Table of Contents

Advertisement

Quick Links

OPERATION AND MAINTENANCE INSTRUCTIONS

DESMI end suction centrifugal pump

DESMI Pumping Technology A/S

Tagholm l, DK-9400 Nørresundby, Denmark

Special pump No. ...............................................

ESLH/-17

Tel.: +45 96 32 81 11

Fax: +45 98 17 54 99

E-mail:

desmi@desmi.com

Internet:

www.desmi.com

Manual:

Language:

T1539

English

Revision:

A(12/2020)

Advertisement

Table of Contents

Summary of Contents for Desmi ESLH/-17

- Page 1 OPERATION AND MAINTENANCE INSTRUCTIONS DESMI end suction centrifugal pump ESLH/-17 DESMI Pumping Technology A/S Tagholm l, DK-9400 Nørresundby, Denmark Tel.: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com Internet: www.desmi.com Manual: Language: Revision: T1539 English A(12/2020) Special pump No.

-

Page 2: Table Of Contents

15. INFORMATION RELEVANT FOR DISASSEMBLY OR DISPOSAL AT END-OF-LIFE .......... 18 16. ASSEMBLY DRAWING ESLH25-180N/-17 ....................18 17. DIMENSIONAL SKETCH ..........................19 _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 3: Product Description

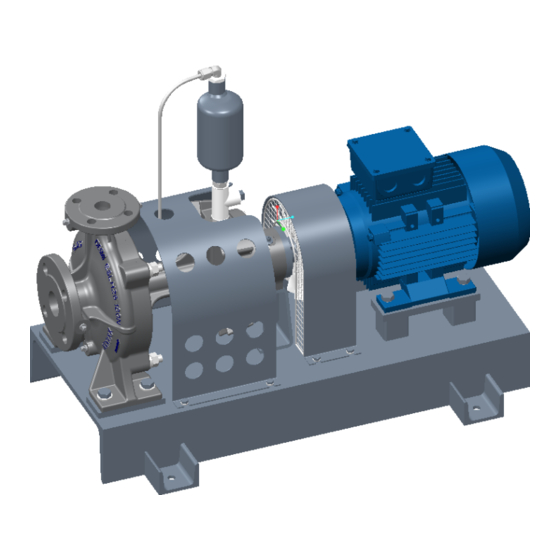

1. PRODUCT DESCRIPTION These operation and maintenance instructions apply to the DESMI ESLH pump in /-17 execution. The ESLH pump is designed for horizontal assembly with the pressure flange pointing upwards. The pump is a single-stage end suction centrifugal pump equipped with stainless steel shaft, balanced mechanical shaft seal mounted in a separate chamber with cooling ribs and fan cooling and closed impeller. -

Page 4: Technical Description

“calc” is the values calculated by the user. At the same time none of the forces or moments may exceed the indicated figure multiplied by 1.4. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 5: Installation

Before shipment the pump is to be fastened securely on pallets or the like. The pump is to be lifted in the following way: The lifting straps must not bear against sharp edges and corners. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 6: Dismantling

Unscrew the coupling point screw and remove the coupling (38) with the cooling fan (47) _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 7: Dismantling Rear Cover And Impeller

Remove rear cover unit. Remove the impeller (5) and O-ring (3) 5.1.3 DISMANTLING SHAFT SEAL & BEARING _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... - Page 8 (32) Take out the shaft with ball bearing Remove the bearing cover (20) _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com...

-

Page 9: Inspection

Replace in case of wear and noise. - Sliding bearing/shaft : Wear= max. 0.5 mm diameter difference. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 10: Assembling

10 revolutions - with water in the pump - but without adding pressure. Then pressure test the pump as normally done. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 11: Fitting Bearing House

Measured the coupling within the limits indicated in the below table. And tighten the set screw (37) after the coupling is in right position . _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 12: Shaft

450 rpm and that a maximum of 1 minute is spent on acceleration from 0 to 450 rpm and 1 minute deceleration from 450 to 0 rpm. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 13: System Balancing

Pump takes air non-return valve not submerged 5. Suction lift too high Check data sheet Q/H curve and 6. Pump and piping system NPSH or contact DESMI wrongly dimensioned The pump uses too 1. Counter-pressure too low Insert orifice plate or check much power 2. -

Page 14: Inspection And Maintenance

When the impeller has been dismantled, Remove the key (19) and loosen the nuts (18) and dismantle the bearing house with shaft and ball bearing unit from the rear cover. Loosen the _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø... -

Page 15: Replacing Ball Bearings

15 g If the ball bearing is to be replaced, it is necessary to disassemble the pump and dismantle the pump shaft (as described in paragraph 5.1.3): _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 16: Operating Data

1.5 x the permissible working pressure. The test pressure is stated in the test certificate and stamped into the discharge flange of the pump. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 17: Eu Declaration Of Conformity

14. EU DECLARATION OF CONFORMITY DESMI Pumping Technology A/S, hereby declare that our pumps of the ESLV and ESLH type are manufactured in conformity with the following essential safety and health requirements in the COUNCIL DIRECTIVE 2006/42/EC on machines, Annex 1. -

Page 18: Information Relevant For Disassembly Or Disposal At End-Of-Life

No damage materials are used in DESMI pumps – please refer to DESMI Green Passport (can be sent on request – contact a DESMI sales office) – i.e. common recycling companies can handle the disposal at end-of-life. Alternatively the pump and motor can be returned to DESMI at end-of-life for safe recycling. -

Page 19: Dimensional Sketch

Cooling fan Support disc Air vent Sunk screw 17. DIMENSIONAL SKETCH Please require a dimensional sketch of the actual pump from DESMI. Connection holes on pump: Manometer: 1/4” BSP. Drain: 1/4” BSP. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø...

Need help?

Do you have a question about the ESLH/-17 and is the answer not in the manual?

Questions and answers