Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Viadrus G 700

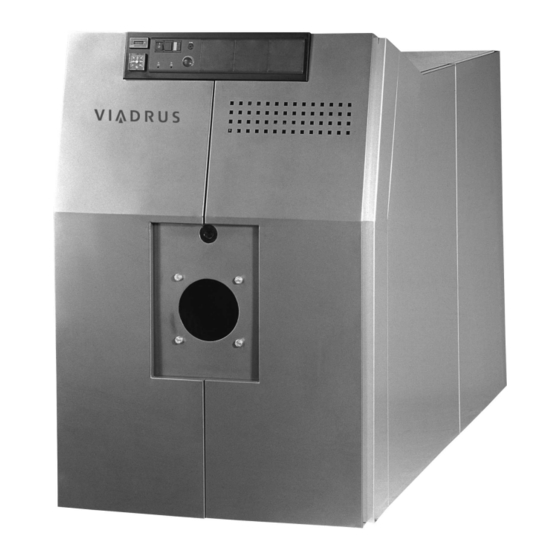

- Page 1 MANUAL for boiler operation and installation VIADRUS G 700...

- Page 2 Dear customer We thank you that you have bought the VIADRUS G 700 boiler thus having shown your confidence in ŽDB a.s.Bohumín, VIADRUS Heating technology Enterprise. For you to get used to a correct way of handling your new product from the beginning please read at first this manual for its usage (first of all the chapter no.8 –...

-

Page 3: Table Of Contents

9. Instructions for product disposal after its service life ………………17 10. Guarantee and liability for defects ………………………………….18 Purchase order: Purchase order specification code (type designation) G 700 X X X X Type of Number of Way of delivery: Type of burner:... -

Page 4: Boiler Use And Advantages

Boiler use and advantages A single-row cast-iron sectional hot-water boiler with an overpressure combustion chamber and a direct firing designed for gas (natural gas) and fluid fuels ( furnace oil extra light ) central heating . The pressure burners used in combination with boiler must correspond to: ČSN EN 676: 2000 –... -

Page 5: Boiler Technical Data

2. Boiler technical data Tab. č. 1 Boiler thermal-technical parameter boiler (fuel : natural gas H, furnace oil extra light) Boiler size-number of sections Nominal output Reduced output According to the power range of particular type of burner Input range Efficiency min. -

Page 6: Description

The gas flow is specified at the gas temperature and 0 °C and 1013,25 mbar air pressure For a particular temperature and pressure the real consumption is calculated as follows : 1013,25 . (273 + t) V = V ---------------------------------------- p . - Page 9 1. frontal section 16. flange 170x170 32. upper part of shell 2. insertion 17. distribution pipe with a sleeve 33. rear part of shell upper, lower 3. central section 18. return water flange 34. rear part of shell central 4. rear section collector 19.

-

Page 10: Electric Wiring Diagram

4.2. Electric wiring diagrams Fig.no.2 Electric panel wiring diagram... - Page 11 Legend to Fig.no.2: F1 fuse 6,3A BT2 service thermostat NOTE: S1 main switch X 10 burner connector Water pressure manostat (PS1) only in design for H1 boiler under voltage signalling H3 burner defect signalling MORA firm, in case it isn’t used connect the Z1 suppression component burner stage...

- Page 13 Fig.no.3 Electric panel wiring diagram...

-

Page 14: Positioning And Installation

4. Positioning and installation 4.1. Boiler positioning in boiler room The boiler is designed to be positioned in closed rooms with low or medium aggressiveness in view of electrical regulations in an ordinary environment (ČSN 33 2000 – 7 – 701:1997). It is suitable for installation in rooms separated from the housing premises (Regulation 91/93 Coll., ČSN 07 0703:1986 Gas boiler rooms). -

Page 15: Regulations And Guidelines

the pump damage. Water for boiler and heating system filling must be clear and colourless , with no suspended materials, oil and aggressive chemicals. Parameters of circulating and refilling water must correspond with standard as follows : Tab. č. 3 The maximum permissible values of heating water according to e ČSN 07 7401:1992 hardness (mmol/l) Ca2+... -

Page 16: Assembly Procedure

Don’t put any objects made of flammable materials on boiler and within a distance smaller than the safe distance from the boiler. 5. Assembly procedure The assembly procedure is described in „ VIADRUS G 700 boiler assembly manual “. 6.Commisioning The boiler commissioning, heat output setting and any interference with boiler electric part or... -

Page 17: Verification Activities Before Commissioning

6.2. Operation The boiler can be operated with both gaseous and liquid fuels and with burners tested and approved by Engineering Testing Institute Brno. Recommended types of burners - see chap. No. 3 – VIADRUS G 700 boiler technical data . -

Page 18: Maintenance

ŽDB a.s. Bohumín, Závod topenářské techniky VIADRUS, the boiler manufacturer , otherwise the guarantee for boiler proper function is void. „ VIADRUS G 700“ boiler quality and completeness certificate” after having been filled by contractual service organization serves as the “Guarantee certificate”. -

Page 19: Instructions For Product Disposal After Its Service Life

All skilled interventions can only be done by a professional contractual service organization trained by the manufacturer. Before the cleaning works you must disconnected the boiler from el. network and the burner from fuel supply, open the closing plate with burner, which makes the combustion chamber and convection parts chambers accessible for cleaning. - Page 20 ČSN EN 1775 to check the boiler regularly once a year. The checks can only be done by an authorized organization (contractual service), accredited by ŽDB a.s. Bohumín, Závod topenářské techniky VIADRUS and the manufacturer of the burner being operated. – To document all records about carried out guarantee and after-guarantee repairs and regular annual checkups in the annex enclosed to this guarantee certificate which belongs to boiler revision book.

- Page 23 1 – frontal section 2 – insertion 3 – central section 4 – rear section 5 - flue gases collector 6 – small cleaning cover 7 –explos. flap holder 8 – explos. flap 9 – closure 10 – closing plate 11 - hinge 12 –...

Need help?

Do you have a question about the G 700 and is the answer not in the manual?

Questions and answers