Table of Contents

Advertisement

WARNING

Improper installation, operation, adjustment, alteration, servicing and or

maintenance may result in property damage and or serious bodily injury!

Ensure all safety symbols described in section

2.2 Safety Symbols

are

observed and their descriptions read thoroughly to understand their

meanings!

Ensure all safety notes detailed in section

2.3 Safety Notes

including

it's sub-sections are read in it's entirety and understood before any

installation, operation, maintenance and or servicing of this machine!

Failure to comply to all safety notes and procedures set out in this manual

may result in property damage and or serious bodily injury!

1

DS-1200 G4i Operator Manual

Issue 4 - Nov 2020

Advertisement

Table of Contents

Summary of Contents for quadient DS-1200 G4i

- Page 1 Failure to comply to all safety notes and procedures set out in this manual may result in property damage and or serious bodily injury! DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 2: Table Of Contents

7.1.1 Defining the mailset .............28 7.1.2 Defining the output settings ..........36 7.1.3 Defining Postage/Metering settings .........39 7.1.4 Saving the Job .............41 7.2 Creating an envelope ..............42 7.3 Creating a document ...............44 DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 3 11 Operator Adjustments ..............58 11.1 Setting the fingers ..............58 11.2 Replacing the sheet feeder pick-up rollers ........61 11.3 Replacing insert & envelope feeder pick-up rollers .....62 12 Troubleshooting guide ..............64 DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 4: Introduction

This product complies with FCC 47CFR Part 15B Class A, Federal Communications Commission (FCC), in all states and territories of the United States. Applicable EU Directives Low Voltage Directive 2014/35/EU Electromagnetic Compatibility Directive 2014/30/EU DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 5: End Of Life

For more information on the correct disposal of this product please contact your local dealer. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 6: Safety

Identifies equipment that is fused. Observe correct fuse ratings where possible before replacing. Caution/Warning Indicates a situation in which minor, moderate, or serious injury could occur because of the hazard present. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 7: Safety Notes

• When the machine is not in use, the mains power cable should be completely disconnected from the electrical power supply, stored and positioned safely. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 8: Power Connections Safety Notes

Insert Head and unplugging the mains power cable completely from the mains electrical power supply, or switching off the wall isolator switch if fitted. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 9: Description Of Machine

(up to 8 sheets C or Z fold, 10 sheets V fold). May be fitted with an op- tional 2-bin sheet diverter. Available in Hi-Cap (5000-sheet) or Standard Cap (2000-sheet) versions. Reading or non-reading versions available. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

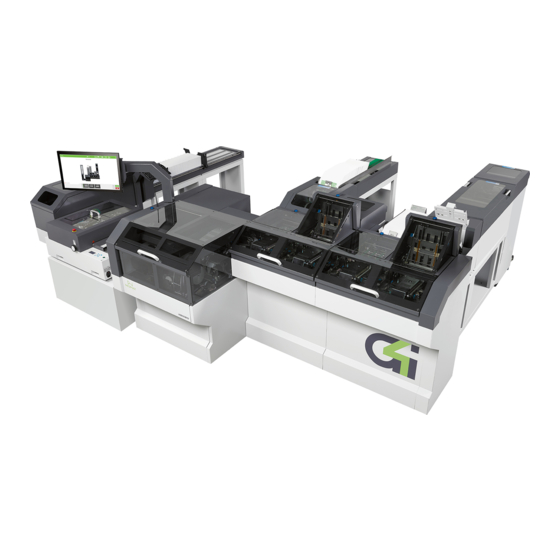

Page 10: Identification Of Parts

No manual setting of the fold plates or envelope closer is required, these being adjusted automatically according to the settings in the selected program. 3.3 Identification of parts The main parts of the machine are shown below: DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 11 Envelope is then turned over for correct orientation and passes to a flap wetter/closer to close the flap. The flap is sealed shut as the filled envelope passes through the exit. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 12: Control Panel

4.1 The Menu Screen The Menu screen can only be accessed if you have the correct access rights. To access, select Libraries functions are described in detail further in this document. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 13: The Job Screen

Press ‘Help’ to access this document. Press ‘Remote Assistant’ to access assistance via Team Viewer - see Remote Assistant for further details. See section 5.1 Running an existing job to run a job directly from this screen. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 14: The Run Screen

Isolator switch located at the rear of the Insert Head to the OFF position. Press F4 to display the counts at all available exits. (Only available with appropriate access rights). DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 15: Counter Settings

This cycles through the main output count, and the counts for the output devices, depending upon the machine configuration, eg. Output Diverts. Also indicates whether the Vertical Stacker jog is on or off. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 16: Fine Tuning Of Settings

This changes the gap on the unit and applies to all jobs: see also Gap Adjust below. • Documents: Changes to the envelope depth, width, flap and throat. • Wetting: changes the amount of wetting (1-8) where higher numbers give greater wetting. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 17 On the Run screen graphic, press anywhere on the Feeder icon. Note that each heading expands. You can change: • Feed control mode: Turn off to disable feeder. • Doubles detect: Turn off if thick or dark documents give false readings. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 18 If documents are not properly picking up, move it forward. The shield is initially set in the inserter unit setup in the Fine Tuning screen. Adjustments will increment or decrement this initial setting. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 19 Separator wear: Adjust separator gap only if needed (1 clock = 0.015mm). This changes the gap on the unit and applies to all jobs: see also Gap Adjust below. • Documents: Changes to the insert depth & width. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 20 Gap Adjust: Adjusts the separator gap for this document only (1 clock = 0.015mm). Note that this is relative to Separator Wear, and adds to or subtracts from that setting. The setting is saved with this document and remains for future uses. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 21: Remote Assistant

Communicate the ID and Password to the support engineer, and the link will then be formed between you. The support engineer will gain full control of the machine’s PC to allow fault diagnosis. To end the Team Viewer session, simply close the App. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 22: Running A Job

Select Jobs button at the top. To run the job currently showing on the Run screen, press Exit. To run a different job instead, select it from the list and press Accept. You will switch to the Run screen with that job. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 23 Load paper and envelopes in hoppers indicated. Press Run. See also section 4.3 The Run Screen for a full description of the controls. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 24: Switching The User

NOTE: Available functions will depend on who you log on as. See section 6.2 User Access Rights for further information. Select User button in Job or Run screen. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 25 Select user from list and press Log On. New jobs can be created by pressing ‘New’. This will only be available to users with the correct access rights. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 26: User Access Rights

The rights available to you will depend on the username you log on as. NOTE: User access rights can be created or modified only if logged in at the appropriate level of user. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 27: Creating A Job

To use an OMR or Barcode definition, it must exist as part of the document creation. See section 7.3 Creating a document for further information. 7.1 Creating the Job Settings Press New in the Job screen to start defining the mailset. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 28: Defining The Mailset

7.1.1 Defining the mailset Selecting the envelope Press Select to choose envelope from the library. Select the required envelope and press OK. To create envelopes in the library, see section 7.2 Creating an envelope. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 29 6. For track speed 7 to 10, the turnover will run at speed 10. Insert track offset: +ve moves track guide outwards to widen track. For Feeder or Folder, applies to that unit only. For Inserter, applies to all units at once. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 30 Selecting the document Press Select to choose document from the library. Select the required document and press OK. To create documents in the library, see section 7.3 Creating a document. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 31 Select fold type required only if you have a requirement to deviate from default. Mark Reading: Set mode of reading required. This will vary depending upon reader type fitted (Off is the only available option for non-reading feeder). DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 32 It will operate downstream of the detection point. The mode will detect and automatically remove sequence errors and assume that the sequence error has been generated by a double document feed. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 33 Speed Control: Unit speed: Set if it is required to vary unit speed from machine speed. Of most use on a Collator where large group sizes will take longer to collate. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 34 Select document type for Additional doc 1 if some documents being fed have an attachment. Repeat in similar manner for remaining units fitted. If you are using Substitution Tables, press Edit Advanced. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 35 Sheet divert 1 is the lower tray, output divert 1 is closest to machine. To delete all substitutions, select Clear all. IMPORTANT: Any substitutions set in the Job setup will apply to only to that job. Press Next when complete. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 36: Defining The Output Settings

(where fitted). Brush offset: Adjusts the degree of contact of the brush with the envelope. this may be need, for example, if you are using thick packs. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 37 On (Dynamic) recieves calculated weight data from the inserter and compares it to the weighed data; if there is a disparity, an error will be flagged. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 38 Select the Diverts button at the top of the screen (if output diverts are fitted). Set the divert category for Envelope divert 1, 2 & 3 and the criteria to trigger Jog 1 & 2 mode (where these are fitted). Press Next when finished. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 39: Defining Postage/Metering Settings

Press the settings button for Postal Product and select an existing product, or New to create one. Enter required options as described below. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 40 The weight of the filled envelope is determined by the weight of each inserted document, and the envelope. These are set in the Document and Envelope options in the Setup screen. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 41: Saving The Job

Divert BCS Character. Options are Off (default) or On (all). Checking: If Checker required is selected, a checker is required to login at the same time as the operator. The checker is responsible for confirming, job settings, processing etc. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 42: Creating An Envelope

7.2 Creating an envelope 7 Creating a job) and select an envelope. Begin creating a job (see section In the Envelope selection box, press New. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 43 Default is 3, maximum is 8. Press Save when done. The envelope is now fully defined and is available for use. Envelopes can also be created from the Menu screen if you have appropriate access rights. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 44: Creating A Document

7.3 Creating a document 7 Creating a job). Begin creating a job (see section In the Document selection box, press New. Enter a document name. Select Form type (usually General type) DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 45 Press Save when done. The document is now fully defined and is available for use. Documents can also be created from the Menu screen if you have appropriate access rights. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 46: Setting Up The Machine

When a trolley is set for a paper type, it should only be used for that paper type, to avoid readjustment. If other paper types are used, further trolleys should be obtained. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 47: Loading The Feeder Hoppers

1. Backstop 2. Ensure inserts are correctly orientated so they enter the envelope the right way. 3. Side guide adjustment knob DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 48: Loading The Envelope Hopper

- it will automatically adjust to the correct tension when the machine starts operating. 1. Backstop 2. Load envelopes stack to follow the contour of the track. Flaps must face upwards and forwards. 3. Side guide adjustment knob. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 49: Vertical Stacker

The Vertical Stacker is fitted with a jog function. may also be fitted with an optional ink marker. This is described in section 7.1.2 Defining the output settings shown in extract below: DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 50 Press and hold the button to run out all envelopes and activate the conveyor. NOTE: If the conveyor is allowed to fill up without emptying, the machine will stop with an error when it is full to capacity. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 51: Operator Maintenance

NOTE: The belts may be moved round using the run-off button when the mains switch is on. Avoid using strong spirit-based cleaners or solvents, as these may damage the belts. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 52: Cleaning Rollers

Clean the conveyor belts and the rollers using a clean, lint-free cloth dampened with water. Turnover Clean the turnover belts and also the large aluminium wheels that they run on. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 53: Cleaning Sensors

Sensor locations are indicated in the Track shuttle figure below. Track shuttle Viewed from behind the machine). Open the top covers of the track stations. Raise the shuttle and the overguide to access the sensors. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 54 Raise the cover at the input end to access the sensors. Pull back the latches and raise the roller covers to access the underside. NOTE: A feeder is also fitted behind the envelope opener - ensure these sensors are also cleaned in the same way. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 55 Envelope Opener Located behind the insert head, just in front of the envelope feeder. Lift the black handle to gain access. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 56 Kicker/Insert area Unlatch the blue handle and lift up the kicker to gain access. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 57 Turnover With the insert cover raised, the sensors will be seen at the bottom of the turnover. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 58: Operator Adjustments

(see section Adjust the throat depth setting on the side of the Kicker to match the envelope and job setting. Tighten the lock screw when finished. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 59 ‘single cycle’ the machine using the remote control until an envelope has appeared at the insert plate. Adjust the finger position by loosening the blue lock screws A and B. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 60 The finger set can be removed from the left-hand and right-hand sides by removing the lock screw on the end of the finger shaft. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 61: Replacing The Sheet Feeder Pick-Up Rollers

These are easily removed by sliding the spring loaded roller assembly to the left and lifting from the right. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... -

Page 62: Replacing Insert & Envelope Feeder Pick-Up Rollers

First remove the steel over guide by pressing the sides together to release the clips from the roller bearings. Slide the complete spring loaded roller assembly to the right to release the drive dog on the left-hand end. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 63 Lift the roller assembly from the left-hand side to remove. IMPORTANT: When replacing the roller assembly, make sure the drive dog is fully engaged as below. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

-

Page 64: Troubleshooting Guide

Check turnover belts are not misplaced. ver eject (under- neath turnover). 8. Filled envelope a) Wetter roller not fully lowered. b) Carrier on wetter conveyor not failing to leave in- fully seated. sert area. DS-1200 G4i Operator Manual Issue 4 - Nov 2020... - Page 65 Feed in one sheet, open collate conveyor and collate exit” er- measure clearance. c) Steel balls restricting entry - contact Service ror message on Department to remove one or more symmetrically. screen. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

- Page 66 Loose ribbon cable connector at front of shuttle. c) Run with inserts opposite way round or invert- ed. d) Feeder output tapes (at far end of shuttle) incorrectly set. DS-1200 G4i Operator Manual Issue 4 - Nov 2020...

Need help?

Do you have a question about the DS-1200 G4i and is the answer not in the manual?

Questions and answers