Table of Contents

Advertisement

Quick Links

UG2019-35

EVAL-IH-R5IPB-A-V1 Evaluation board

User Guide

About this document

Scope and purpose

This application note is a user guide of the evaluation board for IEWS20R5135IPB. It explains the board' s

hardware and provides detailed instructions on how to use it for addressing various measurement tasks. Finally,

practical examples demonstrate the benefits of the IEWS20R5135IPB in the real application.

Intended audience

This document is intended for owners and users of the evaluation board.

Please read carefully the

recommendations provided in this document for safely operating this board.

Important Notice

Environmental conditions have been considered in the design of the Evaluation and Reference Boards provided

by Infineon Technologies. The design of the Evaluation and Reference Boards is tested by Infineon Technologies

only as described in this document. The design is not qualified in terms of safety requirements, manufacturing

and operation over the entire operating temperature range or lifetime.

The Evaluation and Reference Boards provided by Infineon Technologies are subject to functional testing only

under typical load conditions. Evaluation and Reference Boards are not subject to the same procedures as

regular products regarding returned material analysis (RMA), process change notification (PCN) and product

discontinuation (PD).

Evaluation and Reference Boards are not commercialized products and are solely intended to be used for

evaluation and testing purposes. They shall not be used for reliability testing or production. Hence, the

Evaluation and Reference Boards may not comply with CE or similar standards (including but not limited to the

EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other requirements of the country in which they

are operated by the Customer. The Customer shall ensure that each Evaluation and/or Reference Board will be

handled in a way which is compliant with all relevant requirements and standards in the country in which they

are operated.

The Evaluation and Reference Boards are addressed only to qualified and skilled technical staff, for

laboratory usage, and shall be used and managed according to the terms and conditions set forth in this

document and in any other related documentation provided with the respective Evaluation or Reference Board.

It is the responsibility of the Customer's technical staff to evaluate the suitability of the Evaluation and Reference

Boards for the intended application and the completeness of the Evaluation and Reference Board information

provided in this document with respect to such application

The Customer accepts that the Evaluation and

.

Reference Boards are not intended to be used for life-endangering applications such as medical, nuclear,

military, life-critical or other applications, where failure of the Evaluation and Reference Boards or any results

from the use thereof can reasonably be expected to result in personal injury.

Application Note

Please read the Important Notice and Warnings at the end of this document

V 1.1

www.infineon.com

page 1 of 34

2019-11-25

Advertisement

Table of Contents

Summary of Contents for Infineon EVAL-IH-R5IPB-A-V1

-

Page 1: About This Document

Environmental conditions have been considered in the design of the Evaluation and Reference Boards provided by Infineon Technologies. The design of the Evaluation and Reference Boards is tested by Infineon Technologies only as described in this document. The design is not qualified in terms of safety requirements, manufacturing and operation over the entire operating temperature range or lifetime. -

Page 2: Table Of Contents

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation and Reference Boards. Customer is obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or damages arising out of or resulting from any use of the Evaluation and Reference Boards. - Page 3 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Safety precautions VCC: Supply pin of the IEWS20R5135IPB • CS: Current sense pin of the IEWS20R5135IPB • INN: Control pin of the IEWS20R5135IPB • VDET: Voltage detection pin of the IEWS20R5135IPB • VCE: Collector-to-emitter voltage of the IEWS20R5135IPB •...

-

Page 4: Safety Precautions

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Safety precautions Safety precautions Safety Precautions Table 1 Warning: The operating potential of this board are up to 600 V . Peak operating potentials are up to 1350 V. Do NOT touch the board during operation. Even brief... -

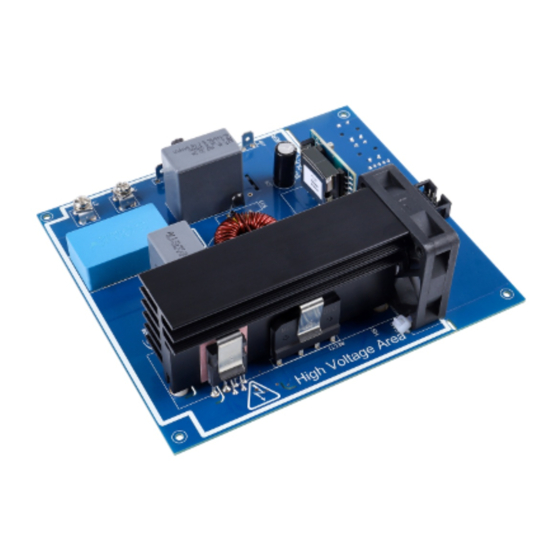

Page 5: Introduction

The evaluation board is delivered together with spare parts and complete documentation in an environmentally friendly carton box as illustrated in Figure 2. As depicted, the box contains: Evaluation board EVAL-IH-R5IPB-A-V1 with a size of 164 mm x 145 mm x 83 mm (LxWxH). •... - Page 6 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Introduction Figure 2 Scope of delivery: evaluation board, spare parts and USB drive with documentation (the picture is only for illustration purpose) For guaranteeing safe measurement procedures, testing points have been provided on the board for the key signals.

-

Page 7: Hardware

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Hardware Hardware This section provides a short description of the board hardware. First, it explains the power circuitry, the auxiliary power stage, the control stage and the connectors. For each of the stages, the main components are presented. - Page 8 IEWS20R5135IPB during operation. An Infineon 32-bit XMC™ 1000 Industrial Microcontroller ARM® Cortex®-M0 has been used as core of the control. The control stage is implemented on a separate area of the evaluation board in order to offer a safe, low-voltage region for controlling the operation of the main converter.

- Page 9 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Hardware The best solution for measuring the collector current is to use a Rogowski current probe, and connect it to • the board as shown in Figure 5b. The measurement of the voltage at the CS pin is particularly tricky, as its value is in the range of hundreds of •...

-

Page 10: Usage

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Usage Usage The main purpose of the evaluation board is to show the features provided by the IEWS20R5135IPB in typical application conditions. While the previous sections explained the basic purpose as well as the hardware of the board, this section provides detailed instructions on how to set up and operate the board. -

Page 11: Tuning Collector-Emitter Voltage Sense Network

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Usage Figure 7 Assembling a device onto the heatsink and the PCB Assembling process is easier than disassembling. Figure 7 presents a possible sequence of steps: 1. Prepare the TO package by cutting the leads to a length of around 5 mm (a). - Page 12 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Usage Figure 8 (a) Schematic of the collector-voltage sensing network; (b) dependence of the over-voltage clamping voltage on the value of RVDET; (c) experimental waveforms of VVDET (green curve, 700 mV/div) and VCE (cyan curve, 200 V/div), time scale: 5 µs/div.

-

Page 13: Tuning Turn-On Detection Point Of The Igbt

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Usage Figure 9 Collector-current sensing: (a) schematic of sense circuit; (b) dependence of the IGBT peak current on the resistance RCS; (c) comparison between IGBT collector current measured by Rogowski coil (yellow curve, 20 A/div) and voltage measured at pin CS (green curve, 60 mV/div), time scale: 10 µs/div. -

Page 14: Tuning Collector-Current Sense Network

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Usage the turn-on point of the IGBT (as shown in Figure 8a). It is recommended to change the value of the resistance only if the value of the resonant capacitance is changed. 4.1.4 Tuning collector-current sense network The IEWS20R5135IPB for induction heating also features an overcurrent protection functionality that allows the IGBT to be switched off as soon as the collector current reaches a selected threshold. -

Page 15: Experimental Results

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Experimental results Operation Once the system has been properly tuned, as explained in the previous sections, the board can be powered up by connecting it to an AC power supply. The nominal value of the AC voltage is 230 V/50 Hz. If not otherwise specified, all the results presented in the following are obtained with such a supply voltage. -

Page 16: Normal Operation And Change Of Output Power

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results 5.1.2 Normal operation and change of output power Table 2 Target output power according to the power setting Power level setting Target input power level (W) 1000 1200 1400 1600 1700 1900 2100 Starting from stand-by mode, by pressing the ON/OFF button once, the system turns on and performs a check to verify the presence of a vessel on the resonant inductor. -

Page 17: Operation In Current Limitation

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results the other hand, when the INN voltage changes from low to high, the IGBT is turned off, with a typical propagation delay of 2.2 µs. The larger propagation delay at turn-off is due to an increased filtering time to avoid spurious turn-off events. - Page 18 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 12 Current limitation operation of IEWS20R5135IPB: (a) 100 Hz envelop, 2 ms/div; (b) single- switching event, 10 µs/div. IC (yellow curve, 20 A/div), VCE (cyan curve, 200 V/div) and INN (magenta curve, 1V/div)

- Page 19 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Application Note 19 of 34 V 1.1 2019-11-25...

-

Page 20: Performing Emc Tests On The Board

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 13 INN voltage change: (a) in overtemperature warning (OTW) operation and (b) in overtemperature shutdown (OTS) (1 V/div – 100 µs/div); (c) schematic of the INN voltage sense Performing EMC tests on the board The most stressful situations for the SEPR-based induction cooking systems occur when the grid voltage experiences sudden changes. - Page 21 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 14 Voltage of the bus capacitor of the SEPR during an instantaneous supply voltage interruption (90 V/div – 5 ms/div): duration of the interruption: 4 ms; amplitude of the interruption: 40% of the peak nominal value...

-

Page 22: Surge Test

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 15 Collector-emitter voltage during the instantaneous supply voltage interruption (200 V/div – 400 µs/div): (a) when current limitation of the IEWS20R5135IPB is active (RCS= 750 Ω); (b) when the current limitation is deactivated (RCS= 0 Ω) As explained previously, a sudden increase of the bus voltage is dangerous for the IGBT as, due to the additional energy that it is stored in the inductance, the VCE peak voltage at turn-off can become extremely high. - Page 23 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 16 Experimental AC input voltage (blue waveform, 200 V/div) and bus capacitor voltage (green waveform, 200 V/div) of the SEPR during a 2 kV surge, time scale: 25 µs/div Figure 17 Experimental waveforms of the IEWS20R5135IPB during a 2 kV surge voltage: IC (yellow waveform, 20 A/div), VCE (cyan waveform, 200 V/div), VINN (magenta waveform, 2 V/div) and bus voltage (green waveform, 200 V/div), time scale: 10 µs/div...

- Page 24 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Experimental results Figure 16 shows the experimental waveforms of the AC input voltage and the bus voltage, during a 2 kV surge event, when the system is in stand-by mode, which means the current in the filter inductor is almost zero. As one can notice, the input AC voltage reaches a peak value of 932 V, limited by the MOV, whilst the bus voltage (green waveform) increases up to 824 V.

-

Page 25: Appendix

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix Appendix Resonant inductor specification The experiment results presented in this document were conducted with a connecting and external coil, suitable for induction cooking systems. As known, the behavior of the SEPR converter is largely dependent on the particular coil and cooking vessel that is used. -

Page 26: Schematic Drawing

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix Schematic drawing Figure 20 Schematic of the board Application Note 26 of 34 V 1.1 2019-11-25... -

Page 27: Board Layout

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix Board layout Figure 21 Layer 1 (top layer) Application Note 27 of 34 V 1.1 2019-11-25... - Page 28 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix Figure 22 Layer 2 (bottom layer) Application Note 28 of 34 V 1.1 2019-11-25...

-

Page 29: Bill Of Materials

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix Bill of materials Designator Description Value Package Reference Power semiconductor IEWS20R5135IPB Infineon Technologies TO-247 6 pin IEWS20R5135IPB Microcontroller XMC1302 ARM Cortex-M0 32-bit MCU Infineon Technologies XMC1302-T038X0200 TSSOP- 38-9 Ceramic Capacitors 47pF/16V/X7R C 0805 10nF/16V/X7R... - Page 30 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix D3, D6 Diode Schottky - VRRM=40V; Vishay Semiconductors SOD-80 IF=400mA LS103A-GS08 D4, D5, D7 Zener Diode VZ=4.7V SOD-80 RECT1 15A Single-Phase Bridge Rectifier, MCC GBJ1510-BP 1000V Thick Film Resistors Current sense resistor Vishay/Dale C 2818 0.010R/10W/1%...

- Page 31 EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Appendix XADC Connector for Auxiliary Supply Daughter Board Mechanical Spring Clip for IEWS20R5135IPB Fischerelektronik THFU 4 Spring Clip for Rectifier Fischerelektronik THFU 1 Isolation pad for IEWS20R5135IPB Al2O3 Ceramic pad for TO- E, L, N...

-

Page 32: Appendix

User Guide Appendix Appendix [1] Infineon Technologies AG: AN2018-34, IPD Protect - features, description and design tips, Revision 1.3. [2] Infineon Flash Programmer Memtool for XMC1000 family, https://www.infineon.com/dgdl/Infineon- TOOL_Tutorial_Memtool_XMC1-TR-v01_00-EN.pdf?fileId=5546d462525dbac401530e93cdc9061f, July 2016 [3] Teledyne LeCroy: Probes – Probe Parts and Kits – Ground Spring – PK007-016, https://teledynelecroy.com/probes/probe-parts-and-kits/pk007-016, September 2017... -

Page 33: Revision History

EVAL-IH-R5IPB-A-V1 Evaluation board User Guide Revision history Revision history Document Date of release Description of changes version v1.0 First release – Giuseppe De Falco V1.1 15-01-2020 BOM update; additional minor changes. Application Note 33 of 34 V 1.1 2019-11-25... - Page 34 For information on the types o you have a question about this given in this application note. in question please contact your nearest Infineon ocument? Technologies office. mail: The data contained in this document is exclusively erratum@infineon.com...

Need help?

Do you have a question about the EVAL-IH-R5IPB-A-V1 and is the answer not in the manual?

Questions and answers