Summary of Contents for Fike Quadnet

- Page 1 Fire Detection & Alarm System Control Panel V3 (Suitable for Quadnet control panels from V2.00) Control Panel Engineering and Commissioning Manual (TO BE RETAINED BY THE COMMISSIONING ENGINEER) 26-0582 Issue 15...

- Page 2 Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every care has been taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability whatsoever in respect of such contents.

-

Page 3: Table Of Contents

Quadnet Control Panel Engineering and Commissioning Manual Contents Introduction .......................... 5 System Design ......................5 Equipment Guarantee ....................5 Anti Static Handling Guidelines ................5 Warning ........................5 EMC .......................... 5 The Quadnet System ......................6 Advantages of Addressable Systems ............... 6 Control Panel ........................ - Page 4 Quadnet Control Panel Engineering and Commissioning Manual Good Practice........................46 Number of Devices ....................46 Label the Loop Ends ....................46 Note the Loop Readings ................... 46 Configuration Printout and Drawings ................ 47 Initialisation .......................... 48 Normal Readings ...................... 48 Initialisation Process ....................

-

Page 5: Introduction

Quadnet Control Panel Engineering and Commissioning Manual Introduction This Manual is intended as a guide to the engineering and commissioning principles of the Quadnet Addressable Intelligent Fire Alarm and Detection system, and covers the system hardware information only. Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on this equipment is essential, and commissioning should only be carried out by competent and approved persons. -

Page 6: The Quadnet System

IMPORTANT NOTE: The Quadnet Panel is a 2 box solution comprising a Control Panel (as per this manual) and a matching Power Supply Unit. This manual describes the Quadnet Control Panel. Please refer to the Quadnet Power Supply Unit Installation Instructions for details of how to install the Power Supply Unit and connect it to the Quadnet Control Panel. -

Page 7: Control Panel

Quadnet Control Panel Engineering and Commissioning Manual Control Panel Mounting the Control Panel First identify the proposed location for the control panel. Ensure that the control panel will be easily accessible, and that account is taken of any subsequent work that may affect access. It should be located at the most likely point of access for the fire services. -

Page 8: Control Panel Disassembly

Quadnet Control Panel Engineering and Commissioning Manual Control Panel Disassembly LOOP CARDS BACKPLANE The panel is normally supplied disassembled to make first fix easier. If the panel is already assembled it must be disassembled in order to fix the backbox to the wall. -

Page 9: Left Hand Side Door (Cie Door) Removal

Quadnet Control Panel Engineering and Commissioning Manual Left Hand Side Door (CIE Door) Removal (if required) If the panel is assembled and it is necessary to remove the left hand door that houses the CIE in order to replace the CIE, the door must be opened to its full extent and the ribbon cables unplugged from the main backplane. -

Page 10: Cabinet Installation

Quadnet Control Panel Engineering and Commissioning Manual Cabinet Installation This backbox is compatible with the Quadnet range of Fire Alarm Control Equipment and is common to the range of control panels, repeater panels and power supply units. Surface Mounting At least four of the five mounting holes should be used to secure the cabinet to a solid wall using suitable screws of at least 50mm in length. -

Page 11: Topology And Cabling

Quadnet Control Panel Engineering and Commissioning Manual Topology & Cabling All system wiring should be installed to comply with BS 5839: Pt 1: 2002: Amendment 2: 2008 and BS 7671 (wiring regulations) and any other standards relevant to the area or type of installation. A cable complying with the BS 5839: Pt 1: 2002 Category 1 (cables required to operate for prolonged periods during fire conditions) is required. -

Page 12: Loop Loading

It can detect the type of the device and, in the case of devices manufactured from March 2010, the subtype from the above list as well. For devices manufactured prior to this date, the Quadnet OSP will attempt to detect the subtype and use the appropriate DLUs. The engineer can override the automatically detected subtype if required ie. -

Page 13: General System Schematic

Quadnet Control Panel Engineering and Commissioning Manual General System Schematic QUADNET CONTROL PANEL ADDRESSABLE LOOPS ALL 2-CORE 1.5mm MAX 2km QUADNET QUADNET (OPTIONAL UP TO 4 MAX PER PANEL) Sita Multipoint Sita MP I/O Sita MCP Remote Indicator Sita Loop I/O Module... -

Page 14: Control Panel Main Pcb

Quadnet Control Panel Engineering and Commissioning Manual Control Panel Main PCB Located on the inside of the front left hand inner door. 10-0050 LED PCB POWER TEST DISABLED FAULT FIRE LED PCB Display ZONE LEDS Main Control Panel 10-0049 CIE PCB... - Page 15 Note that firmware upgrades are only permitted to be carried out by Fike engineers or trained installation engineers operating under specific instructions from Fike Technical Support.

-

Page 16: Control Panel Terminals

Quadnet Control Panel Engineering and Commissioning Manual Control Panel Terminals The Termination and PSU PCB (also known as the backplane) is located at the rear of the main control panel back box. The Loop cards may be plugged into the loop card slots on the backplane. To avoid damage, ensure that the panel is powered down whilst connecting and removing the loop cards. - Page 17 The loop card firmware may be upgraded on site using the external flash utility. The link pin should be left connected for correct field operation and removed for firmware upgrade. Note that firmware upgrades are only permitted to be carried out by Fike engineers or trained installation engineers operating under specific instructions from Fike Technical Support.

- Page 18 The default setting for outputs 5 and 6 causes the circuits to operate as Common Fire Sounder Circuits, where the outputs turn on in the alarm condition. Various other states may also be set using the Quadnet OSP programming software.

- Page 19 Quadnet Control Panel Engineering and Commissioning Manual Inputs 1- 4: MI+, MI-, SCRN ON BOARD PCB FIELD CONNECTIONS N/O CONTACT FIRE RESISTOR SCRN SCREEN Inputs 1-4 may be configured to monitor for open and short circuit faults using a 3k3 EOL resistor, and to activate an alarm link using a 680R ‘firing’...

- Page 20 USB lead to link to a computer. This allows the site specific data to be customised as required. NOTE: It is imperative that the correct version of OSP is used to match your version of Quadnet control panel. The use of an incompatible version may result in incorrect operation of the control panel.

- Page 21 Quadnet Control Panel Engineering and Commissioning Manual Network Port 2 ON BOARD PCB FIELD CONNECTIONS SCREEN NW2B TO NETWORK PORT OF NEXT CONTROL PANEL NW2A Terminal Description SCRN Field cable screen connection (Connect only at 1 end) NW2B Data B connection for Port 2...

-

Page 22: Network

Network Network Topology and Cabling In order to use the networking features of the Quadnet system, each control panel must have the optional Quadnet network card fitted onto the control panel main PCB (CIE). Quadnet repeater panels automatically include this network card as standard since repeaters can only be used on the network. -

Page 23: Network Connection Schematic

NETWORK CARD SCREW CONNECTOR Before any networking facilities may be used, the optional Quadnet network card must be fitted to the control panel main PCB (CIE) as shown above. Network cabling connects to the Network terminals on the backplane PCB. - Page 24 Quadnet Control Panel Engineering and Commissioning Manual All network cables should be 2-core 1.5mm screened and fire-rated. The cable screen must be connected to the control panel (using the SCRN terminal provided, not at any earthing point) at one end only using the terminals provided.

-

Page 25: General Operation Of Control Panel

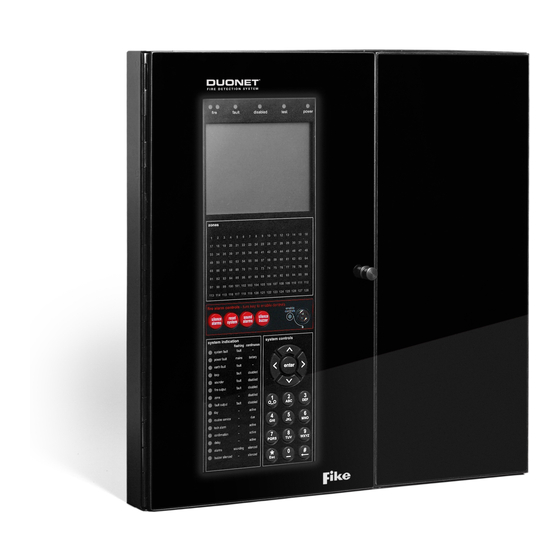

Quadnet Control Panel Engineering and Commissioning Manual General Operation of Control Panel Control Panel Front fire fault disabled test power General Indication LEDs V3.00 Panel 01: PANEL 01 Control Panel Information Window 23/05/11 23:01 NORM QUADNET MULTILOOP FIRE ALARM SYSTEM... -

Page 26: Led Indication

Quadnet Control Panel Engineering and Commissioning Manual LED Indication The operation of the LED indications on the front of the control panel is described below. Description Colour State Reason FIRE Continuous The control panel is in the fire state. Other indicators... - Page 27 Quadnet Control Panel Engineering and Commissioning Manual FAULT OUTPUT Yellow Flashing A monitored output programmed to operate as a Fire Output is in the fault state. Continuous A monitored output programmed to operate as a Fire Output has been disabled.

-

Page 28: Fire Alarm Controls

Quadnet Control Panel Engineering and Commissioning Manual Fire Alarm Controls The main Fire Alarm Controls may be enabled by turning the key switch to the controls enabled position, or by entering a valid Access code. fire alarm controls – turn key to enable controls... -

Page 29: Access Levels And Codes

Level 2A (User), or the correct entry of the relevant code for access to all other levels, in order to protect against unauthorised access to the system. The codes may be changed using the Quadnet OSP software. A valid access level code must be entered in order access any of the menus. -

Page 30: Access Level 2B (Supervisor)

Quadnet Control Panel Engineering and Commissioning Manual Access Level 2B (Supervisor): Controls Enabled LED flashing slowly At Access Level 2B (Supervisor), the main Fire Alarm Controls are enabled, and the following System Controls are accessible: 1. Delay On / Off 2. - Page 31 Quadnet Control Panel Engineering and Commissioning Manual 3. View Logs 2. Current Faults The Active Faults Log will display any current faults. These are displayed in text format and may be scrolled through by pressing the UP and DOWN keys.

- Page 32 Quadnet Control Panel Engineering and Commissioning Manual 4. Disable / Enable 5. Fault Outputs This function allows the global disablement or enablement of all fault outputs on the system. The control panel will indicate that disablements are present and a disablement event will be recorded in the log.

- Page 33 Quadnet Control Panel Engineering and Commissioning Manual 7. Day / Night Mode 1. Override into Day Mode This function allows the user to override any pre-programmed Day / Night timing information and force the system into the less sensitive Day Mode. This will cause the panel buzzer to sound and a disablement to be written to log.

-

Page 34: Access Level 3 (Engineer)

Quadnet Control Panel Engineering and Commissioning Manual Access Level 3 (Engineer): Controls Enabled LED flashing quickly At Access Level 3 (Engineer), the main Fire Alarm Controls are enabled, and the following System Controls are accessible: 1. Current Warnings 1. View Logs 2. - Page 35 Quadnet Control Panel Engineering and Commissioning Manual 1. View Logs 1. Current Warnings The Active Warnings Log will display any current warnings. These are displayed in text format and may be scrolled through by pressing the UP and DOWN keys.

- Page 36 Quadnet Control Panel Engineering and Commissioning Manual 3. Disable / Enable 4. Fire Outputs This function allows the global disablement or enablement of all fire outputs on the system. The control panel will indicate that disablements are present and a disablement event will be recorded in the log.

- Page 37 Quadnet Control Panel Engineering and Commissioning Manual 6. Day / Night Mode 1. Override into Day Mode This function allows the user to override any pre-programmed Day / Night timing information and force the system into the less sensitive Day Mode. This will cause the panel buzzer to sound and a disablement to be written to log.

- Page 38 Note that the system should always be re-configured after a PC download from Quadnet OSP, and then the system should be reset using the ‘reset’ button. If this is not carried out the system may give a Configuration Data Error fault.

- Page 39 Quadnet Control Panel Engineering and Commissioning Manual 7. Engineer Controls 2. View / Edit Attributes 6. View no. of Devices Programmed This function allows the user to view the loop devices programmed and compare with the loop devices present. 7. Engineer Controls 2.

-

Page 40: Printer

Printer Quadnet control panels can have an optional printer fitted if required. This must be specified when ordering a panel and cannot be fitted by the end user or installer as an after market addition. If the printer is fitted it can be setup to print out local events as they occur. -

Page 41: Alarm Confirmation

Cause & Effect sequence is reached. This function requires the use of a PC with Quadnet OSP and it is not possible to use it without. In order to activate the function, install the devices as normal and refer to the Quadnet OSP Programming Manual for... -

Page 42: Alarm Confirmation Delay

(depending on the programming of the system Cause & Effect). Selecting the Devices Any smoke detectors which are to utilise Alarm Confirmation must be selected using the Quadnet OSP programming software. Smoke detectors not selected will operate in a standard manner (depending on the programming of the system Cause &... -

Page 43: Commissioning

The system can only indicate faults present when the loop is fully initialised. If the initialisation fails then you will need to find faults manually. You may run the initialisation backwards by reversing the loop connections, or one ended by removing one end of the loop. You may also use the Quadnet OSP software... -

Page 44: Commissioning

8. Test for correct operation. NOTE: It is imperative that the correct version of OSP is used to match your version of Quadnet control panel. The use of an incompatible version may result in incorrect operation of the control panel. In particular, do not use a V2.xx series OSP with a V3.xx series control panel and do not use a V3.xx series OSP with a V2.xx series control panel. -

Page 45: Configuration Example

These codes must however be available for the responsible persons, so ensure that they are notified correctly. The Quadnet User Guide should be explained and left with the responsible person on site, for storage in an accessible and known location, in order that the responsible person and the service engineer may keep... -

Page 46: Good Practice

The following suggestions are good practice if carried out during commissioning, and may help avoid common problems at a later date. The Fike Safety Technology Technical Support department may be unable to assist if the information is unavailable, and the guidelines not followed. -

Page 47: Configuration Printout And Drawings

Quadnet Control Panel Engineering and Commissioning Manual Configuration Printout and Drawings Make a Text Report printout of the system configuration from Quadnet OSP and store it safely on site along with an up to date site plan marked with devices, serial numbers and wiring order. -

Page 48: Initialisation

Quadnet Control Panel Engineering and Commissioning Manual Initialisation Normal Readings Ensure that your addressable device loop has the correct continuity and insulation integrity. With an electronic test meter there should be a continuity reading of approximately 1.2 ohms per 100m of 1.5mm cable, and no continuity should be read between cores. -

Page 49: Initialisation Faults

Quadnet Control Panel Engineering and Commissioning Manual The number shown under Init Complete gives a count of the total number of devices initialised on the system. If initialisation is completed correctly this is followed by a tick, whereas if there is any failure in initialisation this is followed by a cross. - Page 50 Quadnet Control Panel Engineering and Commissioning Manual All devices up to that point will be operational, but devices beyond will not be active, as the control panel will not initialise from Loop End 2 as it becomes very difficult to understand fully where the problem lies.

-

Page 51: Earth Faults

Quadnet Control Panel Engineering and Commissioning Manual may be replaced. It is not advisable to leave a system with a device missing (positive cores linked together) in this way as all future points will be displaced. The loop must be re-initialised to clear this fault. Always wait at least 3 minutes between stopping a loop and reinitialising. - Page 52 Quadnet Control Panel Engineering and Commissioning Manual Eg, if the resistance reading at Loop end 1 were 9 ohm, and at Loop end 2 were 3 ohm then it may be estimated that the short circuit lay approximately 9/(3+9) = ¾ of the way round the addressable device circuit from Loop end 1.

-

Page 53: General Fault Finding

Quadnet Control Panel Engineering and Commissioning Manual General Fault Finding Common Faults In the event that inexplicable or random faults continue after any obvious indication has been dealt with, take the following steps. Verify that the addressable device loop cable readings are correct and suitable. Take particular note of the screen resistance and rectify any faults found. -

Page 54: Intermittent And Recurring Faults

Quadnet Control Panel Engineering and Commissioning Manual Intermittent and Recurring Faults Smoke Sensor Failed – Signal High Ensure that the correct device is being investigated by comparing its description with the device address, and / or the serial number. Ensure that the Optical Chamber is clean, if not then replace it with a new one and allow it to re-calibrate. - Page 55 Quadnet Control Panel Engineering and Commissioning Manual Broken or missing copper connecting strips (Original style Multipoint only – not ASD). The connection from the connector body to the pin which links to the Multipoint detector is made by the copper connecting strip which may be seen entering the connector with the cable.

-

Page 56: Summary Of Messages

Quadnet Control Panel Engineering and Commissioning Manual Summary of Messages Listed below is a selection of the messages which may be displayed MESSAGE PROMPT DESCRIPTION Alarms silenced The SILENCE ALARMS button has been pressed whilst the sounders were operating, and they have been silenced. - Page 57 Quadnet Control Panel Engineering and Commissioning Manual Earth fault Remove the s/c to earth The control panel has detected a short circuit to earth from one of its supply rails (either 0v or +ve). Remove the circuits connected to the control panel one at a time and reset the system.

- Page 58 Quadnet Control Panel Engineering and Commissioning Manual Open circuit: in –ve Investigate the loop for An open circuit has been detected in the -ve core of the addressable core of loop -ve open circuit device circuit. Stop the loop, wait at least 3 minutes and then reinitialise with one end connected only.

-

Page 59: Advanced Connections

Quadnet Control Panel Engineering and Commissioning Manual Advanced Connections Monitored Relays Monitored Relays Quadnet Control Panel MO+ MO- The relay must be dioded for polarisation and suppression as shown. These diodes should be marked 1N1004 or similar, and may already be located on the relay PCB if it is designed for Fire Alarm Systems. -

Page 60: Technical Data

Quadnet Control Panel Engineering and Commissioning Manual Technical Data Control Panel Quadnet Control and Indicating Equipment Dimensions W x H x D 445mm x 445mm x 110mm No. of zones 128 zones Number of loops Up to 4 loops via plug-... -

Page 61: Power Supply Unit

Panel Versions v3.xx NOTE: It is imperative that the correct version of OSP is used to match your version of Quadnet control panel. The use of an incompatible version may result in incorrect operation of the control panel. In particular, do not use a V2.xx series OSP with a V3.xx series control... -

Page 62: Resistor Colour Codes

Quadnet Control Panel Engineering and Commissioning Manual Resistor Colour Codes On colour coded resistors the band at one end will be spaced further apart than the others. The resistor should be viewed with this band to the right as follows, reading from the left and side of the resistor:... -

Page 63: Battery Calculations

Quadnet Control Panel Engineering and Commissioning Manual Battery Calculations Note: An Excel spreadsheet (document no. 26-1049) is also available to automatically work out both standby battery calculations and loop loading calculations based on the quantities entered. This includes ratings for legacy devices as well as the current models listed below. -

Page 64: Installation Checklist

Quadnet Control Panel Engineering and Commissioning Manual Installation Checklist Use the following checklist to ensure that your work is correct and that the commissioning engineer has the necessary information to complete the commissioning of the system The commissioning engineer will require this sheet, along with ‘Loop Continuity and Insulation Test Results’, correctly marked ‘as-wired’... -

Page 65: Commissioning Checklist

Quadnet Control Panel Engineering and Commissioning Manual Commissioning Checklist The following checklist may be used to ensure that all steps are taken. It serves as a reminder only and may need additional items added if required. Step 1 Description Checked by... -

Page 66: Loop Continuity And Insulation Test Results

Quadnet Control Panel Engineering and Commissioning Manual Loop Continuity and Insulation Test Results After installation of the cable, and termination into all the relevant back-boxes, ensure that the link pins are installed as necessary in order to be able to take cable continuity and insulation readings. Make sure that all the cables are dressed smoothly and neatly into their back-boxes in order that they will not be disturbed after the readings are taken. -

Page 67: Network Continuity And Insulation Test Results

Quadnet Control Panel Engineering and Commissioning Manual Network Continuity & Insulation Test Results After installation of the cable, and termination into all the relevant back-boxes, take cable continuity and insulation readings. Make sure that all the cables are dressed smoothly and neatly into their back-boxes in order that they will not be disturbed after the readings are taken. -

Page 68: Fire Alarm System Notice

Quadnet Control Panel Engineering and Commissioning Manual FIRE ALARM SYSTEM NOTICE To Enable the Control Panel Keys The user controls are accessed from Access Level 2 (User) which is reached as follows: Enter your access code, eg 1234, followed by enter, or insert the key and turn it clockwise. - Page 69 Quadnet Control Panel Engineering and Commissioning Manual FIRE ALARM SYSTEM NOTICE Note The Fire alarm system installed in this building utilises ‘Alarm Confirmation’ technology to help eliminate false alarms. Please read and understand the following information in order to make the most effective use of the system.

-

Page 70: Device Details

Quadnet Control Panel Engineering and Commissioning Manual Device Details Record your device attributes on the following form. Copy as required for all devices in the system. SITE DETAILS: CONTROL PANEL NO.: LOOP NO.: DESCRIPTION: DESCRIPTION: DEVICE SERIAL DEVICE DESCRIPTION ZONE... -

Page 71: Your Notes

Quadnet Control Panel Engineering and Commissioning Manual Your Notes... - Page 72 Quadnet Control Panel Engineering and Commissioning Manual Your Notes...

- Page 73 Quadnet Control Panel Engineering and Commissioning Manual Your Notes...

-

Page 74: Important Points

Quadnet Control Panel Engineering and Commissioning Manual Important Points • Use a 2-core 1.5mm with screen fire rated cable as per the specifications “Cable Specification” “Network Cable Specification”. • For each loop, connect all the devices in a complete loop (returning from the last device to the control panel).

Need help?

Do you have a question about the Quadnet and is the answer not in the manual?

Questions and answers