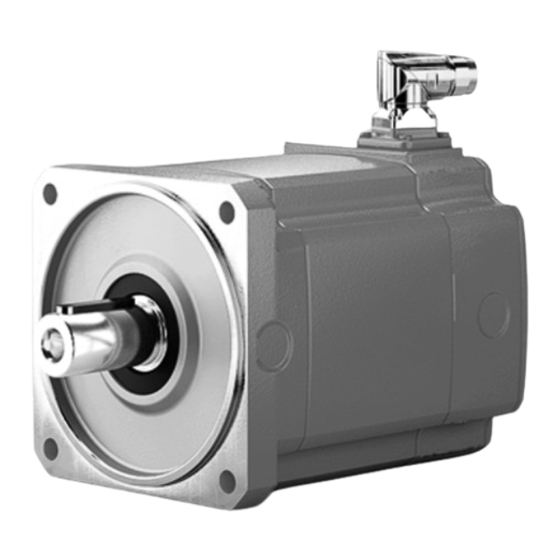

SEW-Eurodrive CM3C Series Operating Instructions Manual

Sunchronous servomotors (medium inerita)

Hide thumbs

Also See for CM3C Series:

- Addendum to operating manual (32 pages) ,

- Addendum to the operating instructions (60 pages)

Summary of Contents for SEW-Eurodrive CM3C Series

- Page 1 *25963872_0420* Drive Technology \ Drive Automation \ System Integration \ Services Operating Instructions Synchronous Servomotors (medium inertia) CM3C63 – 100 Edition 04/2020 25963872/EN...

- Page 2 SEW-EURODRIVE—Driving the world...

-

Page 3: Table Of Contents

Table of contents Table of contents General information........................ 5 About this documentation .................... 5 Other applicable documentation .................. 5 Structure of the safety notes ................... 5 Decimal separator in numerical values ................ 6 Rights to claim under limited warranty ................ 7 Product names and trademarks.................. 7 Copyright notice ...................... 7 Safety notes .......................... - Page 4 Characteristic safety values of BK.. brakes .............. 81 Characteristic safety values of BZ.. brakes.............. 81 Malfunctions.......................... 82 General information ...................... 82 Servomotor malfunctions .................... 82 Brake malfunctions ....................... 83 Encoder malfunctions .................... 84 SEW-EURODRIVE service................... 85 Waste disposal........................ 86 Index ............................ 87 Operating Instructions – CM3C63 – 100...

-

Page 5: General Information

General information About this documentation General information About this documentation The documentation at hand is the original. This documentation is an integral part of the product. The documentation is intended for all employees who perform work on the product. Make sure this documentation is accessible and legible. Ensure that persons respon- sible for the systems and their operation as well as persons who work on the product independently have read through the documentation carefully and understood it. -

Page 6: Decimal Separator In Numerical Values

General information Decimal separator in numerical values This is the formal structure of a safety note for a specific section: SIGNAL WORD Type and source of hazard. Possible consequence(s) if disregarded. • Measure(s) to prevent the hazard. Meaning of the hazard symbols The hazard symbols in the safety notes have the following meaning: Hazard symbol Meaning... -

Page 7: Rights To Claim Under Limited Warranty

General information Rights to claim under limited warranty Rights to claim under limited warranty Read the information in this documentation. This is essential for fault-free operation and fulfillment of any rights to claim under limited warranty. Read the documentation before you start working with the product. Product names and trademarks The brands and product names in this documentation are trademarks or registered trademarks of their respective titleholders. -

Page 8: Safety Notes

Safety notes Preliminary information Safety notes Preliminary information The following general safety notes serve the purpose of preventing injury to persons and damage to property. They primarily apply to the use of products described in this documentation. If you use additional components, also observe the relevant warning and safety notes. -

Page 9: Target Group

Safety notes Target group Target group Specialist for me- Any mechanical work may be performed only by adequately qualified specialists. Spe- chanical work cialists in the context of this documentation are persons who are familiar with the design, mechanical installation, troubleshooting, and maintenance of the product who possess the following qualifications: •... -

Page 10: Transportation/Storage

Safety notes Transportation/storage Transportation/storage Observe the following notes when transporting the device: • Inspect the shipment for damage as soon as you receive the delivery. Inform the shipping company immediately about any damage. If the product is damaged, it must not be assembled, installed or started up. •... -

Page 11: Electric Work

Safety notes Electric work 2.7.1 Restrictions of use The following applications are prohibited unless the device is explicitly designed for such use: • Use in potentially explosive atmospheres • Use in areas exposed to harmful oils, acids, gases, vapors, dust, and radiation Electric work 2.8.1 Carrying out electric work safely... -

Page 12: Warning Notes On The Motor

Safety notes Warning notes on the motor 2.8.4 Electrical connection The connection must be a permanently secure electrical connection (no protruding wire ends). Use the corresponding cable end equipment. Establish a safe PE connec- tion. When the motor is connected, the distances to non-insulated and live parts must not be shorter than the minimum values according to IEC 60664 and national regula- tions. -

Page 13: Inspection/Maintenance

Safety notes Inspection/maintenance Risk of burns due to arcing: Do not disconnect power connections during operation. Do not connect power connections during operation. Mechanical blocking or internal protective functions of the product can cause a motor standstill. Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. -

Page 14: Motor Structure

Motor structure Basic structure Motor structure Basic structure The following figures are schematic representations. Motor size and design may cause deviations. 3.1.1 Structure of the CM3C.. motor without brake INFORMATION The following figures are merely examples. The actual gear units may deviate from the figures depending on the design and size. -

Page 15: Nameplate And Type Designation

Motor structure Nameplate and type designation Nameplate and type designation 3.2.1 CM3C.. motor nameplate The following figure shows the 1st nameplate of a CM3C.. motor: 9007229924815243 Line Information • Type designation • Serial number • Standstill torque • Variable torque •... - Page 16 Motor structure Nameplate and type designation The following figure shows the 2nd nameplate of a CM3C.. motor: 30670076683 Line Information • Type designation • Serial number The following table lists all the markings that can be provided on a nameplate or at- tached to the motor, and an explanation of what they mean.

- Page 17 Motor structure Nameplate and type designation Motors and accessories may fall within the scope of the country-specific application of the WEEE Directive. Dispose of the product and of it's ac- cessories according to the national regulations of your country. Product label with QR code. The QR code can be scanned. You will be re- Digital Services directed to the digital services of SEW‑EURODRIVE.

-

Page 18: Designs And Options

Motor structure Designs and options Designs and options 3.3.1 Synchronous servomotors Designation CM3C.. CM3C.. series (medium inertia) 63, 71, 80, 100 Sizes S, M, L Lengths -20, -30, -45, -60 Rated speeds: -20 = 2000 min -30 = 3000 min -45 = 4500 min -60 = 6000 min A = 400 V... - Page 19 Motor structure Designs and options Designation Option ® /AK1H Absolute encoder, HIPERFACE interface (multi-turn) and sin/ cos interface (high-resolution) 1) Also available in design for functional safety. 3.3.5 Connection options Designation Option /SM1 M23 motor plug connector, socket on motor side only, plug- gable motor and encoder cables /SMB M40 motor plug connector, socket on motor side only, plug-...

-

Page 20: Functional Safety

Motor structure Functional safety Functional safety Motors from SEW‑EURODRIVE are optionally available with functionally safe motor options. These are designed for implementing safety functions. SEW‑EURODRIVE labels a functionally safe motor option at the drive with an FS logo and a 2-digit number on the motor nameplate. The number is a code that indicates which components in the drive are safety-related. -

Page 21: Mechanical Installation

Mechanical installation Before you start Mechanical installation Before you start INFORMATION Observe the safety notes in chapter 2 of this documentation for the mechanical in- stallation. INFORMATION The mounting position for installation must correspond with the specifications on the nameplate. INFORMATION Only SEW‑EURODRIVE... - Page 22 Mechanical installation Motor installation notes CAUTION Sharp edges due to open keyway. Risk of cutting injuries. • Insert the key into the keyway. • Pull a protective tubing over the shaft. CAUTION Inhaling, swallowing brake abrasion that accumulates in small quantities in the termi- nal box.

-

Page 23: Installation Tolerances

Mechanical installation Installation tolerances • For brakemotors with manual brake release, screw in the hand lever (for HR self- reengaging manual brake release). • Turn the rotor by hand and listen for unusual grinding noise. • Check the direction of rotation in decoupled state. 4.2.1 Installation in damp locations or in the open •... -

Page 24: Electrical Installation

Electrical installation General information Electrical installation General information WARNING Danger due to live parts. Severe or fatal injuries. • Comply with the assembly specifications from the manufacturer. • Switch off the electrical system before working on the main switch and prevent it from being switched on accidentally. - Page 25 Electrical installation General information WARNING Magnetic fields can have an impact on the function of pacemakers and other active medical implants. Health risk. ü The product has permanent magnets that generate a magnetic field, even when no current is supplied. During operation, additional electromagnetic fields are generated.

-

Page 26: Additional Regulations

Electrical installation Additional regulations • The motor may only be operated with a frequency inverter. • Observe the operating instructions of the frequency inverter. Additional regulations The generally applicable installation regulations for low-voltage electric equipment (such as DIN IEC 60364, DIN EN 50110) must be complied with when setting up elec- trical machinery. -

Page 27: Brake Controls With Functional Control Input

Electrical installation Brake controls with functional control input Brake controls with functional control input In addition to the voltage supply, the optional brake controls of the BMK., BMKB. and BMV. series offer a control input for a DC 24 V signal with which the brakes can be switched via a PLC. -

Page 28: Connecting The Motor And The Encoder System Via Plug Connector Sm./ Sb

Electric motors are supplied with the SM. plug connector system as standard. / SB. plug connector system. In the basic version, SEW-EURODRIVE delivers electric motors with a connector on the motor end and without mating connector. The encoder system is connected using a separate 12-pin round plug connector (M23). - Page 29 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. INFORMATION To protect the motor protection devices or the brake control from damage, you must not route unshielded supply cables alongside switched-mode power cables. Shielded supply cables may be routed together with switched-mode power lines in one cable.

- Page 30 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. 3. Align the mating connector. 4. Lock the mating connector by turning the union nut to a stop (approx. 90°). Between plug connector and bushing is a gap of 2 mm. 5.5.3 Plug connectors on cable side Unit designation of the plug connectors...

- Page 31 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Cut-off in the DC and AC circuits / rapid application of the brake with SB1, SBB when using a BZ.. brake 2901969419 BMP brake rectifier when using a BZ.. brake Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay with SBB.

- Page 32 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Cut-off in the DC and AC circuits / rapid application of the brake with SBB.. when us- ing a BZ.. brake 2901976459 BMK brake control unit when using a BZ.. brake Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay / DC 24 V control input integrated with SBB.

- Page 33 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. BMKB brake control unit when using a BZ.. brake Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay / DC 24 V control input integrated / LED ready for operation display with SBB. BMKB BMKB 24 V...

- Page 34 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. BSG brake control unit when using BZ.. brake For DC 24 V supply with SBB. 24 V 24 V 2901987211 5.5.4 Wiring diagrams of plug connectors for CM3C.. motors The wiring diagrams of the motors are available in the SEW‑EURODRIVE Online Sup-...

- Page 35 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Connection diagram Assignment for motor without brake Contact Signal Description Reserved Do not connect Reserved Do not connect Reserved Do not connect Reserved Do not connect PE connection Motor connection phase U Motor connection phase W...

- Page 36 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Wiring diagram SM1./SB1. with/without BK.. brake Connect the shield to the metal housing of the connector. The color code corresponds to the cables from SEW‑EURODRIVE. BK (3) BK (1) GNYE GNYE...

- Page 37 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Connection SMB/SBB power plug connector with/without brake The following table shows information about this connection: The wiring diagram of the plug connector depicts the contact end of the connections. Function Power connection Connection type...

- Page 38 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Assignment for brakemotors with BZ../BZ..D brake Contact Signal Description Brake + BZ brake + Brake - BZ brake - Brake Brake (omitted for BZ..D) Reserved Do not connect PE connection Motor connection phase U Motor connection phase W...

- Page 39 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Connection of SM./SB. signal plug connector The following table shows information about this connection: The wiring diagram of the plug connector depicts the contact end of the connections. Function Signal connection Connection type...

- Page 40 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Assignment for motor with AK1H, EK1K, AKOH encoder Contact Signal Description S4 Sin - Sine - Data - Data + Motor protection Motor protection Protective earth Voltage Wiring diagram for RH1M resolver signal plug connectors INFORMATION...

- Page 41 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. 5.5.5 Wiring diagrams of the brake control BK.. or BZ.D brake BMV brake controller DC 24 V DC 24 V 9007212241295115 Connection 1, 2 Power supply Connection 3, 4 Signal (inverter) Braking contactor BS or BZ.D...

- Page 42 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. Direct 24 V brake supply NOTICE Malfunction and damage to the BK.. brake due to reverse polarity. Damage to brake • It is essential that you observe the correct polarity of the brake power supply. •...

- Page 43 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. 5.5.6 Wiring diagrams of the brake control BZ.. brake BME brake rectifier when using a BZ.. brake Cut-off in the AC circuit / standard application of the brake with SB1, SBB. 2901967755 Cut-off in the DC and AC circuits / rapid application of the brake with SB1, SBB when using a BZ..

- Page 44 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. BMH brake rectifier Cut-off in the AC circuit / normal application of the brake with SBB when using a BZ.. brake 2901974795 Cut-off in the DC and AC circuits / rapid application of the brake with SBB.. when us- ing a BZ..

- Page 45 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. BMK brake control unit when using a BZ.. brake Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay / DC 24 V control input integrated with SBB. 24 V 24 V 2901979147...

- Page 46 Electrical installation Connecting the motor and the encoder system via plug connector SM./ SB. BMV brake control unit when using a BZ.. brake Cut-off in the DC and AC circuits / rapid application of the brake / DC 24 V control in- put integrated with SBB.

-

Page 47: Connecting The Motor And Encoder System Via Kk Terminal Box

Electrical installation Connecting the motor and encoder system via KK terminal box Connecting the motor and encoder system via KK terminal box Optionally, you can connect the power and signal cables with conductor end sleeves via a terminal box. INFORMATION To protect the motor protection devices or the brake control from damage, you must not route unshielded supply cables alongside switched-mode power cables. - Page 48 Electrical installation Connecting the motor and encoder system via KK terminal box Terminal box CM3C71.. – 100.. 29314123659 5.6.2 Connection cross section Motor Power connection Encoder / resolver / thermal motor protection Connection Maximum Cable entry Connection Cable entry connection cross sec- tion CM3C63 Spring termi-...

- Page 49 Electrical installation Connecting the motor and encoder system via KK terminal box 5.6.3 Terminal assignment terminal box CM3C63 WARNING Risk of electric shock if conductors of the encoder cable come in contact with power connections. Fatal or serious injuries. • The single conductors of the encoder cable must have a minimum clearance of 4 ...

- Page 50 Electrical installation Connecting the motor and encoder system via KK terminal box Assignment Brake rectifier connection BME.., Terminal [2] Type Note BMP.., BSG.. BMH.., BMK.. – – BK.. brake – – Omitted with BZ..D Brake – – brake BZ.. brake (D) –...

- Page 51 Electrical installation Connecting the motor and encoder system via KK terminal box 5.6.4 Terminal assignment terminal box CM3C71 – 100 WARNING Risk of electric shock if conductors of the encoder cable come in contact with power connections. Fatal or serious injuries. •...

- Page 52 Electrical installation Connecting the motor and encoder system via KK terminal box Assignment Brake rectifier connection BME.., Terminal [2] Type Note BMP.., BSG.. BMH.., BMK.. – – BK.. brake – – Omitted with BZ..D Brake – – brake BZ.. brake (D) –...

- Page 53 Electrical installation Connecting the motor and encoder system via KK terminal box 5.6.5 Wiring diagrams of the brake control for BK.. or BZ.D brake In every application, the BK holding brake can be controlled via the BMV brake relay or a customer relay with varistor overvoltage protection. If the system complies with the specifications for direct brake control, then a BK..

- Page 54 Electrical installation Connecting the motor and encoder system via KK terminal box 5.6.6 Wiring diagram of the brake control for BZ.. brake BME.. brake rectifier Cut-off in the AC circuit / normal application of the brake. 2901990923 Cut-off in the DC and AC circuit / quick application of the brake. 2901992587 Operating Instructions –...

- Page 55 Electrical installation Connecting the motor and encoder system via KK terminal box BMP.. brake rectifier Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay. 2901995275 Operating Instructions – CM3C63 – 100...

- Page 56 Electrical installation Connecting the motor and encoder system via KK terminal box BMH.. brake rectifier Cut-off in the AC circuit / normal application of the brake. 2901997963 Cut-off in the DC and AC circuit / quick application of the brake. 2901999627 Operating Instructions –...

- Page 57 Electrical installation Connecting the motor and encoder system via KK terminal box BMK.. brake control unit Cut-off in the DC and AC circuits / rapid application of the brake / integrated voltage relay. 24 V 2902002315 Connection 1, 2 Power supply Connection 3, 4 Signal (inverter) BSG..

- Page 58 Electrical installation Connecting the motor and encoder system via KK terminal box 5.6.7 Power connection on terminal box The following figure shows the power connection in the terminal box. 18014401410364299 Terminal stud Terminal board Top nut Customer's cable Washer Bottom nut Motor cable Lock washer For designing the terminal box, positions 4, 6 and 7 are regarded as current-carrying.

-

Page 59: Prefabricated Cables

Electrical installation Prefabricated cables Prefabricated cables Prefabricated cables are available from SEW‑EURODRIVE to connect the SM./SB. plug connector system (speedtec). 5.7.1 Prefabricated power cables Fixed installation Cable type Con- Thread Cable cross section Part number nector prefabricated Replacement type cable mating con- nectors SM11... - Page 60 Electrical installation Prefabricated cables Cable carrier installation Cable type Con- Thread Cable cross section Part number nector prefabricated Replacement type cable mating con- nectors SM11 4 × 1.5 mm 28125010 13354698 SM12 4 × 2.5 mm 28125037 13354256 SM14 4 × 4 mm 28125053 13354264 Motor cables...

- Page 61 Electrical installation Prefabricated cables ® ® Cable carrier installation for MOVI-C and MOVIAXIS inverters (D-sub, 15-pin) Part number Connection Prefabricated Replacement Signal encoder Cable cross section (Motor) cable mating con- nector RH1M resolver 5 × 2 × 0.25 mm 28125630 speedtec M23 16447115 AK1H, EK1H, 4 × 2 × 0.25 mm +2 × 0.5 mm 28125673...

- Page 62 Electrical installation Prefabricated cables ® Cable carrier installation for MOVIDRIVE B inverter (D-sub, 15-pin) Part number Connection Prefabricated Replacement Signal encoder Cable cross section (Motor) cable mating con- nector speedtec M23 4 × 2 × 0.25 mm + 2 × 0.5 mm 28125673 16447115 AK1H, EK1H, AK0H encoders Open end 6 × 2 ×0.25 mm 13356305 –...

-

Page 63: Options

Electrical installation Options Options 5.8.1 BK brake BK holding brake – description The BK brake is a permanent magnet holding brake with emergency stop function. For further information, refer to chapter "Technical data of the BK.. brakes" (→ 2 76). 5.8.2 BZ brake BZ.. - Page 64 Electrical installation Options The /PK option consists of a PT1000 platinum sensor, which is installed in one of the 3 motor windings. Unlike the /KY semiconductor sensor, the platinum sensor has an al- most linear characteristic curve and is more accurate. In combination with a frequency inverter containing the thermal model of the motor, the frequency inverter can also provide a motor protection function because of the /PK.

-

Page 65: Startup

Startup General information Startup General information WARNING Risk of injury due to missing or defective protective covers. This can result in severe or fatal injuries. • Install the protective covers of the system according to the instructions. • Never start up the drive if the protective covers are not installed. WARNING Electric shock when disconnecting or connecting voltage-carrying plug connectors. - Page 66 Startup General information WARNING Disabling functional safety devices. Severe or fatal injuries. • Only qualified personnel is allowed to carry out work on functional safety compo- nents. • Any work on functional safety components must be carried out by strictly ob- serving the specifications in the operating instructions at hand and the respective addendum to the operating instructions.

-

Page 67: Before Startup

Startup Before startup Before startup Ensure the following prior to startup: • Operate the motors only in conjunction with a frequency inverter. • Prior to startup, configure the SEW‑EURODRIVE frequency inverter using the suit- able engineering software. • The drive must be undamaged and not blocked. •... - Page 68 Startup Startup after storage The following figure shows the minimum insulation resistance depending on the tem- perature. R/MΩ T/°C 9007202147046283 Resistance/temperature point (RT point) Operating Instructions – CM3C63 – 100...

-

Page 69: Inspection/Maintenance

Inspection/maintenance General information Inspection/maintenance General information WARNING Risk of injury if the drive starts up unintentionally. Severe or fatal injuries. • Before you start working on the unit, disconnect the motor and all connected op- tions from the power supply. •... -

Page 70: Maintenance Intervals

Inspection/maintenance Maintenance intervals CAUTION Inhaling, swallowing brake abrasion that accumulates in small quantities in the termi- nal box. Irritation of the respiratory tract and respiratory organs. ü Wear a respirator of class FFP2 when performing work in the terminal box of brakemotors. -

Page 71: Notes On The Bk

Inspection/maintenance Notes on the BK.. brake Unit/part of unit Time interval What to do? Servomotor • Every 10 000 operating hours Inspect the servomotor: • Check ball bearing. • Clean the cooling air ducts. • Check PE connection for proper func- tioning. - Page 72 Inspection/maintenance Notes on the BZ.. brake • Brake without manual brake release (→ 2 72). • Brake without manual brake release with single-cable technology or terminal box (→ 2 74). Measuring the working air gap for brakes with manual brake release WARNING! Risk of injury! De-energize the motor and brake and safeguard the drive against unintentional power-up.

- Page 73 Inspection/maintenance Notes on the BZ.. brake 32303688203 Litz wires for temperature sensor Litz wires for encoder Holes of the manual brake release Plug-in connection encoder connector / encoder 5. Insert the stud (for information on sizes and tightening torques, refer to chapter "Recommendations for studs" ...

- Page 74 Inspection/maintenance Notes on the BZ.. brake Measuring the working air gap for brakes without manual brake release with single-cable technology or terminal box WARNING! Risk of injury! De-energize the motor and brake and safeguard the drive against unintentional power-up. 2. If installed, remove the forced cooling fan. 3.

-

Page 75: Cleaning

Inspection/maintenance Cleaning Recommendations for studs Brake Screw size Tightening torque BZ05, BZ05D, BZ1,BZ1D, DIN938 M5 × 110 BZ3 BZ3D BZ5, BZ5D DIN938 M6 × 110 Cleaning Dirt, dust or chips on the drive increase the operating temperature as the optimum heat dissipation of the motor is no longer possible. Clean the servomotor regularly, depending on the operating and ambient conditions. -

Page 76: Technical Data

Technical data Boundary conditions Technical data Boundary conditions The technical data of the CM3C.. servomotors apply under the following conditions: • Maximum ambient temperature 40 °C • System voltage 400 V • Pulse width modulation frequency (PWM frequency) at least 8 kHz • Flange surface made from aluminum, painted black •... - Page 77 Technical data Technical data of the BZ.. brakes 8.2.1 Operating currents for BK.. brakes BK05 BK06 BK08 Braking torque M in Nm 4, 100 °C Nominal power brake coil in W 13.4 14.1 Operating current in A 0.56 0.63 0.59 0.75 = 24 (21.6 – 26.4) VDC Braking torque M in Nm 4, 100 °C...

-

Page 78: Technical Data Of The Bz

Technical data Technical data of the BZ.. brakes • Holding current I • Nominal voltage U The acceleration current I only flows for a short time (ca. 150 ms) when the brake is released or during voltage dips below 70% of nominal voltage. The values for the holding currents I are rms values (with DC 24 V arithmetic mean value). - Page 79 Technical data Technical data of the BZ.. brakes Acceleration current Holding current, rms value in the incoming cable to the SEW brake rectifier Direct current with direct DC voltage supply Nominal voltage (rated voltage range) 8.3.2 Resistance values of BZ.. brake coils BZ05 BZ05D BZ1D...

- Page 80 Technical data Technical data of the BZ.. brakes 8.3.3 Manual brake release BZ.. brake INFORMATION Manual brake release can only be used up to a maximum oscillation and shock load of 1 g. In brakemotors with /HR option “Manual brake release with automatic reengaging function,”...

-

Page 81: Characteristic Safety Values Of Bk.. Brakes

Technical data Characteristic safety values of BK.. brakes Characteristic safety values of BK.. brakes The values specified in the following table apply to BK.. brakes in standard applica- tions. Characteristic safety values according to EN ISO 13849-1 Classification Category B System structure 1-channel (Cat. B) MTTF value Calculation via B... -

Page 82: Malfunctions

Malfunctions General information Malfunctions General information WARNING Risk of injury if the drive starts up unintentionally. Severe or fatal injuries. • Before you start working on the unit, disconnect the motor and all connected op- tions from the power supply. •... -

Page 83: Brake Malfunctions

Inverter not optimized Check the inverter Running noise on mo- Bearing damage Contact SEW-EURODRIVE. Replace the motor Vibration of rotating parts Rectify cause, possible imbalance Forced cooling fan: Foreign bodies Clean cooling air ducts... -

Page 84: Encoder Malfunctions

Brake connected incorrectly. Check brake connection. Max. permitted working air gap ex- Contact SEW-EURODRIVE. ceeded because brake lining worn Replacement of the brake lining carrier by down. SEW‑EURODRIVE-trained staff. Brake coil has interturn fault or short cir- Check switching devices. -

Page 85: Sew-Eurodrive Service

Malfunctions SEW-EURODRIVE service SEW-EURODRIVE service If you are unable to rectify a fault, contact SEW‑EURODRIVE Service. For the ad- dresses, refer to www.sew‑eurodrive.com. When contacting SEW‑EURODRIVE Service, always specify the following information so that our service personnel can assist you more effectively: •... - Page 86 Waste disposal Waste disposal Dispose of the product and all parts separately in accordance with their material struc- ture and the national regulations. Put the product through a recycling process or con- tact a specialist waste disposal company. If possible, divide the product into the follow- ing categories: •...

-

Page 87: Index

Index Index Crimping area SM1/SB1 ............ 62 BK brake SMB/SBB ............ 62 BK brake coil resistance......... 77 Crimping diameter .......... 62 Operating currents.......... 77 Technical data .......... 76 Brake control BK../BZ.. brake Decimal separator .......... 6 Wiring diagrams .......... 41 Designated use ............. - Page 88 Index Servomotor malfunctions........ 82 Section-related safety notes ........ 5 Manual brake release BZ.. brake ...... 80 Serial number ............ 17 Mark, nameplate.......... 16 Setup .............. 21 Mating connector .......... 62 Signal cable Mechanical installation ........ 21 Prefabricated .......... 60 Motor Signal words in safety notes........

- Page 89 Index Waste disposal ............ 86 Plug connector .......... 34 Wiring diagram Plug connector brake control...... 43 BME.. brake rectifier........ 54 Wiring diagrams of the brake control of BZ.. brakes – Plug connector BMH.. brake rectifier........ 56 BME............ 30, 43 BMK.. brake control unit ......... 57 BMH ............

- Page 92 SEW-EURODRIVE—Driving the world SEW-EURODRIVE GmbH & Co KG Ernst-Blickle-Str. 42 76646 BRUCHSAL GERMANY Tel. +49 7251 75-0 Fax +49 7251 75-1970 sew@sew-eurodrive.com www.sew-eurodrive.com...

Need help?

Do you have a question about the CM3C Series and is the answer not in the manual?

Questions and answers