Table of Contents

Advertisement

OPERATION AND MAINTENANCE INSTRUCTIONS

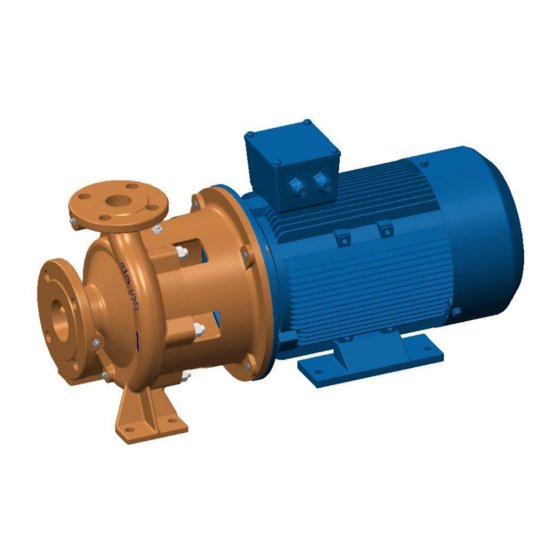

DESMI end suction centrifugal pump

DESMI Pumping Technology A/S

Tagholm l, DK-9400 Nørresundby, Denmark

Manual:

T1528

Special pump No. ...............................................

ESLV and ESLH Monobloc

Tel.: +45 96 32 81 11

Fax: +45 98 17 54 99

E-mail:

desmi@desmi.com

Internet:

www.desmi.com

Language:

English

Revision:

F(11/2019)

Advertisement

Table of Contents

Summary of Contents for Desmi ESLV Series

- Page 1 OPERATION AND MAINTENANCE INSTRUCTIONS DESMI end suction centrifugal pump ESLV and ESLH Monobloc DESMI Pumping Technology A/S Tagholm l, DK-9400 Nørresundby, Denmark Tel.: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com Internet: www.desmi.com Manual: Language:...

-

Page 2: Table Of Contents

17. ASSEMBLY DRAWING ESLV/H65-180/-12-COMB ..................23 18. ASSEMBLY DRAWING ESLV/H80-180E/-12-COMB ..................24 19. ASSEMBLY DRAWING ESLV/H100-180/-12-COMB ..................25 _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... - Page 3 20. ASSEMBLY DRAWING ESLV/H80/100-180N/-12 AND ESLV/H65-180M/-12-COMB ........26 21. DIMENSIONAL SKETCH ..........................27 _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com...

-

Page 4: Product Description

1. PRODUCT DESCRIPTION These operation and maintenance instructions apply to the DESMI ESLV and ESLH Monobloc pump. The pump is a single-stage end suction centrifugal pump equipped with stainless steel shaft, mechanical shaft seal, and closed impeller. The impeller is mounted on the motor shaft at a shaft extension. The pumps are equipped with a mechanical seal shaft and have holes in the bracket for inspection of leaks. -

Page 5: Technical Description

The permissible loads on the flanges appear from the following table. The values apply to standard pumps in bronze (Rg5) and cast iron (GG20). As to pumps in SG iron (GGG40) the values are to be increased by factor 1.5. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 6: Installation

3.2 WIRING Wiring to be carried out by authorised skilled workmen according to the rules and regulations in force. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 7: Transport/Storage

Before shipment the pump is to be fastened securely on pallets or the like. The pump is to be lifted in the following way: The lifting straps must not bear against sharp edges and corners. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 8: Dismantling

5.1 DISMANTLING OF ESLV/H25/40/65/80/100-180 Before dismantling 1.Remove nut (15) and 2.Remove screw(20) and stud(14); washer(23); _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... - Page 9 6.Press out the seat(22); 7.If necessary, remove pointed screw(11) to pull off the shaft. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail:...

-

Page 10: Dismantling Of Eslv/H65-180M, Eslv/H80/100-180N

4. Remove shaft seal (22) 5. Remove set screw (10) and key (19) and rear cover (4) _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 11: Inspection

- Shaft seal/shaft seal cover: Check the seat for flatness and cracks. Check the rubber parts for elasticity. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 12: Assembling

(8) and pump shaft flange (6), adjust the motor coupling to make it resist on the shims to ensure it is at the right axial position. Tighten the _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 13: Shaft

Pumps which are not in operation during frost periods are to be drained to avoid frost damage. Remove the plug at the bottom to empty the pump. Alternatively, it is possible to use anti-freeze liquids in normal constructions. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 14: Start-Up

Should the pump not function as intended, please proceed according to the fault-finding list. Bear in mind, though, that the pump was carefully checked and tested at the factory and that the majority of faults stem from the piping system _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... - Page 15 Pump takes air non-return valve not submerged 5. Suction lift too high Check data sheet Q/H curve and 6. Pump and piping system NPSH or contact DESMI wrongly dimensioned The pump uses too 1. Counter-pressure too low Insert orifice plate or check much power 2.

-

Page 16: Inspection And Maintenance

Clean the bore for seat and shaft thoroughly of dirt and rust. Remove persistent coatings, if any, by grinding the shaft lightly with very fine emery cloth. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 17: Replacing Ball Bearings In Motor

Normally, the pump shaft is to go relatively smoothly on the motor shaft (manually or by means of light strokes with a plastic hammer). _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 18: Operating Data

1.5 x the permissible working pressure. The test pressure is stated in the test certificate and stamped into the discharge flange of the pump. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark... -

Page 19: Eu Declaration Of Conformity

13. EU DECLARATION OF CONFORMITY DESMI Pumping Technology A/S, hereby declare that our pumps of the ESLV and ESLH type are manufactured in conformity with the following essential safety and health requirements in the COUNCIL DIRECTIVE 2006/42/EC on machines, Annex 1. -

Page 20: Information Relevant For Disassembly Or Disposal At End-Of-Life

No damage materials are used in DESMI pumps – please refer to DESMI Green Passport (can be sent on request – contact a DESMI sales office) – i.e. common recycling companies can handle the disposal at end-of-life. Alternatively the pump and motor can be returned to DESMI at end-of-life for safe recycling. -

Page 21: Assembly Drawing Eslv/H25-180/-12-Comb

Pointed screw Stud Mechanical shaft seal Washer Plug Washer Guard Manometer Nipple Sleeve _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 22: Assembly Drawing Eslv/H40-180/-12-Comb

Pointed screw Stud Wear ring Plug Mechanical shaft seal Washer Manometer Nipple Sleeve _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 23: Assembly Drawing Eslv/H65-180/-12-Comb

Plug Screw Stop ring Mechanical shaft seal Washer Pointed screw Manometer Nipple Sleeve _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 24: Assembly Drawing Eslv/H80-180E/-12-Comb

Plug Screw Stop ring Mechanical shaft seal Washer Pointed screw Manometer Nipple Sleeve _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... -

Page 25: Assembly Drawing Eslv/H100-180/-12-Comb

Plug Screw Stop ring Mechanical shaft seal Washer Pointed screw Manometer Nipple Sleeve _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com... - Page 26 Wear ring Plug Screw Mechanical shaft seal Washer Washer Set screw Guard BH-Screw _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark Tel: +45 96 32 81 11 Fax: +45 98 17 54 99 E-mail: desmi@desmi.com...

- Page 27 21. DIMENSIONAL SKETCH Please require a dimensional sketch of the actual pump from DESMI. Connection holes on pump: Manometer: 1/4” BSP. Drain: 1/4” BSP. Air vent: 1/8” BSP. _______________________________________________________________________________ DESMI Pumping Technology A/S www.desmi.com Tagholm 1 9400 Nø rresundby – Denmark...

Need help?

Do you have a question about the ESLV Series and is the answer not in the manual?

Questions and answers