Summary of Contents for Burkert 2080 INOX Series

- Page 1 Type 2080 INOX 2/2 way valve with piston actuator and PTFE bellows Operating Instructions...

- Page 2 We reserve the right to make technical changes without notice. © Bürkert Werke GmbH & Co. KG, 2021 Operating Instructions 2103/00_ENen_00815386 / Original DE...

-

Page 3: Table Of Contents

Type 2080 Type 2080 nhalt Operating instructiOns ........................5 symbols ............................5 1.2 Definition of the term “device” ....................5 intended use ............................6 Basic safety instructiOns ......................7 general nOtes...........................8 4.1 Contact address ...........................8 4.2 Warranty ............................8 4.3 Information on the Internet ......................8 structure and functiOn .......................9 5.1 Modularity ............................9 5.2 Design ............................9 technical data ..........................10 6.1 Operating conditions .........................10... - Page 4 Type 2080 7.1.3 Installation........................14 Maintenance, MalfunctiOns ......................15 8.1 Maintenance / cleaning ......................15 8.2 Change bellows ..........................15 8.2.1 Exploded view of spare part replacement Type 2080 INOX ........16 8.3 Faults ............................17 spare parts ............................18 transpOrtatiOn, stOrage, dispOsal ..................19 English...

-

Page 5: Operating Instructions

Type 2080 Operating instructions OperaTing insTrucTiOns The operating instructions describe the entire life cycle of the device. Keep these instructions ready to hand at the operation site. Important safety information! ▶ Carefully read these instructions. ▶ Observe in particular the safety instructions, intended use and operating conditions. ▶... -

Page 6: Intended Use

Type 2080 Intended use inTended use Improper use of the bellows valve type 2080 INOX may be hazardous to people, nearby equipment and the environment. The device is designed to control the flow of liquid and gaseous media. ▶ Be sure to observe the permissible data, operating conditions and conditions of use. These are descri- bed in the contract documents, on the type label and in the operating instructions (chapter “5 Structure and function”... -

Page 7: Basic Safety Instructions

Type 2080 Basic safety instructions Basic safeTy insTrucTiOns These safety instructions do not take into account any unforeseen circumstances or events occurring during installation, operation and maintenance. The operator is responsible for observing the location-specific safety regulations, also with reference to personnel. Risk of injury from high pressure. -

Page 8: General Notes

Bürkert Fluid Control Systems Sales Center Christian-Bürkert-Str. 13-17 D-74653 Ingelfingen Tel. +49 (0) 7940 - 10-91 111 Fax +49 (0) 7940 - 10-91 448 E-mail: info@burkert.com international The contact addresses can be found on the back pages of the printed Quickstart. They are also available online at: www.burkert.com Warranty A precondition for the warranty is that the device is used as intended and that the specified usage condi- tions are taken into account. -

Page 9: Structure And Function

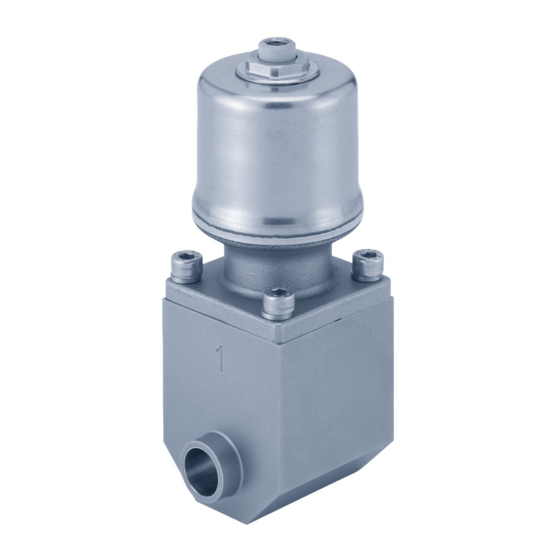

Type 2080 Structure and function sTrucTure and funcTiOn Modularity The device has a modular design and can be supplied with different media connections (also customised) and actuator versions depending on the application. Design The device consists of a pneumatically operated piston actuator with a return spring, a stainless steel housing and a PTFE bellows. -

Page 10: Technical Data

Type 2080 Technical data Technical daTa Operating conditions Ambient temperature –10 ... +90 °C Medium temperature –30 ... +160 °C (see PT diagramm) Flow media Neutral to aggressive gases and liquids, technical vacuum Restrictions For valves with flow direction above the seat: Warning! Risk of injury from pressure surge. -

Page 11: Mechanical Data

Type 2080 Technical data Mechanical data Dimensions See data sheet Materials Valve body Stainless steel 316TI (1.4571) Actuator housing Stainless steel 316L (1.4404) / 316 (1.4408) Bellows PTFE Stroke bellows 2.5 mm Surface quality pipe interior Ra = 0.8 µm Fluidic data Circuit functions 2/2 way valve, externally controlled, closed by spring force without pilot pressure, actuation with pilot valve, valve island or similar. -

Page 12: Type Label (Example)

Type 2080 Technical data Type label (example) Type Control function (CF) DN (diaphragm size) Seal material Body material max. permissible operating pressure permissible pilot pressure range Date of manufacture (encrypted) Order no. Port connection size English... -

Page 13: Installation

Type 2080 Installation insTallaTiOn Warning! Risk of injury due to improper installation. ▶ Installation may be carried out by authorised technicians only and with the appropriate tools. Risk of injury due to unintentional activation of the system and uncontrolled restart. ▶ Secure the system against unintentional activation. ▶ Following installation, ensure a controlled restart. Fluidic installation Danger! High pressure danger! Acute risk of injury when intervening with the system. -

Page 14: Installation

Type 2080 Installation 7.1.3 Installation Warning! Danger due to medium leakage. Leaky connections with incorrect seating of the seals. ▶ Install all connections carefully and make sure the seals are seated properly. Use suitable sealing material to seal the threaded connections (PTFE tape is recommended). For threaded connections: Use open-end wrenches of the appropriate size to screw in the pipelines and do not use the valve actuator as a screw-in lever. -

Page 15: Maintenance, Malfunctions

Type 2080 Maintenance, malfunctions MainTenance, MalfuncTiOns Danger! ▶ Danger due to high pressure in the system. Acute risk of injury when intervening in the system. ▶ Before loosening lines and valves, turn off the pressure and vent the lines. Risk of injury from discharge of pressure and escaping medium. Dismantling a device that is under pressure is hazardous due to a sudden discharge of pressure or escaping medium. -

Page 16: Exploded View Of Spare Part Replacement Type 2080 Inox

Type 2080 Maintenance, malfunctions Change bellows → Unscrew the bellows from the spindle. → Clean the inside of the valve body. → Screw the new bellows onto the spindle with two fingers until it stops (tightening torque approx. 0.2 Nm; too much tightening torque can damage the bellows!). Install actuator →... -

Page 17: Faults

Type 2080 Maintenance, malfunctions Faults Check in case of faults: • Port connections • Operating pressure • Pilot air supply to the valve actuator • Bellows • O-ring Replace the O-ring if damaged (see chapter “8.2 Change bellows”). → If the valve still does not actuate, contact your local Bürkert Service representative. English... -

Page 18: Spare Parts

Type 2080 Spare parts spare parTs Caution! Risk of injury and/or damage due to incorrect parts. Incorrect accessories and unsuitable spare parts may cause injuries and damages to both the device and the area around it. ▶ Use only original accessories and original replacement parts from Bürkert. Spare parts order table Spare part Description Order no. -

Page 19: Transportation, Storage, Disposal

Type 2080 Transportation, storage, disposal TranspOrTaTiOn, sTOrage, dispOsal note! Transport damages. Inadequately protected devices may be damaged during transport. ▶ Protect the device against moisture and dirt in shock-resistant packaging during transportation. ▶ Avoid exceeding or dropping below the permitted storage temperature. Incorrect storage may damage the device.

Need help?

Do you have a question about the 2080 INOX Series and is the answer not in the manual?

Questions and answers