Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Peri RCS-2

- Page 1 RCS-2 Climbing Device and Hydraulics Assembly, Commissioning and Maintenance Spare Parts and Circuit Diagrams Assembly Instructions – Issue 08/2020 Climbing Device-2 RCS 50 Hydraulic Unit RCS MAX Item no. 135413 2x 210bar, 380-460V Item no. 135500...

-

Page 2: Table Of Contents

B1 Storage and transportation measures Appendix B2 Packaging Maintenance chart Pallett RP Hydraulic Pump RCS MAX Declaration of incorporation Commissioning and maintenance Program overview C1 Initial commissioning RCS-2 Climbing Device and Hydraulics C2 Commissioning Measures taken during commissioning Electrical connection Hydraulic oil Hydraulic hoses Hydraulic unit C3 Maintenance Maintenance and repairs... -

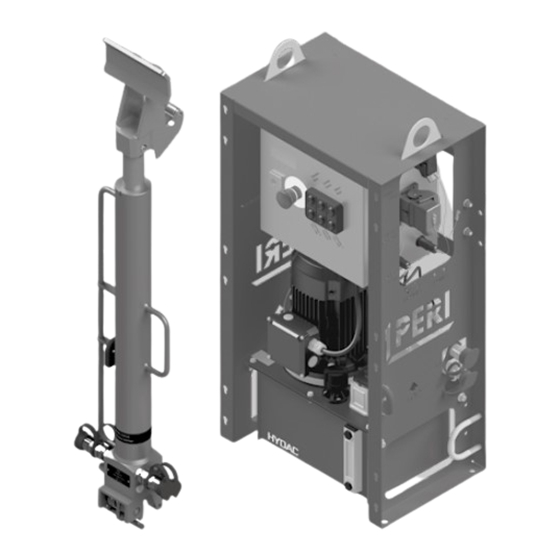

Page 3: Main Components

Overview Main components Climbing Device-2 RCS 50 Hydraulic Twin Hose RCS 10 m Hydraulic Unit RCS MAX 2 x 210 bar, 380-460V RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 4: Key

Signal word Type and source of hazard! Consequences of non-compliance. Arrows ⇒ Preventative measures. Arrow representing an action Arrow representing a reaction of an action* Arrow representing forces * If not identical to the action arrow. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 5: Target Groups

Instructions for Assembly and Use (e.g. for RCS C or RCS CL) ■ Instructions for Use (e.g. for Lifting Beam RCS 9t) ■ PERI PI separate product information (e.g. for permissible anchor loads) ■ Manufacturer’s assembly instructions for the hydraulic unit ■ Hydraulic oil safety data sheet ■... -

Page 6: Intended Use

Anything other than the use that is stallation in a climbing system. tential safety risk. PERI shall not be specified in Point 1 is considered con- held liable in this case. trary to the designated use! -

Page 7: Regular Assembly

210 bar (21.0 MPa) Hydraulic Unit RCS MAX 2x 210bar, 380-460V Power supply 400 V/50 Hz ( 3 phases) Output 1.3 l/min per cylinder Power supply 480 V/60 Hz ( 3 phases) Output 1.6 l/min per cylinder Sound emissions 60 dB (A ) at a distance of 1.0 m RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 8: Cleaning And Maintenance Instructions

PERI. Do not clean the hydraulic unit and hydraulic cylinder with a high pressure cleaner. Use PERI original parts as spare parts. Concrete adhesion on the Climbing De- vice-2 RCS 50 and hydraulic unit must be removed immediately after the con- creting process. -

Page 9: Safety Instructions

To facilitate understanding, detailed il- lustrations are sometimes incomplete. The contractor must ensure that the PERI products must be stored in such a The safety installations which have pos- way that they are protected against the Assembly Instructions, the Instructions... - Page 10 Crushing risk! Do not touch if the load is moving! PERI climbing hydraulics must not be used if the type plate is missing, in- complete or illegible. Climbing procedure Only anchor climbing units to the next RCS-2 Climbing Device and Hydraulics...

-

Page 11: Components And Tools

Connector Data Cable RCS MAX 135505 Remote Control RCS MAX 15 m 135506 Display RCS MAX 135507 Conversion Set Climbing Device-2 RCS 50 135411 Bolt ISO 4017 M12 x 60-8.8 126001 Washer ISO 7089 200 HV, A12 780702 Nut ISO 4034 M12-8 723805 Data Connection RCS MAX wireless 136531 Remote Control RCS MAX wireless 136530 Pallett RP Hydraulic Pump RCS MAX 136165 Power Cable RCS MAX 2m 136532 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 12: Checklist Prior To Climbing

Attach Extension RCS (10) to Climbing Rails RCS-CL. ■ Attach Climbing Device-2 RCS 50 to the climbing shoe. ■ Connect hydraulic hoses. ■ Switch on the hydraulic system. ■ Check the functionality of the hydraulic system. ■ Carry out the manufacturer’s assembly instructions. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 13: A1 Climbing Device-2 Rcs 50

To prevent the quick-couplers from col- liding with the platforms or other parts of the climbing unit when climbing, it is possible to arrange the couplings verti- cally using angle pieces. Fig. A1.01a → Contact PERI RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 14: A2 Modification Of Climbing Device Rcs 50

(Item no. 109765) at an operating pressure of up to 210 bar, it must be modified. ■ Observe the separate modification instructions. Components Climbing Device RCS 50 Conversion Set Climbing Device-2 RCS 50 15.1 Lowering brake valve 15.2 Label RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 15: A3 Connections Rcs-2

A3 Connections RCS-2 Hydraulic Twin Hoses Hydraulic Twin Hose RCS 10 m (Item no. 110069) Hydraulic Twin Hose RCS 20 m (Item no. 110070) Accessories 2.1 Hydraulic Quick-coupler (bushing) 2a/2b Item no. 110822/128993 2.2 Hydraulic Quick-coupler (clip) Item Fig. A3.01 no. 110823/128992 2.3 Retaining ring (bushing) Hydraulic Single Hoses Hydraulic Hose 2SN-DN08-FF 1.0 m (Item no. - Page 16 A3 Connections RCS-2 Power cables Power Cable RCS MAX CEE-32A 2 m 4.1 Manual Phase Inverter Fig. A3.06 Fig. A3.09 7a Power Connection Cable RCS MAX 10 m 7b Power Connection Cable RCS MAX 20 m Connector Power Cable RCS MAX 7a/7b Power Cable RCS MAX 2m Fig. A3.07 Fig. A3.08 Accessories 13.3...

-

Page 17: A4 Hydraulic Unit Rcs Max

3.12 Interlink out “Group” 3.13 Hydraulic connection A1 3.14 Hydraulic connection B1 3.15 Remote control/display connection 3.14 3.27 3.27 RFID chip To connect an individual pump to a 3.13 group. To connect groups. Fig. A4.02 Fig. A4.03 RCS-2 Climbing Device and Hydraulics Assembly Instructions... - Page 18 3.16 3.17 3.19 3.16 Emergency Stop button 3.17 “Operation Mode” button 3.18 “Cylinder Extend” button 3.19 “Status/Reset” button 3.20 “Cylinder 2 On/Off” button 3.21 “Cylinder Retract” button 3.22 “Cylinder 1 On/Off” button 3.20 3.22 3.21 Fig. A4.04 RCS-2 Climbing Device and Hydraulics Assembly Instructions...

-

Page 19: A5 Climbing Shoe Rcs

Climbing Shoe RCS 5.1 Climbing pawl 5.2 Folding runner 5.3 Safety pins 5.4 Pawl lock 5.5 Hinged clamp 5.6 Spring lock 5.7 Locating pin for climbing device Fig. A5.01 Climbing shoe closed Climbing shoe open Fig. A5.01a Fig. A5.01b RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 20: A6 Climbing Device In Use

A6 Climbing device in use For use in the Self-climbing System RCS C with Wall Shoe RCS Components Climbing Device-2 RCS 50 Climbing Shoe RCS Wall Shoe RCS Climbing Rail RCS 9.1 Climbing bolt (spacer in the climbing rail) Fig. A6.01 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 21: B1 Storage And Transportation Measures

(do not go below the minimum ■ Store hydraulic units in appropriate bending radius.) containers, e. g. pallets, see Section B2 “Packaging” . ■ For more details see the manufactur- er’s assembly instructions. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 22: B2 Packaging

Climbing Device-2 RCS 50 27 .0 kg Item no. 135413 Hydraulic Unit RCS MAX 47 .0 kg Item no. 135500 Hydraulic Twin Hose RCS Length 10 m 9.0 kg Item no. 110069 Length 20 m 16.0 kg Item no. 110070 All weight details do not include the oil. Fig. B2.02 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 23: Pallett Rp Hydraulic Pump Rcs Max

1. Open and fold in the metal clip. 2. Attach the Hydraulic Units RCS MAX to the crane and move them onto the earmarked positions on the pallet. 3. Close the metal clip and secure with a cotter pin. (Fig. B2.04 + B2.05) Fig. B2.05 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 24: C1 Initial Commissioning

Clean the bushings and clips of all tions. quick-couplers prior to coupling and 14. Install hydraulic cylinder. check for damage. 15. Put the system into operation. ■ For more commissioning details, see the manufacturer’s assembly instruc- tions. Fig. C1.01 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 25: C2 Commissioning

Observe the manufacturer’s assem- 6. Check the functionality of the hydrau- bly instructions. lic cylinders. Accessories 7 . Check components and connections ■ for signs of external leakage. Power Cable RCS MAX CEE-32A 2m, art. no.: 135499. ■ Power Cable RCS MAX 2m, Item no.: 136532. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 26: Hydraulic Oil

-5 °C Hydraulic oil ISO 11158 HVI46 ±0 °C ... +70 °C +10 °C In general, use PERI hydraulic oils within viscosity range 16 to 400 mm²/s. A cold start is required from 200 mm²/s. Hydraulic hoses Hydraulic unit Observe DGUV [German Statutory Ac- Observe the manufacturer’s assembly... -

Page 27: C3 Maintenance

■ Refer to the maintenance table of the manufacturer for the hydraulic unit maintenance intervals. PERI recommends shortened mainte- nance intervals: ■ for equipment showing signs of heavy wear. ■ with high thermal and mechanical loads. -

Page 28: D1 Assembly Of The Hydraulic Unit

4x Bolt ISO 4017 M12 x 60-8 (16), Washer ISO 7089 200 HV, A12 (17) and Nut ISO 4034 M12-8 (18). 4. Fasten Hydraulic Unit RCS MAX (3) onto the lower handrail board with 2x Bolt ISO 4017 M12 x 60-8 (16), Wash- er ISO 7089 200 HV, A12 (17) and Nut ISO 4034 M12-8 (18). (Fig. D1.02) RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 29: D2 Installation Of Climbing Device-2 Rcs 50

Climbing group Climbing unit 1 Climbing unit 2 Climbing unit 3 Cylinder 1 Cylinder 2 Cylinder 1 Cylinder 2 Power connection Data connection RCS MAX RCS MAX Power supply Fig.D2.01 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 30: Special Brackets With 3 Climbing Rails

(short piece of tub- ing). Climbing group Climbing unit 2 Climbing unit 1 Cylinder 2 Cylinder 3 Short circuit connec- tion Cylinder 1 Power connection Data connection RCS MAX RCS MAX Power supply Fig.D2.02 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 31: Connecting Hydraulic Hoses

(right or left) to secure it. → Accidental disconnection is thus 2a – 2h prevented. 4. Arrange the hoses so they do not pose a safety risk, and secure their position, e.g. with cable ties. Fig.D2.04 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 32: Rail Climbing System Rcs C

Are the claws (1.1) fully engaged un- der the climbing bolts (9.1)? ■ Are the hydraulic hoses arranged in such a way that they do not get tan- gled or change their position during the climbing procedure? Fig.D2.06 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 33: Rail Climbing System Rcs Cl

Are the claws (1.1) fully engaged un- der the climbing bolts (10.1)? ■ Are the hydraulic hoses arranged in such a way that they do not get tan- gled or change their position during the climbing procedure? RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 34: D3 Preparation Prior To Climbing

■ Lubricate Climbing Rails RCS. ■ Check whether the platforms in the area of the climbing rails collide with the quick-couplers or hydraulic hoses during climbing. Carry out the climbing procedure from the planned position. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 35: D4 Climbing Procedure

Power Ca- ble RCS MAX CEE-32A 2 m (4), see Section D7 “Remedial Action for Mal- functions” . 6. Carry out any additional steps in the manufacturer’s assembly instruc- tions. → The pumps are prepared. Fig. D4.02 RCS-2 Climbing Device and Hydraulics Assembly Instructions... - Page 36 1. Press the “Cylinder Extend” button (13.1) on the remote control. → The climbing device extends. (Fig. D4.04) If multiple remote controls are connect- ed, they must all be activated simulta- neously, otherwise the climbing sys- tem will not move. RCS-2 Climbing Device and Hydraulics Assembly Instructions...

- Page 37 1. Press the “Cylinder Retract” button (13.2) on the remote control. → The climbing device retracts. Fig. D4.06 If multiple remote controls are connect- ed, they must all be activated simulta- neously, otherwise the climbing sys- tem will not move. RCS-2 Climbing Device and Hydraulics Assembly Instructions...

- Page 38 30 sec- onds. ■ When the power supply is interrupt- ed, the hydraulic unit switches off completely. RCS-2 Climbing Device and Hydraulics Assembly Instructions...

-

Page 39: Inserting Into The Climbing Shoe At Rcs C

(19), the inclination of the top climb- ing rail (9A) is adjusted relative to the bottom climbing rail (9B). ■ In the event of a lateral offset, extend the cylinders to the same height. Fig. D4.09 RCS-2 Climbing Device and Hydraulics Assembly Instructions... - Page 40 – pressing the “Cylinder Extend” button on the keypad. – pressing the “Cylinder Extend” button on the connected remote control. 4. Press the “Operation Mode” button (3.17) until the button lights up green. → Interlink-mode operation is activat- RCS-2 Climbing Device and Hydraulics Assembly Instructions...

-

Page 41: Inserting Into The Climbing Shoe At Rcs Cl

– pressing the “Cylinder Extend” button on the keypad. – pressing the “Cylinder Extend” button on the connected remote control. 4. Press the “Operation Mode” button (3.17) until the button lights up Fig. D4.12 green. → Interlink-mode operation is activat- RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 42: Final Stroke

Are all climbing shoes serving as verti- cal bearings activated? After climbing ■ Open access points (make building edges safe, if necessary). ■ Uncouple hydraulic hoses. ■ Remove Climbing Device-2 RCS 50. ■ Dismantle Climbing Rail Extension RCS. (For RCS-CL) RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 43: D5 Operation Of Climbing Shoes

Assembly and Use for Rail 5. Proceed in the same manner with Climbing System RCS C or RCS CL. the other folding runner. Top view Runner closed Runner opened 3D view Runner closed Runner opened Fig. D5.01 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 44: Activating The Climbing Shoe

(5.1). → The climbing pawl is activated and operational. Fig. D5.02 ■ Does the climbing pawl (5.1) auto- matically fold out of the climbing shoe? ■ Is the hinged clamp (5.5) in a clear position? Fig. D5.02a RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 45: Deactivating The Climbing Shoe

(5.4) and then let go of the pawl lock. The hinged clamp (5.5) is then wedged and blocks the climbing pawl. → The climbing pawl is locked and non-operational. Is the hinged clamp (5.5) in a clear posi- tion? Fig. D5.03a RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 46: D6 Dismantling The Climbing Device

3. Lift the climbing device out of the climbing shoe. 4. Transport the climbing device up- wards and re-tighten the hoses. Fig. D6.03 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 47: D7 Remedial Measures For Malfunctions

Cause Remedial measure Air in the hydraulic system. Vent the system. Replace climbing device. Pressure-retaining valve is defective. Repairs carried out by PERI. Cylinder sinks. Replace climbing device. Seals defective. Repairs carried out by PERI. Replace climbing device. Dirt in the hydraulic cylinder. - Page 48 Release the climbing pawl by hand. Spring in the climbing shoe is broken. Replace climbing shoe. Repairs carried out by PERI. Locking lever in the cylinder base not en- Correctly place the cylinder base on the bolts of gaged correctly.

-

Page 49: Venting The System

Manual end position compensation If the synchronisation deviation is too great when under load, then carry out a manual end position compensation with the aid of a short-circuit connec- tion. RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 50: Extending The Cylinders To The Same Height

– pressing the “Cylinder Extend” button on the keypad. – pressing the “Cylinder Extend” button on the connected remote control. 4. Press the “Operation Mode” button (3.17) until the button lights up green. → Interlink-mode operation is activat- RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 51: Releasing The Climbing Pawl By Hand

→ The climbing pawl is activated. (Fig. D7 .04 + D7 .04a) 3. Retract the hydraulic cylinder until Fig. D7 .04a the climbing bolt (9.1) is positioned on the pawl (5.1). Are all pawls (5.1) engaged? RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 52: Dismantling The Climbing Device In The Event Of A Broken Spring

Fig. D7 .05 dure can then be completed. ■ After completing the climbing proce- dure, replace the climbing device or have repair work carried out by PERI. Procedure 1. Retract piston until the claw (1.1) is guided around the climbing bolts (9.1). -

Page 53: Changing The Phase

Fig. D7 .06 round. Changing 1. Turn the phase inverter in the Pow- er Cable RCS MAX CEE-32A 2 m (4) through 180°. → The rotary field is changed. (Fig. D7 .06 + D7 .06a) Fig. D7 .06a RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 54: E1 Hydraulic Connection Diagram

Display RCS MAX to one climbing group. Single climbing unit Cylinder 1 Cylinder 2 Power supply Fig. E1.01 Climbing group Climbing unit 2 Climbing unit 3 to maximum Climbing unit 1 climbing unit 8 Power supply Fig. E1.02 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 55: Connection Of Multiple Climbing Groups

E1 Hydraulic connection diagram Connection of multiple climbing groups Remote control Remote control Fig. E1.03 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 56: E2 Climbing Device Circuit Diagram

E2 Climbing device circuit diagram Climbing Device-2 RCS 50 Item no.: 135413 230 bar Fig. E2.01 RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 57: F1 Maintenance Chart

Maintenance chart Maintenance lo- Name/Signa- cation Comment Date ture RCS-2 Climbing Device and Hydraulics Assembly Instructions... -

Page 58: F2 Declaration Of Incorporation

Declaration of incorporation RCS-2 Climbing Device and Hydraulics Assembly Instructions... - Page 59 Declaration of incorporation RCS-2 Climbing Device and Hydraulics Assembly Instructions...

- Page 60 Declaration of incorporation This document is a translation into English from the German original. RCS-2 Climbing Device and Hydraulics Assembly Instructions...

- Page 61 Declaration of incorporation RCS-2 Climbing Device and Hydraulics Assembly Instructions...

-

Page 62: Rcs-2 Climbing Device And Hydraulics

Hydraulic Unit RCS MAX 2x 210bar, 380-460V Note 135500 47 .000 Hydraulic unit for driving 2x Observe the manufacturer’s assembly instructions! Climbing Device-2 RCS 50. For Technical Data see PERI Product Information. Only use original PERI Hydraulic Oil. Accessories 135606 0.100 Return Flow Filter RCS MAX 135607 0.100... - Page 63 RCS-2 Climbing Device and Hydraulics Item no. Weight kg Power Connection Cable RCS MAX Note 135498 2.500 Power Connection Cable RCS MAX 10 m Observe the manufacturer’s assembly instructions! 135501 4.700 Power Connection Cable RCS MAX 20 m For power supply between max. 8 Hydraulic Units RCS Max 2x 210 bar.

- Page 64 For wireless data connection between Group IN and Group OUT modules are paired with Hydraulic Units RCS Max 2x 210 bar groups of one another. two. For Technical Data see PERI Product Information. Remote Control RCS MAX 15 m Note 135506 2.500 Remote control for simultaneous operation of one Observe the manufacturer’s assembly instructions!

- Page 65 RCS-2 Climbing Device and Hydraulics Item no. Weight kg Display RCS MAX Note 135507 1.600 For monitoring of information via Observe the manufacturer’s assembly instructions! RCS Max Hydraulic Unit 2 x 210 bar. Cable length: 1.5 m Accessories Display Holder RCS MAX 163043 0.100 Display Holder RCS MAX Complete with 136043 0.100 Spare part for Display RCS MAX for attachment to 1 pc.

- Page 66 RCS-2 Climbing Device and Hydraulics Item no. Weight kg 135606 0.100 Return Flow Filter RCS MAX Note Spare part for Hydraulic Unit RCS Max 2 x 210 bar. Observe the manufacturer’s assembly instructions! Ø 135607 0.100 Air Filter RCS MAX Note Spare part for Hydraulic Unit RCS Max 2 x 210 bar.

- Page 67 RCS-2 Climbing Device and Hydraulics Item no. Weight kg 135411 1.000 Conversion Set Climbing Device-2 RCS 50 Note Conversion set for conversion of Always observe the conversion set instructions Climbing Device RCS 50 to a Climbing Device-2 (see Document DO-19-0265205). RCS 50. Hydraulic Twin Hose RCS Complete with 110069 8.500 Hydraulic Twin Hose RCS 10 m...

- Page 68 18.300 Hydraulic oil ISO 11158 HVI46, 20L oil, in particular for transport, storage and dispos- High-quality synthetic hydraulic oils for PERI al! Observe the technical documentation for the hydraulic units with different viscosities suitable hydraulic unit! Product data sheet on request.

- Page 69 201.000 Hydraulic oil ISO 11158 HVI46, 210 l oil, in particular for transport, storage and dispos- High-quality synthetic hydraulic oils for PERI al! Observe the technical documentation for the hydraulic units with different viscosities suitable hydraulic unit! Product data sheet on request.

- Page 70 FF Coupling Pair X-GE12PSR-ED+ Complete with 129424 0.440 Spare parts set for PERI hydraulic components 1 x 128992 Plug ISO16028 DN10 R3/8IG with quick-release couplings X-GE12PSR-ED+. 1 x 128993 Socket ISO16028 DN10 R3/8IG 2 x 051750 Screw fitting X-GE 12PSR-ED...

- Page 71 RCS-2 Climbing Device and Hydraulics Item no. Weight kg 128992 0.140 Plug ISO16028 DN10 R3/8IG SW27 128993 0.280 Socket ISO16028 DN10 R3/8IG SW27...

- Page 72 1 x 135174 Imbus SHR Screw Insert AF 06 1 x 135175 Imbus SHR Screw Insert AF 08 1 x 135176 Imbus SHR Screw Insert AF 10 1 x 135177 SHR Screw Piece 6. Tl. Slot/PH 2 x 711035 PERI Label 128 x 65 mm 1 x 126434 Service Case Contents List 126001 0.060 Bolt ISO 4017 M12 x 60-8.8, galv.

- Page 73 RCS-2 Climbing Device and Hydraulics Item no. Weight kg 780702 0.006 Washer ISO 7089 200 HV, A12, galv. Corresponds to old standard DIN 125 Form A 723805 0.017 Hex Nut ISO 4034 M12-5 SW 18...

- Page 74 Bridge Formwork Tunnel Formwork Shoring Systems Construction Scaffold Facade Scaffold Industrial Scaffold Access Protection Scaffold Safety Systems System-Independent Services Accessories PERI GmbH Formwork Scaffolding Engineering Rudolf-Diesel-Strasse 19 89264 Weissenhorn Germany Tel. +49 (0)7309.950-0 Fax +49 (0)7309.951-0 info @ peri.com www.peri.com...

Need help?

Do you have a question about the RCS-2 and is the answer not in the manual?

Questions and answers