Summary of Contents for Landoll Brillion SSB

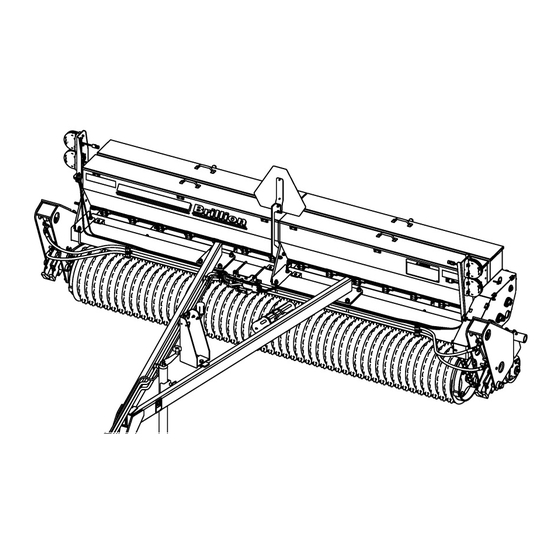

- Page 1 Sure Stand Seeder Models SSB, SSP and SSBP 8’, 10’ and 12’ Operators Manual LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM 1P480rev0718 07/2018 – Present...

-

Page 3: Table Of Contents

Table of Contents Introduction and Safety Information Introduction ..............1-1 Description of Unit . - Page 4 Blade/Cage Agitator ............2-28 Seed Box Dividers .

- Page 5 Agitator Box Slide ............. 4-8 LED Warning Lamps .

-

Page 7: Introduction And Safety Information

Proper assembly, within 10 days of retail purchase, using the Landoll maintenance and safe operation will allow this machine Corporation Ag Products on-line registration process. -

Page 8: Safety

INTRODUCTION AND SAFETY INFORMATION Safety When applying decals to the machine, be sure to clean the surface to remove any dirt or residue. Where possible, sign placement should protect the sign from NOTE abrasion, damage, or obstruction from mud, dirt, oil etc. Investigation has shown that nearly 1/3 of all farm accidents are caused by careless use of machinery. -

Page 9: Attaching, Detaching And Storage

INTRODUCTION AND SAFETY INFORMATION Attaching, Detaching and Storage NOTE 1. Do not stand between the tractor and machine when To relieve hydraulic pressure: Depending on tractor attaching or detaching machine unless both are not hydraulic system, some can be relieved by actuating moving. -

Page 10: Safety Chain

INTRODUCTION AND SAFETY INFORMATION Safety Chain 3. Attach the chain to the Tractor Drawbar Support or specified anchor location. Never attach the chain to 1. Use a Safety Chain to help control drawn machinery an intermediate support. Allow only enough slack in should it separate from the Tractor Drawbar. -

Page 11: Safety Decals

INTRODUCTION AND SAFETY INFORMATION Safety Decals Figure 1-3: Safety Decals 1P480rev0718... - Page 12 INTRODUCTION AND SAFETY INFORMATION Figure 1-4: Safety Decals Locations 1P480rev0718...

- Page 13 INTRODUCTION AND SAFETY INFORMATION Figure 1-5: Safety Decals Locations 8 Foot Models 1P480rev0718...

- Page 14 INTRODUCTION AND SAFETY INFORMATION Figure 1-6: Safety Decals Locations 10 Foot Models 1P480rev0718...

- Page 15 INTRODUCTION AND SAFETY INFORMATION Figure 1-7: Safety Decals Locations 12 Foot Models 1P480rev0718...

- Page 16 INTRODUCTION AND SAFETY INFORMATION Figure 1-8: Safety Decals Locations SD 8 Models 1-10 1P480rev0718...

- Page 17 INTRODUCTION AND SAFETY INFORMATION Figure 1-9: Safety Decals Locations SDP 8 Models 1P480rev0718 1-11...

- Page 18 INTRODUCTION AND SAFETY INFORMATION Figure 1-10: Safety Decals Locations SD 10 Models 1-12 1P480rev0718...

- Page 19 INTRODUCTION AND SAFETY INFORMATION Figure 1-11: Safety Decals Locations SDP 10 Models 1P480rev0718 1-13...

- Page 20 INTRODUCTION AND SAFETY INFORMATION Figure 1-12: Safety Decals Locations SD 12 Models 1-14 1P480rev0718...

- Page 21 INTRODUCTION AND SAFETY INFORMATION Figure 1-13: Safety Decals Locations SDP 12 Models 1P480rev0718 1-15...

- Page 22 INTRODUCTION AND SAFETY INFORMATION Table provided for general use. NOTES: 1-16 1P480rev0718...

-

Page 23: Assembly

Chapter 2 Assembly IMPORTANT CAUTION All harnesses must be firmly attached to machine Do Not Work On Or Under This Machine Unless frame members, so they don’t sag or become torn Securely Blocked And Supported By A Hoist Or loose by field debris. -

Page 24: 3Pt Seeder Assembly

ASSEMBLY 3Pt Seeder Assembly CAUTION When shipped, seeder comes assembled except for Do not disengage pin unless seeder is fully lights and 3Pt Hitch. attached to a tractor. Seeder may be rear-heavy 1. Support Seeder Assembly with a hoist or by similar and tip backward on frame means capable of supporting its weight without tipping. - Page 25 ASSEMBLY Figure 2-4: Attach 3Pt Hitch 1P480rev0718...

-

Page 26: Pull Type Seeder Assembly

ASSEMBLY Pull Type Seeder Assembly When shipped, Seeder comes assembled except for Lights, Hub and Spindle Assemblies, Tire and Wheels Assemblies and Drawbar. 1. Untie the two rolled up Drawbar Hydraulic Hoses near the center of the Frame Tube. Ensure the hoses are not interfering with where the Drawbar is to be attached. -

Page 27: Tire And Wheel Installation

ASSEMBLY 6. Apply anti-seize to Spindles and insert a Hub and Spindle Assemblies into each Wheel Arm. Secure in Spindles farthest hole from the Hub with 1/2-13 x 3 Bolts and Locknuts. See Figure 2-7. Figure 2-7: Hub and Spindle Tire and Wheel Installation ... -

Page 28: Hydraulics

ASSEMBLY Hydraulics 1. Restrictors installed in Cylinder Ports, connect 45 Degree Fitting so they are free to swivel. Connect top Hydraulic Hose to the Cylinder Base and bottom WARNING Hydraulic Hose to the Cylinder Rod End. Position the Hydraulic Hoses so that the Cylinder Base End Escaping fluid under pressure can be nearly points downward and the Cylinder Rod End points invisible and have enough force to penetrate the... - Page 29 ASSEMBLY Figure 2-11: Drawbar Hydraulic Hoses 1P480rev0718...

-

Page 30: Purge The Hydraulic Lift System

ASSEMBLY Purge the Hydraulic Lift System The Hydraulic system is not filled with oil and should be purged of air before transporting and field operations. Lift Circuit approximate oil requirement: 0.4 gallons. 1. Carefully Hitch the Seeder to the Tractor and connect the Hydraulic Lift Hoses. - Page 31 ASSEMBLY Table provided for general use. NOTES: 1P480rev0718...

-

Page 32: Warning Lamp Installation, 8 Ft And 10 Ft

ASSEMBLY Warning Lamp Installation, 8 Ft IMPORTANT and 10 Ft All Harnesses must be firmly attached to Machine Frame members or Hydraulic Hoses so they do not NOTE sag or become torn loose by field debris. 13. Attach the SMV sign to the SMV Mount located on 10 Ft Drawbar model is shown, 10 Ft 3Pt, 8 Ft Drawbar Center Bracket with 5/16-18 x 1 Bolts, Flat Washers, and 8 Ft 3Pt models similar. - Page 33 ASSEMBLY Figure 2-15: LED Warning Lights, 8 Ft and 10 Ft Models 1P480rev0718 2-11...

-

Page 34: Warning Lamp Installation, 12 Ft

ASSEMBLY Warning Lamp Installation, 12 Ft 13. Attach the Connector Holder to the 3Pt Hitch or Drawbar Hose Holder with 1/4-20 x 1 Bolts, Flat Washers, and Locknuts. NOTE NOTE 12 Ft 3Pt model is shown, drawbar model similar. The 7-pin plug on the other end of the 7 Pin Harness connects to the Tractor Socket when in use. - Page 35 ASSEMBLY Figure 2-17: LED Warning Lights, 12 Ft Models 1P480rev0718 2-13...

-

Page 36: Electric Clutch Kit - Optional

ASSEMBLY Electric Clutch Kit - Optional IMPORTANT At no time use high pressure water or air to clean the Electric Clutch as damage could occur. 1. Verify that the Electric Clutch has 1/8” clearance between the Clutch Housing and Rubber Bumper Stop. - Page 37 ASSEMBLY Table provided for general use. NOTES: 1P480rev0718 2-15...

-

Page 38: Acre Meter Kit - Optional

ASSEMBLY Acre Meter Kit - Optional 3. Attach the Pick-up Switch Bracket to the front of the Transmission. 4. Attach the Pick-up Switch to the top of the Pick-up NOTE Switch Bracket with two #8-32 x 1-1/4 Machine The Acre Meter Kit consists of three main parts, the Acre Screws, Flat Washers, Lock Washers and Nuts. - Page 39 ASSEMBLY 7. Attach the Pick-up Switch Ground Wire to the small hole in the Pick-up Switch Mount with a #6-32 x 1/2 Screw, removing paint under the wire connector to assure a good electrical ground connection. See Figure 2-20. 8. Plug the Extension Harness into the Acre Meter Cord.

-

Page 40: Seed Shaft Sensor Kit - Small Seed Box

ASSEMBLY Seed Shaft Sensor Kit - Small 3. Identify the seed cups on either side of the Magnet Wheel Assembly and remove the 1/4-20 hardware. Seed Box Insert Sensor into Shaft Sensor Bracket slot. Note: 8 and 10 foot seeders use Sensor Bracket with 8-1/2” 1. - Page 41 ASSEMBLY Figure 2-24: Small Box Seed Sensor Brackets 1P480rev0718 2-19...

-

Page 42: Seed Shaft Sensor Kit - Brome Box

ASSEMBLY Seed Shaft Sensor Kit - Brome 1. At the Transmission/left side of Seeder remove 1/4 x 1-1/2 Roll Pin from Seed Shaft Coupler.See Figure 2-26. 2. Replace Coupler with Coupler with Magnet, insert existing Roll Pin 3. Insert Sensor into Shaft Sensor Bracket slot. 4. - Page 43 ASSEMBLY 8. On the right hand side of Seeder, slide Magnet Mount Assembly onto Seed Shaft, ensure groove is aligned with Seed Shaft Roll Pin. Secure Set Screw to Seed Shaft. See Figure 2-28. 9. Remove two 5/16-18 x 1-3/4 Bolts, Nuts and Lock Washers from the Seed Shaft Retaining Plate.

-

Page 44: Seed Shaft Sensor Console And Harness Installation

ASSEMBLY Seed Shaft Sensor Console and 5. On left side connect plug labeled “Electric Clutch Power” to the Electric Clutch lead. If you do not have Harness Installation an Electric Clutch, seal the plug end using a 2-Pin Shroud and Cavity Plug to protect it from the Mount Console with Clutch Control on Tractor. - Page 45 ASSEMBLY Table provided for general use. NOTES: 1P480rev0718 2-23...

-

Page 46: Agitator Box

ASSEMBLY Agitator Box 2. Install coupling on transmission output shaft and secure with 1/4” x 1-1/2 Roll Pin. See Figure 2-31. Installation of the Agitator (Brome) Box: Loose parts are 3. Loosen U-Bolts which fasten front seed box to frame shipped in a bag assembly placed in the left seed box. - Page 47 ASSEMBLY Figure 2-32: Extended Supports 4. Install the left and right boxes as shown. Left box 6. Position the shift handles on rear of boxes so the pin fastens to transmission with 5/16 x 1-1/2 and 3/8 x 1 in the bottom of each handle engages the slotted Bolts, Lock Washers and Nuts.

-

Page 48: Brush Agitator Installation, Optional

ASSEMBLY Brush Agitator Installation, Optional IMPORTANT Before proceeding with brush agitator installation, be sure to determine the direction of shaft rotation on your particular seeder model. Direction of rotation is not the same on all models due to transmission differences. Check seed compatibility, not all varieties work with brush agitators. - Page 49 ASSEMBLY CAUTION The brushes will be destroyed if installed backwards. 4. Install the Rear Box Reel Washers on each end of Agitators to prevent seed leakage out of the bushing and to reduce agitator end play between bearing brackets. With the Agitators properly seated in the boxes, replace the Drive Shafts, End Washers and Retainer Plate.

-

Page 50: Blade/Cage Agitator

ASSEMBLY Blade/Cage Agitator IMPORTANT Before proceeding with blade agitator installation, be sure to determine the direction of shaft rotation on your particular seeder model. Direction of rotation is not the same on all models due to transmission differences. See Figure 2-39. NOTE For installation of the Blade/Cage Agitator. -

Page 51: Warning Lamp Installation Dimensions- Sd Pulverizer

ASSEMBLY Warning Lamp Installation Dimensions- SD Pulverizer Figure 2-40: SD Pulverizer - Warning Lamp Installation Dimensions 1P480rev0718 2-29... -

Page 52: Sd Pulverizer Warning Lamp Installation Drawbar Models

ASSEMBLY SD Pulverizer Warning Lamp IMPORTANT Installation Drawbar Models All Harnesses must be firmly attached to Machine Frame members or Hydraulic Hoses so they do not NOTE sag or become torn loose by field debris. 13. Attach the SMV Mount to the center of frame with On 8 and 10 foot models both the Amber and Red 3/8-16 U-Bolt, Lock Washer and Nut. - Page 53 ASSEMBLY Figure 2-42: SD Pulverizer - Warning Lamp Installation, Drawbar Model 1P480rev0718 2-31...

-

Page 54: Sd Pulverizer Warning Lamp Installation 3Pt Models

ASSEMBLY SD Pulverizer Warning Lamp IMPORTANT Installation 3Pt Models All Harnesses must be firmly attached to Machine Frame members or Hydraulic Hoses so they do not NOTE sag or become torn loose by field debris. On 8 and 10 foot models both the Amber and Red Lamp’s are mounted to the Light Brackets on the outer 13. - Page 55 ASSEMBLY Figure 2-44: SD Pulverizer - 3Pt Model, LED Warning Light Installation 1P480rev0718 2-33...

-

Page 56: Scraper Kit - Optional

ASSEMBLY Scraper Kit - Optional 2. Attach the LH and RH Angle Brackets to the Brackets with 1/2-13 x 3-1/4 x 4-9/16 U-Bolts, Lock Washers and Nuts. Do Not tighten at this time. IMPORTANT 3. Attach the Scraper Angle to the LH and RH Angle Cannot be used with Coil Tine Track Remover Kit. - Page 57 ASSEMBLY Figure 2-46: Scraper Kit 1P480rev0718 2-35...

-

Page 58: S-Tine Tire Track Remover Kit - Optional

ASSEMBLY S-Tine Tire Track Remover Kit - 2. Attach the Tooth Tube to the S-Tine Brackets approximately 5 inches from each end of the Tooth Optional Tube with Straps, 1/2-13 x 6 Bolts, Lock Washers and Nuts. See Figure 2-47. IMPORTANT 3. - Page 59 ASSEMBLY Figure 2-48: S-Tine Track Remover Kit - Optional 1P480rev0718 2-37...

-

Page 60: Coil Tine Track Remover Kit - Optional

ASSEMBLY Coil Tine Track Remover Kit - Optional NOTE Cannot be used with the Scraper Kit 1. Slide the Coil Tines onto the Round Bar so that the straight leg is frontward. See Figure 2-49. 2. Mount an Arm Weldment and a Coil Tine to the Round Bar second hole from the right end and the third hole from the left end with 3/8-16 x 3 Bolts, Flat Washers, Lock Washers and Nuts. - Page 61 ASSEMBLY Figure 2-49: Coil Tine Track Remover - Optional 1P480rev0718 2-39...

- Page 62 ASSEMBLY Table provided for general use. NOTES: 2-40 1P480rev0718...

-

Page 63: Operation

Chapter 3 Operation DANGER CAUTION Never allow anyone to ride on the seeder at any When transporting farm machines on public time. Allowing a person to ride on the machine roads, it is the responsibility of the operator to can inflict serious personal injury or death to that abide by state and local laws concerning wide person. -

Page 64: Seeder Operation

This chapter covers the basic operation and usage bushings. Be sure to use the hardware provided and procedures for the Landoll Brillion Sure Stand Seeder. is in good working order. See Figure 3-1. Be sure to read and understand the Safety Procedures 7. - Page 65 OPERATION Figure 3-1: 3 Point Hitch 1P480rev0718...

-

Page 66: Attaching/Detaching 3Pt Hitch Seeder

OPERATION Attaching/Detaching 3Pt Hitch Seeder WARNING To prevent the machine from tipping backward on the frame, disengage parking pin only when the seeder is fully attached to the tractor. Be sure to observe the following sequences. Figure 3-3: Parking Pin Disengaged Figure 3-2: Parking Pin Hooking Up the Seeder: 1. -

Page 67: Tractor Preparation/Attaching Of Pull Type Seeder

OPERATION Tractor Preparation/Attaching of Pull Type Seeder DANGER Do not allow any bystanders to stand between the tractor and the machine while backing up to the machine. 1. Align the Tractor Drawbar with the machine. Raise or lower the Drawbar, as needed, using the Jack. Attach the unit with proper size Hitch Pin and Safety Clip. -

Page 68: Attaching/Detaching Pull Type Seeder

OPERATION Attaching/Detaching Pull Type Seeder Attaching the Seeder for Field Operations: Seeder parked lowered 1. Attach Seeder to the Tractor. 2. Raise the Seeder fully to extend the Hydraulic Lift Cylinders and rotate the Transport Locks in the engaged position over the Cylinder Rod. Secure with the Clevis Pins and Hairpin Cotters. -

Page 69: Hydraulic Lift System

OPERATION Hydraulic Lift System Transmission Electric Clutch - Optional The Seeder is equipped with a Hydraulic Lift System to raise and lower the unit in the field. IMPORTANT WARNING At no time use high pressure water or air to clean the Electric Clutch as damage could occur. -

Page 70: Seed Rate Adjustment

OPERATION Seed Rate Adjustment IMPORTANT If equipped, the Clutch must be disengaged when WARNING Seed Shafts are turned manually for Calibration. Seed Rate Charts specific to Seeder Model are located • To prevent damage to seed meters, do not inside the Seed Box Cover and in this manual. - Page 71 OPERATION Table 3-1: Table for 8 Ft Seed Box INDICATOR SETTING ALFALFA (UNCOATED) BAHIA BERMUDA (HULLED) BIRDSFOOT TREFOIL (BROADLEAF) BLUEGRASS (KENTUCKY) BLUE GRASS (PARK KENTUCKY) BLUE GRASS (SHERMAN BIG) CANOLA CENTIPEDE CLOVER,(ALSIKE, LADINO, SWEET, RED) CLOVER, ALYCE, CALIFORINA BUR, CRIMSON, HUMBAM CRESTED WHEAT CROWN VETCH FLAX...

- Page 72 OPERATION Table 3-2: Table for 10 Ft Seed Box INDICATOR SETTING ALFALFA (UNCOATED) BAHIA BERMUDA (HULLED) BIRDSFOOT TREFOIL (BROADLEAF) BLUEGRASS (KENTUCKY) BLUE GRASS (PARK KENTUCKY) BLUE GRASS (SHERMAN BIG) CANOLA CENTIPEDE CLOVER,(ALSIKE, LADINO, SWEET, RED) CLOVER, ALYCE, CALIFORNIA BUR, CRIMSON, HUMBAM CRESTED WHEAT CROWN VETCH FLAX...

- Page 73 OPERATION Table 3-3: Table for 12 Ft Seed Box INDICATOR SETTING ALFALFA (UNCOATED) BAHIA BERMUDA (HULLED) BIRDSFOOT TREFOIL (BROADLEAF) BLUEGRASS (KENTUCKY) BLUE GRASS (PARK KENTUCKY) BLUE GRASS (SHERMAN BIG) CANOLA CENTIPEDE CLOVER,(ALSIKE, LADINO, SWEET, RED) CLOVER, ALYCE, CALIFORNIA BUR, CRIMSON, HUMBAM CRESTED WHEAT CROWN VETCH FLAX...

-

Page 74: Transmission Drive Bolt

Seed Shafts are turned manually for Calibration. Electrical Power is required to disengage the Clutch. Landoll assumes no liability pertaining to Seeding Rates achieved with this Seeder. Rates listed are general in nature and should be used as starting points only. Seed varieties and blends listed represent those calibrated through in-house test meters. - Page 75 OPERATION Figure 3-12: Transmission Drive 1P480rev0718 3-13...

-

Page 76: Speed-Up Kit

OPERATION Speed-Up Kit 5. Move the shaft far enough to the right to remove the 13 Tooth Sprocket. Seed rates can be doubled by using a 26 Tooth Sprocket 6. Install the new 26 Tooth Sprocket. and following the procedure below: 7. -

Page 77: Rear Agitator Seed Box Seed Rate Adjustment

Cage Agitators can be used to plant cereal grains such as wheat, oats, rye, barley and others. However, Landoll does not recommend it as a harvestable crop because the seed will only be placed in the top 1/4” to 1/2” of soil which is too shallow for a harvestable crop. -

Page 78: Seed Rate Calibration

OPERATION Seed Rate Calibration 1. Rates are intended as a guide only. variations in seed size and cleanliness will affect rates. check The provided chart was determined by laboratory tests acreage and pounds of seed used for best results. on various samples. To find rates for specific seed lots or 2. - Page 79 OPERATION Figure 3-15: Rear Agitator Seed Chart 1P480rev0718 3-17...

-

Page 80: Acre Meter - Optional Settings For Loup Acre Meters After 05/15/2012

OPERATION Acre Meter - Optional Settings To clear the total acre count, press and hold the UP and for Loup Acre Meters After DOWN buttons for two seconds. If a password has been entered, you will not be able to clear the total acre count. 05/15/2012 Total acres will count from.1 to 99999 acres. -

Page 81: Quick-Start Settings For Acre Meters Prior To 05/15/2012

OPERATION If the display shows “Ent”: You must enter your 6. Press the function button to set the width. (If screen password using the UP and DOWN buttons. When your goes blank before you press the function button, password is displayed, press the /FUNC button to test repeat steps 4 and 5). - Page 82 OPERATION Table 3-5: Acre Meter Settings (After 05/15/2012) Pulses Width MODEL per 400 Ft SSPT604 SSP4 SSP5 SSP6 SSP8 SSBP8 SSB8 SSP10 SSBP10 SS10 SSB10 10.0 SSP12 SSBP12 SS12 SSB12 12.0 SSP16 16.0 SSP108 SS108 SSP110 SS110 10.0 SSP112 SS112 12.0 SSP208/2081 SS208/2081...

- Page 83 OPERATION Table 3-6: Acre Meter Settings (Prior to 05/15/2012) MODEL Pulses Width SSP T604 SSP4 SSP5 SSP6 SSP8 SSP10 SS10 SSP12 SS12 SSP108 SS108 SSP110 SS110 SSP112 SS112 SSP208 SSP2081 SS208 SS2081 SSP210 SSP2101 SS210 SS2101 SSP212 SSP2121 SS212 SS2121 SSP308 SS308 SSP310...

-

Page 84: Seed Shaft Sensor Console With Clutch Control - Optional

OPERATION Seed Shaft Sensor Console with CAUTION Clutch Control - Optional Excessive speed may result in loss of control of Basic Operation: the tractor and machine, reduced braking ability, or failure of the machine tire or structure. Do not During normal operation the Console LED for the Seed exceed the machines maximum specified ground Shaft will not be illuminated. - Page 85 OPERATION WARNING Failure to use transport lock pins during transport may result in permanent equipment damage, serious injury, or death. • Check all tires for proper inflation, and that lug nuts are properly torque. See “Tires” on page 4-3. •...

- Page 86 OPERATION Table provided for general use. NOTES: 3-24 1P480rev0718...

-

Page 87: Maintenance

Chapter 4 Maintenance General Torque Specifications (rev. 4/97) This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used. -

Page 88: Hydraulic Fitting Torque Specifications

MAINTENANCE Hydraulic Fitting Torque Specifications 37 degree JIC, ORS, &ORB (REV. 10/97 This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used. -

Page 89: Tires

MAINTENANCE Tires 9. Tighten the Slotted Nut while rotating the Hub until there is a slight resistance to wheel rotation. Then, Seeder recommended Tire Size: back the Slotted Nut off one notch, until the wheel rotates freely without end play. 9.5L x 15 - 8 Ply Rating 10. - Page 90 MAINTENANCE Figure 4-2: Lubrication Intervals 1P480rev0718...

-

Page 91: Hydraulic Maintenance

MAINTENANCE Hydraulic Maintenance IMPORTANT To maximize seed germination, peaks on Rear Roller IMPORTANT Wheels should line up with valleys on the Front Lower the unit to the ground, and relieve hydraulic Roller Wheels. This will require adjusting the Clamp pressure before attempting to service any hydraulic Bands on each end of the Rear Roller Drum and component. -

Page 92: Chain Tension

MAINTENANCE Chain Tension To adjust the Transmission Chain, loosen the 5/8” Idle Axle Bolt and then use the Clevis Bolt to obtain about Clevis Drawbolt 1/8” -1/4” sag. Re-tighten the Axle Bolt. Be careful not to over-tighten this chain. See Figure 4-4. Idler Axle Bolt Adjust the chain between the Front Roller and Transmission to have approximately 2”... -

Page 93: Seed Meter Adjustment

MAINTENANCE Seed Meter Adjustment IMPORTANT Ensure the Seed Shaft can turn freely without any IMPORTANT binding when the Seed Meters are open or closed The Clutch must be disengaged when Seed Shafts after servicing. are turned manually for Calibration. 1. 1/2-13 Locknuts on both ends of the Adjusting Screw are used to adjust all Seed Meters the same amount. -

Page 94: Agitator Box Slide

MAINTENANCE Agitator Box Slide LED Warning Lamps When properly adjusted, the holes in the slide should line When plugging in the Lamp 7 Pin Warning Lamp up with the holes in the box, when the Control Handle is Connector: set at “6”. To make an adjustment: 1. -

Page 95: Acre Meter Troubleshooting

MAINTENANCE Acre Meter Troubleshooting 4. If step 3 works then wave a magnet in front of the Pick-up Switch face with it re-connected to the display and see if the display increments up. If not, IMPORTANT put an ohm meter or continuity tester on the contacts Acre Meter is dust and splash resistant, under no of the Pick-up Switch harness and place a magnet in circumstances should this unit be submerged in any... -

Page 96: Service Tip For Brome Box

MAINTENANCE Service Tip for Brome Box • Check that Seed Boxes are level and straight from end to end. Loosen and adjust Seed Boxes from the center Problem – Brome box shaft working out to the right hand and right hand end brackets if necessary. It may also be end of the Seeder and wearing out the roll pin and necessary to make an adjustment of the Left Hand Seed retainer plate. -

Page 97: Reference Tables And Specifications

Chapter 5 Reference Tables and Specifications Table 5-1: 8 Foot Models... - Page 98 REFERENCE TABLES AND SPECIFICATIONS Table 5-2: 10 Foot Models 1P480rev0718...

- Page 99 REFERENCE TABLES AND SPECIFICATIONS Table 5-3: 12 Foot Models 1P480rev0718...

- Page 100 REFERENCE TABLES AND SPECIFICATIONS Table provided for general use. NOTES: 1P480rev0718...

- Page 101 Document Control Revision Log: Date Revision Improvement(s) Description and Comments 07/2008 205rev0708 Initial Release 07/2011 205rev0711 Updated Pictures and Drawings. Incorporated ECN 35017 09/2013 205rev0913 Added LED Warning Lights 07/2018 0718 Update tractor preparation section, product attributes...

- Page 102 Equipment from Landoll Company, LLC is built to exacting standards ensured by ISO 9001 registration at all Landoll manufacturing facilities. Sure Stand Seeder Models SS, SSB, SSP and SSBP 8’, 10’ and 12’ Operator’s Manual Re-Order Part Number 1P480rev0718 LANDOLL COMPANY, LLC...

Need help?

Do you have a question about the Brillion SSB and is the answer not in the manual?

Questions and answers

I purchased a SS12 to seed Kentucky bluegrass not knowing the seed rate. I would need to apply 60 lbs per acre. Can I convert my Brillion SS12 with bigger sprockets? Know it says I can go to a 26 tooth but still not even close to where I need to be.

Yes, you can use bigger sprockets to adjust the seed rate on a Landoll SS12. The Speed-Up Kit allows seed rates to be doubled by using a 26-tooth sprocket and following the specified procedure. However, actual seeding rates depend on calibration, and you should follow the calibration instructions inside the seed box cover for accurate results.

This answer is automatically generated

I am planting B-dahl bluestem fluffy grass seed. I have a ssb12 Brillion drill. My question is what agitator shall I use. The Brillion has 3 different agitators. Brush, cage and blade. Which one would be the best one to use.

The best agitator to use with a Landoll Brillion SSB12 drill for planting B-dahl bluestem fluffy grass seed is the cage agitator. Brush agitators are not suitable for fluffy or small seeds as they can be damaged or destroyed, and blade agitators may not handle fluffy seeds effectively.

This answer is automatically generated

How do I determine what to set the gauge on the back of the seat box on?

The gauge on the back of the seed box for a Landoll Brillion SSB is set using the provided seed chart. Follow these steps:

1. Refer to the Seed Chart – Use Tables 3-4 and 3-15 to determine the appropriate indicator setting for the type of seed you are planting.

2. Adjust the Indicator Setting – Locate the indicator on the back of the seed box and set it to the value corresponding to your seed type and desired planting rate.

3. Consider the Agitator Configuration – If using a 26-tooth driver, double the values listed in the seed chart.

4. Calibrate If Necessary – If planting a seed type not listed, use the calibration procedure as described in the manual.

This ensures accurate seed distribution for optimal planting results.

This answer is automatically generated