Summary of Contents for Viadrus G 700

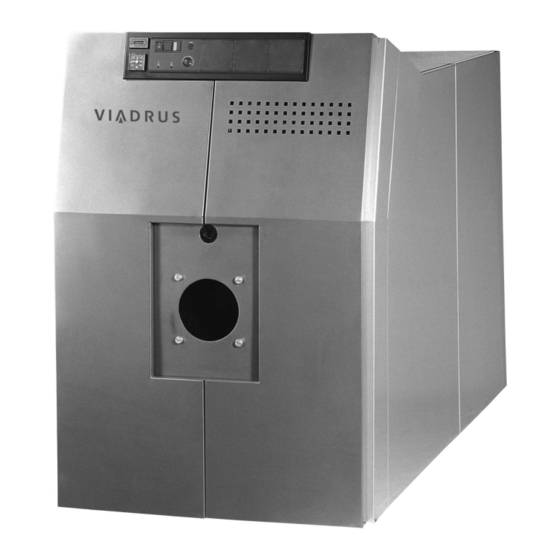

- Page 1 VIADRUS G 700 Herc ules U26 MANUAL FOR BOILER OPERATION Návod k obsluze AND INSTALLATION...

-

Page 2: Table Of Contents

Table of Contents: page Boiler use and advantages ........................3 Boiler technical data ..........................4 Description ..............................5 Boiler construction ..........................5 Electric wiring diagrams ........................8 Positioning and installation ........................9 Boiler positioning in boiler room ......................9 Regulations and guidelines .......................10 Order, delivery and assembly .........................12 Order ..............................12 Delivery and accessories ........................12 Assembly procedure .........................12... -

Page 3: Boiler Use And Advantages

Dear customer, we thank you that you have bought the VIADRUS G 700 boiler thus having shown your confidence in VIADRUS a.s. For you to get used to a correct way of handling your new product from the beginning please read at first this manual for its usage (first of all the chapter no.7 –... -

Page 4: Boiler Technical Data

Boiler technical data Tab. no. 1 Thermo – technical Parameters of the Boiler (Fuel: Natural gas H, heating oil extra light) Boiler size (number of sections) Nominal power Lower step Power In accordance with a range of selected burner type Power Intake range Minimum efficiency 91,5... -

Page 5: Description

The gas flow is specified at the gas temperature and 0 °C and 1013,25 mbar air pressure. For a particular temperature and pressure the real consumption is calculated as follows: 1013,25. (273 + t) V = V ---------------------------------------- p. 273 gas volume at a given pressure and temperature gas volume at 0°C and 1013,25 mbar gas temperature (°C) - Page 7 Legend: frontal section 25. side part of shell frontal right insertion 26. side part of shell central section 27. side part of shell rear rear section collector 28. frontal part of shell segment 2 right flue gases 29. frontal part of shell segment 2 left small cover for cleaning 30.

-

Page 8: Electric Wiring Diagrams

Electric wiring diagrams BOILER REGULATION Fig. No.2 RZ 20 Regulation wiring diagram... -

Page 9: Positioning And Installation

Positioning and installation Boiler positioning in boiler room The installation of the boiler must comply with all requirements of ČSN 06 1008 The boiler is equipped with a movable mains supply and a plug. The boiler must be according to EN 60 335 –... -

Page 10: Regulations And Guidelines

Tab. no. 3 Grade of reaction to fire Examples of building materials and products included in the reaction to fire Grade of reaction to fire (Extract from EN 13 501-1 + A1) A1 – incombustible Granite, sandstone, concrete, bricks, ceramic tiles, mortars, fireproof plasters, … A2 –... - Page 11 EN 1775 Gas supply - Gas pipework for buildings - Maximum operating pressure less than or equal to 5 bar - Functional recommendations. EN 12007-1 Gas supply systems – Pipelines for maximum operating pressure up to and including 16 bar – Part 1: General functional recommendations EN 12007-2 Gas supply systems –...

-

Page 12: Order, Delivery And Assembly

VIADRUS G 300, G 700 model 2007 At request boiler equipment isn’t included in boiler basic price. Assembly procedure The assembly procedure is described in „VIADRUS G 700 boiler assembly manual“. Boiler jacket (with insulation) Complete boiler body... -

Page 13: 5.3.1 Boiler Jacketing

! Warning ! The anchor bolts are fit with springs in back side, which must be pressed in length of 32 mm. At boiler transportation and handling may come to release or spring compression. Before jacket mounting on boiler body there is necessary to check above-mentioned compression. If the length is bigger than specified length –... - Page 14 11 – 12 13 – 14 sections sections sections sections Side jacket part – front left one Front jacket part – 2 left one Upper jacket part Electropanel cover Front right side jacket part Front jacket part – 2 right ones Back jacket part, back one and bottom one Back jacket part –...

-

Page 15: Commissioning

Commissioning The boiler commissioning, heat output setting and any interference with boiler electric part or connection of additional control elements can only be done by a contractual service organization authorized to do the service works and a firm authorized to service the burner being operated. 1. -

Page 16: Important Warnings

1. Main switch 6. Thermomanometer 2. Blind flange 7. Blind flanges 3. Safety thermostat 8. Fuse 10 A 4. Service thermostat 9. Burner failure signalling 5. Running hours counter 10. Heating water temperature exceeded – signalling Fig.no. 6 Electric panel Important warnings The boiler only can be used for the purpose that it is destined for. -

Page 17: Maintenance

16. The user is obliged to have the commissioning, regular maintenance and defects elimination done by professional contractual service accredited by VIADRUS a.s., the boiler manufacturer, otherwise the guarantee for boiler proper function is void. „VIADRUS G 700“ boiler quality and completeness certificate” after having been filled by contractual service organization serves as the “Guarantee certificate”. -

Page 18: Instructions For Product Disposal After Its Service Life

Instructions for product disposal after its service life VIADRUS a.s., is contractual partner of firm EKO – KOM a.s. with client number F00120649. The packages comply with EN 13427. Because the product is made of common materials its individual components are recommended to be... - Page 19 Information for customer Packaging identification Assessment reference PE Plastic sacks, folie, corrugated board, iron and plastic fix line Identification of principal materials used. Paper, Polyethylene, iron, wood Part 1: Summary of assessment Standard/Report Assessment requirement Claim Note 1.1 Prevention by source reduction 1.2 Heavy metals and ensure below maximum permitted levels...

- Page 20 Date of revision 16/2013 – model 2007 – GB...

Need help?

Do you have a question about the G 700 and is the answer not in the manual?

Questions and answers