Subscribe to Our Youtube Channel

Summary of Contents for Retsch BB50

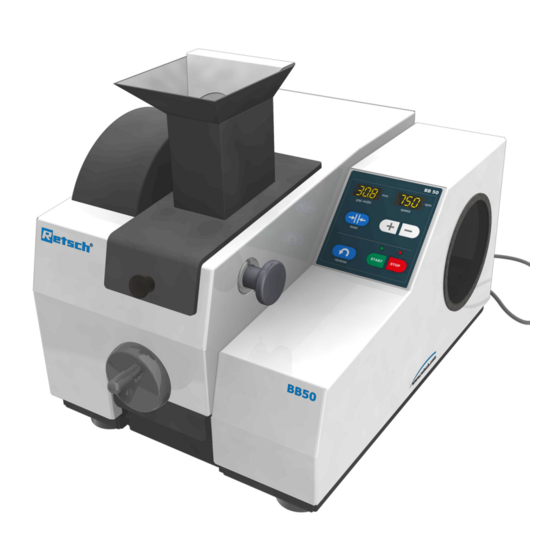

- Page 1 Manual Jaw Crusher BB50 Translation © Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 06.07.2016 0003...

- Page 2 Copyright © Copyright by Retsch GmbH Haan, Retsch-Allee 1-5 D-42781 Haan Federal Republic of Germany...

-

Page 4: Table Of Contents

Notes on the Operating Manual ......................6 Explanations of the safety warnings ....................7 General safety instructions ........................ 8 Repairs ............................... 9 Confirmation ............................10 Technical data ............................11 Use of the machine for the intended purpose.................. 11 3.1.1 Properties of the grinding material ....................11 Working instructions ........................ - Page 5 7.1.2 Removing the splash-back protection ..................29 7.1.3 Removing the grinding chamber cover ..................29 Service ............................. 29 7.2.1 Replacing the breaking jaws ......................30 7.2.2 Replacing the front breaking jaw ....................30 Wear ..............................33 7.3.1 Resetting the wear alert ....................... 33 7.3.1.1 Setting the operating time until the calibration alert is displayed .........

-

Page 6: Notes On The Operating Manual

This operating manual does not contain any repair instructions. If faults arise or repairs are necessary, please contact your supplier or get in touch with Retsch GmbH directly. -

Page 7: Explanations Of The Safety Warnings

Pos : 2.2 /0020 Ü bersc hriften/1.1 Übersc hriften/1.1 Übersc hriften BD A/11 Er kl ärungen z u den Sicherheits warnungen @ 0\mod_1222344569771_9.doc x @ 2484 @ 2 @ 1 1.1 Explanations of the safety warnings Pos : 2.3 /0010 R ETSCH Standard Kapitel General M odul Warnhinweis e Er kl ärung neu @ 0\mod_1234858329746_9.doc x @ 6190 @ @ 1 In this Operating Manual we give you the following safety warnings Serious injury may result from failing to heed these safety warnings. -

Page 8: General Safety Instructions

Target group : All persons concerned with the machine in any form This machine is a modern, high performance product from Retsch GmbH and complies with the state of the art. Operational safety is given if the machine is handled for the intended purpose and attention is given to this technical documentation. -

Page 9: Repairs

Pos : 2.12 /0010 RET SCH Standard KapitelGener al Modul R eparatur en @ 0\mod_1228722954535_9.doc x @ 4079 @ @ 1 This operating manual does not contain any repair instructions. For your own safety, repairs may only be carried out by Retsch GmbH or an authorized representative or by Retsch service engineers. -

Page 10: Confirmation

Pos : 3.2 /0010 BDA Software/Übersc hriften/1. Ü bersc hriften/1 Bestätigung (F ormular für den Betr eiber) @ 0\mod_1208870841095_9.doc x @ 430 @ 1 @ 1 Bes tätigung 2 Confirmation Pos : 3.3 /0005 R ETSCH /0099 RET SCH Standar d Kapitel/Gener al M odul Bes tätigung @ 0\mod_1228722962707_9.doc x @ 4114 @ @ 1 This operating manual contains essential instructions for operating and maintaining the device which must be strictly observed. -

Page 11: Technical Data

Pos : 5.4 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/BB50/0005 Tec hnisc he Daten/0010 BB50 Modul Ei nsatz bei besti mmungsg emäß er Ver wendung @ 5\mod_1345704057222_9.doc x @ 34350 @ 3 @ 1... -

Page 12: Working Instructions

3.2 Working instructions Pos : 5.7 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/BB50/0005 Tec hnisc he Daten/0060 BB50 Modul Funkti ons weis e @ 5\mod_1345706543471_9.doc x @ 34478 @ @ 1 Fig. 1: Diagram of grinding The grinding process in this machine takes place using pressure. -

Page 13: Protective Equipment

3.3 Protective equipment Pos : 5.9 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/BB50/0005 Tec hnisc he Daten/0065 BB50 Modul Sc hutz einric htung en @ 5\mod_1345714560248_9.doc x @ 34488 @ @ 1 Fig. 2: Protective devices... -

Page 14: Dimensions And Weight

3.10 Dimensions and weight Pos : 5.23 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0005 T ec hnis che D aten/0035 BB50 M odul Abmess ungen und Gewic ht @ 5\mod_1345704767776_9.doc x @ 34424 @ @ 1 When closed:... -

Page 15: Transport, Scope Of Delivery, Installation

Transport, scope of delivery, installation Pos : 7.1 /0020 Ü bersc hriften/1. Ü bers chriften/1 Ver pac kung, Tr ans port und Aufstellung @ 0\mod_1226494451893_9.doc x @ 3380 @ 1 @ 1 4 Transport, scope of delivery, installation Pos : 7.2 /0020 Ü bersc hriften/1.1 Übersc hriften/1.1 Übersc hriften BD A/11 Verpac kung @ 0\mod_1226495088973_9.doc x @ 3392 @ 2 @ 1 4.1 Packaging Pos : 7.3 /0005 R ETSCH /0099 RET SCH Standar d Kapitel/Gener al M odul Ver pac kung @ 0\mod_1228984618355_9.doc x @ 4892 @ @ 1 The packaging has been adapted to the mode of transport. -

Page 16: Electrical Connection

Transport, scope of delivery, installation Pos : 7.13 /0025 War nhi nweis e/H 0011 H INWEIS Luftfeuchtigkeit @ 0\mod_1228918882628_9.doc x @ 4788 @ @ 1 NOTICE Atmospheric humidity – Electronic and mechanical components may be damaged and the performance data alter to an unknown extent. •... -

Page 17: Removing Transport Safeguards

4.7 Removing Transport Safeguards Pos : 7.20 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0006 Ver pac kung, Tr ansport und Aufs tellung/0005 BB50 Modul Trans porthilfe entfer nen @ 5\mod_1345721568835_9.doc x @ 34508 @ @ 1 Fig. 5: Carrying the machine - preparation •... -

Page 18: Removing The Transport Safeguard

4.8 Removing the transport safeguard Pos : 7.22 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0006 Ver pac kung, Tr ansport und Aufs tellung/0010 BB50 Modul Trans portsic herung entfer nen @ 5\mod_1357546736532_9.doc x @ 37050 @ @ 1 Fig. -

Page 19: Operating The Machine

5.1 Views of the Instrument Pos : 9.3 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/BB50/0007 Bedi enung/0005 BB50 M odul Ansichten des Ger ätes @ 5\mod_1345555394077_9.doc x @ 34280 @ @ 1 Fig. 8: Front view H,K,L Fig. - Page 20 Operating the machine Fig. 10: Machine partially open Pos : 9.4 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/------- Seitenumbruc h ----------- @ 0\mod_1222344373758_0.doc x @ 2386 @ @ 1...

-

Page 21: Overview Table Of The Parts Of The Device

5.2 Overview table of the parts of the device Pos : 9.6 /0005 R ETSCH /0005 RET SCH Bedienungs anl eitung en Kapi tels ammlungen/BB50/0007 Bedi enung/0006 BB50 M odul Ü bersichtstabelle Geräteteile @ 5\mod_1345618254846_9.doc x @ 34290 @ @ 1... -

Page 22: Operating Elements And Displays

5.4 Overview Table of the Operating Elements and the Display Pos : 9.11 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0007 Bedi enung/0008 BB50 M odul Ü bersic hts tabelle Bedi enfel d @ 5\mod_1345622654959_9.doc x @ 34310 @ @ 1... -

Page 23: Switching On And Off

Pos : 9.15 /0020 Übersc hriften/1.1 Ü bersc hriften/1.1 Ü berschriften BDA/11 Spaltweite auf Nulls tell ung s etzen @ 5\mod_1345445748972_9.doc x @ 34160 @ 2 @ 1 5.6 Setting the gap width to zero position Pos : 9.16 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0007 Bedi enung/0011 BB50 M odul Spaltweite Nulls tell ung @ 5\mod_1346050929641_9.doc x @ 34540 @ @ 1 NOTICE The gap width may only be adjusted during idling without grinding material. -

Page 24: Setting The Gap Width

Pos : 9.17 /0020 Übersc hriften/1.1 Ü bersc hriften/1.1 Ü berschriften BDA/11 Spaltweite eins tell en @ 5\mod_1345445670122_9.doc x @ 34150 @ 2 @ 1 5.7 Setting the gap width Pos : 9.18 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0007 Bedi enung/0010 BB50 M odul Spaltweiteneins tell ung @ 5\mod_1346050883310_9.doc x @ 34530 @ @ 1 NOTICE Before starting the machine, do not put any grinding material in the grinding chamber or fill hopper. -

Page 25: Reverse Grinding

5.8 Reverse grinding Pos : 9.20 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0007 Bedi enung/0012 BB50 M odul R evers e-Ver mahlung @ 5\mod_1346050964001_9.doc x @ 34551 @ @ 1 Fig. 16: Bridging effect in the grinding chamber Fig. -

Page 26: Starting The Grinding Process

Pos : 9.23 /0020 Übersc hriften/1.1 Ü bersc hriften/1.1 Ü berschriften BDA/11 M ahl vorgang starten @ 0\mod_1227185008190_9.doc x @ 3861 @ 2 @ 1 5.10 Starting the grinding process Pos : 9.24 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0007 Bedi enung/0014 BB50 M odul M ahl vorgang starten @ 5\mod_1346050969994_9.doc x @ 34661 @ @ 1 Fig. 19: Start grinding •... -

Page 27: Sample Receptacle

Pos : 11.2 /0020 Übersc hriften/1.1 Ü bersc hriften/1.1 Ü berschriften BDA/11 F ehler mel dungen @ 0\mod_1222344568006_9.doc x @ 2435 @ 2 @ 1 6.1 Fault messages Pos : 11.3 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0009 Sicherheits funktionen und Fehler anz eige/0008 BB50 M odul F ehler mel dungen @ 5\mod_1346844648119_9.doc x @ 34851 @ @ 1 DESCRIPTION Switch machine off and back on. -

Page 28: Cleaning, Wear And Service

Removing the feed hopper Pos : 12.6 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0010 R einigung Wartung Versc hleiß /0006 BB50 M odul Einfülltric hter entfer nen @ 5\mod_1346078728003_9.doc x @ 34710 @ @ 1 Fig. 1: Opening the hopper flap •... -

Page 29: Removing The Splash-Back Protection

Pos : 12.9 /0005 RET SCH/0005 R ETSCH Bedienungsanlei tungen Kapitelsamml ung en/BB50/0010 R einigung Wartung Versc hleiß /0007 BB50 M odul R üc ks pritzsc hutz entfernen @ 5\mod_1346078784486_9.doc x @ 34721 @ @ 1 Fig. 22: Removing the splash-back protection •... -

Page 30: Replacing The Breaking Jaws

Replacing the breaking jaws Pos : 12.15 /0005 R ET SCH/0005 RET SCH Bedi enungsanleitungen Kapitels ammlungen/BB50/0010 R einigung Wartung Verschl eiß/0009 BB50 Modul Br ec hbac ken vorn austaus chen @ 5\mod_1346078785877_9.doc x @ 34743 @ 3 @ 1 7.2.2... - Page 31 Cleaning, wear and service Fig. 26: Using the (bolt) removal tool • Pull the bolt (G) out of the guide. • Place the bolt (G) in the removal groove (Rn) of the front crusher arm. Fig. 27: Removing the breaking jaw •...

- Page 32 (RL). Pos : 12.16 /0005 R ET SCH/0005 RET SCH Bedi enungsanleitungen Kapitels ammlungen/BB50/0010 R einigung Wartung Verschl eiß/0010 BB50 Modul Br ec hbac ken hi nten austausc hen @ 5\mod_1346078786485_9.doc x @ 34754 @ @ 1 Fig.

-

Page 33: Wear

Pos : 12.17 /0020 Ü berschriften/1.1 Ü bers chriften/1.1 Ü bersc hriften BD A/11 Versc hleiß @ 0\mod_1226909713106_9.doc x @ 3619 @ 2 @ 1 7.3 Wear Pos : 12.18 /0005 R ET SCH/0005 RET SCH Bedi enungsanleitungen Kapitels ammlungen/BB50/0010 R einigung Wartung Verschl eiß/0011 BB50 Modul Versc hleiß @ 5\mod_1346078787141_9.doc x @ 34765 @ 34 @ 1 7.3.1... - Page 34 Cleaning, wear and service • Simultaneously press the buttons RESET+STOP for 2 seconds. The currently set operating time until calibration flashes in the gap width (F1) display (default: 50h) and h is displayed in the speed (F2) display. • Briefly press the button (F4 +) to increase the operating time in increments of •...

-

Page 35: Disposal

Disposal Pos : 13.2 /0005 RET SCH/0015 R ETSCH Reparatur- und M ontag eanleitungen/00000 Ü berschriften/1. Übersc hriften/1 Ents orgung @ 0\mod_1234258746831_9.doc x @ 6173 @ 1 @ 1 8 Disposal Pos : 13.3 /0010 RET SCH Standard KapitelGener al Modul Entsorgung @ 0\mod_1234269404935_9.doc x @ 6180 @ @ 1 Please observe the respective statutory requirements with respect to disposal. -

Page 36: Index

9 Index 88.8/888 27 Gap width 24 General safety instructions 8 Grinding process 12 Aligning the gap width 23 Grinding speed 25 Ambient temperature 15 Amperage 17 Atmospheric humidity 15 H41; H43 27 Bar code 17 Installation height 18 Bonding 30 Installation of the machine 18 Bridging effect 25 IP20 13... - Page 37 Removing the transport lock 18 Technical data 11 Removing the transport safeguard 18 Temperature fluctuation and condensed water 15 Removing Transport Safeguards 17 Transport 15 Repairs 9 Transport, scope of delivery, installation 15 Replacing the breaking jaws 30 Type plate 16 Required floor space 14 type plate description 16 Reverse 25...

- Page 44 Copyright ® Copyright by Retsch GmbH Haan, Retsch-Allee 1-5 D-42781 Haan Federal Republic of Germany...

Need help?

Do you have a question about the BB50 and is the answer not in the manual?

Questions and answers