Table of Contents

Advertisement

Quick Links

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

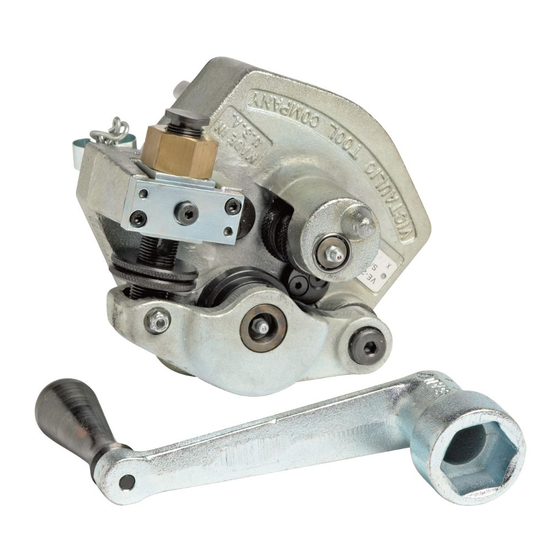

VE26 Pipe/Tubing Roll Grooving Tool

VE26S, VE26SS, VE26P, VE26C, VE26BC, VE26DIN, AND VE26AC

MANUAL FEED, IN-PLACE ROLL GROOVING TOOLS

ADAPTABLE FOR MOTORIZED OPTION

WARNING

If you need additional copies of any literature, or if you have questions concerning the safe

and proper operation of this tool, contact Victaulic, P.O. Box 31, Easton, PA 18044-0031,

Phone: 1-800-PICK VIC, E-Mail: pickvic@victaulic.com.

REV_C

WARNING

Failure to follow instructions and warnings could result in serious

personal injury, property damage, and/or product damage.

• Before operating or servicing any roll grooving tools, read all

instructions in this manual and all warning labels on the tool.

• Wear safety glasses, hardhat, foot protection, and hearing

protection while working around this tool.

• Save this operating and maintenance manual in a place

accessible to all operators of the tool.

Original Instructions

TM-VE26

TM-VE26

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Victaulic VE26 Series

- Page 1 If you need additional copies of any literature, or if you have questions concerning the safe and proper operation of this tool, contact Victaulic, P.O. Box 31, Easton, PA 18044-0031, Phone: 1-800-PICK VIC, E-Mail: pickvic@victaulic.com.

-

Page 3: Table Of Contents

TM-VE26 / Operating and Maintenance Instructions Manual TABLE OF CONTENTS Maintenance ..... . 28 Hazard Identification ....4 Parts Ordering Information . -

Page 4: Hazard Identification

CAUTION is always readily available . Additional copies of this manual are available upon request through • The use of the word “CAUTION” Victaulic . identifies possible hazards or unsafe WARNING practices that could result in personal injury and product or property damage if instructions, including recommended Wear proper apparel. - Page 5 . Follow the instructions power drive is stable . for lubricating tool components . Disconnect electrical power before 10. Use only Victaulic replacement parts servicing the tool. Only authorized and accessories. Use of any other parts personnel should attempt to perform may result in a voided warranty, improper maintenance on the tool .

-

Page 6: Introduction

• The tool, along with this operating and maintenance instructions manual, contains trademarks, copyrights, and/or patented features that are the exclusive property of Victaulic. The Victaulic VE26 series is designed for roll grooving pipe/tubing to receive Victaulic grooved Qty. Description pipe/tubing products, and can be operated manually or with a power drive . -

Page 7: Power Requirements

VE26 tools are designed for manual operation 12 gauge 12 gauge 10 gauge or operation with a power drive . For power operation, tools mount directly onto a Victaulic VPD752 Power Drive or a Ridgid ® 300 Power Drive . Consult the drive manufacturer’s instructions for proper operation of the drive . -

Page 8: Tool Nomenclature

• Drawings and/or pictures in this manual may be exaggerated for clarity. • The tool, along with this operating and maintenance instructions manual, contains trademarks, copyrights, and/or patented features that are the exclusive property of Victaulic. Pipe-End Tool Body Stop (2) -

Page 9: Tool Dimensions And Specifications

TM-VE26 / Operating and Maintenance Instructions Manual TOOL DIMENSIONS AND SPECIFICATIONS 9.00 in/ 229 mm 3.00 in/ 76 mm 8.75 in/ 222 mm 4.13 in/ 105 mm 6.00 in/ 152 mm Tool weight is 29 pounds/13 kilograms . Tool weight includes the tool head assembly, mounting plate, drive shaft/adapter, and hardware . The tool head assembly alone weighs approximately 22 pounds/10 kilograms . -

Page 10: Tool Setup

. the piping system before attempting to disassemble any PIPE VISE SETUP Victaulic piping products. 1. When grooving pipe/tubing that is supported • Pipe hangers must be capable of with a pipe vise, select a location for the tool... -

Page 11: Power Drive Mounting Plate Kit Installation

TM-VE26 / Operating and Maintenance Instructions Manual POWER DRIVE MOUNTING PLATE KIT INSTALLATION 2. Insert the hex head bolt through the holes in the drive shaft/drive-adapter assembly and the inner grooving roll shaft . Thread the hex nut with nylon insert onto the end of the hex head bolt, as shown above . -

Page 12: Power Drive Setup

• Accidental startup of the tool could result in serious personal injury. The VE26 tool is intended for field or shop setup and can be attached to a Victaulic VPD752 Power Drive or a Ridgid 300 Power Drive with a 38-rpm maximum chuck speed . The power... - Page 13 TM-VE26 / Operating and Maintenance Instructions Manual 4a. Extend the two tubular support arms to their full extension beyond the chuck of the power drive . 4b. Secure the two tubular support arms in position . Refer to the power drive manufacturer’s 3.

- Page 14 TM-VE26 / Operating and Maintenance Instructions Manual DANGER • To reduce the risk of electric shock, check the electrical source for proper grounding. • Before performing any maintenance on the tool, turn the switch on the power drive to the “OFF” position, or disconnect the power cord from the electrical source.

-

Page 15: Preparation For Grooving

. Have the power drive repaired if the Foreign material may interfere with or wobble persists . damage grooving rolls, resulting in distorted grooves and grooves that are out of Victaulic specifications. REV_C TM-VE26_15... -

Page 16: Pipe Lengths Suitable For Grooving

NOTICE piece is as long as (or longer than) the minimum length specified . Refer to the example that • Grooved pipe/tubing nipples, shorter than follows . those listed in the following tables, are available from Victaulic. REV_C TM-VE26_16... -

Page 17: Long Pipe/Tubing Lengths

TM-VE26 / Operating and Maintenance Instructions Manual LONG PIPE/TUBING LENGTHS EXAMPLE: A 20-foot, 4-inch (6 . 1 9-m) length of 6-inch diameter steel pipe is required to When roll grooving pipe/tubing that exceeds the finish a section, and only 20-foot (6 .09-m) maximum length shown in Table 1, a roller-type lengths are available . -

Page 18: Groove Depth Adjustment

“C” dimension, is listed under the “Roll Groove Specifications” table . In • All other Victaulic roll grooving tools addition, a label is affixed to the tool, which lists require pipe positioning that is below the “C”... - Page 19 TM-VE26 / Operating and Maintenance Instructions Manual 4a. Using the groove depth gauge like a feeler gauge, turn the depth stop collar until it contacts the groove depth gauge firmly against the top of the trunnion . Turn the second collar until it is locked firmly against the depth stop collar .

-

Page 20: Grooving Operation For Pipe Vise Setup Or Groove-In-Place Setup

Failure to follow this instruction could 7. If the groove diameter (“C” dimension) is not overload the tool, resulting in reduced tool within Victaulic specifications, the depth stop life and/or damage to the tool. collars must be adjusted . 7a. To adjust for a smaller groove diameter, turn 1. - Page 21 TM-VE26 / Operating and Maintenance Instructions Manual VE26 FEED RATES Recommended Turns of Feed Nut to Wall Advance the Pipe Thickness Grooving Tools Material inches/mm Roll 0.135 – 0.216 1/4 Turn 3.4 – 5.5 Steel and 0.120 – 0.134 VE26S Stainless 1/3 Turn VE26SS...

-

Page 22: Dismounting The Tool

TM-VE26 / Operating and Maintenance Instructions Manual 9. Advance the grooving roll by turning the feed 12. Crank the tool one to three additional full nut clockwise . Refer to the table on the previous turns around the pipe/tubing to ensure groove page for the recommended amount of turns of completion . -

Page 23: Grooving Operation For Power Drive Setup

TM-VE26 / Operating and Maintenance Instructions Manual GROOVING OPERATION FOR POWER DRIVE SETUP CAUTION • This tool must be used ONLY for the roll grooving of pipe/tubing designated in the “Tool Rating and Roll Selection” section of this manual. Failure to follow this instruction could overload the tool, resulting in reduced tool life and/or damage to the tool. - Page 24 . On the Victaulic VPD752 Power Drive or the Keep hands away from the grooving rolls Ridgid 300 Power Drive, place the switch in the during operation.

- Page 25 TM-VE26 / Operating and Maintenance Instructions Manual 6. Insert a length of pipe/tubing that is the correct size and thickness onto the lower roll . Ensure that the pipe/tubing end contacts the two pipe-end stops completely . 7a. Draw the rolls together by turning the feed nut clockwise .

- Page 26 TM-VE26 / Operating and Maintenance Instructions Manual VE26 FEED RATES Recommended Turns of Wall Pipe Feed Nut to Tools Thickness Material Advance the inches/mm Grooving Roll 0.135 – 0.216 1/4 turn 3.4 – 5.5 Steel and VE26S 0.120 – 0.134 Stainless 1/3 turn VE26SS...

- Page 27 TM-VE26 / Operating and Maintenance Instructions Manual 11. Continue grooving by turning the feed nut 15. To release the pipe/tubing, turn the feed nut counterclockwise to retract the roll arm to the to advance the grooving roll until the depth stop collar contacts the trunnion .

-

Page 28: Maintenance

PARTS ORDERING INFORMATION DANGER When ordering parts, the following information is required for Victaulic to process the order and send the correct part(s) . Request the RP-26 Repair Parts List for detailed drawings and parts listings . Tool Model Number – VE26 Tool Serial Number –... -

Page 29: Accessories

. Contact Victaulic for details . VAPS 224 VICTAULIC ADJUSTABLE PIPE STAND The Victaulic VAPS 224 contains features that are similar to the VAPS 112, but it is suitable for 2- to 24-inch pipe sizes . Contact Victaulic for details . REV_C TM-VE26_29... -

Page 30: Troubleshooting

The “A” Gasket Seat or “B” Incorrect tool was selected for the Select the correct tool by referring to the “Tool Rating and Roll Groove Width dimensions pipe material. Selection” section on page 32. do not meet Victaulic specifications. REV_C TM-VE26_30... -

Page 31: Tools Installed On A Power Drive

Reposition the pipe support. Refer to the “Long length of pipe. Pipe is “over-tracking. ” Pipe/Tubing Lengths” section on page 17. In the event of tool malfunction outside the scope of the troubleshooting section, contact Victaulic Engineering Services for assistance . REV_C... -

Page 32: Tool Rating And Roll Selection

TM-VE26 / Operating and Maintenance Instructions Manual TOOL RATING AND ROLL SELECTION VE26S FOR STEEL AND SCHEDULE 40 STAINLESS STEEL PIPE VE26P FOR ALUMINUM AND PVC PIPE Pipe Size Dimensions - inches/millimeters VE26S VE26P Actual Steel Pipe Aluminum Pipe Nominal Outside Wall Thickness Stainless Steel... -

Page 33: Steel Pipe

TM-VE26 / Operating and Maintenance Instructions Manual VE26SS FOR LIGHT-WALL STAINLESS STEEL PIPE Nominal Wall Thickness Dimensions Pipe Size inches/millimeters * Stainless Steel (Types 304, 304L, 316, and 316L) Actual Nominal Size Outside Diameter inches inches/mm Minimum Maximum 2.375 0.065 0.109 60.3 2.875... -

Page 34: Astm Drawn Copper Tubing

TM-VE26 / Operating and Maintenance Instructions Manual VE26C FOR CTS US STANDARD – ASTM DRAWN COPPER TUBING Nominal Wall Thickness Dimensions Tube Size inches/millimeters * † Copper Tubing Wall Thickness Actual Nominal Size Outside Diameter inches inches/mm Minimum Maximum 2.125 0.042 0.083 54.0... -

Page 35: As 1432 Drawn Copper Tubing

TM-VE26 / Operating and Maintenance Instructions Manual VE26AC FOR AUSTRALIAN STANDARD – AS 1432 DRAWN COPPER TUBING Nominal Wall Thickness Dimensions Tube Size millimeters/inches * † Copper Tubing Wall Thickness Actual Nominal Size Outside Diameter millimeters mm/inches Minimum Maximum 50.8 DN 50 2.000 0.035... - Page 36 NOTICE FOR STANDARD COUPLINGS WITH RATINGS ON LIGHT-WALL STAINLESS STEEL PIPE: • Victaulic RX rolls MUST be used when roll grooving light-wall stainless steel pipe for use with standard couplings. Pipe Outside Diameter – Nominal NPS Pipe Size (ANSI B36.10) and Basic Metric Pipe Size (ISO 4200) –...

- Page 37 “T” Dimension – The “T” dimension is the lightest grade (minimum nominal wall thickness) of pipe that is suitable for cut or roll grooving . Pipe that is less than the minimum nominal wall thickness for cut grooving may be suitable for roll grooving or adapted for Victaulic couplings by using Vic-Ring ®...

-

Page 38: Aluminum, And Pvc Pipe

TM-VE26 / Operating and Maintenance Instructions Manual REV_C TM-VE26_38... -

Page 39: Hard-Drawn Copper Tubing

TM-VE26 / Operating and Maintenance Instructions Manual REV_C TM-VE26_39... -

Page 40: Copper Tubing

TM-VE26 / Operating and Maintenance Instructions Manual REV_C TM-VE26_40... -

Page 41: Copper Tubing

TM-VE26 / Operating and Maintenance Instructions Manual REV_C TM-VE26_41... - Page 43 TM-VE26 / Operating and Maintenance Instructions Manual REV_C TM-VE26_43...

- Page 44 TM-VE26 OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL VE26 Pipe/Tubing Roll Grooving Tool UPDATED 04/2016 TM-VE26 0981 REV C RM00026000 VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2016 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Need help?

Do you have a question about the VE26 Series and is the answer not in the manual?

Questions and answers