Summary of Contents for Dini Argeo WWS

- Page 1 Wheel and axle weighing platforms MANUALE D’USO USER MANUAL ITALIANO ENGLISH www.diniargeo.com...

-

Page 3: Table Of Contents

FUNCTION INDEX Introduction Safety information - Warnings The range of WWS platforms Technical features of the platform with cable Technical features of the wireless platform Definition of the wheel-weighing system Definition of the axle-weighing system Main setups Two platforms Three platforms... -

Page 4: Introduction

Dear customer, Thank you for choosing a DINI ARGEO weighing system. The WWS platforms are weighing units that, adequately combined together, provide weighing scales to weigh vehicles/objects/structu- res with several support points of any size and capacity. Thanks to the quality materials and top specifications, these platforms provide accuracy and optimal performance over time. -

Page 5: Technical Features Of The Platform With Cable

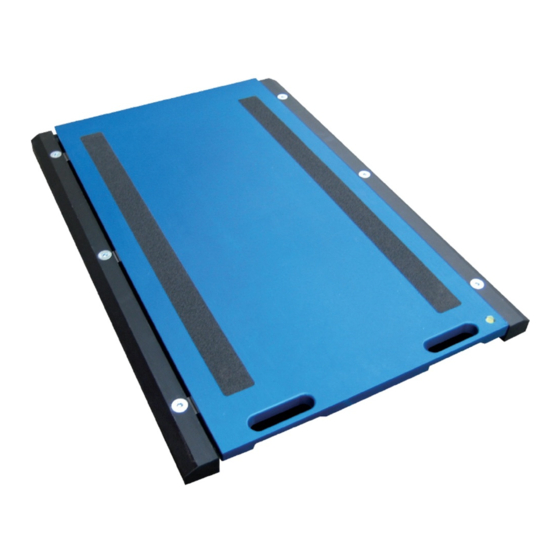

Technical features of the platform with cable Up/down • Special aluminium alloy loading platform. ramps • Built-in up/down ramps Transport and • Watertight stainless steel load cells, OIML type-ap- positioning wheels proved, oversized. • Watertight connections. Handle Positioning bands • Specific cable for mobile applications. -

Page 6: Definition Of The Wheel-Weighing System

Definition of the wheel-weighing system A wheel-weighing system consists of as many platforms as many vehicle wheels to be weighed and is used to weigh the whole vehicle in a single step. A wheel-weighing system provides the following benefits: • weighing accuracy comparable to that of a weighbridge (0.05% end-of-scale);... - Page 7 Automatic dynamic axle weighing Each axle is automatically acquired as the vehicle passes over the platforms. System that can only be made with wired platforms. 1. Pass on the platform at low speed. 2. The weight acquisition takes place dynamically and automatically.

-

Page 8: Main Setups

Main setups Two platforms APPLICATIONS Weighing of each axle of the vehicle or trailers with one axle. Available both in a wired and wireless version. Three platforms APPLICATIONS Weighing of small planes, three-wheeled vehicles or trailers with a support pin. Available both in a wired and wireless version. -

Page 9: Five Platforms

Five platforms APPLICATIONS Weighing of two-axle trailers with a support pin. Available both in a wired and wireless version. When you need to weigh both ways, we recommend adding the sixth platform, but placing it as shown in the figure. The size and capacity of the fifth platform can differ from those of the... -

Page 10: Over 10 Platforms (Wireless Version Only)

Over 10 platforms (wireless version only) APPLICATIONS Weighing of vehicles with several axles or structures featuring several support points in a single step. This setup is used to manage up to 16 pla- tforms. For weighing vehicles or special structures that might influence wireless communication (shielding effect), we recommend using the “dual”... -

Page 11: Installing The Platforms

Choosing the weighing area RECOMMENDATIONS FOR AN OPTIMAL SYSTEM INSTALLATION WWS platforms can be installed on any type of surface, though for optimal use and to obtain the best weighing results we recommend: • Choosing a weighing area that is large enough to allow easy manoeuvres for vehicles under 100% safe conditions. -

Page 12: How To Position The Platforms

How to position the platforms To make the positioning and adjustment of the platforms easier, you can use the built-in wheels: Keep your back straight when lifting the platforms. To speed up operations without taking measurements, we recommend positioning the platforms directly in front of the wheels of the vehicle to be weighed: Pay the upmost attention to When installing the scale, we... -

Page 13: How To Position And Connect The Cables

How to position and connect the cables Also ensure you do not pass cables in transit areas, under the load cells and under the central box of the platform. = Position of the cable We recommend placing the cables as follows The connection of the cables must comply with the numbering shown on the connectors How to position the wireless platforms •... -

Page 14: How To Use The Platforms Correctly

How to use the platforms correctly Transit area Positioning bands In case of wireless platforms, to preserve the correct operation of the built-in weight indicator, we recommend avoiding transit over the display, thereby preventing accidental scratches. Respect the transit area and positioning indicated in the previous drawing. -

Page 15: Maintenance Of The Platforms

WEIGHBRIDGE Periodical maintenance and cleaning of the weighing area • Remove from the weighing area and the area under the WWS platform any debris that may prevent the loading surface from ben- ding correctly. • Clean the platform with non-aggressive substances. -

Page 16: Accessories

Accessories Levelling modules for axle-weighing systems They are used to create weighing lanes according to the desired length to align all the wheels of the weighted vehicle, thereby considerably improving the weighing accuracy. This also improves the quality of transit surface and reduces the uneven nature of the ground. APPLICATIONS Ideal for mobile axle weighing stations. -

Page 17: Pit Frames For Floor-Level Installations

Pit frames for floor-level installations They are used to integrate the platforms into the roadbed, thereby improving the distribution of the loads. APPLICATIONS Ideal for fixed axle weighing stations. ACTIVATION The pit frames are optional accessories. Standard pit frame As an alternative to standard pit looms, to achieve greater flexibility in terms of use you can create a pit of an adequate length inside which you can adjust the distance between the platforms, while still keeping them at floor level: Additional ramps for easier up/down movements Used to make it easier to move the platforms up and down. -

Page 18: Weighing Of Objects Or Structures

Weighing of objects or structures Thanks to their modularity, these handy platforms can be moved in any position, directly below the point in which the structure must be weighed. To use them correctly, please follow this procedure: 1. lower the load up to an approximate height of 10 cm from the ground 10 cm 2. -

Page 19: Faq - Frequently Asked Questions

Messages of the wireless platforms MESSAGE DESCRIPTION If the wws radios are type-approved, the display does not show the PL1 PL2 PL3 PL4 ... weight, but the platform number Weight reset in progress. If the message persists, contact our techni- ZERo cal support service. - Page 20 Note...

- Page 21 Note...

- Page 22 Note This publication, or portions thereof, may not be duplicated without written permission from the Manufacturer. All information contained in this manual is based on the data available at the time of its publication; the Manufacturer reserves the right to make changes to its products at any time without notice and without incurring any penalty.

- Page 24 HEAD OFFICE Via Della Fisica, 20 41042 Spezzano di Fiorano, Modena - Italy Tel. +39.0536 843418 - Fax +390536 843521 info@diniargeo.com SERVICE ASSISTANCE Via Dell'Elettronica, 15 41042 Spezzano di Fiorano, Modena - Italy Tel. +39.0536 921784 - Fax +390536 926654 service@diniargeo.com...

Need help?

Do you have a question about the WWS and is the answer not in the manual?

Questions and answers