Table of Contents

Advertisement

Quick Links

HDM-0002

Document No.

13

RS0743

12

RS0617

11

RS0612

10

RS0550

Rev.

ECN

Confidential C

ISH

CONNECTOR

®

ISH

V CONNECTOR

®

ISH

VS CONNECTOR

®

Instruction Manual

September 18, 2020

August 21, 2019

July 9, 2019

December 18, 2018

Date

H.Naoi

K.Hanaki

S.Tanaka

S.Tanaka

Prepared by

I-PEX Inc.

1 / 29

J.Tateishi

J.Tateishi

J.Tateishi

J.Mukunoki

Checked by

E.Kawabe

E.Kawabe

E.Kawabe

T.Osuga

Approved by

QKE-DFFDE09-03 REV.8

Advertisement

Table of Contents

Summary of Contents for I-PEX ISH Series

- Page 1 September 18, 2020 RS0617 August 21, 2019 K.Hanaki J.Tateishi E.Kawabe RS0612 July 9, 2019 S.Tanaka J.Tateishi E.Kawabe RS0550 December 18, 2018 S.Tanaka J.Mukunoki T.Osuga Rev. Date Prepared by Checked by Approved by Confidential C I-PEX Inc. QKE-DFFDE09-03 REV.8 1 / 29...

-

Page 2: Table Of Contents

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 Contents ・・・・・ Sheet 3 1. Purpose ・・・・・ Sheet 3 2. Applicable items ・・・・・ Sheet 4 3. Crimping procedure ・・・・・ Sheet 13 4. Terminal insertion ・・・・・ Sheet 15 5. Secondary lock installation ・・・・・... -

Page 3: Purpose

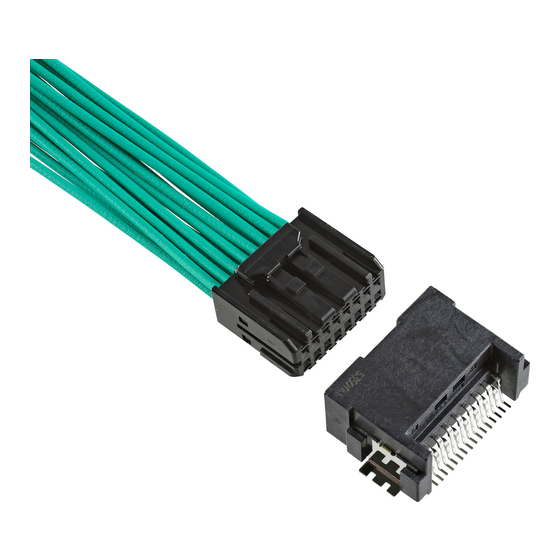

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 1.Purpose The Manual explains the handling of ISH CONNECTOR・ISHV CONNECTOR and ISHVS CONNECTOR. 2. Applicable items The Manual is applicable to the items listed below. Name Part No. Plating Image VT001-512 FEMALE TERMINAL... -

Page 4: Crimping Procedure

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 3. Crimping procedure 3-1. Applicable wires Part No. Applicable Wire VT001-512 wire size:0.3mm ・0.5mm VT001-552 Insulation outer diameter :Φ1.60mm MAX. 3-2. Wire strip length ①Strip the insulation off by 3.0±0.1mm (see Fig.1) ②Check to see that there is no damage to the conductors or insulation, cut off conductors, short conductors and deformed conductors as shown in Fig. - Page 5 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 3-3. Terminal part names Fig 3. Terminal part names 3-4. Crimping requirements (1) Crimp dimension Crimped female terminals must satisfy the crimp dimension specified in Table 1. Table 1. Crimp dimension Insulation Part No.

- Page 6 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 Measuring method for crimp dimension is described below. Use the micrometer shown in Fig.4 for measurement of each part. Fig 4. Micrometer (1)-1. Measuring method for wire barrel crimp height is described below. To measure the wire barrel crimp height, pinch the top of the wire barrel (winding side) and the bottom of the wire barrel with a micrometer.

- Page 7 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 (1)-3. Measuring method for wire barrel crimp width is described below. To measure the wire barrel crimp width, pinch the side of the wire barrel with a micrometer. (see Fig.7) Secure terminals firmly to obtain accurate measurement.

- Page 8 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 (2) Bottom burrs Burrs produced during crimping process must not extend beyond the bottom surface. (see Fig.9) Bottom surface of terminal Bottom burrs 【Good】 【No good】 Fig 9. Bottom burrs (3) Bellmouth,excess conductors and cut-off tab Bellmouth,excess conductors and cut-off tab must satisfy the dimensions shown in Fig.

- Page 9 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 (4) Unaligned wire barrel ends Unaligned wire barrel ends is 0.1mm MAX..(Fig.11) ※If wire barrel ends are not aligned, resulting in different dimension of excess conductors or bellmouth between the sides,dimensions must be measured on larger side and be satisfied. (In the case shown in Fig.12, measure excess conductors:[a],bellmouth:[b].) Fig 11.

- Page 10 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 (6) Terminal twist Terminal twist is 1.2°MAX. from the wire barrel (baseline). (see Fig. 14) Fig 14. Terminal twist (7) Bend up and Bend down Bend up is 1.90mm MAX., and no Bend down, the hight from the wire barrel(baseline) to the terminal box(measurement point).

- Page 11 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 3-5. Defective criteria Terminals with the following conditions are deemed defective. (1) No rear bellmouth Rear bellmouth is not formed. (see Fig.17) Fig 17. No rear bellmouth (2)Insufficient conductors insertion Conductors are insufficiently inserted into the wire barrel.

- Page 12 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 ※Description of faults:Excessive conductors out & Incomplete conductors crimping Please make sure there is no excessive conductors out and incomplete conductors crimping. When retainer is inserted, excess conductors could push into adjacent terminals, causing short circuit.

-

Page 13: Terminal Insertion

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 4. Terminal insertion ①Ensure that the terminal is crimped correctly and there is no damage, deform or dirt present. ②Hold the wire to insert the female terminal as shown in Fig.25and 26. ③Insert the terminal into the corresponding corehole of the housing, as deeply as possible, in the orientation as shown in Fig. - Page 14 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 ⑤Terminals won’t fit into the housing coreholes, if inserted in the wrong orientation (see Fig.27). Keys prevent incorrect insertion Fig27.FEMALE HOUSING Incorrect terminal insertion Notes: ①Terminals must be inserted in the orientation instructed. Forcibly inserting terminals in any other orientation may result in damage or deformation.Furthermore,if the terminals are inserted with incorrect orientation, terminal key prevents insertion into coreholes.

-

Page 15: Secondary Lock Installation

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 5. Secondary lock installation 5-1.Secondary lock part Table5. PART NO.: FEMALE HOUSING No. of NAME PART NO. Poles ISH CONNECTOR 3P FEMALE HOUSING V0013-91003-211 ISHV CONNECTOR 3P FEMALE HOUSING V0037-91003-211 ①After terminal insertion is complete, close the secondary lock part. - Page 16 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 ④ Do not use fingertips to install secondary lock part as shown in Fig. 30. No good Good No good:Do not use fingertip Good:Use fingerpad ⇒Possible damage by fingernails (see Fig.31) ⇒Prevent damage by fingernails Fig.30.

- Page 17 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 5-2. Retainer Table5. PART NO.: FEMALE HOUSING,RETAINER FEMALE HOUSING FEMALE RETAINER No. of NAME Poles PART NO. PART NO. V0016-91006-211 ISH CONNECTOR 6P V0016-92006-211 V0016-91006-212 V0020-91008-212 V0020-91008-213 ISH CONNECTOR 8P V0027-92008-211 V0020-91008-214 V0020-91008-215...

- Page 18 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 ④Do not forcefully insert in any other position than those shown in Fig.34. When inserting into multi-pin housing, retainer may be easily bent and damaged. Fig34. Insufficient retainer installation ⑤The retainer cannot be inserted, when it is inserted in incorrect orientation to the female housing, as shown in Fig.35.

-

Page 19: How To Release Secondary Lock

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 6. How to release secondary lock 6-1. Secondary lock part ①Place the releasing jig into the secondary lock part taper situated at the bottom of the female housing, and move the jig to the direction shown in Fig. - Page 20 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 6-2. Retainer ①Place the releasing jig into the releasing apertures situated on the side of the housing (Pos.1side), and push out the retainer (see Fig.37). Retainer releasing JIG: Part No. AP0004-02-001、AP0031-02-001 Refer to Table 6 for the Part No.

-

Page 21: How To Release Female Terminals

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 7. How to release female terminals (※Female terminal releasing Jig dimentions see Fig39.) ①Ensure that the secondary lock part and the retainer have been removed. ②Hold the wire and push in the female terminal lightly. Place the female terminal releasing jig into the releasing apertures of the female housing (see Figs. - Page 22 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 Direction of release Pivot of releasing jig Terminal releasing jig Terminal releasing jig Fig40. Correct orientation of the releasing jig and the housing lance Fig41. Terminal releasing jig in operation Notes ①Do not pry with the releasing jig or female terminals during operation.

-

Page 23: Rear Cover Installation

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 8.Rear cover installation (Only housing correspond to rear cover)(Rear cover : Individual part) ① Verify that pin numbers of the female housing and the rear cover are the same and also the female housing corresponds to rear cover. -

Page 24: Mating Of Connector

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 9. Mating of connector ①Push the female connector that has been inestalled the secondary lock part and the retainer in the direction of mating until makes an audible click(see Fig.50). While mating the female connector,please do not touch the lock arm to prevent insufficient mating. -

Page 25: Unmating Of Connector

Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 10. Unmating of connector ①Hold the female connector and push it in lightly. ②While holding the female connector in, press down fully on the end of the arm (see Fig. 52). ③Keep pressing the lock down, and pull out the female connector. - Page 26 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 11. Handling of Product 11-1. Conductivity test 11-1-1. Male connector ①When carrying out conductivity test of the male connector, place the probe on the tip of the male terminal(Load:0.5N MAX.) If load exceeds 0.5N, male terminal(s) may be damaged or deformed.

- Page 27 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 Reference:Probe pin position on female housing ① Female housing - single row ② Female housing - double row Distance between probe pin insert hole bottom surface and female terminal Distance between probe pin insert hole bottom surface and female terminal Housing thickness Housing thickness...

- Page 28 Document No. ISH & ISHV & ISHVS CONNECTOR Instruction Manual HDM-0002 12. Storage of housings and terminals ①Store housings and terminals in a warehouse which is controlled temperature and humidity. (Recommend : Temperature 27℃MAX. , Humidity 65%MAX.) ②Store housings in a cardboard box. Avoid storing in a way that may cause damage to the boxes, e.g. placing boxes on top of other boxes or storing in a precarious way to cause the boxes to fall.

- Page 29 ⑧Do not insert any terminals into housing other than those specified. ⑨Follow this Manual for using the products. Do not use in any way other than instructed. 15. Contact Tokyo office Sales Dept. I-PEX Inc. TEL: 03-5479-7410 FAX: 03-5479-7411 Confidential C 29 / 29...

Need help?

Do you have a question about the ISH Series and is the answer not in the manual?

Questions and answers