Summary of Contents for LaserLine QUAD 1000HDD

- Page 1 Rev: 2.28.19 Rev. 3.11.19 VERTICAL CONTROL LASER OWNERS MANUAL P/N 3003-1041 1810 SE First Street, Suite H, Redmond, OR 97756 Phone: 541-548-0882 ● Fax: 541-548-0892 ● Email: laserline@laserline.net Website: www.laserlinemfg.com...

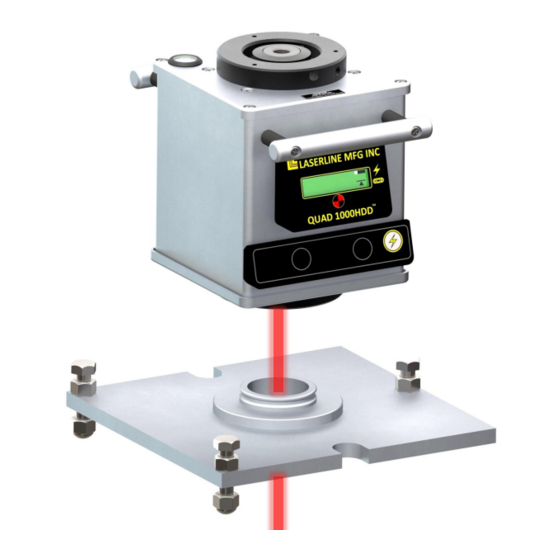

- Page 2 QUAD 1000HDD Laser Package Includes: QUAD 1000HDD Laser P/N 4003-0000 5 arc second nadir (Downward) laser featuring electronic servo self-leveling with variable temperature compensation for the most accurate and consistent readings. Downward nadir laser to 2,000 feet (610m) with one button operation and bright backlit LCD display.

- Page 3 OVERVIEW The Quad 1000HDD projects a precise laser beam straight down (Nadir) to 2,000 feet/610m for the purpose of providing plumb control for your project. The Quad 1000HDD is a self- leveling instrument with electronic temperature compensation. It measures or senses ambient temperature changes while in operation and continually recalibrates itself to maintain the highest degree of accuracy possible.

- Page 4 Once the platform is positioned and welded in place, the Quad 1000HDD can be precisely positioned on the platform. One method would be to attach the Quad 1000HDD to the rotational mount on the trivet mount, attach a survey-prism to the 5/8 thread on the top of the Quad 1000HDD.

- Page 5 SETTING UP (Continued) QUAD 1000HDD Laser Trivet Mount Job built steel plate platform with oversized hole. (Flat-Level-Rigid) Position laser over or under plumb point Make sure bulls-eye bubble remains centered using the three adjustment Knobs. Once in place, lock adjustment knobs and secure trivet to mounting platform.

- Page 6 ALIGNMENT / TEMPLATE TARGETS (2ea.) A) They can be used as a centering template for floor/deck marking as described above. (4 template notches) B) The targets are made of a translucent material allowing the laser spot to be read from the opposite side that the laser spot is impacting the target face.

-

Page 7: Maintenance

1. Place the target / template precisely centered on the laser spot at the lowest point possible below the Quad 1000HDD. (At least 100 feet if possible) Secure the target so it will not move. 2. Rotate the Quad 1000HDD on its rotational mount 180°. - Page 8 LABELS (Required for this product) Non-Interlocked Warning Label (Top) Explanatory and Warning Label-Hazard Symbol Identification and Certification Aperture Label (Bottom)

-

Page 9: Laser Specifications

LASER SPECIFICATIONS Self-leveling: Electronic servo with variable temperature compensation Plumb beam accuracy: ±5 arc seconds (± 1/32 inch per 100 feet) (.793mm per 30.48 meters) Range: Downward 2,000 feet (610 meters) Laser “Down” spot size: At Source = .87” (2.2cm) 1000 feet (305m) = 1.1”... -

Page 10: Warranty

This product is guaranteed against defects in materials and workmanship for both parts and labor, under normal working conditions for two years from the date of purchase, except as noted herein. LaserLine Mfg., Inc. liability under this warranty is limited to repairing or replacing any product returned to an authorized service center for that purpose. - Page 11 NOTES...

Need help?

Do you have a question about the QUAD 1000HDD and is the answer not in the manual?

Questions and answers