Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

ROTARY TEDDER

P4-420 – 4 rotors

P4-471 – 4 rotors

P4-531 – 4 rotors

P6-651 – 6 rotors

P6-771 – 6 rotors

P8-790 – 8 rotors

P8-890 – 8 rotors

Serial No.:

The original instruction

SaMASZ Sp. z o.o.

Poland, 16-060 Zabłudów, ul. Trawiasta 1

Established – 1984

NIP PL-966-159-29-76

tel. (+48) (85) 664 70 31

fax (+48) (85) 664 70 41

e-mail: samasz@samasz.pl

www.samasz.pl

IN0683EN001

2018-10-31

EDITION No 1

Advertisement

Table of Contents

Summary of Contents for SaMASZ P4-420

- Page 1 (+48) (85) 664 70 31 fax (+48) (85) 664 70 41 e-mail: samasz@samasz.pl www.samasz.pl OPERATOR’S MANUAL ROTARY TEDDER P4-420 – 4 rotors P4-471 – 4 rotors P4-531 – 4 rotors P6-651 – 6 rotors P6-771 – 6 rotors P8-790 – 8 rotors P8-890 –...

- Page 2 Well-proven design with thousands of machines in regular use in many countries and quality materials ensure high durability and reliability of SaMASZ tedders. We congratulate you on the purchase of your new SaMASZ tedder and wish you much pleasure and the very best work results through the years to come.

-

Page 3: Table Of Contents

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 Contents page 1. IDENTIFYING THE MACHINE......................2 2. INTRODUCTION ............................2 3. PROPER USE .............................. 3 3.1. Technical data ............................3 3.2. -

Page 4: Identifying The Machine

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 1. IDENTIFYING THE MACHINE Data plate (Fig. 2) is mounted to the tedder’s main frame in the place shown below in Fig. 1. -

Page 5: Proper Use

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 3. PROPER USE Rotary tedder is designer to tedding cut forage and dry hay in order to accelerate their drying process. WARNING! Use of the tedder for other purposes than the above mentioned is forbidden. -

Page 6: Design And Working Principle

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 3.2. Design and working principle 3.2.1. 4- rotary tedder Overview of 4- rotary tedder is provided in Fig. 3. 3-point linkage frame (1) with catch (2) enables connecting tedder to the tractor 3-point linkage suspension. -

Page 7: 6- Rotary Tedder

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 3.2.2. 6- rotary tedder Overview of 6- rotary tedder is provided in Fig. 4. 3-point linkage frame (1) with catch (2) enables connecting tedder to the tractor 3-point linkage suspension. Drive with tractor PTO is transmitted by intersectional gears onto rotors. -

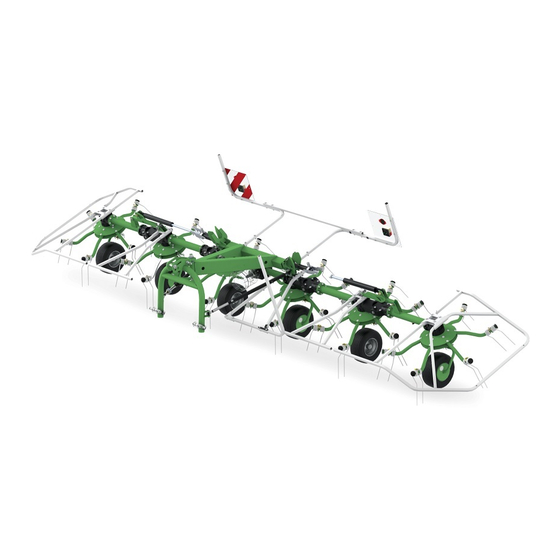

Page 8: 8- Rotary Tedder

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 3.2.3. 8- rotary tedder Overview of 8- rotary tedder is provided in Fig. 5. 3-point linkage frame (1) with catch (2) enables connecting tedder to the tractor 3-point linkage suspension. Drive with tractor PTO is transmitted by intersectional gears onto rotors. -

Page 9: Standard Equipment And Spare Parts

Points shown in Fig. 6 and Fig. 7 should be lubricated every 50 hours. The articulated telescoping shaft should also be lubricated before and after longer periods of disuse. PTO shafts of other brands with equivalent parameters could be used after SaMASZ permission. - 7 -... -

Page 10: Safety Advice

In case of tractors equipped with EHR, operating with hydraulic lift is done by the buttons mounted outside the tractor’s cabin. When operating be extremely careful. Locking pawl line and “field edge” mechanism line (in the case of the P4-420 tedder) should be mounted with relevant tolerance in the tractor cabin When switching from working to transport position unmount the whole or at least one end (from tractor’s PTO) of PTO shaft. - Page 11 Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 Due to risk of tipping, it is not permissible to fold rotors for work on cants (across the slope). Setting the machine should be performed on an even ground or upwards/down the slope.

-

Page 12: Qualifications Of Operator

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 In case of a fatal failure, stop the machine's drive, turn the tractor's engine off and take out the ignition key. Then call for technical service, and if an accident (in this case: road accident) occurs, respect first aid rules and contact responsible authorities. -

Page 13: Working Parts

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 transport belts, belt suspensions, ropes cannot be damaged. Whenever damages to these parts are spotted replace these with new ones, when mounting slings, chains, handles etc. always pay attention to setting the machine's center of gravity properly (Fig. -

Page 14: Pto Shaft

Useful life for hydraulic hoses is 5 years from their production date. 4.8. Residual risk Despite the fact, that company SaMASZ – the manufacturer of the tedder takes the responsibility for design and manufacturing of the tedder, in order to eliminate dangerous situations, certain risk during tedder operation is unavoidable. -

Page 15: Residual Risk Evaluation

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 2. Danger of injury, abrasion and damage of skin This kind of risk occurs during replacement of working parts with sharp edges, cleaning the machine and removal of any clogging and seizure. -

Page 16: Safety Decals And Their Meaning

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 When the risk of exposing to noise cannot be avoided or eliminated by any group protective means or organization of work, employer (farmer) must: 1) provide the operator with individual means of noise protection, if the noise level in work place exceeds 80 dB. - Page 17 Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 N-49 N-50 N-52 N-55 Never stand near tractor’s 3- Do not stay in the swinging Wear protective gloves point linkage while steering area of tedder’s parts...

-

Page 18: Operation

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 N-01; N-03; N-04; N-06 N-07; N-23; N-49; N-50 N-117; N-167; N-168; N-183 N-68 N-29 N-62 N-15; N-67 N-68 N-52; N-202 Fig. 9. Warning decals placed on the tedder 5. -

Page 19: Preparing The Tedder For Transport

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 Fig. 10. Connecting the tedder to the tractor: a) upper link (G) in transport position; b) upper link (G) in working position, c) pairs of hydraulic hoses (H1) –... -

Page 20: Preparing The Tedder For Transport On Public Roads

WARNING! In the case of P4-420 tedder, it is FORBIDDEN to folding up tedding arms in position of tedding on the field edge. See point 5.8.1. Fig. 11. Locking pawls in transport position lift the tedder with tractor hydraulic lift until the lower lift pins of the tedder 3-point linkage frame raise about 50 cm above the ground (Fig. -

Page 21: Mounting Pto Shaft

When driving on public roads the machine overall width should not be greater than 3 m. Since the SaMASZ tedder operating height of drive wheels can be is adjustable, change of this setting may lead to alternation of the machine transport width when folded. Therefore, the tedder transport width should be controlled prior to driving onto public roads and if needed wheels 1 setting should be changed (Fig. -

Page 22: Switching From Transport To Working Position

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 WARNING! If need be, shorten the PTO shaft according to its operator’s manual given by the shaft’s manufacturer (Fig. 13). Fig. 13. Instruction of PTO shaft shortening... - Page 23 Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 In the case of P4 and P6 tedders, by means of hydraulic cylinder lower the rotors until they are on the ground in a possibly slow way.

- Page 24 Fig. 15. Stages of P8 tedder unfolding SaMASZ tedders P4 and P6 are equipped with repellent mechanism for mobile tedder arms. Thanks to it, arms can be folded with no need of leaving the tractor cabin. It may however be limited by the slope, on which the machine is being folded.

-

Page 25: Switching 6-Rotary Tedder From Transport Position (For Loading) To Working Position

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 WARNING! Do not unfold the tedder on sloping terrain (Fig. 17). If the tedder's arm is blocked on sloping terrain, the actuator in the land following opening could become blocked. -

Page 26: Preparing The Tedder For Work

PTO shaft tip on the PTO of the tractor (if only one tip has been removed) or install the entire PTO shaft, by means of 3-point linkage by lowering or raising adjust the inclination of the tedder (recommended around 15°, for P4-420 about 13º). Tedders feature range spreading angle adjustment. - 24 -... - Page 27 Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 For P8 rotary tedders, there are two spreading angles available: 15° or 18° depending on the position of the chassis. In order to change the angle, perform the following:...

-

Page 28: Operation

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 slowly engage PTO clutch and wait until the rotors reach their rated speed 540 rpm./min. The speed should be as low as possible in order to reduce fuel consumption of the tractor, engage tractor gear and drive slowly into the meadow. - Page 29 Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 Fig. 25. Tedding to a) the left or b) to the right on meadow edges It is possible thanks to proper adjustment of wheels. The regulation is done by lever R, which after being put into proper hole adjusts the wheels.

- Page 30 Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 For P4-420 tedder, the wheels’ position is adjusted using the "Field edge" system (Fig. 28). Fig. 28. The "Field edge" system: L — control cable, Z — the system's ratchet...

-

Page 31: Headland Position

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 5.8.2. Headland position (For P8 tedder) The headland position of the 8-rotor tedders can be used to easily make sharp turns when driving. -

Page 32: Removing Clogging And Jams

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 5.8.3. Removing clogging and jams When operating the tedder pay attention to variable conditions on field, which may influence the tedder clogging and jams, such as: terrain unevenness, height and density of grass as well as other objects in the grass (stones, branches, piles of soil). -

Page 33: Mounting And Adjustments

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 dismount the PTO shaft and place it on a PTO shaft holder, which is standard-delivered with the machine, detach the machine from the tractor. -

Page 34: Daily Maintenance

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 WARNING! Before you change the tine check rotor turns (Fig. 32, Fig. 33 and Fig. 34). 6.2. Daily maintenance Every day after work please carry out the following maintenance: check all visible units and parts and their connections;... -

Page 35: Lubrication

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 In the absence of specific torque values, the following chart can be used as a guide to the maximum safe torque for a particular size and grade of fastener. There is no torque difference for fine or coarse threads. -

Page 36: Joints

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 Fig. 37. Inspection points and oil change points in angular gearboxes on carousels 7.3. Joints The tedder construction includes many moving parts – joints requiring periodic lubrication. -

Page 37: Defects And Their Repairs

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 The product is flammable. In case of fire, use adequate fire-extinguishing means (e.g. foam, water mist, extinguishing powders). Do not use water jets. -

Page 38: Disassembly And Withdrawal From Use

Rotary tedder P4-420, P4-471 and P4-531 Operator’s manual Rotary tedder P6-651 and P6-771 Rotary tedder P8-790 and P8-890 9. DISASSEMBLY AND WITHDRAWAL FROM USE 9.1. Repair Before starting any repair or service the tedder should be cleaned and any grass or dirt removed. -

Page 39: Warranty Terms

2. The warranty period is for two years from the date of sale to the purchaser, stated above. 3. Any repair which is subject to warranty should be carried out by an authorised SaMASZ dealer. Upon completion of the repair the dealer must submit a warranty claim within 14 days. -

Page 40: Warranty Repairs Record

The manufacturer reserves the right to introduce changes in construction. WARNING! Company SaMASZ is working constantly on development of all types and models. That is why, there is always a possible change of form, equipment and technology of delivered products. Any claims arising from data, drawings and descriptions included in this operator’s manual and spare parts list cannot be...

Need help?

Do you have a question about the P4-420 and is the answer not in the manual?

Questions and answers