HWH 610 Series Operator's Manual

Computer-controlled leveling system

Hide thumbs

Also See for 610 Series:

- Service manual (38 pages) ,

- Operator's manual (18 pages) ,

- Operator's manual (12 pages)

Advertisement

Quick Links

OPERATOR'S MANUAL

HWH COMPUTER-CONTROLLED

LEVELING SYSTEM

TOUCH PANEL CONTROL

HYDRAULIC LEVELING

STRAIGHT-ACTING JACKS

ROOM EXTENSION SYSTEM

(WITH SYNCHRONIZING CYLINDER)

HWH COMPUTERIZED LEVELING

l

OFF

UNDERSTAND OPERATOR'S MANUAL BEFORE USING. BLOCK FRAME AND TIRES

SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

(800) 321-3494 / (563) 724-3396

INTERNET: http: //www.hwhcorp.com

H

W

CORPORATION

610 SERIES

FEATURING:

EXCESS

ON

SLOPE

LEVEL

NOT IN

STORE

PARK

TRAVEL

CAUTION!

HWH CORPORATION

(ON I-80, EXIT 267 SOUTH)

2096 MOSCOW ROAD

MOSCOW, IOWA 52760

H

R

ML17005/MP05.5209

21MAR01

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for HWH 610 Series

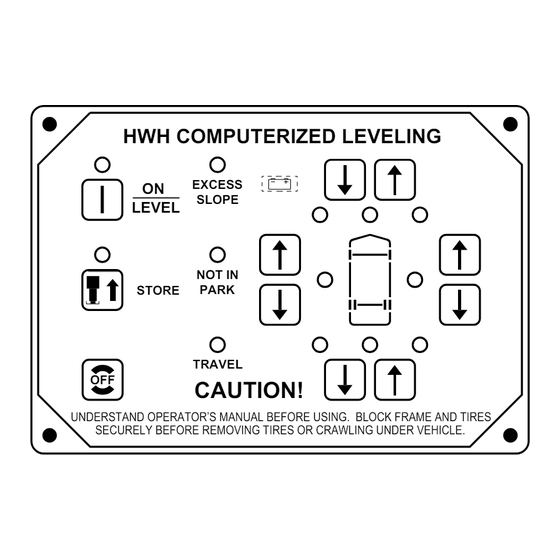

- Page 1 CORPORATION OPERATOR’S MANUAL HWH COMPUTER-CONTROLLED LEVELING SYSTEM 610 SERIES FEATURING: TOUCH PANEL CONTROL HYDRAULIC LEVELING STRAIGHT-ACTING JACKS ROOM EXTENSION SYSTEM (WITH SYNCHRONIZING CYLINDER) HWH COMPUTERIZED LEVELING EXCESS SLOPE LEVEL NOT IN STORE PARK TRAVEL CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. BLOCK FRAME AND TIRES SECURELY BEFORE REMOVING TIRES OR CRAWLING UNDER VEHICLE.

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Control Identification

"EXCESS SLOPE" LOW BATTERY LIGHT LIGHT FRONT RETRACT BUTTON "NOT IN PARK" LIGHT FRONT EXTEND BUTTON HYDRAULIC OPERATION LIGHT HWH COMPUTERIZED LEVELING WARNING LIGHTS (4- Red) EXCESS "I" ON BUTTON SLOPE LEVEL STORE LIGHT RIGHT SIDE EXTEND BUTTON NOT IN... - Page 4 CONTROL IDENTIFICATION ROOM OPERATOR’S PANEL CORPORATION HYDRAULIC ROOM EXTENSION EXTEND ROOM CONTROL KEY SWITCH SWITCH CAUTION! UNDERSTAND OPERATOR’S MANUAL BEFORE USING. KEEP PEOPLE AND OBSTRUCTIONS RETRACT CLEAR OF ROOM WHEN OPERATING. CONTROL FUNCTIONS KEY SWITCH: The KEY SWITCH controls power to the ROOM ROOM CONTROL SWITCH: The ROOM CONTROL SWITCH CONTROL SWITCH.

-

Page 5: Operating Procedures

OPERATING PROCEDURES GENERAL INSTRUCTIONS If parking on soft ground ar asphalt paving, wood blocks or If the hand / auto brake is not set when the "I" button is pres- pads must be placed under the jacks. sed, the "NOT IN PARK/BRAKE" light will come on and the system will not operate. - Page 6 KEEP PEOPLE AND OBSTRUCTIONS room. DO NOT reverse direction of the room, contact CLEAR OF ROOM WHEN OPERATING. HWH Customer Service for assistance 1-800-321-3494. NOTE: Make sure there is adequate clearance to fully NOTE: Releasing the ROOM CONTROL SWITCH will halt extend the room.

- Page 7 DO NOT force the 2. Press the "HYD" BUTTON. room. DO NOT reverse direction of the room, contact HWH Customer Service for assistance 1-800-321-3494. NOTE: To retract the room the HYDRAULIC OPERATION LIGHT must be illuminated. A WARNING LIGHT does NOT...

- Page 8 OPERATING PROCEDURES JACK RETRACTION EXTEND POSITION STORE/TRAVEL POSITION CAUTION: CAUTION: THE OPERATOR MUST BE SURE DO NOT MOVE THE VEHICLE WHILE THE THAT THERE ARE NO OBJECTS UNDER THE VEHICLE LEVELING JACKS OR THE ROOM EXTENSION ARE STILL AND THAT ALL PEOPLE ARE CLEAR OF THE VEHICLE. IN CONTACT WITH THE GROUND OR IN THE EXTEND POSITION.

- Page 9 OPERATING PROCEDURES MANUAL HYDRAULIC OPERATION 1. Place transmission in the recommended position for parking (or retract) in pairs to raise (or lower) a side or end of the vehicle. the vehicle, and set the parking brake. Turn the ignition to the Any jack not used for leveling can be extended to the ground.

- Page 10 Follow steps 2 and 3 and try pushing the room in. To extend the WINCH STRAP firmly grasp WINCH HANDLE, Contact the vehicle manufacturer or HWH Customer place RATCHET LEVER in its OFF position, and slowly rotate Service at 1-800-321-3494 or 563-724-3396 for assistance.

- Page 11 NOTE: All major components of the system can be replaced with ice. This may cause the leveling system to function with rebuilt parts or can be sent to HWH CORPORATION to improperly. To eliminate this problem, periodically check the be rebuilt, when the system is out of warranty.

- Page 12 NOTE: If any of the previous checks or inspections LEVEL SENSING UNIT reveal a problem or if there are other problems or BELOW THE SURFACE MOUNTING questions, consult a qualified RV repair center, your vehicle or coach manufacturer, or HWH CORPORATION MOUNTING for service or repair. REAR SURFACE...

- Page 13 TROUBLE SHOOTING ROOM EXTENSION The following is a list of problems, and possible solutions, which might occur to the room extension systems. NOTE : Only qualified technicians should install or repair room systems. A knowledge of hydraulic, welding, the vehicle,s sus- pension and electrical systems is required.

- Page 14 HYDRAULIC LINE CONNECTION DIAGRAM 610 SERIES LEVELING SYSTEM DUAL CYLINDER ROOM EXTENSION SYSTEM W/SYNCHRONIZING CYLINDER LEVELING SYSTEM SHUTTLE VALVE MANIFOLD VALVE RELEASE VALVE "T" HANDLE RELEASE "T" HANDLES EXTEND ROOM VALVE EXTENSION RETRACT MANIFOLD VALVE 3/16" HIGH PRESSURE HOSE (B)

- Page 15 HYDRAULIC SCHEMATIC BI-AXIS LEVELING WITH STRAIGHT-ACTING JACKS RELIEF VALVE 12 VOLT D.C. HYDRAULIC SOLENOID MANIFOLD POWER UNIT ASSEMBLY RETURN PRESSURE PRESSURE/RETURN 3000 PSI SHUTTLE VALVE SWITCH CHECK SOL.VALVE SOL.VALVE SOL.VALVE SOL.VALVE VALVE INNER CHECK VALVE OUTER LEFT RIGHT FRONT FRONT JACK PRESSURE SWITCH...

- Page 16 AIR LINE CONNECTION DIAGRAM SUSPENSION AIR BAGS FROM WIRE HARNESS SEE ELECTRICAL AIR DUMP SOLENOID VALVES DIAGRAM FOR ARE ACTIVATED (OPENED) BY CONNECTION A +12 SIGNAL. 4 AIR DUMP SOLENOID VALVES AND 4 HEIGHT CONTROL VALVES ARE SHOWN. THE AIR DUMP VALVE IS TO TEE INTO THE LINE BETWEEN THE AIR BAG AND THE HEIGHT CONTROL VALVE.

- Page 17 ELECTRICAL CONNECTION INFORMATION CONTROL BOX LEVELING SYSTEM LR - (BROWN) 4400 LR GROUND - RR - (ORANGE) 3400 (YELLOW/BLACK) LF - (BLUE) 1400 7601 RF - (GREEN) 2400 RF GROUND - (YELLOW) 7600 LEVELING SYSTEM CONTROL BOX MANIFOLD PRESSURE SWITCH - LR FUSE (BLACK) 8100 PUMP - (GRAY) 8600...

- Page 18 ELECTRICAL CONNECTION DIAGRAM 610 SERIES LEVELING SYSTEMS TO PARK TO BRAKE #10 WIRE TO GROUND STUD - (WHITE) 6230 BRAKE LIGHT ON TOUCH SWITCH DASH (LABELED) - (LABELED) - PANEL 9000 9001 SEE CONTROL BOX +12 (PURPLE) 6121 CONNECTION INFORMATION...

- Page 19 CONTROL BOX CONNECTION INFORMATION ROOM EXTENSION SYSTEM LEVELING SYSTEM CONTROL BOX ROOM EXTENSION CONTROL BOX EXTEND FUSE RETRACT FUSE ROOM RETRACT SOLENOID EXTENSION MANIFOLD VALVE - (BLACK) 5100 NOTE: THE (4) DIGIT WIRE NUMBER HARNESS SUPERSEDES ANY AND ALL WIRE EXTEND SOLENOID COLORS.

- Page 20 TERMINAL SWITCH DETAIL "A" TERMINAL 13 - (BLACK) 7502 TERMINAL 12 - (YELLOW) 7501 SEE CONTROL BOX CONNECTION INFORMATION ROOM EXTENSION SYSTEM HWH ROOM EXTENSION CONTROL SWITCH ROOM EXTENSION HARNESS MANIFOLD HARNESS LEVELING SYSTEM MANIFOLD ROOM EXTENSION HYDRAULIC EXTEND MANIFOLD...

- Page 21 ELECTRICAL CONNECTION DIAGRAM MASTER AND PUMP RELAY FOR 610 SERIES LEVELING SYSTEMS NOTE: THE (4) DIGIT WIRE NUMBER RELAY B SUPERSEDES ANY AND ALL WIRE CONNECTION DIAGRAM COLORS. FROM HYDRAULIC CABLE TO HARNESS - PUMP (GRAY) 8600 "+" STUD MANIFOLD/PUMP...

- Page 22 WIRING DIAGRAM MANIFOLD FOR 610 SERIES LEVELING SYSTEMS RIGHT RIGHT LEFT LEFT REAR FRONT FRONT REAR SEE ELECTRICAL CONNECTION DIAGRAM ROOM EXTENSION SYSTEM PRESSURE SWITCH (Rear 3000 PSI view) (Front view) GROUNDING STUD (SEE GROUNDING INSTRUCTIONS) - (WHITE) 6234 NOTE: PRESSURE SWITCH...

- Page 23 GROUNDING INSTRUCTIONS POWER UNIT/HARNESS WELDED PUMP MOUNT MANIFOLD PRESSURE USE GROUNDING STUD AND 3/8" SWITCH STAR LOCKWASHERS AS SHOWN. (WHITE) 6234 IMPORTANT: STAR LOCKWASHER MUST BE USED BETWEEN GROUNDING SURFACE AND WIRE TERMINALS GROUND CABLE NOTE: THE (4) DIGIT WIRE NUMBER STRAP (NOT USED SUPERSEDES AN AND ALL WIRE COLORS.

- Page 24 ELECTRICAL CONNECTION DIAGRAM MASTER LIGHT/BUZZER CONNECTION 610 SERIES COMPUTER-CONTROLLED LEVELING SYSTEM TO +12 PURPLE IGNITION POWER 5 AMP SEE CONTROL BOX FUSE CONNECTION DIAGRAM LEVELING SYSTEM (PURPLE) 6111 BUZZER 7699 7699 NEGATIVE NEGATIVE JACKS DOWN LIGHT (BROWN) 7699 INCLUDED IN HARDWARE KIT MP85.5280...

Need help?

Do you have a question about the 610 Series and is the answer not in the manual?

Questions and answers