Summary of Contents for CAME GARD PT Series

- Page 1 Automatic road barriers FA01354-EN GARD PT Brushless GPT40AGS GPT40RGS INSTALLATION MANUAL English...

- Page 2 DEVICE MANUAL RELEASE The unlocking operation may constitute a danger to the user, in case the correct boom fastening and conditions have been compromised by an accident or by installation errors. In these cases, the tensioned springs no longer guarantee the boom balancing which could suddenly rotate during the unlocking phase. With unlocked gearmotor, the operator does not work.

- Page 3 GENERAL PRECAUTIONS FOR INSTALLERS Important safety instructions. Follow all of these instructions. Improper installation can cause serious bodily harm. Before continuing, also read the general precautions for users. Use this product only for its specifically intended use. Any other use is hazardous. • The manufacturer can not be held liable for any damage caused by improper, unreasonable, and erroneous use.

-

Page 4: Dismantling And Disposal

DISMANTLING AND DISPOSAL CAME S.p.A. employs an Environmental Management System at its premises. This system is certified and compliant with the UNI EN ISO 14001 regulation standard to ensure that the environment is respected and safeguarded. Please continue safeguarding the environment. At CAME we consider it one of the fundamentals of our operating and market strategies. -

Page 5: Intended Use

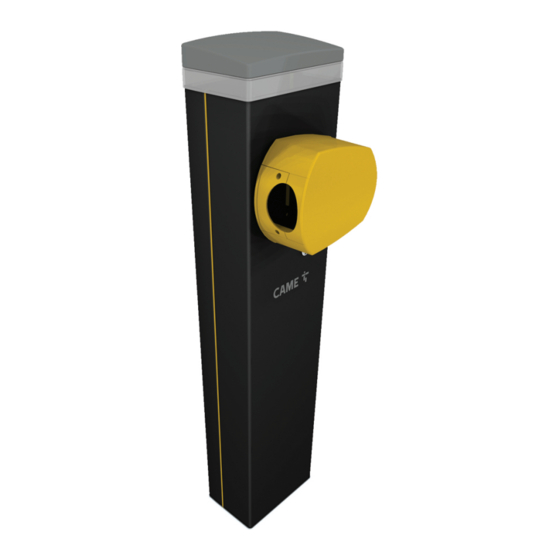

PRODUCT DATA AND INFORMATION Legend This symbol shows which parts to read carefully. This symbol shows which parts describe safety issues. This symbol shows which parts to tell users about. The measurements, unless otherwise stated, are in millimeters. Description GPT40AGS - Automatic barrier with reversible gearmotor and brushless motor, painted aluminium cabinet. GPT40RGS - Automatic barrier with reversible gearmotor and brushless motor, painted aluminium cabinet. - Page 6 Control board 1 -Buttons for programming 16 -Terminal board for NC contact for gearmotor release 17 -Terminal block associated with the RSE_2 connector for CRP or CAME KEY 2 -Display connection 3 -USB stick connector 18 -Terminal block associated with the RSE_1 connector for combined or...

- Page 7 Dimensions 206.5 3800 max Limits to use MODELS GPT40AGS GPT40RGS Maximum clearance width of the passage (m) Technical data MODELS GPT40AGS GPT40RGS Power supply (V - 50/60 Hz) 230 AC 50/60Hz 120 AC 50/60Hz Motor power supply (V) 36 DC 36 DC Stand-by consumption (W) Power (W)

- Page 8 Cable types and minimum thicknesses CABLE LENGTH (m) < 10 from 10 to 20 from 20 to 30 230 V AC Power supply 3G x 1.5 mm² 3G x 1.5 mm² 3G x 2.5 mm² 24 V AC - DC Flashing light 2 x 1 mm²...

-

Page 9: Installation

INSTALLATION The following illustrations are just examples, as the space available for fitting the operator and accessories varies depending on the area where it is installed. In case of manual handling, have one person for every 20 kg that need hoisting; for non manual handling use proper hoisting equipment in safe conditions. During the fixing phases, the operator could be unstable and overturn. - Page 10 Fill the hole with earth around the concrete block. Remove the nuts from the bolts. Fit the electric cables into the tubes so that they come out about 1500 mm. Preparing the barrier With the cover open, the operator does not work. ❸...

-

Page 11: Boom Installation

Change of the boom opening direction The barrier is set up for installing on the left. Check that the lever arm is positioned vertically. Remove the mechanical stop. Attach the mechanical stop to the right of the lever arm. Edit the parameter in function [Opening direction]. <... -

Page 12: Boom Set Up

Fit the boom into the fastening flange Tighten the screws firmly. Cut the slot cover profiles of the same size as the boom slot minus 10 millimeters. Insert the slot cover profiles in the appropriate grooves on both sides of the boom. Fit the rubber terminal cap into the corresponding housing Insert the anti-impact rubber profile into the groove, making it fit with the end cap. - Page 13 Establishing the travel end points with mechanical limit-switches Check that the boom is parallel to the road surface when it is in the closed position and at about 89° when it is in the open position. Correct the boom's horizontal position Release the gearmotor Open the inspection hatch.

-

Page 14: Electrical Connections

ELECTRICAL CONNECTIONS Electric cables passage The electrical cables must not touch any parts that may overheat during use (such as the motor and the transformer). Make sure that the moving mechanical elements have adequate distance from the wiring made. The cables must pass through the ferrite included in the supply. Input voltage Make sure the mains power supply is disconnected during all installation procedures. -

Page 15: Signalling Devices

Maximum capacity of contacts Device Output Power supply (V) Power (W) Accessories 10 - 11 24 DC Additional light 10 - E1 24 AC/DC Flashing light 10 - E1 24 AC/DC Operator status warning light 10 - 5 24 AC/DC Strip LED RGB 13,5 The sum of the connected accessories input must not exceed 40 W. -

Page 16: Safety Devices

Command and control devices MOTOR BLOCK S1GND FA FC TAMPER 11 E1 E6 TS 1 3 3P 4 2 CX CY CZ Antenna with RG58 cable Control device - OPEN ONLY function - NO contact Card reader For opening only. Transponder selector switch The contact must be used only for operators working in paired mode. - Page 17 DIR / DELTA-S photocells DIR / DELTA-S photocells Standard connection Connection with safety test Multiple photocell pairs can be connected. Multiple photocell pairs can be connected. See function F5, safety devices test. DIR / DELTA-S Collegamento test sicurezza MOTOR MOTOR BLOCK BLOCK S1GND...

- Page 18 PROGRAMMING Function of the programming buttons ESC button The ESC key is used to perform the operations described below. Exiting the menu Delete the changes Return to the previous screen Stop the operator < > buttons The <> keys are used to perform the operations described below. Navigate through the menu items Increasing or decreasing values Close or open the operator...

- Page 19 CZ input Associate a function with the CZ input. CZ input OFF (Default) C1 = Reopening while closing (Photocells) C4 = Obstacle wait (Photocells) C5 = Immediate closing at the opening travel end C7 = Reopening while closing (sensitive safety-edges) C9 = immediate closing at the travel end during opening with obstacle waiting, during closing C10 = Immediate closing during opening with obstacle waiting during closing...

- Page 20 Electric lock It allows to choose the electric lock activation mode during the boom maneuvering phases. Electric lock OFF (Default) 1 = The electric lock is deactivated during the boom opening and remains deactivated until the boom is closed again. 3 = The electric lock is deactivated during the boom opening or closing operations, but it is active when the barrier is open or closed.

- Page 21 RSE1 Configures the function to be performed by the board connected to the RSE1 connector. RSE1 OFF (Default) 1 = Combined 4 = Compass Saving data It saves user data, timings and configurations to the memory device (memory roll or USB key). The function is displayed only when a USB memory stick is inserted into the USB port or when a memory roll is inserted into the control board.

- Page 22 The operation can be carried out by using a transmitter or other control device. The boards that manage the control devices (AF - R700 - R800) must be plugged into the connectors. From the docs.came.com portal, download the LIST OF REGISTERED USERS form, type L20180423. Add User...

- Page 23 Remove all It removes all registered users. Remove all OFF (Default) Radio-frequency decoding For choosing the type of radio coding of the transmitters enabled to control the operator. Choosing the type of radio coding of the transmitters [Rolling code] or [TW key block], the transmitters with different type of radio coding previously stored, will be deleted.

-

Page 24: Getting Started

Updates the FW from USB Updated the firmware version of the device. The function is displayed only when a USB memory stick is inserted. Make sure the USB stick contains the firmware update file. Updates the FW from USB OFF (Default) Getting started Once the electrical connections have been completed, proceed with commissioning. -

Page 25: Final Operations

FINAL OPERATIONS ❶ ❹ ❸ ❷... -

Page 26: Combined Operation

COMBINED OPERATION Single command of two connected operators. Electrical connections Connect the two electronic boards with a UTP CAT 5 cable. Fit a RSE card on both control boards, using the RSE_1 connector. Proceed with the electrical connection of the devices and accessories. For electrical connections of the devices and accessories, see the ELECTRICAL CONNECTIONS chapter. -

Page 27: Alternate Operation

ALTERNATE OPERATION Opening of the first barrier, passage of the vehicle, closing of the first barrier, opening of the second barrier, passage of the vehicle and closing of the second barrier. Electrical connections Connect the two electronic boards with a UTP CAT 5 cable. Fit a RSE card on both control boards, using the RSE_1 connector. - Page 28 ONLY OPEN command (2-3) on barrier B OPEN-CLOSE command (2-7) on barrier A or B for emergency opening...

- Page 29 MCBF Models 803BB-0070 Std boom L = 3.05 m Boom L = 4.05 m -0 % Boom L = 3.05 m with joint -0 % Boom L = 4.05 m with joint -0 % The percentages indicate how much the number of cycles should be reduced in relation to the type and number of accessories installed. The type of intervention and the maintenance frequency are decided by the installer, considering the use, place of installation and number of daily cycles.

-

Page 30: Error Messages

ERROR MESSAGES Adjustment error Encoder failure error Services test failure error Operating time error Open release-hatch error Obstacle detected during closing Obstacle detected during opening Exceeded the maximum number of obstacles consecutively detected Serial communication error Incompatible transmitter error Open SLAVE-motor hatch error Arm/boom drop-down error on ARM connector USB device error Arm/boom drop-down error on MOTOR BLOCK connector... - Page 32 CAME S.p.A. Via Martiri della Libertà, 15 31030 Dosson di Casier Treviso - Italy Tel. (+39) 0422 4940 Fax (+39) 0422 4941...

Need help?

Do you have a question about the GARD PT Series and is the answer not in the manual?

Questions and answers