Summary of Contents for Bosch Rexroth GTM Series

- Page 1 Industrial Electric Drives Linear Motion and Service Mobile Hydraulics and Controls Assembly Technologies Pneumatics Automation Hydraulics Rexroth GTM R911297321 Planetary Gearboxes Edition 01 Project Planning Manual...

- Page 2 Date DOK-GEAR**-GTM********-PR01-EN-P 10/2003 First edition 2003 Bosch Rexroth AG Copyright Copying this document, giving it to others and the use or communication of the contents thereof without express authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the grant of a patent or the registration of a utility model or design (DIN 34-1).

-

Page 3: Table Of Contents

Planetary Gearboxes Content Content Introduction to the Product About this Documentation......................1-3 Important Instructions on Use Intended Use ..........................2-1 Introduction ..........................2-1 Fields of Use and Application ....................2-2 Non-Intended Use......................... 2-2 Safety Instructions for Electric Drives and Controls Introduction ........................... - Page 4 Content Planetary Gearboxes Permittable shaft loading ......................6-5 GTM060........................... 6-6 GTM075........................... 6-7 GTM100........................... 6-8 GTM140........................... 6-9 GTM180..........................6-10 GTM240..........................6-11 Dimensional Details GTM060 ............................7-1 GTM075 ............................7-2 GTM100 ............................7-3 GTM140 ............................7-4 GTM180 ............................7-6 GTM240 ............................7-8 Type codes Type codes for the GTM060 ......................

- Page 5 Planetary Gearboxes Content 11.5 Troubleshooting .......................... 11-3 Excess Temperature of Gearbox Housing ................11-4 Gearbox-motor unit generates vibrations ................11-4 Specified position is not attained ................... 11-4 12 How to order 12-1 13 Service & Support 13-1 13.1 Helpdesk ............................. 13-1 13.2 Service-Hotline ...........................

- Page 6 Content Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 7: Introduction To The Product

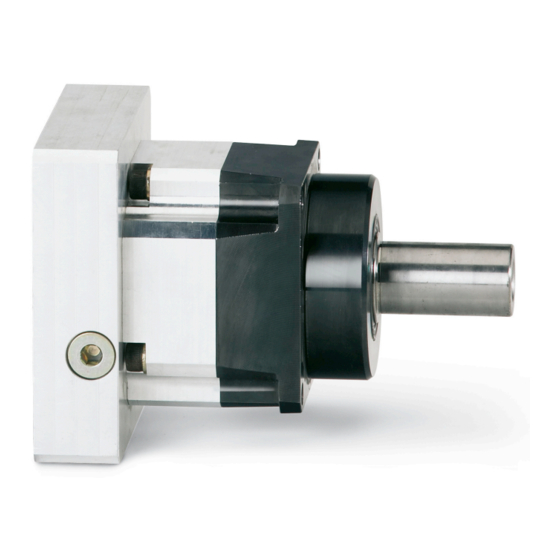

Introduction to the Product MG000001v01_NN.jpg Fig. 1-1: Mounting example: GTM Planetary gearbox on an MKD motor In combination with the drive and control systems of BOSCH REXROTH, Fields of application GTM planetary gearboxes, provide a low-cost automation system for various sectors of industry. - Page 8 Introduction to the Product Planetary Gearboxes The GTM series of planetary gearboxes offers a coaxial input and output. Mode of functioning The output shaft of the motor is connected to the sun gear with a compression clamp coupling. This sun gear drives the planetary gears, which revolve within the ring gear.

-

Page 9: About This Documentation

Planetary Gearboxes Introduction to the Product About this Documentation This document contains safety regulations, technical data, and operating instructions for gearboxes. The individual chapters can be subdivided into the following focal points: Chapter Title Content Introduction to the Product General information Important Instructions on Use Safety Safety Notes... - Page 10 Documents and sheets on standards are subject to copyright protection and may therefore not be passed on to third parties by Bosch Rexroth. If necessary, please contact your local authorized sales outlet or, in Germany, contact: BEUTH Verlag GmbH...

-

Page 11: Important Instructions On Use

Note: For damage caused by products not being used as intended, Bosch Rexroth gives no warranty, assumes no liability, and will not pay for any damages. Any risks resulting from the products not being used as intended are the sole responsibility of the user. -

Page 12: Fields Of Use And Application

(e.g. operation under water, under extreme variations in temperature or extreme maximum temperatures is not permitted), • the intended application is not explicitly released by Bosch Rexroth. Please be absolutely sure to also observe the statements made in the general safety instructions. -

Page 13: Safety Instructions For Electric Drives And Controls

If you do not have the user documentation for your equipment, contact your local Bosch Rexroth representative to send this documentation immediately to the person or persons responsible for the safe operation of this equipment. -

Page 14: Hazards By Improper Use

Safety Instructions for Electric Drives and Controls Planetary Gearboxes Hazards by Improper Use High voltage and high discharge current! Danger to life or severe bodily harm by electric shock! DANGER Dangerous movements! Danger to life, severe bodily harm or material damage by unintentional motor movements! DANGER High electrical voltage due to wrong... -

Page 15: General Information

Planetary Gearboxes Safety Instructions for Electric Drives and Controls General Information • Bosch Rexroth AG is not liable for damages resulting from failure to observe the warnings provided in this documentation. • Read the operating, maintenance and safety instructions in your language before starting up the machine. - Page 16 Safety Instructions for Electric Drives and Controls Planetary Gearboxes • Operation is only permitted if the national EMC regulations for the application are met. The instructions for installation in accordance with EMC requirements can be found in the documentation "EMC in Drive and Control Systems".

-

Page 17: Protection Against Contact With Electrical Parts

Planetary Gearboxes Safety Instructions for Electric Drives and Controls Protection Against Contact with Electrical Parts Note: This section refers to equipment and drive components with voltages above 50 Volts. Touching live parts with voltages of 50 Volts and more with bare hands or conductive tools or touching ungrounded housings can be dangerous and cause electric shock. -

Page 18: Protection Against Electric Shock By Protective Low Voltage (Pelv)

Safety Instructions for Electric Drives and Controls Planetary Gearboxes To be observed with electrical drive and filter components: High electrical voltage on the housing! High leakage current! Danger to life, danger of injury by electric shock! ⇒ Connect the electrical equipment, the housings of all DANGER electrical units and motors permanently with the safety conductor at the ground points before power is... -

Page 19: Protection Against Dangerous Movements

Planetary Gearboxes Safety Instructions for Electric Drives and Controls Protection Against Dangerous Movements Dangerous movements can be caused by faulty control of the connected motors. Some common examples are: • improper or wrong wiring of cable connections • incorrect operation of the equipment components •... - Page 20 Safety Instructions for Electric Drives and Controls Planetary Gearboxes Dangerous movements! Danger to life, risk of injury, severe bodily harm or material damage! ⇒ Ensure personal safety by means of qualified and tested higher-level monitoring devices or measures DANGER integrated in the installation. Unintended machine motion is possible if monitoring devices are disabled, bypassed or not activated.

-

Page 21: Protection Against Magnetic And Electromagnetic Fields During Operation And Mounting

Planetary Gearboxes Safety Instructions for Electric Drives and Controls Protection Against Magnetic and Electromagnetic Fields During Operation and Mounting Magnetic and electromagnetic fields generated near current-carrying conductors and permanent magnets in motors represent a serious health hazard to persons with heart pacemakers, metal implants and hearing aids. -

Page 22: Protection Against Contact With Hot Parts

3-10 Safety Instructions for Electric Drives and Controls Planetary Gearboxes Protection Against Contact with Hot Parts Housing surfaces could be extremely hot! Danger of injury! Danger of burns! ⇒ Do not touch housing surfaces near sources of heat! Danger of burns! CAUTION ⇒... -

Page 23: Battery Safety

3-11 Planetary Gearboxes Safety Instructions for Electric Drives and Controls 3.11 Battery Safety Batteries contain reactive chemicals in a solid housing. Inappropriate handling may result in injuries or material damage. Risk of injury by incorrect handling! ⇒ Do not attempt to reactivate discharged batteries by heating or other methods (danger of explosion and cauterization). - Page 24 3-12 Safety Instructions for Electric Drives and Controls Planetary Gearboxes Notes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 25: Dimensioning And Selection

Planetary Gearboxes Dimensioning and selection Dimensioning and selection Dimensioning Applications for GTM planetary gearboxes are characterized by the following curves: • Triangular speed curve with pause interval • Operation with constant speed and pause interval • Operation with trapezoidal speed curve and pause interval •... - Page 26 Dimensioning and selection Planetary Gearboxes This mode of operation is characteristic for the most highly-dynamic Triangle operation with pause interval feeds. They can be found in loaders and handling systems in nearly all industry sectors. Speed v resp. rotation speed n Time t GK000004v01_en.EPS Fig.

-

Page 27: Selection

Planetary Gearboxes Dimensioning and selection Selection The selection of the suitable motor/-gearbox combination, operating with Drive-determined sizes a drive-control device, is to be taken the following into consideration: • Frictional torque • Starting torque • Processing torque • Accelerating torque •... - Page 28 Dimensioning and selection Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 29: Notes Regarding Application

Planetary Gearboxes Notes Regarding Application Notes Regarding Application Conditions for Use Maximum ambient temperature, The power data as stated in the selection data will be reached at the maximum elevation following conditions: Ambient temperature 0..+ 40°C Elevation: 0...1,000 m above sea level The power data must be reduced according to the diagram below at deviating conditions. -

Page 30: Operation S5 (Intermittent Operation)

Notes Regarding Application Planetary Gearboxes The second code number defines the degree of protection against water. The code number 5 means • Protection against a water jet from a nozzle directed against the housing from all directions (jet water) The housings are primed and can additionally painted with up to 40 µm of Housing paint paint. -

Page 31: Continuous Operation (S1)

Planetary Gearboxes Notes Regarding Application Continuous Operation (S1) GTM planetary gearboxes are suited for S1 operation according to EN 60034-1. DOK-GEAR**-GTM********-PR01-EN-P... -

Page 32: Mechanical Features

Notes Regarding Application Planetary Gearboxes Mechanical features GTM Rexroth planetary gearboxes are manufactured for flange mounting. Construction, installation position The installation positions can be done as described in Fig. 5-4 according to EN 60034-7:1996-06 Gearbox Permittable Construction !!! !!! Important Installation Construction according to Note!!! - Page 33 Planetary Gearboxes Notes Regarding Application Shaft loading To properly check the shaft loading, the axial and radial shaft loads have to be checked separately: The radial shaft load must be checked with respect to • the point of application of force and •...

-

Page 34: Combination Possibilities Of Gtm Planetary Gearboxes With Ac-Motors

Notes Regarding Application Planetary Gearboxes Combination possibilities of GTM planetary gearboxes with AC-motors The following table shows the combination possibilities of GTM planetary gearboxes with Bosch Rexroth AC-Servo motors. Planetary gearbox Motor type MKE035 MKD025 MKE037 GTM060 MHD041 MHP041 MKD041... -

Page 35: Technical Data

Planetary Gearboxes Technical Data Technical Data Technical data for intermittent and continuous operation Ratio-dependent data Description Symbol Ratio GTM060 GTM075 GTM100 GTM140 GTM180 GTM240 4000 3200 2500 2000 5000 5000 4000 3200 2500 2000 one-stage 6300 6300 5000 4000 3200 2500 input speed Max. - Page 36 Technical Data Planetary Gearboxes Description Symbol Ratio GTM060 GTM075 GTM100 GTM140 GTM180 GTM240 2300 1800 1300 3000 3000 2500 2000 1500 1000 one-stage 4000 4000 3000 2500 2000 1200 Nominal initial 5000 5000 4000 3000 2500 1500 , nenn speed rpm 6000 6000 5000...

- Page 37 Any sort of overload of the gearbox is classified as non-intended use. Any changes made to the gearbox voids all liability on the part of Bosch- Rexroth for any damages. DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 38: Technical Data For Increased Lifetime

Technical Data Planetary Gearboxes Technical data for increased lifetime The technical data described in chapter 6.1 are based on a calculated gearbox-lifetime of L = 20,000 hours. If a gearbox-lifetime of more than 20,000h is required, the technical data described in chapter 6.1 regarding torque and speed have to be reduced by the following diagram. -

Page 39: Permittable Shaft Loading

Planetary Gearboxes Technical Data Permittable shaft loading GG000009v01_en.EPS permittable axial force permittable radial force Distance between shaft shoulder on the output shaft and point of application of the radial force average output speed of the cycle Fig. 6-4: permittable shaft load of the GTM Basis of design: The GTM gearboxes are designed for an L bearing life of 30,000 hours. -

Page 40: Gtm060

Technical Data Planetary Gearboxes GTM060 GTM060/1; GTM060/2 with regard to L10h = 30,000h Permittable radial force F n2m:[min-1] 3000 2400 1800 1200 1000 1500 2000 Mass X / Dimension X [mm] Guilty for Fa <0,4* Fr Boundary load for output shaft with keyway GM000001v01_en.EPS Fig. -

Page 41: Gtm075

Planetary Gearboxes Technical Data GTM075 GTM075/1; GTM075/2 with regard to L = 30,000h Permittable radial force F 4500 n2m:[min-1] 4000 3500 3000 2500 2000 1500 1000 1500 2000 1000 16 20 24 28 Maß X / Dimension X [mm] Guilty for FA < 0,4 * Fr Boundary load for output shaft with keyway GM000002v01_en.EPS Fig. -

Page 42: Gtm100

Technical Data Planetary Gearboxes GTM100 GTM100/1; GTM100/2 with regard toL = 30,000h Permittable radial force F 8500 7500 n2m:[min-1] 6500 5500 4500 3500 1000 2500 1500 2000 1500 12 18 24 30 36 42 48 54 Mass X / Dimension X [mm] Guilty for Fa<... -

Page 43: Gtm140

Planetary Gearboxes Technical Data GTM140 GTM140/1; GTM140/2 with regard to L = 30,000h Permittable radial force F 14000 13500 13000 12500 12000 11500 n2m:[min-1] 11000 10500 10000 9500 9000 8500 8000 7500 7000 6500 6000 5500 5000 4500 4000 3500 1000 3000 0 10... -

Page 44: Gtm180

6-10 Technical Data Planetary Gearboxes GTM180 GTM180/1; GTM180/2 with regard to L = 30,000h Permittable radial force F 24000 22000 20000 n2m: [min-1] 18000 16000 14000 12000 10000 8000 1000 6000 0 10 Maß X / Dimension X [mm] Guilty for Fa < 0,4 * Fr Boundary load for output shaft with keyway GM000005v01_en.EPS Fig. -

Page 45: Gtm240

6-11 Planetary Gearboxes Technical Data GTM240 GTM240/1; with regard to L = 30000h Permittable radial force F 34000 32000 30000 28000 n2m: [min-1] 26000 24000 22000 20000 18000 16000 14000 12000 10000 8000 6000 Mass X / Dimension X [mm] Guilty for Fa <... - Page 46 6-12 Technical Data Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 47: Dimensional Details

Planetary Gearboxes Dimensional Details Dimensional Details GTM060 45° 45° Motor Centering hole Motor length according to (see appropriate DIN 332, Bl.2, motor documentation) Form DR M5 x 12,5 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) -

Page 48: Gtm075

Dimensional Details Planetary Gearboxes GTM075 45° 45° Motor Centering hole Motor length according to (see appropriate DIN 332, Bl.2, motor documentation) Form DR M8 x 19 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) -

Page 49: Gtm100

Planetary Gearboxes Dimensional Details GTM100 45° 45° Motor Centering hole according to Motor length DIN 332, Bl.2, (see appropriate Form DR motor documentation) M12 x 28 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) -

Page 50: Gtm140

Dimensional Details Planetary Gearboxes GTM140 45° 45° Motor Centering hole Länge Motor according to 12,5 (siehe zugehörige DIN 332, Bl.2, Motordokumentation) Form DR M16 x 36 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) - Page 51 Planetary Gearboxes Dimensional Details Connected to motor type Two-stage One-stage o o o o K [mm] [mm] [mm] [mm] [mm] MHD115 265.6 NN19 NN19 MHP115 MKE116 245.6 MKE118 1) biggest flange size Fig. 7-8: GTM140 dimensions - one and two-stage gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 52: Gtm180

Dimensional Details Planetary Gearboxes GTM180 45° 45° Motor Centering hole Motor length according to (see appropriate DIN 332, Bl.2, motor documentation) Form DR M20 x 42 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) - Page 53 Planetary Gearboxes Dimensional Details Connected to motor type Two-stage One-stage o o o o K [mm] [mm] [mm] [mm] [mm] MKE116 32.5 335.2 MKE118 MHD131 60.5 Not possible Not possible 2AD132 2AD134 ADF132 60.5 Not possible Not possible ADF134 ADP134 1) biggest flange size Fig.

-

Page 54: Gtm240

Dimensional Details Planetary Gearboxes GTM240 45° 45° Motor Centering hole Motor length according to (see appropriate DIN 332, Bl.2, motor documentation) Form DR M20 x 42 Positional accuracy regarding concentricity, axial eccentricity and concentricity to the shaft according to the tolerance class N, DIN 42955: 1981-12 Output shaft smooth shaft (preferred type) with key according to DIN 6885 B1.1 (Attention! Balanced with half keyway, DIN ISO 8821) -

Page 55: Type Codes

Planetary Gearboxes Type codes Type codes Type codes for the GTM060 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 G T M 0 6 0 - N N 1 - 0 0 4 A - N N 0 3 Example:... -

Page 56: Type Codes For The Gtm075

Type codes Planetary Gearboxes Type codes for the GTM075 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 Example: G T M 0 7 5 - N N 1 - 0 0 4 A - N N 0 3 Product... -

Page 57: Type Codes For The Gtm100

Planetary Gearboxes Type codes Type codes for the GTM100 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 Example: G T M 1 0 0 - N N 1 - 0 0 4 A - N N 0 6 Product... -

Page 58: Type Codes For The Gtm140

Type codes Planetary Gearboxes Type codes for the GTM140 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 Example: G T M 1 4 0 - N N 1 - 0 0 4 A - N N 0 6 Product... -

Page 59: Type Codes For The Gtm180

Planetary Gearboxes Type codes Type codes for the GTM180 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 Example: G T M 1 8 0 - N N 1 - 0 0 4 A - N N 0 9 Product... -

Page 60: Type Codes For The Gtm240

Type codes Planetary Gearboxes Type codes for the GTM240 Abbrev. Column 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 1 2 3 4 6 7 8 9 Example: G T M 2 4 0 - N N 1 - 0 0 4 A - N N 0 9 Product... -

Page 61: Handling, Transport And Storage

Planetary Gearboxes Handling, transport and storage Handling, transport and storage Handling Identifying the Goods A single copy of the delivery note is enclosed to each delivery. The Delivery delivery note lists all components with their description and their designations. If the contents are distributed among several parcels (transport containers), this is noted on the delivery note, or it can be seen from the freight bill. -

Page 62: Transport

Handling, transport and storage Planetary Gearboxes The type label is provided for • identification of the motor • procurement of spare parts in case of a failure, • service information. Note: The description of the motor is also stored in the feedback memory. - Page 63 Planetary Gearboxes Handling, transport and storage Damage to motor and loss of warranty possible! Motor/-gearbox combination Any improper storage may cause damage to the motor. In addition, any warranty claim will expire. ⇒ For that reason, please observe the following WARNING instructions.

-

Page 64: Storage

Handling, transport and storage Planetary Gearboxes Storage It is recommended to store the gearboxes in their original packaging in a Gearbox horizontal position until the are ready for use. For long-term storage, it is recommended to store the gearboxes in a dry environment temperatures from 0°C to +30°C. -

Page 65: Assembly

When combining Bosch Rexroth motors with GTM gearboxes always choose motors with smooth shafts. The motor is centered by using pilot diameter of the Bosch Rexroth motor and the pilot diameter of the gearbox´s input flange. The compression couplings are matched to the corresponding motor shaft diameters when necessary by using a slotted. -

Page 66: Motor Connection

The gearboxes are provided with the proper adapter parts necessary for the stipulated motor type according to the type code in the order. Adapter parts makes it possible for the gearboxes to be mounted on every Bosch Rexroth servo motor listed in the type code. -

Page 67: Mounting Procedure

10-3 Planetary Gearboxes Assembly 10.2.2 Mounting procedure The following assembly procedure is recommended: 1. Clean and check the parts. Check for damage to the motor shaft, compression coupling bore and any bushing, as well as the faces of motor and gearbox flanges and clean them thoroughly. Do not clean the parts with compressed air. - Page 68 10-4 Assembly Planetary Gearboxes 3. Connect the motor to the gearbox. Insert the motor shaft into the gearbox coupling until the gearbox`s connecting flange and the motor face are fully in contact. It should be possible to accomplish this without excessive force. The gearbox is equipped with an integrated thermal length compensation to compensate for the thermal expansion of the motor shaft.

- Page 69 10-5 Planetary Gearboxes Assembly 4. Connect the motor to the gearbox. To assure a proper connection, tighten all fastening bolts with the correct tightening torque using the crossover pattern (see Fig. 10-6). 5. Tightening the bolts of the compression coupling step-by-step. To avoid unnecessary binding of the compression couplings, tightening the clamping bolts step-by-step as shown below up to the proper torque.

- Page 70 10-6 Assembly Planetary Gearboxes 6. Reinsert the cap screws. To ensure an IP 65 sealed drive-system, the cap screws (as described in step 2) have to be reinserted and tightened with the specified torque. Cap screws Tightening torque [Nm] DIN 908 M12x1,5 M16x1,5 Fig.

-

Page 71: Gearbox Mounting

10-7 Planetary Gearboxes Assembly 10.3 Gearbox mounting Remove the protective cap from the gearbox shaft and thoroughly clean the pilot diameter, the contact surface and the output shaft. Mounting of the gearbox to machine (or robot, etc.) is to be made via the output pilot diameter of the gearbox and with four through holes on the gearbox housing. - Page 72 10-8 Assembly Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 73: Startup, Operation, And Maintenance

⇒ Damaged products must not be put into operation. ⇒ Contact Bosch Rexroth for missing information or support during commissioning! Execution When all prerequisites have been fulfilled, proceed as follows: 1. -

Page 74: Deactivation

11-2 Startup, Operation, and Maintenance Planetary Gearboxes Commissioning of motors, drive controllers and the control may require additional steps. The inspection of the functioning and performance of the systems is not part of the commissioning of the gearbox; instead, it is carried out within the framework of the commissioning of the machine as a whole. -

Page 75: Maintenance

⇒ Do not work on hot surfaces. ⇒ Protect open supply cables and connections against penetration of pollution. Bosch Rexroth recommends the following maintenance measures, based on the maintenance plan of the machine manufacturer: Measure Interval... -

Page 76: Excess Temperature Of Gearbox Housing

11-4 Startup, Operation, and Maintenance Planetary Gearboxes Excess Temperature of Gearbox Housing Status The housing temperature of the gearbox climbs to unusually high values. Possible causes 1. Original processing cycle has been changed. 2. Original drive parameters have been changed. 1. -

Page 77: How To Order

Mounted to Pos. 1 GTM gearboxes for use on third- It is possible to mount the GTM planetary gearboxes on servomotors, party motors” which are not delivered by Bosch Rexroth. In such cases, please contact your sales office for further information. DOK-GEAR**-GTM********-PR01-EN-P... - Page 78 12-2 How to order Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

-

Page 79: Service & Support

13-1 Planetary Gearboxes Service & Support Service & Support 13.1 Helpdesk Unser Kundendienst-Helpdesk im Hauptwerk Lohr Our service helpdesk at our headquarters in Lohr am am Main steht Ihnen mit Rat und Tat zur Seite. Main, Germany can assist you in all kinds of inquiries. Sie erreichen uns Contact us 49 (0) 9352 40 50 60... -

Page 81: Kundenbetreuungsstellen - Sales & Service Facilities

Tel. +49 (0) 9352 40 42 22 Tel.: +49 (0)171 333 88 26 Vertriebsgebiet Süd Vertriebsgebiet West Gebiet Südwest Germany South Germany West Germany South-West Bosch Rexroth AG Bosch Rexroth AG Bosch Rexroth AG Landshuter Allee 8-10 Regionalzentrum West Service-Regionalzentrum Süd-West 80637 München Borsigstrasse 15 Siemensstr.1... - Page 82 - Italien Netherlands - Niederlande/Holland Netherlands – Niederlande/Holland Bosch Rexroth S.p.A. Bosch Rexroth S.p.A. Bosch Rexroth Services B.V. Bosch Rexroth B.V. Via Mascia, 1 Via Isonzo, 61 Technical Services Kruisbroeksestraat 1 80053 Castellamare di Stabia NA 40033 Casalecchio di Reno (Bo) Kruisbroeksestraat 1 (P.O.

- Page 83 - Tschechien Czech Republic - Tschechien Hungary - Ungarn Poland – Polen DEL a.s. Bosch -Rexroth, spol.s.r.o. Bosch Rexroth Kft. Bosch Rexroth Sp.zo.o. Strojírenská 38 Hviezdoslavova 5 Angol utca 34 ul. Staszica 1 591 01 Zdar nad Sázavou 627 00 Brno 1149 Budapest 05-800 Pruszków...

- Page 84 Australia - Australien Australia - Australien China China AIMS - Australian Industrial Bosch Rexroth Pty. Ltd. Shanghai Bosch Rexroth Shanghai Bosch Rexroth Machinery Services Pty. Ltd. No. 7, Endeavour Way Hydraulics & Automation Ltd. Hydraulics & Automation Ltd. 28 Westside Drive...

- Page 85 13-5 Planetary Gearboxes Service & Support Taiwan Thailand Bosch Rexroth Co., Ltd. NC Advance Technology Co. Ltd. Taichung Branch 59/76 Moo 9 1F., No. 29, Fu-Ann 5th Street, Ramintra road 34 Xi-Tun Area, Taichung City Tharang, Bangkhen, Taiwan, R.O.C. Bangkok 10230...

- Page 86 Canada West - Kanada West Mexico Mexico Bosch Rexroth Canada Corporation Bosch Rexroth Canada Corporation Bosch Rexroth Mexico S.A. de C.V. Bosch Rexroth S.A. de C.V. Burlington Division 5345 Goring St. Calle Neptuno 72 Calle Argentina No 3913 3426 Mainway Drive Burnaby, British Columbia Unidad Ind.

-

Page 87: Appendix

14-1 Planetary Gearboxes Appendix Appendix 14.1 List of Standards Standard Version Title Conformity 1996-06 Rotating electrical machines – part 7: EN 60034-7 (1993-01); DIN EN 60034-7; Description for structural shapes and lists (IM IEC 60034-7 (1992-12) VDE 0530 Part 7 code) (IEC 60034-7:1992) German Version: EN 60034-7:1993 89/392/EEC... - Page 88 14-2 Appendix Planetary Gearboxes DOK-GEAR**-GTM********-PR01-EN-P...

- Page 90 Bosch Rexroth AG Electric Drives and Controls P.O. Box 13 57 97803 Lohr, Germany Bgm.-Dr.-Nebel-Str. 2 97816 Lohr, Germany Phone +49 93 52-40-50 60 +49 93 52-40-49 4 1 service.svc@boschrexroth.de www.boschrexroth.com Printed in Germany R911297321 DOK-GEAR**-GTM********-PR01-EN-P...

Need help?

Do you have a question about the Rexroth GTM Series and is the answer not in the manual?

Questions and answers