Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Aerotech ALAR SP Series

-

Page 1: Alar Hardware Manual

ALAR Hardware Manual Revision: 1.09.00... - Page 2 This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and may be trademarks of their respective companies.

-

Page 3: Table Of Contents

3.3. Motor and Feedback Specifications 3.4. Limits, Marker, and Machine Direction 3.5. Motor and Feedback Phasing Chapter 4: Maintenance 4.1. Service and Inspection Schedule 4.2. Cleaning 4.3. Troubleshooting Appendix A: Warranty and Field Service Appendix B: Revision History Index www.aerotech.com... -

Page 4: List Of Figures

Motor and Feedback Wiring (-E1 to -E6 Encoder Options) Figure 3-3: Motor and Feedback Wiring (-E7 Encoder Option) Figure 3-4: Machine Direction Figure 3-5: Hall Phasing Figure 3-6: Analog Encoder Phasing Reference Diagram Figure 3-7: Encoder Phasing Reference Diagram (Standard) www.aerotech.com... -

Page 5: List Of Tables

Maximum Speed Per Encoder Option (ALAR-LP) Table 3-13: Maximum Speed Per Encoder Option (ALAR-XP) Table 3-14: ALAR-SP Motor Specifications (ALAR100SP, ALAR150SP, and ALAR200SP) Table 3-15: ALAR-SP Motor Specifications (ALAR250SP and ALAR325SP) Table 3-16: ALAR-LP Motor Specifications Table 3-17: ALAR-XP Motor Specifications www.aerotech.com... - Page 6 Table of Contents ALAR Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 7: Safety Procedures And Warnings

Danger or Warning symbol in this manual. If you do not obey these precautions, injury to you or damage to the equipment can occur. If you do not understand the information in this manual, contact Aerotech Global Technical Support. This product has been designed for light industrial manufacturing or laboratory environments. The protection provided by the equipment could be impaired if the product is used in a manner not specified by the manufacturer. - Page 8 Safety ALAR Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 9: Eu Declaration Of Incorporation

ALAR Hardware Manual Declaration of Conformity EU Declaration of Incorporation Manufacturer: Aerotech, Inc. 101 Zeta Drive Pittsburgh, PA 15238-2811 herewith declares that the product: ALAR Stage is intended to be incorporated into machinery to constitute machinery covered by the Directive 2006/42/EC as amended;... - Page 10 Declaration of Conformity ALAR Hardware Manual This page intentionally left blank. www.aerotech.com...

-

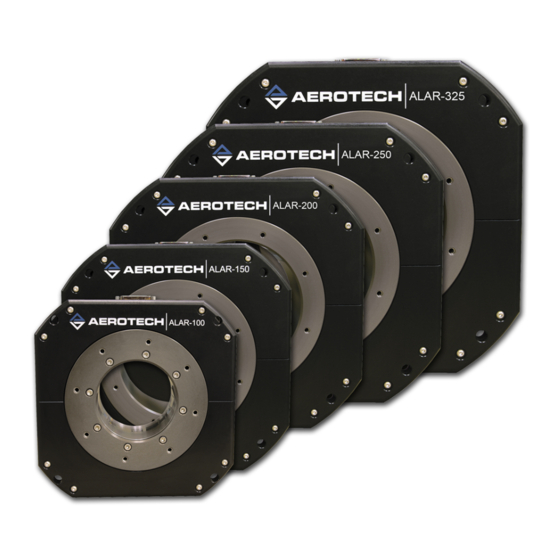

Page 11: Chapter 1: Overview

Overview Chapter 1: Overview N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any time. All drawings and illustrations are for reference only and were complete and accurate as of this manual’s release. Refer to www.aerotech.com for the most up-to-date information. -

Page 12: Environmental Specifications

Indoor use only 1.2. Accuracy and Temperature Effects Aerotech products are designed for and built in a 20°C (68°F) environment. Extreme temperature changes could cause a decrease in performance or permanent damage to the ALAR. At a minimum, the environmental temperature must be controlled to within 0.25ºC per 24 hours to ensure the ALAR specifications are repeatable over an extended period of time. -

Page 13: Basic Specifications

Overview 1.3. Basic Specifications N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any time. All drawings and illustrations are for reference only and were complete and accurate as of this manual’s release. Refer to www.aerotech.com for the most up-to-date information. -

Page 14: Table 1-4: Alar-Sp Series Specifications (Alar250Sp And Alar325Sp)

9.7 µrad (2.0 arc sec) 1. Square-wave digital encoder options will limit maximum speed below the listed value. 2. Resolution assumes -E1 encoder with 2000X controller multiplication. 3. Certified with each stage.Requires the use of an Aerotech controller. Chapter 1 www.aerotech.com... -

Page 15: Table 1-5: Alar-Lp Series Specifications (Alar100Lp, Alar150Lp, And Alar200Lp)

2. Resolution assumes -E1 encoder with 2000X controller multiplication. 3. The ALAR-LP base must be fully supported by a rigid mounting plate to achieve this moment load. 4. Certified with each stage.Requires the use of an Aerotech controller. www.aerotech.com Chapter 1... -

Page 16: Table 1-6: Alar-Lp Series Specifications (Alar250Lp And Alar325Lp)

2. Resolution assumes -E1 encoder with 2000X controller multiplication. 3. The ALAR-LP base must be fully supported by a rigid mounting plate to achieve this moment load. 4. Certified with each stage. Requires the use of an Aerotech controller. Chapter 1... -

Page 17: Table 1-7: Alar-Xp Series Specifications (Alar250Xp And Alar325Xp)

108 kg 129 kg 134 kg 1. Resolution assumes -E1 encoder with 2000X controller multiplication. 2. Certified with each stage. Requires the use of an Aerotech controller. 3. Maximum speed assumes a bus voltage of 320 VDC. www.aerotech.com Chapter 1... -

Page 18: Vacuum Operation

Because of this, consider all continuous torque ratings to be 40 to 60% lower than the value specified for operation in normal atmospheric environment. Reduce motor usage accordingly. Chapter 1 www.aerotech.com... -

Page 19: Chapter 2: Mechanical Specifications And Installation

Allowing it to stabilize to room temperature will ensure that all of the alignments, preloads, and tolerances are the same as they were when tested at Aerotech. Use compressed nitrogen or clean, dry, oil-less air to remove any dust or debris that has collected during shipping. -

Page 20: Figure 2-1: Alar With Lifting Bolts

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-1: ALAR with Lifting Bolts Chapter 2 www.aerotech.com... -

Page 21: Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation 2.2. Dimensions Figure 2-2: ALAR100SP Dimensions www.aerotech.com Chapter 2... -

Page 22: Figure 2-3: Alar100Lp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-3: ALAR100LP Dimensions Chapter 2 www.aerotech.com... -

Page 23: Figure 2-4: Alar150Sp Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation Figure 2-4: ALAR150SP Dimensions www.aerotech.com Chapter 2... -

Page 24: Figure 2-5: Alar150Lp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-5: ALAR150LP Dimensions Chapter 2 www.aerotech.com... -

Page 25: Figure 2-6: Alar200Sp Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation Figure 2-6: ALAR200SP Dimensions www.aerotech.com Chapter 2... -

Page 26: Figure 2-7: Alar200Lp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-7: ALAR200LP Dimensions Chapter 2 www.aerotech.com... -

Page 27: Figure 2-8: Alar250Sp Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation Figure 2-8: ALAR250SP Dimensions www.aerotech.com Chapter 2... -

Page 28: Figure 2-9: Alar250Lp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-9: ALAR250LP Dimensions Chapter 2 www.aerotech.com... -

Page 29: Figure 2-10: Alar250Xp Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation Figure 2-10: ALAR250XP Dimensions www.aerotech.com Chapter 2... -

Page 30: Figure 2-11: Alar325Sp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-11: ALAR325SP Dimensions Chapter 2 www.aerotech.com... -

Page 31: Figure 2-12: Alar325Lp Dimensions

ALAR Hardware Manual Mechanical Specifications and Installation Figure 2-12: ALAR325LP Dimensions www.aerotech.com Chapter 2... -

Page 32: Figure 2-13: Alar325Xp Dimensions

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-13: ALAR325XP Dimensions Chapter 2 www.aerotech.com... -

Page 33: Securing The Stage To The Mounting Surface

Table 2-1: Stage to Mounting Surface Hardware Mounting Hardware Typical Screw Torque M6 SHCS (ALAR100SP/LP, ALAR150SP/LP) 7 N·m M8 SHCS (ALAR200SP/LP, ALAR250SP/LP, ALAR325SP/LP) 17 N·m M12 SHCS (ALAR250XP, and ALAR325XP models) 57 N·m www.aerotech.com Chapter 2... -

Page 34: Figure 2-14: Alar Stage Mounting Holes

Mechanical Specifications and Installation ALAR Hardware Manual Figure 2-14: ALAR Stage Mounting Holes Chapter 2 www.aerotech.com... -

Page 35: Attaching The Payload To The Stage

N O T E : If your ALAR was purchased with Aerotech controls, it might have been tuned with a representative payload based on the information provided at the time of order. If the ALAR is started up without a payload, the servo gains provided by Aerotech with the shipment may not be appropriate and servo instability can occur. -

Page 36: Travel Adjustment

The internal hard stop is used at the factory to set the electrical and mechanical limit travels. It is not a functional hard stop. Aerotech recommends that you install external hard stops (not supplied) after you receive the stage. The hard stops will need to be designed around application specific parameters such as payload and acceleration. -

Page 37: Electrical Limits

The stage can then continue into the hard stop or do so the next time it is enabled. If you are unsure how to adjust the electrical limit, contact Aerotech for support. ALAR-SP and ALAR-LP: Stages shipped with the -TR340 option can be retrofitted to achieve a different limit travel. Determine the amount of travel required and use the procedure that follows. -

Page 38: Figure 2-15: Alar Limit Flag Adjustment

6. Verify travel with the controller by hand, and adjust the limit flag locations as necessary. 7. Reattach the top covers to the stage with the button head cap screws removed in Step 2. 8. Reconnect the motor cable. Figure 2-15: ALAR Limit Flag Adjustment Chapter 2 www.aerotech.com... -

Page 39: Chapter 3: Electrical Specifications And Installation

W A R N I N G : Electrical installation must be performed by properly qualified personnel. Aerotech motion control systems are adjusted at the factory for optimum performance. When the ALAR is part of a complete Aerotech motion control system, setup usually involves connecting the ALAR to the appropriate drive chassis with the cables provided. -

Page 40: Motor And Feedback Connectors

N O T E : Refer to the other documentation accompanying your Aerotech equipment. Call your Aerotech representative if there are any questions on system configuration. N O T E : If using standard Aerotech motors and cables, motor and encoder connection adjustments are not required. -

Page 41: Table 3-1: 4-Pin Motor Connector Pinout

Reserved Reserved Reserved Reserved Reserved Frame ground (motor protective ground) Table 3-2: Mating Connector Part Numbers for the Motor Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Sockets [QTY. 4] ECK00659 ITT Cannon #DM53744-6 Connector ECK00657 ITT Cannon #DBM9W4SA197 www.aerotech.com... -

Page 42: Table 3-3: 25-Pin Feedback Connector Pinout For The -E1 To -E6 Encoder Options

Signal indicating maximum travel produced by negative/CCW stage direction Reserved 1. Only available on stages with limit option (otherwise RESERVED). Table 3-4: Mating Connector Part Numbers for the Feedback Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Connector... -

Page 43: Table 3-5: 25-Pin Feedback Connector Pinout For The -E7 Encoder Option

Common ground Reserved Reserved Signal indicating stage maximum travel produced by negative/CCW stage direction Reserved Table 3-6: Mating Connector Part Numbers for the Feedback Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Connector ECK00300 FCI DB25S064TLF www.aerotech.com... -

Page 44: Motor And Feedback Wiring

All motor and controller manufacturers have their own designations for motor phases A/B/C and Hall signals A/B/C (refer to Section 3.5. for motor phasing). Shielded cables are required for the motor and feedback connections. Figure 3-2: Motor and Feedback Wiring (-E1 to -E6 Encoder Options) Chapter 3 www.aerotech.com... -

Page 45: Figure 3-3: Motor And Feedback Wiring (-E7 Encoder Option)

ALAR Hardware Manual Electrical Specifications and Installation Figure 3-3: Motor and Feedback Wiring (-E7 Encoder Option) www.aerotech.com Chapter 3... -

Page 46: Motor And Feedback Specifications

Hall-Effect Sensors, Encoder, and (if present) Limit Switches are connected to one common 5 VDC supply. Refer to Figure 3-2 Figure 3-3. Chapter 3 www.aerotech.com... -

Page 47: Table 3-8: Alar-Sp Encoder Specifications

Table 3-10: ALAR-XP Encoder Specifications Encoder Option ALAR250XP ALAR325XP Fundamental Resolution 64800 76800 (lines/rev) -E1 (arcsec / line) 0.003 0.002 -E6 (arcsec / line) 0.084 -E7 (arcsec / line) 0.0003 0.0003 1. Resolution assumes 2000X controller multiplication. www.aerotech.com Chapter 3... -

Page 48: Table 3-11: Alar-Sp Maximum Speed Per Encoder Option

90 rpm 120 rpm Table 3-13: Maximum Speed Per Encoder Option (ALAR-XP) Encoder Option ALAR250XP ALAR325XP 180 rpm 100 rpm 134 rpm 100 rpm 180 rpm 100 rpm 1. Digital encoder option (-E6) will limit max speed. Chapter 3 www.aerotech.com... -

Page 49: Table 3-14: Alar-Sp Motor Specifications (Alar100Sp, Alar150Sp, And Alar200Sp)

7. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 8. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 9. All Aerotech amplifiers are rated A ; use torque constant in N·m/A when sizing www.aerotech.com... -

Page 50: Table 3-15: Alar-Sp Motor Specifications (Alar250Sp And Alar325Sp)

6. Specifications given are for the motor only. When integrated into a housing with bearings additional losses should be considered. 7. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 8. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 9. All Aerotech amplifiers are rated A ;... -

Page 51: Table 3-16: Alar-Lp Motor Specifications

6. Specifications given are for the motor only. When integrated into a housing with bearings additional losses should be considered. 7. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 8. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 9. All Aerotech amplifiers are rated A ;... -

Page 52: Table 3-17: Alar-Xp Motor Specifications

5. All performance and electrical specifications ±10% 6. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 53: Limits, Marker, And Machine Direction

Electrical Specifications and Installation 3.4. Limits, Marker, and Machine Direction Aerotech stages are configured to have positive and negative "machine" directions. The machine direction defines the phasing of the feedback and motor signals and is dictated by the stage wiring (refer to Section 3.5. -

Page 54: Motor And Feedback Phasing

Electrical Specifications and Installation ALAR Hardware Manual 3.5. Motor and Feedback Phasing Motor phase voltage is measured relative to the virtual wye common point. Figure 3-5: Hall Phasing Chapter 3 www.aerotech.com... -

Page 55: Figure 3-6: Analog Encoder Phasing Reference Diagram

ALAR Hardware Manual Electrical Specifications and Installation Figure 3-6: Analog Encoder Phasing Reference Diagram Figure 3-7: Encoder Phasing Reference Diagram (Standard) www.aerotech.com Chapter 3... - Page 56 Electrical Specifications and Installation ALAR Hardware Manual This page intentionally left blank. Chapter 3 www.aerotech.com...

-

Page 57: Chapter 4: Maintenance

Any external metal surface of the ALAR can be cleaned with isopropyl alcohol on a lint-free cloth. Avoid getting excess cleaning solvent on the surfaces, as it could damage the delicate electronics inside. www.aerotech.com Chapter 4... -

Page 58: Troubleshooting

Encoder (sine and cosine) signal connections (refer to Chapter 3 Stage moves Controller documentation). uncontrollably Motor Connections (refer to Chapter 3 and the Controller documentation). Gains misadjusted (refer to the Controller documentation). Stage oscillates or squeals Encoder signals (refer to the Controller documentation). Chapter 4 www.aerotech.com... -

Page 59: Appendix A: Warranty And Field Service

Aerotech makes no warranty that its products are fit for the use or purpose to which they may be put by the buyer, whether or not such use or purpose has been disclosed to Aerotech in specifications or drawings previously or subsequently provided, or whether or not Aerotech’s... - Page 60 Aerotech's approval. On-site Warranty Repair If an Aerotech product cannot be made functional by telephone assistance or by sending and having the customer install replacement parts, and cannot be returned to the Aerotech service center for repair, and if Aerotech determines the problem could be warranty-related, then the following policy applies:...

-

Page 61: Appendix B: Revision History

Model Numbering System updated 1.02.00 Socket head cap screw specification changed from 6 mm to M6 Basic Specifications table updated Added clarification on which models contain hall effect limit switches 1.01.00 Dimensions Section added 1.00.00 New Manual www.aerotech.com Appendix B... - Page 62 Revision History ALAR Hardware Manual This page intentionally left blank. Appendix B www.aerotech.com...

-

Page 63: Index

ALAR250XP-M2 Specifications ALAR250XP Motor Specifications Maximum Speed Per Encoder Option ALAR325LP Motor Specifications Motor Specifications ALAR325LP Specifications ALAR100LP ALAR325SP-M1 Specifications ALAR100SP ALAR325SP-M2 Specifications ALAR150LP ALAR325SP Motor Specifications ALAR150SP ALAR325XP-M1 Specifications ALAR200LP ALAR325XP-M2 Specifications ALAR200SP ALAR325XP Motor Specifications ALAR250LP www.aerotech.com Index... - Page 64 ALAR Hardware Manual ALAR250SP ALAR250XP ALAR325LP ALAR325SP ALAR325XP mounting surface cleaning securing stage part number Protection Rating protective ground connection serial number shimming solvents stabilizing stage stage distortion stabilizing Support Technical Support Thermistor Specifications Vibration Warranty and Field Service Index www.aerotech.com...

Need help?

Do you have a question about the ALAR SP Series and is the answer not in the manual?

Questions and answers