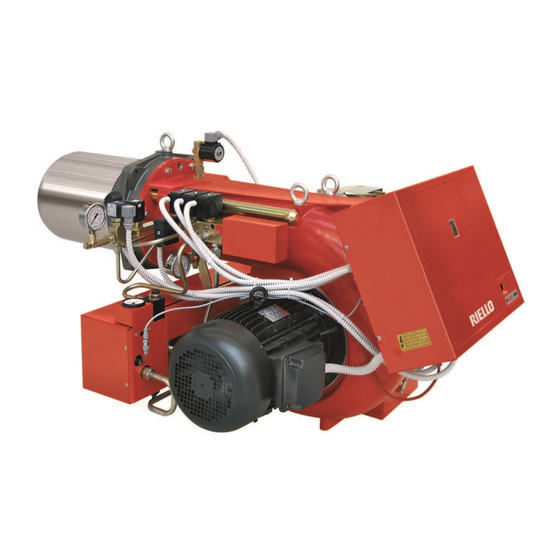

Riello PRESS 140 T/N Installation, Use And Maintenance Instructions

Heavy oil burners

Hide thumbs

Also See for PRESS 140 T/N:

- Installation, use and maintenance instructions (60 pages) ,

- Installation, use and maintenance instructions (52 pages)

Summary of Contents for Riello PRESS 140 T/N

- Page 1 Installation, use and maintenance instructions Heavy oil burners CODE MODEL TYPE 3436885 PRESS 140 T/N 466 T80 3436886 PRESS 140 T/N 466 T80 2915831 (4) - 11/2012...

-

Page 2: Technical Data

TECHNICAL DATA Thermal power - Output 320 / 1600 kW - 28 / 140 kg/h (See page 3) Operation stage - 2 stage - 3 stage Oil with max. viscosity 50 mm /s (7°E) at 50°C Fuel with kit: max. viscosity 500 mm /s (65°E) at 50°C Pump 350 kg/h at 25 bar... - Page 3 DIMENSIONS *It is possible with a spacer, upon request COMBUSTION CHAMBER PRESSURE - MAXIMUM OUTPUT (Three nozzles in operation) Operation field: Limit Safety kg/h When the burner operates with only one or two nozzles, the pressurization conditions are improved and no problems arise.

- Page 4 OPERATION AND EFFICIENCY OF THE BURNER POWER AND OUTPUT STAGE MINIMUM MAXIMUM kg/h kg/h nozzle: ignition phase 1060 nozzle: intermediate phase 1595 nozzle: operation phase POWER AND OUTPUT STAGE MINIMUM MAXIMUM kg/h kg/h nozzle: ignition phase 1060 nozzle: 1 stage of operation 1595 nozzle: 2 stage of operation...

- Page 5 HEAVY OIL SUPPLY LINE RING SUPPLY LINE (for heavy oil with viscosity up to 50°E at 50°C) 1 - Tank (heated for heavy oil) 2 - Filter (with resistance for oil > 7°E at 50°C) 3 - Forwarding pump 4 - Control manometer 5 - Shutter valves (in couple) excluding the burner 6 - Burner (provided for kit for heavy oil code no.

-

Page 6: Internal Wiring Diagram

INTERNAL WIRING DIAGRAM (carried out by the factory) 2618 LEGEND Fan motor contact maker Burner earth Commutator Electronic thermostat Resistor contact maker Maximal thermostat Photoresistance Minimal thermostat Burner terminal strip Timer Fan motor Lamps for 1° stage Control box Lamps for 2° stage Overload Lamps for 3°... - Page 7 WIRING CONNECTIONS TO THE TERMINAL BOARD (carried out by the installer 2645 220V 380V A Ampere B Ampere C mm D mm Remote lock-out signal Limit control device system Optional switch on-off burner Safety control device system MB Burner terminal strip Load control system for 2 stage Reset push - button...

- Page 8 CHOICE: OF THE NOZZLES - OF THE PUMP PRESSURE - OF THE COMBUSTION HEAD ADJUSTMENT • First of all state the maximum output required with all three nozzles in operation. • On the base of the maximum output choose, from table A, three related nozzles. Nozzles: 60°...

- Page 9 Nozzles delivery Combustion head adjustment Pump pressure Maximum output Suggested pressure - Light oil: 25 bar - Heavy oil: 28 bar (transformation kit) Rated nozzles deliveries are listed on the table. A tollerance of ± 5% concerns the real delivery against the rated one. The pump leaves the factory set at 25 bar.

- Page 10 AIR SHUTTERS ADJUSTMENTS The adjustment of the air shutters shall be set each time, with reference to the nozzles deliveries and the combustion chamber pressurization. Fig. 3 Fig. 2 Fig. 2 shows the positioning of the air shutters. Fig. 3 shows the positioning of the cams of the motor. Air shutters adjustments stage: manual regulation carried out by acting on the sector A (fig.

- Page 11 SPRAY TEMPERATURE ADJUSTMENT Thermostat for adjustment - maximum value - minimum value Electronic adjustment thermostat By means of information relayed from a PT100 probe immersed in the oil in the delivery manifold, the thermostat adjusts spray temperature. (The correct conditions for fuel spray are shown in the temperature/viscosity graph below).

- Page 12 CYCLE OF THE BURNER START-UP Lock-out because Normal no ignition Thermostat Motor Ignition transformer Pre-purge stage valve stage valve stage valve Lock-out lamp 2848 Factory setting: 20 s. D3211 This time determines the heavy oil tempera- ture at ignition. It can be adjusted, accord- ing to the fuel’s viscosity, by the timer 22) (Fig.

-

Page 13: Burner Start-Up Cycle Diagnostics

BURNER START-UP CYCLE DIAGNOSTICS During start-up, indication is according to the followin table: COLOUR CODE TABLE Sequences Colour code Pre-purging Ignition phase Operation, flame ok Operating with weak flame signal Electrical supply lower than ~ 170V Lock-out Extraneous light Key: Yellow Green OPERATING FAULT DIAGNOSTICS... - Page 16 RIELLO S.p.A. I-37045 Legnago (VR) Tel.: +39.0442.630111 http:// www.riello.it http:// www.rielloburners.com Subject to modifications...

Need help?

Do you have a question about the PRESS 140 T/N and is the answer not in the manual?

Questions and answers