Summary of Contents for AVANT A35945

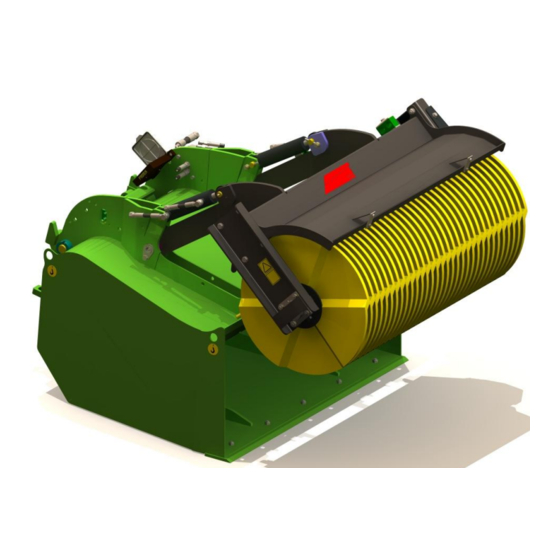

- Page 1 Bucket Broom 2015 1 Operator's Manual for Attachment Bucket Broom Product number 1000 mm A35945 1000 mm with water spraying system A36023 1500 mm A35689 1500 mm with water spraying system A36024 www.avanttecno.com...

- Page 2 Bucket Broom 2015 1...

-

Page 3: Table Of Contents

Bucket Broom 2015 1 CONTENTS 1. Foreword ................................. 4 2. Designed purpose of use ..........................5 3. Safety instructions ............................6 4. Technical specifications ..........................9 Safety labels and main components of the attachment ....................9 5. Attaching the broom to the loader ......................11 Connecting and disconnecting the hydraulic hoses ...................... -

Page 4: Foreword

If you sell or transfer the equipment, be sure to hand over this manual to the new owner. If the manual is lost or damaged, you can request a new one from your Avant dealer or from the manufacturer. -

Page 5: Designed Purpose Of Use

Using the broom is allowed only by using the controls of the loader while sitting on the driver’s seat of the loader. For cleaning large yard or road areas we recommend the Avant Collecting Broom. -

Page 6: Safety Instructions

6 (26) 3. Safety instructions Please bear in mind that safety is the result of several factors. The loader-attachment combination is highly powerful and improper or careless use or maintenance may cause serious personal injury or property damage. Due to this, all operators must carefully familiarise themselves about correct use and the operator's manuals of both the loader and the attachment before starting operation. - Page 7 7 (26) Shut down the loader and place the attachment to a safe position as shown in Safe stopping procedure before any cleaning, maintenance, or adjustments. Pay attention to the surroundings and any other persons and machines moving in the vicinity.

- Page 8 8 (26) Never allow anyone to get under the raised load or the loader boom. Keep in mind that the loader boom can be lowered or tilted even if the engine has been shut down (crushing hazard). The loader is not intended to be left to keep a load elevated for longer periods.

-

Page 9: Technical Specifications

22,5 MPa (225 bar) 22,5 MPa (225 bar) Suitable AVANT loader: See Table 1 4.1 Safety labels and main components of the attachment Listed below are the labels and markings, which must be visible on the equipment. Replace the warning labels, if they have become unclear or if they have detached completely. - Page 10 10 (26) Attachment identification plate Table 3 - Decal locations and warning messages Decal Warning message A46771 Read instructions before use. A46772 Do not go under a raised attachment or loader boom; stay away from raised equipment. A46803 Crushing hazard, floating attachment bracket and side turning.

-

Page 11: Attaching The Broom To The Loader

11 (26) 5. Attaching the broom to the loader Attaching the attachment to the loader is quick and easy, but it must be done carefully. The attachment is mounted to the loader boom by using the quick attach plate on the loader boom and the counterpart on the attachment. -

Page 12: Connecting And Disconnecting The Hydraulic Hoses

On 400-700 series loaders hydraulic hoses are connected using the multi connector system. If you have an Avant 300-700 series loader with the conventional quick couplers and wish to change to the multi connector system, contact your Avant dealer or service point for instructions or installation services. -

Page 13: Uncoupling And Storage Of The Broom

13 (26) To disconnect the multi connector system, 1. Switch off the auxiliary hydraulics of the loader. 2. While pushing unlock button, turn the lever to disconnect the connector. Conventional quick couplings (alternative couplings for some loader models): Before connecting or disconnecting the standard quick couplings, the residual pressure must be released as shown below. -

Page 14: Using The Broom

14 (26) To prevent freezing of the watering system, ensure that during cold seasons all water is drained from the system. The pump of the watering system will get damaged if water gets frozen inside it. Disconnect the water hoses to drain the system completely. 6. -

Page 15: Checks Before Use

15 (26) 6.1 Checks before use Before starting work, remove large items that can’t be collected with the broom from the working area. Drive carefully on uneven terrain and note the effect of heavy load at the front of the loader to the stability and handling of the loader. -

Page 16: Operating The Broom

16 (26) 6.2 Operating the broom The broom is operated with the auxiliary hydraulics of the loader. The broom has two operating modes: Auxiliary hydraulics control lever: (or electric joystick buttons): Lower broom down Broom rotate Lif broom up Direction of operation: The broom is intended to rotate only to its normal operating direction so that the... - Page 17 17 (26) Rotating speed: Use high engine rpm for best collecting results. Depending on the loader model and drive speed, one or two hydraulic pumps may be used. Note that unnecessarily high rotating speed will wear the broom down more quickly, so the speed should be set according to operating conditions, material being handled, and the drive speed.

-

Page 18: Broom Position Support Pins

18 (26) 6.2.1 Broom position support pins In the lower position, the broom rests on its suppoerting pins. These pins determine the gap between the broom and the edge of the bucket. Set the pins so that when the broom is positioned as in the figure above, the broom will press the ground lightly, and make sure that there will be a gap between... -

Page 19: Water Spraying System

19 (26) 6.3 Water spraying system A water spraying system is available for reducing the spreading of dust during use of the broom. The system contains: 1. 150-litre water tank and an electric pump under the tank 2. shut off valve 3. -

Page 20: Installing The Water Spraying System

20 (26) 6.3.1 Installing the water spraying system The fixing points for the watering system are on the broom as standard and the watering system can be installed later. The installation kit includes all necessary components and the electric harness to operate the watering system. -

Page 21: Maintenance And Service

Finding any fault means that the hydraulic hose or component must be replaced and the equipment must not be used until it is repaired. Spare parts are available from your nearest AVANT retailer or authorised service point. Leave the repair work to professional service technicians, if you don’t have adequate knowledge and... -

Page 22: Cleaning And Lubrication

22 (26) 7.2 Cleaning and lubrication Clean the broom as soon as possible after use, so that it is easier to remove all dirt. A pressure washer and mild detergent can be used. Avoid using solvents or spraying directly at the bristles or hydraulic parts at high pressure. -

Page 23: Bucket Edge Plate

23 (26) 7.4 Bucket edge plate The edge plate of the bucket can be replaced as needed. The spare part code for Bucket broom 1100 is A416775 and for 1500 A416406. Replace also the fasteners of the plate. Replace the plate before the frame of the bucket gets in contact with the ground. - Page 24 SFS-EN ISO 12100, SFS-EN ISO 4413 Mallit / Modeller / Modeller / Modeller / Models / Modellen: Avant Hydraulitoiminen harjalaite; Avant-kuormaajan työlaite Hydraulisk sopvals; arbetsredskap för Avant lastare A35945 Hydraulisk feiemaskin; redskap for Avant minilastere A36023 Hydraulisk rotorkost; redskab til Avant Minilæssere Hydraulic broom;...

Need help?

Do you have a question about the A35945 and is the answer not in the manual?

Questions and answers