MICRO-EPSILON optoNCDT 1900 Series Operating Instructions Manual

Hide thumbs

Also See for optoNCDT 1900 Series:

- Assembly instructions (2 pages) ,

- Operating instructions (2 pages) ,

- Operating instructions manual (144 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for MICRO-EPSILON optoNCDT 1900 Series

- Page 1 Operating Instructions optoNCDT 1900 ILD1900-10 ILD1900-25 ILD1900-50...

- Page 2 Intelligent laser optical displacement measurement MICRO-EPSILON MESSTECHNIK GmbH & Co. KG Koenigbacher Str. 15 94496 Ortenburg / Germany Tel. +49 (0) 8542 / 168-0 Fax +49 (0) 8542 / 168-90 e-mail info@micro-epsilon.com www.micro-epsilon.com...

-

Page 3: Table Of Contents

Contents Safety ............................9 Symbols Used ..............................9 Warnings ................................9 Notes on CE Marking ............................ 10 Intended Use ..............................11 Proper Environment ............................11 Laser Safety ..........................12 Functional Principle, Technical Data ..................14 Short Description ............................14 Advanced Surface Compensation ........................ 15 Technical Data ............................... - Page 4 Electrical Connections ........................... 27 5.4.1 Connection Possibilities ....................... 27 5.4.2 Pin Assignment ..........................29 5.4.3 Supply voltage ..........................30 5.4.4 Laser On ............................31 5.4.5 Analog Output ..........................32 5.4.6 Multifunction Input ........................33 5.4.7 RS422 Connection with USB Converter IF2001/USB ..............33 5.4.8 Digital Output ..........................

- Page 5 7.5.5 Masking the Evaluation Range, ROI .................... 57 7.5.6 Exposure Mode ..........................58 7.5.7 Peak Selection ..........................59 7.5.8 Error Processing ........................... 59 Signal Processing ............................60 7.6.1 Preliminary Remark ........................60 7.6.2 Averaging ............................60 7.6.2.1 General ........................60 7.6.2.2 Moving average ......................

- Page 6 Cleaning ..........................85 Software Support with MEDAQLib ..................85 Liability for Material Defects ....................86 Decommissioning, Disposal ....................86 Service, Repair ........................86 Appendix Optional Accessories ............................. 87 Factory Setting ............................... 89 ASCII Communication with Sensor ....................... 90 A 3.1 General ................................

- Page 7 A 3.2.3.6 TRIGGERCOUNT, Number of Output Measurement Values ........102 A 3.2.3.7 TRIGGERSW, Software Trigger Pulse ..............102 A 3.2.4 Interfaces ............................ 103 A 3.2.4.1 BAUDRATE, RS422 ....................103 A 3.2.4.2 ERROROUT1/2, Activate Switching Output............103 A 3.2.4.3 ERRORLEVELOUT1/2, Output Level Switching Output ......... 103 A 3.2.4.4 ERRORLIMITCOMPARETO1/2 ................

- Page 8 A 3.2.9 Data output ..........................112 A 3.2.9.1 OUTPUT, Selection of Measurement Value Output ..........112 A 3.2.9.2 OUTREDUCEDEVICE, Output Reduction of Measurement Value Output ..... 112 A 3.2.9.3 OUTREDUCECOUNT, Data Output Rate ..............112 A 3.2.9.4 OUTHOLD, Error Processing .................. 112 A 3.2.9.5 GETOUTINFO_RS422, Query Selected Data ............

-

Page 9: Safety

Safety Safety The handling of the sensor assumes knowledge of the operating instructions. Symbols Used The following symbols are used in this operating instructions: Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury. Indicates a situation that may result in property damage if not avoided. Indicates a user action. -

Page 10: Notes On Ce Marking

Safety Avoid shocks and impacts to the sensor. > Damage to or destruction of the sensor Mount the sensor only to the existing holes on a flat surface. Clamps of any kind are not permitted > Damage to or destruction of the sensor The power supply may not exceed the specified limits. -

Page 11: Intended Use

Safety Intended Use - The optoNCDT 1900 system is designed for use in industrial and laboratory applications. - It is used ƒ for measuring displacement, distance, position and thickness ƒ for in-process quality control and dimensional testing - The system must only be operated within the limits specified in the technical data, see Chap. 3.3. - The sensor must be used in such a way that no persons are endangered or machines and other material goods are damaged in the event of malfunction or total failure of the sensor. -

Page 12: Laser Safety

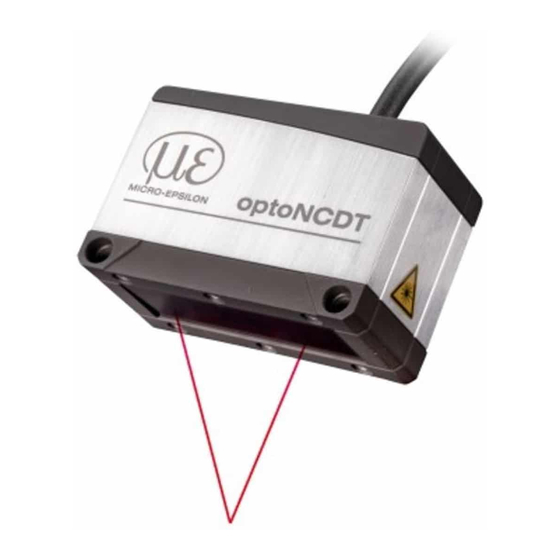

Laser Safety Laser Safety The optoNCDT 1900 sensors operate with a semiconductor laser with a wavelength of 670 nm (visible/red). The sensors fall within Laser Class 2. The laser is operated on a pulsed mode, the maximum optical power is ≤ 1 mW. The pulse frequency depends on the adjusted measuring rate (0.25 ... - Page 13 Laser Safety During operation of the sensor, the pertinent regulations according to IEC 60825-1 on „Safety of laser products“ must be fully ob- served at all times. The sensor complies with all applicable laws for the manufacturer of laser devices. Fig.

-

Page 14: Functional Principle, Technical Data

Functional Principle, Technical Data Functional Principle, Technical Data Short Description The optoNCDT 1900 uses the principle of optical triangulation, that is, a visible, modulated point of light is projected onto the target surface. The diffuse part of the reflection of this point of light is displayed depending on distance on a position-resolving element (CMOS) by an receiver optic which is arranged to the optical axis of the laser beam in a defined angle. -

Page 15: Advanced Surface Compensation

Functional Principle, Technical Data Advanced Surface Compensation The optoNCDT 1900 is equipped with an intelligent surface control feature. New algorithms generate stable measurement results even on demanding surfaces where changing reflections occur. Furthermore, these new algorithms compensate for ambient light up to 50,000 lux. -

Page 16: Technical Data

Functional Principle, Technical Data Technical Data Model ILD1900- Measuring range 10 mm 25 mm 50 mm Start of measuring range 20 mm 25 mm 40 mm Midrange 25 mm 37.5 mm 65 mm End of measuring range 30 mm 50 mm 90 mm Continuously adjustable between 0.25 ... - Page 17 FSO = Full Scale Output, SMR = Start of measuring range, MMR = Mid of measuring range, EMR = End of measuring range The specified data apply to a white, diffuse reflecting surface (Micro-Epsilon reference ceramic for ILD sensors) 1) Factory setting: 4 kHz measuring rate, Median 9; to change the factory setting requires an IF2001/USB converter (see accessories)

-

Page 18: Delivery

Delivery Delivery Unpacking, Included in Delivery - 1 Sensor ILD1900 - 1 Assembly instruction - 1 Calibration protocol - Accessories (2 pieces screw M3x40 and 2 pieces centering elements) Carefully remove the components of the measuring system from the packaging and ensure that the goods are forwarded in such a way that no damage can occur. -

Page 19: Installation

Installation Installation Instructions for Installation 5.1.1 Reflection Factor of the Target Surface In principle the sensor evaluates the diffuse part of the reflected laser light. Laser beam Laser beam Laser beam 2 Ideal diffuse reflection Direct mirror reflection Real reflection Fig. -

Page 20: Error Influences

Installation 5.1.2 Error Influences 5.1.2.1 Light from other Sources Thanks to their integrated optical interference filters the optoNCDT 1900 sensors offer outstanding performance in suppressing light from other sources. However, this does not preclude the possibility of interference from other light sources if the objects being mea- sured are shiny and if lower measuring rates are selected. -

Page 21: Surface Roughness

Installation 5.1.2.6 Surface Roughness Laser-optical sensors detect the surface using an extremely small laser spot. They also track slight surface unevenness. In contrast, a tactile, mechanical measurement, e.g. using a caliper, detects a much larger area of the measurement object. In case of traversing measurements, surface roughnesses of 5 µm and more lead to an apparent distance change. -

Page 22: Angle Influences

Installation 5.1.2.7 Angle Influences Tilt angles of the target in diffuse reflection both around the X and the Y axis of less than 5 ° only have a disturbing effect with surfaces which are highly reflecting. These influences have to be explicitly considered when scanning profiled surfaces. Basically the angle behavior of triangulation is li- able to the reflectivity of the measuring object surface. -

Page 23: Optimizing The Measuring Accuracy

Installation 5.1.3 Optimizing the Measuring Accuracy Color strips Direction of movement In case of rolled or polished metals that are moved past the sensor the sen- sor plane must be arranged in the direction of the rolling or grinding marks. The same arrangement must be used for color strips. -

Page 24: Mounting, Dimensions

Installation Mounting, Dimensions 5.2.1 General The optoNCDT 1900 sensor is an optical system for measurements with micrometer accuracy. The laser beam must be directed per- pendicularly onto the surface of the target. Make sure it is handled carefully when installing and operating. Mount the sensor only to the existing holes on a flat surface. - Page 25 Installation 70 (2.76) Mount the sensor only to the existing holes on a flat surface. Clamps of any kind are not permitted. (.43) (.24) 6 (.24) MR = Measuring range (.24) 5 (.20) 60 (2.36) SMR = Start of measuring range (.71) 2 (.08) (.55)

-

Page 26: Indicator Elements At Sensor

Installation Indicator Elements at Sensor LED State Meaning LED state green Measuring object within sensor range LED output yellow Mid range no displacement value available - e.g. Poor target or out of range Function Laser off LED Output Meaning Select green RS422 measurement value output on, analog output off The digital outputs are active. -

Page 27: Electrical Connections

Installation Electrical Connections 5.4.1 Connection Possibilities Source Cable/Supply Interface End device PC1900-x/OE PC1900-x/OE IF2030/PNET IF2030/ENETIP IF2001/USB IF2004/USB PS 2020 PC1900-x/IF2008 (IF2008-Y) PC1900-x/IF2008 and IF2008-Y adapter cable IF2008/PCIE PC1900-x/C-Box Sensor supply Ethernet is done by peripheral. C-Box/2A Fig. 12 Connection examples on ILD1900 optoNCDT 1900 Page 27... - Page 28 Installation 0.3 m ILD1900 with pigtail ILD1900 with open ends The different periphery devices, see Fig. 12, can be connected by the illustrated connection cables to the 17-pin sensor male plug resp. to the open ends. Sensor Power supply for the Power supply Peripheral Interface...

-

Page 29: Pin Assignment

Installation 5.4.2 Pin Assignment Signal Pin Color sensor cable PC1900-x/OE, Specification, Wiring Description 5 red Supply voltage (11 ... 30 VDC) System ground for power supply, 14 blue switch signals (Laser on/off, Zero, Limits) < (U - 6 V) / 20 mA, Current 4 ... -

Page 30: Supply Voltage

11 ... or similar sources of pulse interference at 30 VDC ILD1900 the same time. MICRO-EPSILON recom- mends using an optional available power supply unit PS2020 for the sensor. blue Ground Fig. 14 Connection of supply voltage... -

Page 31: Laser On

Installation 5.4.4 Laser On The measuring laser on the sensor is activated via an switch input (HTL or TTL level). This is advantageous if the sensor has to be switched off for maintenance or similar. Switching can be done with a transistor (for example open collector in an optocoupler), a relay contact or a digital TTL/HTL signal. -

Page 32: Analog Output

Installation 5.4.5 Analog Output The sensor alternatively provides a - current output with 4 ... 20 mA or a - voltage output with 0 ... 5 V resp. 0 ... 10 V. The output may not be continuously operated in short circuit operation without load resistor. The short circuit operation leads to durable thermal overload and thus for automatic overload shutdown of the output. -

Page 33: Multifunction Input

Sensor End device (converter) Symmetric differential signals acc. to Type IF2001/USB EIA-422, not galvanically isolated from 17-pin male Sensor from MICRO-EPSILON supply voltage. cable connector cable Use a shielded cable with twisted cores Tx + (Pin 8) grey Rx + (Pin 3) e.g. -

Page 34: Digital Output

Installation 5.4.8 Digital Output The switching characteristic (NPN, PNP , Push-Pull, Push-Pull negated) of both digital outputs depends on the programing. The NPN output is e.g. suitable for adjustment to TTL logics with an auxiliary voltage U = +5 V. The digital outputs are protected against reverse polarity, overloading (>... -

Page 35: Connector And Sensor Cable

The fixed connected sensor cable is cable carriers suitable. Unused open cable ends must be insulated to protect against short circuits or malfunction of the sensor. MICRO-EPSILON recommends to use the cable carriers suitable standard connection cable PC1900 of the optional accessories, see Chap. -

Page 36: Operation

Operation Operation Getting Ready for Operation Install and assemble the optoNCDT 1900 in accordance with the instructions set out, see Chap. Connect the sensor with the indicator or monitoring unit and the power supply. The laser diode in the sensor can only be activated if at the input Laser on/off Pin 3 is connected with Pin 14, see Chap. 5.4.4. Once the power supply has been switched on the sensor runs through an initialization sequence. -

Page 37: Operation Via Web Interface

Operation Operation via Web Interface 6.2.1 Preconditions In the sensor a webserver is implemented. The web interface contains among other things the current settings of the sensor and the periphery. The operation is only possible as long as an RS422 connection to the sensor exists. The sensor is connected to a PC/notebook via a RS422 converter, supply voltage persist. -

Page 38: Access Via Web Interface

Operation 6.2.2 Access via Web Interface Start the web interface of the sensor, see Chap. 6.2.1. Interactive web pages you can use to configure the sensor are now displayed in the web browser. The sensor is active and supplies measurement values. The horizontal navigation includes the functions below: - The search function permits... - Page 39 Operation For configuration, you can switch between the video signal and a display of the measured values over time. Averaging Description In the area Signal quality you can switch between four given Balanced Median with 9 values + basic settings (static, balanced, dynamic and no averaging). You can Moving with 64 values instantly see the reaction in the diagram and system configuration.

-

Page 40: Measurement Configuration

Operation 6.2.3 Measurement Configuration Common measurement configurations (presets) for various target surfaces are stored on the sensor. Those enable to quickly start the respective measurement task. Choosing a preset suitable to the target surface causes a predefined configuration of the settings which achieves the best results for the chosen material. -

Page 41: Measurement Presentation Via Web Browser

Operation 6.2.4 Measurement Presentation via Web Browser Start the measurement value display with the tab Measurement chart in the horizontal navigation bar. Fig. 23 Website measurement (distance measurement) The LED visualizes the status of the transmission of measured values: - green: transmission of measured values is running. - yellow: waiting for data in trigger mode - gray: transmission of measured values stopped Data queries are controlled by using the Play/Pause/Stop/Save buttons of the measured values that were transmitted. - Page 42 Operation For scaling the measurement value axis (y-axis) of the graphics you can either choose Auto (= autoscaling) or Manual (= manual setting). The search function enables time-saving access to functions and parameters. In the text boxes above the graphics current values for distance, current measuring rate and timestamp are displayed. Mouse over function.

-

Page 43: Video Signal Via Web Browser

Operation 6.2.5 Video Signal via Web Browser Start the video signal display with the function Video in the area Diagram type. The diagram in the big graphic window on the right displays the video signal of the recipient filed. The video signal in the graphic window displays the intensity distribution above the pixels of the recipient field. - Page 44 Operation The LED visualizes the status of the transmission of measured values: - green: transmission of measured values is running. - yellow: waiting for data in trigger mode - gray: transmission of measured values stopped Data queries are controlled by using the Play/Pause/Stop/Save buttons of the measured values that were transmitted. Stop stops the diagram;...

-

Page 45: Parametrization Via Ascii Commands

Operation Scaling of the x-axis: you can enlarge (zoom) the overall signal by means of the left slider during ongoing measurement. If the diagram is stopped, you can also use the right slider. The zoom window can also be moved by means of the mouse in the middle of the zoom window (arrow cross). -

Page 46: Menu Structure, Operation Via Membrane Keys

Operation Menu Structure, Operation via Membrane Keys Initialization select The parameters interface and key Call menu Reset Select key is Bootloader Select key is function can be changed during basic settings factor settings pressed during pressed before function the initialization sequence only. boot sequence power on LED Output... - Page 47 Operation Press the key function Measurement function for a long mode period to leave the function settings menu Call menu Key function Mastering / Key lock after 5 min measurement Teaching active (ex factory) function settings LED Output LED Output LED Output grün yellow...

-

Page 48: Setting Sensor Parameters

Setting Sensor Parameters Setting Sensor Parameters Preliminary Remarks about the Setting Possibilities There are different ways to parametrize the optoNCDT 1900: - using the web browser via the ILD1900 DAQ tool and the sensor web interface - using the ASCII command set and the terminal program via RS422 If the parametrization is not permanently stored on the sensor, the settings will be lost after switching off the sensor. -

Page 49: Inputs

Setting Sensor Parameters Inputs Change to the Input menu in the Settings tab. Laser power Full / Reduced / Off The laser light source is active only, if pin 3 is connected to GND (pin 14). Synchronization Slave / If several sensors measure the same target synchronously, the Slave alternating sensors may be synchronized with each other. -

Page 50: Synchronization

Setting Sensor Parameters Synchronization 7.4.1 Synchronization via Sync +/- Connections If two sensors measure against the same target, the sensors can be synchronized. The optoNCDT 1900 distinguishes between two types of synchronization. Type Used for Simultaneous Both sensors measure Measurement of differences (thickness, difference in height) on opaque objects. Here, Sen- synchronization in the same cycle sor 1 must be programmed as the “Master“... - Page 51 Setting Sensor Parameters Sensor alternately synchronizes another sensor The signals Sync-in/out or /Sync-in/ of same polarity are connected in parallel with each other. A sensor is to program as a synchronous master, which supplies the subsequent slave sensor with symmetric synchronous pulses, RS422-level. In the slave sensor the ILD 1900 ILD 1900 terminating resistor is activated of 120 Ohm, see Chap.

-

Page 52: Synchronization Via Multi-Function Input

Setting Sensor Parameters 7.4.2 Synchronization via Multi-Function Input Do not ever connect two masters with each other. If two masters are connected to one another, the laser diodes switch off. No measurement is possible. TTL/HTL source simultaneously synchronizes other sensors If you synchronize the sensor with an external signal source, the levels of the Out+ signal source have to comply with the EIA-422-specificaions, see Chap. -

Page 53: Data Recording

Setting Sensor Parameters Data Recording 7.5.1 Preliminary Remark Change to the Data recording menu in the Settings tab . According to the previous setting in the Diagram type area, a diagram is displayed in the right part of the display. The diagram is active and all settings become immediately visible. -

Page 54: Triggering

- Triggering does not influence the preset measuring rate or the timing so that 4 cycles + 1 cycle (jitter) are between the trigger event (level change) and the output reaction - Micro-Epsilon does not recommend any data reduction e.g. by subsampling when the trigger is used. - The multi-function or synchronization inputs are used as external trigger inputs, see Chap. 5.4.6. - Page 55 Setting Sensor Parameters Implemented trigger conditions: Level triggering with High level / Low level. Continuous value input/output for as long as the selected level is ac- tive. Then the data recording/output stops. Pulse duration must last for at least one cycle. The subsequent pause must also last for at least one cycle.

-

Page 56: Triggering Data Recording

Setting Sensor Parameters 7.5.4.2 Triggering Data Recording The data recording trigger processes measurements which are recorded from the trigger event. Previously acquired measurement values are rejected. The record triggering therefore directly influences the subsequent processing of measured values. In particular, the average calculation only includes values measured from the trigger event. -

Page 57: Masking The Evaluation Range, Roi

Setting Sensor Parameters 7.5.5 Masking the Evaluation Range, ROI Masking limits the evaluating range (ROI - Region of Interest) for the distance calculation in the video signal. This function is used in order to e.g. suppress interfering reflections or ambient light. Masked area Measuring range Fig. -

Page 58: Exposure Mode

Setting Sensor Parameters 7.5.6 Exposure Mode Exposure mode Automatic mode Standard / Intelligent control / Background suppression 50 Range [%] 100 Standard: the sensor determines the optimal exposure time in order to achieve the highest possible signal intensity Intelligent control: the intelligent control algorithm is benefi- cial when measuring moving objects or material transitions. -

Page 59: Peak Selection

Setting Sensor Parameters 7.5.7 Peak Selection Peak selection First peak / Defines which signal is used for the close Sensor faraway Highest peak / evaluation in the line signal. Highest Last peak / First peak: Nearest peak to sensor. Last peak Widest peak peak... -

Page 60: Signal Processing

Setting Sensor Parameters Signal Processing 7.6.1 Preliminary Remark Change to the Signal processing menu in the Settings tab. According to the previous setting in the Diagram type area, a diagram is displayed in the right part of the display. The diagram is active and all settings become immediately visible. -

Page 61: Moving Average

Setting Sensor Parameters The defined type of average value and the averaging number must be stored in the sensor to ensure they are hold after it is switched off. Averaging has no effect on the measuring rate or data rate in case of digital measurement value output. The averaging numbers can also be programmed via the digital interfaces. -

Page 62: Recursive Average

Setting Sensor Parameters 7.6.2.3 Recursive average Formula: Measurement value, MV + (N-1) x (n) = rek (n-1) Averaging number, Measurement value index Averaging value respectively output value Methods: The weighted value of each new measured value MV(n) is added to the sum of the previous average values M (n-1). -

Page 63: Output Trigger

Setting Sensor Parameters 7.6.3 Output Trigger Details can be found in Triggering, see Chap. 7.5.4. 7.6.4 Data Reduction, Output Data Rate Data reduction Value Indicates the sensor which data is to be excluded from output, thus the data amount to be transmitted is reduced. Reduction relates to RS422 / Analog / Chart Interfaces to be used for undersampling are to be selected via the checkbox. -

Page 64: Outputs

Setting Sensor Parameters Outputs 7.7.1 Overview RS422 Baud rate 9.6 / 115.2 / 230.4 / 460.8 / 691.2 / 921.6 / 2000 / Transmission speed, binary data format 3000 / 4000 kBps Output data Distance / Non-linearized focal point / Intensity / Data to be transmitted are to be activated Exposure time / Sensor state / Measuring rate via the checkbox. - Page 65 Setting Sensor Parameters Output interface RS422 / Analog output / digital output 1 / digital output 2 Defines which interface is used for output of mea- sured values. A parallel output of measured values via multiple channels is not possible. RS422 and analog output cannot be operated simultaneously.

-

Page 66: Digital Output, Rs422

Setting Sensor Parameters 7.7.2 Digital Output, RS422 7.7.2.1 Values, Ranges The digital measurement values are issued as unsigned digital values (raw values). 16 or 18 bits can be transferred per value. Below you will find a compilation of the output values and the conversion of the digital value. Value Length Variables Value range... - Page 67 Setting Sensor Parameters Time Stamp 2 words, digital value Lo [0; 65535] à 16 Bit (65536y + x) digital value Hi [0; 65535] 1000 time stamp in µs [0; 1h11m34.967s] Unlinearized 18 Bit digital value [0; 262143] center of gravity US = 262143 center of gravity in %...

-

Page 68: Behavior Of The Digital Output

Setting Sensor Parameters 7.7.2.2 Behavior of the Digital Output Master values based on the zeroing or master function are coded with 18 bits. Master value range: 0 ... 2x measuring range. The examples demonstrate the behavior of the digital value with an ILD1900-100, measuring range 100 mm. Target with 16% of the measuring range Target with 60% of the measuring range Target with 60% of the measuring range... - Page 69 Setting Sensor Parameters Target with 80% of the measuring range (80 mm) Setting master value 200 mm Digital Digital 242411 163768 229304 150661 164424 163768 131000 Dig. 131000 Distance in mm 176875 98232 Distance after 98232 mastering in mm 97576 50 % 100 % 120 SMR‘...

-

Page 70: Analog Output

Setting Sensor Parameters 7.7.3 Analog Output 100 % 7.7.3.1 Output Scaling Standard characteristic Analog output - Max. output range: 4 mA ... 20 mA or 0 V ... 5 V / 0 V ... 10 V - Output amplification DI : 16 mA or : 5 V / 10 V;... -

Page 71: Output Scaling With The Select Button

Setting Sensor Parameters 7.7.3.2 Output Scaling with the Select Button Preparation Measuring Position the Position the - Deactivate key lock (menu Select Select Select measuring measuring System settings) object (Teach 1) object (Teach 2) min. min. - Teaching process with Select 30 ms 30 ms button... -

Page 72: Output Scaling Via Hardware Input

Setting Sensor Parameters 7.7.3.3 Output Scaling via Hardware Input Scaling the analog output is possible via a pulse at the multi-function input, at pin 10 pigtail or the white-green wire of the sensor cable or PC1900-x. Preparation: Measuring Start Position the target Teach in 1 Position the Teach in 2... -

Page 73: Calculation Of The Measurement Value At The Current Output

Setting Sensor Parameters 7.7.3.4 Calculation of the Measurement Value at the Current Output Current output (without mastering, without teaching) Variables Value range Formula [3.8; < 4] SMR reserve current in mA [4; 20] Measuring range - 4) [> 20; 20,2] EMR reserve * MR Measuring range in mm {10/25/50}... -

Page 74: Calculation Of The Measurement Value From The Voltage Output

Setting Sensor Parameters 7.7.3.5 Calculation of the measurement value from the voltage output Voltage output (without mastering, without teaching) Variables Value range Formula [-0.05; < 0] SMR reserve * MR [0; 5] Measuring range [> 5; 5.05] EMR reserve Voltage in V [-0.1;... -

Page 75: Switching Outputs

Setting Sensor Parameters 7.7.4 Switching Outputs Example - Digital output 1: Distance out of limit, both The two switching outputs can be used independently of each - Digital output 2: Full-scale error other for error or limit value monitoring of the output value Dis- tance 1. -

Page 76: Data Output

Setting Sensor Parameters Full-scale error Distance outside Distance is out of the analog range limit Minimum hold time Hysteresis Fig. 42 Use of the parameters minimum hold time and hysteresis with the individual monitoring functions The function of the switching outputs is generally independent of the analog output. When active, the respective transistor of a switching output is conductive. -

Page 77: System Settings

Setting Sensor Parameters System Settings 7.8.1 General When programming has been completed, store all settings permanently in a set of parameters to ensure that these settings are avail- able when the sensor is switched on the next time. 7.8.2 Unit, Language The web interface promotes the units millimeter (mm) and inch when displaying measuring results. -

Page 78: Load And Save

Setting Sensor Parameters 7.8.4 Load and Save All settings on the sensor can be permanently saved in user programs, so-called setups, in the sensor. Fig. 44 Administration of user settings Mange setups in the sensor, possibilities and procedure Store the Settings Activate existing setup Save changes in active Define setup after booting... - Page 79 Setting Sensor Parameters Exchange setups with PC/notebook, possibilities Safe setup on PC Load setup from PC Menu Load & Save Menu Load & Save Click on the desired setup with the left mouse button, area A. Click on New setup with the left mouse button. The dialog measurement settings opens.

-

Page 80: Import, Export

Setting Sensor Parameters 7.8.5 Import, Export A parameter set includes the current settings, setup(s) and the initial setup when booting the sensor. The Import & Export menu enables easy exchange of parameter sets with a PC/notebook. Exchange of parameter sets with PC/notebook, possibilities Storing parameter set on PC Loading parameter set from PC Menu Import &... -

Page 81: Access Authorization

Setting Sensor Parameters 7.8.6 Access Authorization Assigning passwords prevents unauthorized changes to sensor settings. Password protection is not enabled as a factory setting. The sensor works on the Professional level. After the sensor has been configured, you should enable password protection. The standard password for the Professional level is “000”. -

Page 82: Reset Sensor

All passwords are case-sensitive. Numbers are allowed, but special characters are not permitted. The maximum length is 31 characters. User level when User / Defines the user level that is enabled when the sensor starts the next time. MICRO-EPSILON restarting Professional recommend to select User level. -

Page 83: Digital Interfaces Rs422

Digital Interfaces RS422 Digital Interfaces RS422 Preliminary Remarks The interface RS422 has a maximum baud rate of 4 MBaud. The factory-set baud rate is 921.6 kBaud. Data format: Measurement values in binary format, commands as an ASCII string. Interface parameter: 8 Data bits, no parity, one stop bit (8N1). Disconnect or connect the D-sub connection between RS422 and USB converter when the sensor is disconnected from power supply only. -

Page 84: Conversion Of The Binary Data Format

The sensor continues to deliver measurement values to the RS422 output even while communicating with the sensor. For the data transmission with a PC the MICRO-EPSILON IF2008/PCIE PCI BUS interface card is suitable. This can be connected to the sensor via the PC1900-x/IF2008 interface cable, which is also available as an option. The IF2008/PCIE combines the three bytes for the data word and saves them in the FIFO. -

Page 85: Cleaning

- features by identical functions for the communication (commands), - provides a consistent transmission format for all MICRO-EPSILON sensors. For C/C++ programmers MEDAQLib contains an additional header file and a library file. You will find the latest driver / program rou- tine at: www.micro-epsilon.com/service/download/... -

Page 86: Liability For Material Defects

The liability for material defects is 12 months from delivery. Within this period, defective parts, except for wearing parts, will be repaired or replaced free of charge, if the device is returned to MICRO-EPSILON with shipping costs prepaid. Any damage that is caused by improper handling, the use of force or by repairs or modifications by third parties is not covered by the liability for material defects. -

Page 87: Appendix

D/A conversion of a digital measurements, output through current and volt- age output. IF2030/PNET Interface module for PROFINET or Ethernet connection of a Micro-Epsilon IF2030/ENETIP sensor with RS485 or RS422 interface, suitable for PC1900-x/OE cables, top- hat rail housing, incl. GSDML file for software integration in the PLC... - Page 88 Appendix | Optional Accessories PS2020 Power supply for mounting on DIN rail, input 230 VAC, output 24 VDC/2.5 A IF2008/PCIE The IF2008/PCIE interface card enables the synchronous capture of 4 digital sensor signals series optoNCDT 1750 or others or 2 encoders. In combina- tion with IF2008E a total of 6 digital signals, 2 encoder, 2 analog signals and 8 I/O signals can be acquired synchronously.

-

Page 89: A 2 Factory Setting

Appendix | Factory Setting Factory Setting Averaging Median with 9 values RS422 921.6 kBaud Password „000“ Peak selection Highest peak Trigger mode No trigger Measuring rate 4 kHz Output Analog and switching output 1 Language German 100 % FSO: I = 20 mA , digital 163768 Measuring range Error handling Error output, no measurement... -

Page 90: A 3 Ascii Communication With Sensor

Appendix | ASCII Communication with Sensor ASCII Communication with Sensor A 3.1 General The ASCII commands can be sent to the sensor via the RS422 interface. All commands, inputs and error messages are effected in English. One command always consists of a command name and zero or several parameters, which are separated by blanks and are com- pleted with LF. - Page 91 Appendix | ASCII Communication with Sensor Declarations on format: „a | b“ Value of the parameter can be set to the value “a“ or “b“. „ P1 P2“ It requires that both parameters “P1“ and “P2“ are set. The parameters “P1“, “P2“ and “P3“ can be set, whereby “P2“ may only be set, if “P1“ is set and “P3“ only if “P1“ „...

-

Page 92: Overview Commands

Appendix | ASCII Communication with Sensor A 3.2 Overview Commands Group Chapter Command Short description General Chap. A 3.2.1.1 HELP Help on commands Chap. A 3.2.1.2 GETINFO Request sensor information Chap. A 3.2.1.3 LANGUAGE Determine language of the web interface Chap. - Page 93 Appendix | ASCII Communication with Sensor Interfaces Chap. A 3.2.4.1 BAUDRATE Setting transmission rate of RS422 Chap. A 3.2.4.2 ERROROUT1/2 Activating switching outputs Chap. A 3.2.4.3 ERRORLEVELOUT1/2 Output level switching outputs Chap. A 3.2.4.4 ERRORLIMITCOMPARETO1/2 Monitoring function switching outputs Chap. A 3.2.4.5 ERRORLIMITVALUES1/2 Threshold switching output...

- Page 94 Appendix | ASCII Communication with Sensor Measurement Chap. A 3.2.8.1 TARGETMODE Choice of material-dependent measurement algorithm Chap. A 3.2.8.2 MEASPEAK Peak selection, diffuse sensor arrangement Chap. A 3.2.8.3 MEASRATE Select a Measuring Rate Chap. A 3.2.8.4 SHUTTER Exposure time Chap. A 3.2.8.5 SHUTTERMODE Automatic or manual exposure time...

-

Page 95: A 3.2.1 General Commands

Appendix | ASCII Communication with Sensor A 3.2.1 General Commands A 3.2.1.1 HELP Issues a help for every command. Command without parameter <Command> // Command is executed. Command with parameter. <Command> // Show current parameter value <Command> <Parameter1> [<Parameter2> [...]] // Set parameters, number of parameters varies <Command>... -

Page 96: A 3.2.1.2 Getinfo, Sensor Information

Appendix | ASCII Communication with Sensor Examples: // Use a or b // Both parameters are required a [b [c]] // Indefinite number of parameters: a, a b, or a b c PASSWD <Old password> // In order to change the password, all parameters are required. <New password>... -

Page 97: A 3.2.1.4 Reset, Boot Sensor

Appendix | ASCII Communication with Sensor A 3.2.1.4 RESET, boot sensor RESET The sensor is restarted. A 3.2.1.5 RESETCNT, Reset counter RESETCNT [TIMESTAMP] [MEASCNT] Resets the internal counter in the sensor. - TIMESTAMP: resets the time stamp - MEASCNT: resets the measured value counter A 3.2.1.6 ECHO, Switching the Command Reply, ASCII Interface ECHO ON|OFF... -

Page 98: A 3.2.1.7 Print, Sensor Settings

Appendix | ASCII Communication with Sensor A 3.2.1.7 PRINT, Sensor settings PRINT Print serves the output of all sensor settings Example response: GETUSERLEVEL PROFESSIONAL OUTPUT RS422 STDUSER PROFESSIONAL OUTHOLD NONE UNIT MM OUTREDUCEDEVICE RS422 LANGUAGE DE OUTREDUCECOUNT 1000 KEYLOCK AUTO 5 (IS_ACTIVE) OUT_RS422 DIST1 COUNTER BAUDRATE 921600 ANALOGRANGE 0-10V... -

Page 99: A 3.2.1.8 Sync

Appendix | ASCII Communication with Sensor A 3.2.1.8 SYNC SYNC NONE | MASTER | MASTER_ALT | SLAVE | SLAVE_ALT | SLAVE_MFI Setting the type of synchronization: - NONE: No synchronization - MASTER: The sensor is master, i.e. it transmits synchronization pulses on the output. - MASTER_ALT: The sensor is master, i.e. -

Page 100: A 3.2.2 User Level

Appendix | ASCII Communication with Sensor A 3.2.2 User Level A 3.2.2.1 LOGIN, Change of the User Level LOGIN <Password> Enter the password to switch to a different user level. The following user levels exist: - USER (standard user): “read-only” access to all elements and graphical display of output values of web interface - PROFESSIONAL (Expert): Read/write access to all elements A 3.2.2.2 LOGOUT, Change into User Level... -

Page 101: A 3.2.3 Triggering

Appendix | ASCII Communication with Sensor A 3.2.3 Triggering The multi-function input also serves as trigger input A 3.2.3.1 TRIGGERLEVEL, Active level triggering TRIGGERLEVEL HIGH | LOW - HIGH: Edge triggering: Rising edge, level triggering: High-active - LOW: Edge triggering: Falling edge, level triggering: Low-active A 3.2.3.2 TRIGGERMODE TRIGGERMODE EDGE | PULSE... -

Page 102: A 3.2.3.6 Triggercount, Number Of Output Measurement Values

Appendix | ASCII Communication with Sensor A 3.2.3.6 TRIGGERCOUNT, Number of Output Measurement Values TRIGGERCOUNT INFINITE | <n> <1...16382> Number of Output Measurement Values with Triggering - INFINITE: Start of continuous output after the first trigger event - <n>: Number of measured values to be output after every trigger event n = 1 …16382. A 3.2.3.7 TRIGGERSW, Software Trigger Pulse TRIGGERSW SET|CLR... -

Page 103: A 3.2.4 Interfaces

Appendix | ASCII Communication with Sensor A 3.2.4 Interfaces A 3.2.4.1 BAUDRATE, RS422 BAUDRATE 9600|115200|230400|460800|691200|921600|2000000|3000000|4000000 Set the baud rate for the RS422 interface. A 3.2.4.2 ERROROUT1/2, Activate Switching Output ERROROUT1 DIST|TEACH|LI1 ERROROUT2 DIST|TEACH|LI1 Choose error signal of the ERROR switching output. - DIST: no peak found or beyond measuring range (out of range) - TEACH: Distance is out of scaled analog range - LI1: Distance is greater than the limit value (ERRORLIMIT) -

Page 104: Errorlimitvalues1/2

Appendix | ASCII Communication with Sensor A 3.2.4.5 ERRORLIMITVALUES1/2 ERRORLIMITVALUES1 [<lower limit [mm]> [<upper limit [mm]>]] ERRORLIMITVALUES2 [<lower limit [mm]> [<upper limit [mm]>]] Defines the lower and upper limit value for the switching outputs. Value range: - <lower limit [mm]> = (-2 ... 2) * measuring range [mm] - <upper limit [mm]>... -

Page 105: A 3.2.5 Handling Of Setups

Appendix | ASCII Communication with Sensor A 3.2.5 Handling of Setups A 3.2.5.1 IMPORT IMPORT [FORCE] [APPLY] <ImportData> Import of data in JSON format to the sensor. First, the import command returns a prompt (->). Afterwards, data can be sent. After importing a prompt (->) is returned. - FORCE: Overwriting measurement settings (=MEASSETTINGS) with the same name (otherwise an error message is displayed when the name is the same). -

Page 106: A 3.2.5.3 Meassettings, Load / Save Measurement Settings

Appendix | ASCII Communication with Sensor A 3.2.5.3 MEASSETTINGS, Load / Save Measurement Settings MEASSETTINGS <Subcommands> [<Name>] Settings of the measurement task. Loads proprietary presets and user-specific settings from the sensor or stores user-specific setups in the sensor. Subcommands: ƒ PRESETMODE: Returns the currently used Preset mode. ƒ... -

Page 107: A 3.2.6 Analog Output

Appendix | ASCII Communication with Sensor A 3.2.6 Analog Output A 3.2.6.1 ANALOGRANGE ANALOGRANGE [0-5V|0-10V|4-20mA] Sets the type of the analog output. A 3.2.6.2 ANALOGSCALEMODE, Scaling the Analog Output ANALOGSCALEMODE STANDARD|TWOPOINT Choice of the scaling type of the analog output. - STANDARD: using the measuring range of the sensor - TWOPOINT: two-point scaling within the analog range ƒ... -

Page 108: A 3.2.7 Key Function

Appendix | ASCII Communication with Sensor A 3.2.7 Key Function A 3.2.7.1 KEYLOCK, Set Key lock KEYLOCK NONE | ACTIVE | AUTO [<timeout period>] Key lock configuration - NONE: Key is active, no key lock - ACTIVE: Key lock is activated immediately after restart - AUTO: Key lock is only activated <timeout period>, 1 ... -

Page 109: A 3.2.8.4 Shutter, Exposure Time

Appendix | ASCII Communication with Sensor A 3.2.8.4 SHUTTER, Exposure Time SHUTTER <exposure time> Sets the exposure time to a fixed value with manual exposure time. The maximum exposure time is the reciprocal of the measuring rate. Therefore, the manual exposure time is smaller than/equal to the maximum exposure time. -

Page 110: A 3.2.8.9 Comp , Averaged Measurements

Appendix | ASCII Communication with Sensor A 3.2.8.9 COMP , Averaged Measurements COMP [CH01 [<id>]] COMP CH01 <id> MEDIAN <signal> <median data count> COMP CH01 <id> MOVING <signal> <moving data count> COMP CH01 <id> RECURSIVE <signal> <recursive data count> COMP CH01 <id> NONE - <id>... -

Page 111: A 3.2.8.11 Master

Appendix | ASCII Communication with Sensor A 3.2.8.11 MASTER MASTER [DIST1] MASTER ALL|DIST1 SET|RESET The function uses the measurement value (DIST1) in order to generate an offset. This offset is then applied to the following measure- ment values. Example: Zero is defined as master value, DIST1 currently provides 0.5 mm as measured value. Therefore, -0.5 mm is applied as offset to DIST1. -

Page 112: A 3.2.9 Data Output

Appendix | ASCII Communication with Sensor A 3.2.9 Data output A 3.2.9.1 OUTPUT, Selection of Measurement Value Output OUTPUT NONE | ([RS422 | ANALOG] [ERROROUT1 | ERROROUT2 | ERROROUT1 ERROROUT2]) - NONE: No measurement value output - RS422: Output of measurement values via RS422 - ANALOG: Output of measurement values via analog output - ERROROUT1/2: Output of an error/status information via the switching outputs. -

Page 113: A 3.2.9.5 Getoutinfo_Rs422, Query Selected Data

Appendix | ASCII Communication with Sensor A 3.2.9.5 GETOUTINFO_RS422, Query Selected Data GETOUTINFO_RS422 The command lists all output data chosen for the RS422 interface. The displayed order corresponds to the output sequence. A 3.2.9.6 List of Possible RS422 Signals META_OUT_RS422 List of possible data for RS422. -

Page 114: A 3.3 Example Command Sequence During Selection Of Measurement Value

Appendix | ASCII Communication with Sensor A 3.3 Example Command Sequence During Selection of Measurement Value Command Content MEASPEAK Peak selection with distance measurement MEASRATE Measuring rate (by taking into consideration reflectivity and movement of the target) Averaged measurements (by taking into consideration reflectivity, structure and COMP movement of the target) OUTPUT... - Page 115 Appendix | ASCII Communication with Sensor E234 Wrong or unknown parameter type A transmitted parameter has a wrong type or a wrong number of parameters were transmitted. E236 Value is out of range or the format is invalid The parameter value is outside the range of values. E262 Active signal transfer, please stop before One measurement data output is active.

- Page 116 Appendix | ASCII Communication with Sensor Warning Description W320 The measuring output has been adapted automatically. The measurement value output has been adapted automatically. W570 The input has been adapted automatically to a limited range. The input has been adapted automatically to a limited range. optoNCDT 1900 Seite 116...

-

Page 117: A 4 Control Menu

Appendix | Control Menu Control Menu A 4.1 Tab Home Measurement Presets Standard Suitable for materials made of ceramics, metal or task filled plastics Multi-Surface Suitable for printed circuit boards, hybrid material Light penetration Suitable for plastics, materials with large penetration depth of the laser Setups Setup 1 ... -

Page 118: Data Recording

Appendix | Control Menu A 4.2.2 Data Recording Measuring rate 250 Hz / 500 Hz / 1 kHz / 2 kHz / 4 kHz / Use a high measuring rate for bright and mat measurement objects. Use 8 kHz / 10 kHz a low measuring rate for dark or shiny measurement objects (e.g. - Page 119 Appendix | Control Menu Exposure mode Automatic mode In the automatic mode, the sensor determines the / Manual mode optimal exposure time in order to achieve the high- est possible signal intensity. In the manual mode, when the video signal is displayed, the user determines the exposure time Vary the exposure time in order to achieve a signal quality up to a maximum of 95 %.

-

Page 120: A 4.2.3 Signal Processing

Appendix | Control Menu A 4.2.3 Signal Processing Averaging Inactive Measurement values are not averaged. Moving N values 2 / 4 / 8 ... 4096 Value Indication of averaging mode. The averaging number N indi- cates the number of consecutive measurement values to be Recursive N values 2 ... -

Page 121: Outputs

Appendix | Control Menu A 4.2.4 Outputs RS422 Baud rate 9.6 / 115.2 / 230.4 / 460.8 / 691.2 / 921.6 / Transmission speed, binary data format 2000 / 3000 / 4000 kBps Output data Distance / Non-linearized focal point / Inten- Data to be transmitted are to be activated via the sity / Exposure time / Sensor state / checkbox. - Page 122 Appendix | Control Menu Output interface RS422 / Analog output / digital output 1 / digital output 2 Defines which interface is used for output of mea- sured values. A parallel output of measured values via multiple channels is not possible. RS422 and analog output cannot be operated simultaneously.

-

Page 123: System Settings

Appendix | Control Menu A 4.2.5 System Settings Unit web interface mm / Inch Unit in measurement value display Key lock Automatic Countdown 1 ... 60 [min] Value The key lock starts after expiry of the defined time. Click- ing the button Refresh extends the interval until key lock Refresh starts. - Page 124 Read only permission Logout / Login Button starts change of access permission. Sets the user level the sensor starts with after re- User level when boot. In this case MICRO-EPSILON recommends the Professional / User restarting selection user. password Value Case-sensitive rules are observed for all passwords.

- Page 125 Appendix | Control Menu Reset sensor Measurement settings The settings for measuring rate, trigger, evaluation range, selection of peak, error handling, averaging, Zeroing/Mastering, reduction of data and setups are deleted. The 1st preset is loaded. Device settings The settings baud rate, language, unit, key lock and echo mode are deleted and the default parameters are loaded.

- Page 126 MICRO-EPSILON MESSTECHNIK GmbH & Co. KG X9751416-A032090MSC Koenigbacher Str. 15 · 94496 Ortenburg / Germany Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90 MICRO-EPSILON MESSTECHNIK info@micro-epsilon.com · www.micro-epsilon.com *X9751416-A03* Your local contact: www.micro-epsilon.com/contact/worldwide/...

Need help?

Do you have a question about the optoNCDT 1900 Series and is the answer not in the manual?

Questions and answers