suitable. 5. Connect the pump nozzles to the piping. Etanorm FXV 20 of 62...

-

Page 21: Permissible Forces And Moments At The Pump Nozzles

200 2350 2100 1900 3680 1150 800 150 1600 1400 1750 2754 880 250-150-400 250 3340 2980 2700 5227 1780 1260 1460 150 1600 1400 1750 2754 880 Correction coefficients depending on material and temperature (see diagram below). Etanorm FXV 21 of 62... -

Page 22: Auxiliary Connections

Damage to pump, motor and coupling! ▷ Always check the coupling after the pump has been installed and connected to the piping. ▷ Also check the coupling of pump sets supplied with pump and motor mounted on the same baseplate. Etanorm FXV 22 of 62... - Page 23 5 Installation at Site Fig. 11: Non-spacer-type coupling, checking the coupling alignment Straight edge Gauge Fig. 12: Spacer-type coupling, checking the coupling alignment Straight edge Gauge Fig. 13: Double Cardan spacer-type coupling, checking the coupling alignment Straight edge Gauge Etanorm FXV 23 of 62...

-

Page 24: Aligning The Pump And Motor

ü The coupling guard and the footboard for the coupling guard, if any, have been removed. 1. Check the coupling alignment. 2. Unscrew the hexagon head bolts (1) at the motor and the locknuts (3) at the baseplate. Etanorm FXV 24 of 62... -

Page 25: Levelling The Pump Set Without Adjusting Screws

Risk of injury by rotating shafts! ▷ Always operate the pump set with a coupling guard. If the customer specifically requests not to include a coupling guard in KSB's delivery, then the operator must supply one! ▷ Observe all relevant regulations for selecting a coupling guard. -

Page 26: Electrical Connection

Damage to the pump! ▷ Refer to the arrow indicating the direction of rotation on the pump. ▷ Check the direction of rotation. If required, check the electrical connection and correct the direction of rotation. Etanorm FXV 26 of 62... - Page 27 The motor's direction of rotation must match the arrow indicating the direction of rotation on the pump. 3. If the motor runs in the wrong direction of rotation, check the electrical connection of the motor and the control system, if necessary. Etanorm FXV 27 of 62...

-

Page 28: Commissioning/Start-Up/Shutdown

Check that coupling/shaft can be easily rotated by hand. 4. Fit the coupling guard and its footboard, if any. 5. Check the distance between coupling and coupling guard. The coupling guard must not touch the coupling. Etanorm FXV 28 of 62... -

Page 29: Starting Up For A Test Run

1. Tighten the nuts on the gland follower by 1/6 turn. 2. Monitor the leakage for another five minutes. Excessive leakage: Repeat steps 1 and 2 until the minimum value has been reached. Not enough leakage: Slightly loosen the nuts at the gland follower. Etanorm FXV 29 of 62... -

Page 30: Switching The Pump Set Off After Testing

If the start-ups are evenly spaced over the period indicated, the following limits serve as orientation for start-up with the discharge-side gate valve slightly open: The frequency of starts shall not exceed 6 start-ups per hour (h). Etanorm FXV 30 of 62... -

Page 31: Fluid Handled

ü Sufficient fluid is supplied for the functional check run of the pump. 1. For prolonged shutdown periods, start up the pump (set) regularly between once a month and once every three months for approximately five minutes. VdS-approved flow rate Etanorm FXV 31 of 62... -

Page 32: Returning To Service

▷ As soon as the work is completed, properly re-install and re-activate any safety- relevant devices and protective devices. NOTE If the equipment has been out of service for more than one year, replace all elastomer seals. Etanorm FXV 32 of 62... -

Page 33: Servicing/Maintenance

NOTE All maintenance work, service work and installation work can be carried out by KSB Service or authorised workshops. For contact details please refer to the enclosed "Addresses" booklet or visit "www.ksb.com/contact" on the Internet. - Page 34 After prolonged false-alarm operation, always dismantle the pump and inspect it for any signs of wear or damage; if necessary, repair it by replacing any affected components. Etanorm FXV 34 of 62...

-

Page 35: Inspection Work

Table 11: Grease quality to DIN 51825 Soap basis NLGI grade Worked penetration at Drop point 25° C in mm/10 Lithium 2 to 3 220-295 ≥ 175 °C ▪ Free of resin and acid ▪ Not liable to crumble ▪ Rust-preventive characteristics Etanorm FXV 35 of 62... - Page 36 1. Remove the outer cover plate of each bearing with a suitable tool. Dispose of the cover plates. 2. Only half-fill the bearing cavities with grease. Continue using the bearings without the outer cover plates (variant Z C3). Etanorm FXV 36 of 62...

-

Page 37: Drainage/Cleaning

▷ Use suitable transport devices, lifting equipment and lifting tackle to move heavy assemblies or components. Always observe the safety instructions and information. For any work on the motor, observe the instructions of the relevant motor manufacturer. Etanorm FXV 37 of 62... -

Page 38: Preparing The Pump Set

In the event of damage you can always contact our service departments. NOTE All maintenance work, service work and installation work can be carried out by KSB Service or authorised workshops. For contact details please refer to the enclosed "Addresses" booklet or visit "www.ksb.com/contact" on the Internet. -

Page 39: Removing The Impeller

161 from bearing bracket 330. 4. Remove gland follower 452 from casing cover 161 and remove the packing. 5. Remove stuffing box ring 454. 6. Remove packing rings 461 and lantern ring 458, if any. Etanorm FXV 39 of 62... -

Page 40: Dismantling The Bearing Assembly

6. Remove pump-end bearing cover 360.01 and drive-end bearing cover 360.02. 7. Press shaft 210 out of the shaft seat. 8. Remove radial ball bearings 321.01 and 321.02, and place them on a clean and level surface. Etanorm FXV 40 of 62... -

Page 41: Reassembling The Pump Set

Coat the locating surfaces of the individual components with graphite or similar before reassembly. Tightening torques For reassembly, tighten all screws and bolts as specified in this manual. (ð Section 7.6, Page 47) (Also see general assembly drawing and data sheet.) Etanorm FXV 41 of 62... -

Page 42: Installing The Bearing Assembly

7. Fit the coupling hub on pump shaft 210. For split-hub coupling designs, fit the hub halves on pump shaft 210. Fit and tighten the screws clamping the hub halves together. Observe the tightening torques. (ð Section 7.6, Page 47) 8. Secure the coupling hub with a grub screw. Etanorm FXV 42 of 62... -

Page 43: Fitting The Shaft Seal

4. Carefully insert the mating ring. Make sure to apply pressure evenly. 5. On variants with a bolted casing cover loosen forcing screws 901.31. 6. Place casing cover 161 into the locating fit of bearing bracket 330. Etanorm FXV 43 of 62... - Page 44 Mechanical seal Casing cover Table 13: Installation dimensions of the mechanical seal Shaft unit Installation dimension b 7,5 mm 10 mm 15 mm 7.5.3.2 Fitting the gland packing Fig. 18: Gland packing chamber Shaft unit see data sheet. Etanorm FXV 44 of 62...

- Page 45 81-92.02 with transport locks 901.98 and lock washers 554.98. The casing cover is now fastened to the bearing bracket. For operation with positive suction head and suction pressure > 0.5 bar, the lantern ring is replaced by 2 additional packing rings. Etanorm FXV 45 of 62...

-

Page 46: Fitting The Impeller

1. Shift the motor to connect it to the pump via the coupling. 2. Fasten the motor to the baseplate. 3. Align pump and motor. (ð Section 5.7, Page 24) 4. Connect the motor to the power supply (refer to manufacturer's product literature). Etanorm FXV 46 of 62... -

Page 47: Tightening Torques

Fig. 20: Tightening points: model with bolted casing cover and grease lubrication (a), model with clamped casing cover (b) and oil lubrication (c) Table 15: Tightening torques Position Thread Tightening torques [Nm] M12 × 1,5 M24 × 1,5 M30 × 1,5 Etanorm FXV 47 of 62... -

Page 48: Tightening Torques For The Pump Set

Motor on baseplate or motor on adjusting screws or bases Coupling (only for spacer-type coupling made by Flender) Coupling (only for double Cardan spacer- type coupling and split- hub coupling design, make: KTR) Coupling guard Etanorm FXV 48 of 62... -

Page 49: Spare Parts Stock

(set) 50 % Shaft sleeve 50 % Shaft protecting sleeve 50 % Gland packing (set) 100 % Lantern ring 100 % 400.10 Gasket 150 % 400.15 Gasket 150 % For double mechanical seal If fitted Etanorm FXV 49 of 62... - Page 50 7 Servicing/Maintenance Part No. Description Number of pumps 10 and more 400.75 Gasket 150 % 411.15 Joint ring 150 % 412.15 O-ring 150 % Etanorm FXV 50 of 62...

-

Page 51: Trouble-Shooting

If problems occur that are not described in the following table, consultation with the KSB service is required. A Pump delivers insufficient flow rate B Motor is overloaded... - Page 52 Clean the impeller. Re-balance the impeller. - Defective bearing(s) Replace. ✘ ✘ ✘ ✘ Flow rate is too low. Increase the minimum flow rate. ✘ - Incorrect inflow of circulation liquid Increase the free cross-section. Etanorm FXV 52 of 62...

-

Page 53: Related Documents

9 Related Documents 9 Related Documents 9.1 General assembly drawing with list of components 9.1.1 Etanorm FXV 903.03 411.03 400.10 920.01 902.01 502.02 920.15 502.01 360.01 902.15 321.02 932.01 411.77 932.02 360.02 321.01 931.95 411.78 920.95 940.02 914.02 901.04 81-92.01 81-92.02... - Page 54 554.98 902.02 920.02 02-32 903.01 400.75 411.01 Fig. 23: General assembly drawing of version with gland packing, type P1 - Na 02-32 902.02 920.02 400.75 Fig. 24: Version with gland packing, type P2 - Nb 931.95 550.95 920.95 Fig. 25: Impeller fastening elements WS_25 Etanorm FXV 54 of 62...

- Page 55 For versions with gland packing only For sizes 65-40-250, 65-50-200, 65-50-250 and 80-65-200 only Not for sizes 100-80-200 and 125-100-200 For versions with mechanical seal only For sizes 80-65-315, 100-80-315, 125-100-315, 150-125-315, 200-150-400, 250-150-400 only Etanorm FXV 55 of 62...

- Page 56 Table 21: List of components for version with reinforced bearing assembly (shaft units 50, 60, 60.1) Part No. Description Part No. Description Support foot 507.01 Thrower Shaft 901.01/.02/.04 Hexagon head bolt Bearing bracket 930.01 Lock washer 321.01/.02 Deep groove ball bearing 940.02 360.01/.02 Bearing cover Etanorm FXV 56 of 62...

-

Page 57: Eu Declaration Of Conformity

10 EU Declaration of Conformity 10 EU Declaration of Conformity Manufacturer: KSB SE & Co. KGaA Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the product: Etanorm FXV, Etanorm FXM KSB order number: ....................▪ is in conformity with the provisions of the following directives / regulations as amended from time to time: –... -

Page 58: Certificate Of Decontamination

We confirm that the above data and information are correct and complete and that dispatch is effected in accordance with the relevant legal provisions....................................Place, date and signature Address Company stamp Required field Etanorm FXV 58 of 62... -

Page 59: Index

Spare parts 49 Function 16 Storage 12, 32 Gland packing 29 Tightening torques 47, 48 Grease lubrication Transport 11 Grease quality 35 Intervals 35 Warnings 7 Impeller type 15 Warranty claims 6 Installation Installation on a foundation 18 Installation at site 18 Intended use 8 Key to safety symbols/markings 7 Etanorm FXV 59 of 62... - Page 62 KSB SE & Co. KGaA Johann-Klein-Straße 9 • 67227 Frankenthal (Germany) Tel. +49 6233 86-0 www.ksb.com...

Need help?

Do you have a question about the Etanorm FXV and is the answer not in the manual?

Questions and answers