HWH 625 Series Operator's Manual

Computer-controlled leveling system and room extension systems for trailers

Hide thumbs

Also See for 625 Series:

- Operator's manual (41 pages) ,

- Checklist (3 pages) ,

- Operator's manual (18 pages)

Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

HWH COMPUTER-CONTROLLED

625 SERIES LEVELING SYSTEM

SPACEMAKER ROOM EXTENSION SYSTEMS

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP40391

H H

W

CORPORATION

R

AND

R

FOR TRAILERS

FEATURING:

Touch Panel Leveling Control

BI-AXIS Hydraulic Leveling

R

Straight-Acting Jacks

Multiple Room Extensions

No Jack Stop Rods

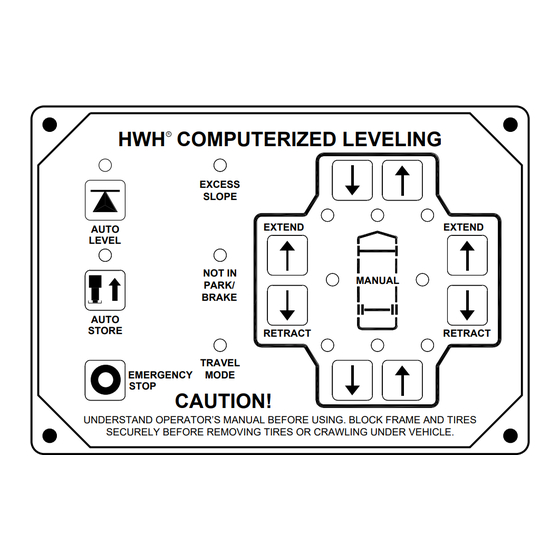

HWH COMPUTERIZED LEVELING

R

EXCESS

SLOPE

AUTO

LEVEL

NOT IN

PARK/

BRAKE

AUTO

STORE

TRAVEL

EMERGENCY

MODE

STOP

CAUTION!

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

R

EXTEND

EXTEND

MANUAL

RETRACT

RETRACT

ML40392/MP04.2801

08MAR07

Advertisement

Table of Contents

Summary of Contents for HWH 625 Series

- Page 1 CORPORATION OPERATOR’S MANUAL HWH COMPUTER-CONTROLLED 625 SERIES LEVELING SYSTEM SPACEMAKER ROOM EXTENSION SYSTEMS FOR TRAILERS FEATURING: Touch Panel Leveling Control BI-AXIS Hydraulic Leveling Straight-Acting Jacks Multiple Room Extensions No Jack Stop Rods HWH COMPUTERIZED LEVELING EXCESS SLOPE EXTEND EXTEND AUTO...

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Control Functions

CONTROL IDENTIFICATION 625 SERIES LEVELING SYSTEM COMPUTER-CONTROL "EXCESS SLOPE" LOWER FRONT Indicator light AUTO LEVEL Manual button Indicator light RAISE FRONT Manual button "AUTO LEVEL" Button HWH COMPUTERIZED LEVELING JACK DOWN "NOT IN PARK" Indicator light EXCESS Indicator light (4) red... -

Page 4: Control Identification

CONTROL IDENTIFICATION ROOM OPERATOR’S PANEL CORPORATION HYDRAULIC ROOM EXTENSION EXTEND ROOM CONTROL KEY SWITCH SWITCH CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. KEEP PEOPLE AND OBSTRUCTIONS RETRACT CLEAR OF ROOM WHEN OPERATING. CONTROL FUNCTIONS KEY SWITCH: The KEY SWITCH controls power to the ROOM ROOM CONTROL SWITCH: The ROOM CONTROL SWITCH CONTROL SWITCH. -

Page 5: Operating Procedures

OPERATING PROCEDURES GENERAL INSTRUCTIONS Maintain adequate clearance in all directions for vehicle, room Any time a hydraulic leveling process is interrupted, retract extensions, awnings, doors, steps, etc. Vehicle may move in the jacks according to the JACK RETRACTION Section and any direction due to jacks extending or retracting, settling of then restart the leveling process. - Page 6 1. Trailer must be unhitched from the tow vehicle before level- NOTE: The front yellow LEVEL light must be on before ing. The HWH front jacks may be used to lift the trailer for automatic leveling will function. unhitching. If auxiliary jacks are used to unhitch the trailer, extend the HWH front jacks to the ground and retract the 3.

- Page 7 OPERATING PROCEDURES PREPARATION FOR TRAVEL CAUTION: CAUTION: THE OPERATOR MUST BE SURE THAT ONLY USE THE "AUTO STORE" THERE ARE NO OBJECTS UNDER THE VEHICLE AND THAT BUTTON IF THE TRAILER IS HITCHED TO A TOW ALL PEOPLE ARE CLEAR OF THE VEHICLE. VEHICLE OR SECURELY SUPPORTED BY THE EXISTING LANDING GEAR.

-

Page 8: Manual Leveling

1. Trailer must be unhitched from the tow vehicle before level- 3. A lit yellow LEVEL light indicates that the side, end or corner ing. The HWH front jacks may be used to lift the trailer for of the trailer is low. Pushing the up arrow for corresponding yellow unhitching. - Page 9 Use the manual valve release for retracting the jacks only 4. Retract the front jacks by opening the correct valves. if the STORE feature on the HWH control panel will not Slowly turn the manual valve releases counter clockwise retract the jacks.

- Page 10 Use the manual valve release for retracting the jacks only 4. Retract the rear jacks by opening the correct valves. if the STORE feature on the HWH control panel will not Slowly turn the manual valve releases counter clockwise retract the jacks.

- Page 11 DO NOT reverse direction of the room, contact 3. Unlock all room-locking devices to include travel HWH Customer Service for assistance 1-800-321-3494. clamps/locks supplied by manufacturers other than HWH. NOTE: Releasing the ROOM CONTROL SWITCH will NOTE: If the MANUAL RETRACT WINCH is attached to halt the operation of the room.

- Page 12 DO NOT reverse direction of the room, contact 1. The park brake must be set, if applicable. HWH Customer Service for assistance 1-800-321-3494. The room will not operate if the park brake is not set. NOTE: Releasing the ROOM CONTROL SWITCH will 2.

- Page 13 Follow steps 2 and 3 and try pushing the room in. it to the room according to the vehicle manufacturer’s Contact the vehicle manufacturer or HWH Customer instructions. To extend the WINCH STRAP firmly grasp Service at 1-800-321-3494 or 563-724-3396 for assistance.

-

Page 14: Maintenance

Dexron automatic transmission fluid contains red dye and can cause staining should a leak occur. DO NOT USE All jacks and any HWH room extension cylinders should be brake fluid or hydraulic jack fluid. Use of these can damage completely retracted before checking the oil level. The oil seals. -

Page 15: Maintenance & Service

MAINTENANCE/SERVICE SENSING UNIT ADJUSTMENT Level the vehicle by placing a bubble level in the center of NOTE: If opposing LED’s are lit, there is a problem with the freezer floor or upon whichever surface within the vehicle the Sensing Unit. that is to be level. - Page 16 BREATHER CAP - DIPSTICK - 1/4" NUT DRIVER 1 1/2" DIAMETER VALVE RELEASE SOLENOID VALVE NOTE: DO NOT turn the valve release nut more than 4 and 1/2 (four and one half) turns counter clockwise. Damage to the valve may result. VALVE RELEASE PLASTIC PLUG 2 1/4"...

Need help?

Do you have a question about the 625 Series and is the answer not in the manual?

Questions and answers