Advertisement

Quick Links

Instruction Manual

EN 354

Ref. LB 100 xx

EN 358

The universal safety lanyard can be used as:

- a component of personal fall arrest equipement (with energy bsorber) and complies with EN 354 ;

- a supplement of personal fall arrest equipment when is used as the work positioning device and

complies with EN 358.

BASIC EQUIPMENT

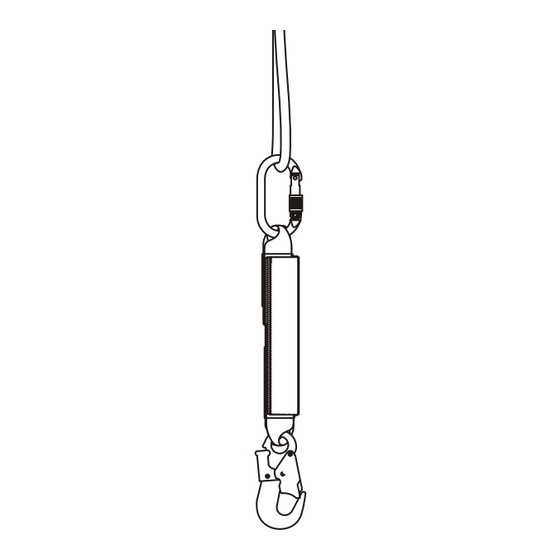

The lanyard is made of polyamide kernmantle rope of diameter ø12 mm ended with loop equiped with

plastic thimble from the one side and loop with adjusting buckle from the second one.

Maximal length up to 2,0 m

polyamide

seam

kernmantle rope ø12 mm

ATTENTION!

The universal safety lanyard LB 100 can be equipped only with certified (according to EN 362) snap

hooks.

CONTENT OF THE LANYARD IDENTITY LABEL

UNIVERSAL ADJUSTABLE

SAFETY LANYARD

POLYAMIDE

LB 100 xx

LENGTH x,x m

SERIAL NUMBER:

DATE OF MANUFACTURE:

0001

08.2004

EN 354

EN 358

1 0

THE IDENTITY CARD SHOULD BE FILLED BY PERSON RESPONSIBLE IN THE COMPANY FOR THE FALL ARREST EQUIPMENT

IDENTITY CARD

SERIAL NUMBER

LENGTH

USER NAME

DATE OF PURCHASE

ANNUAL INSPECTIONS

DATE

1

2

3

4

5

UNIVERSAL

ADJUSTABLE

S A F E T Y

LANYARD

steel

identity

seam

adjusting buckle

label

1. type of the device

1

2. material of the device is made of

3. reference number of the device -

2

length, e.g.: xx=15 - length 1,5 m

3

4. length of the device

4

5

5. number of the manufacturing series

6

6. month/year of the device manufacture

7

7. European standards

8

9

8. caution: read the manual

9. identity number of the authorized body

10. name of the manufacturer or distributor

DATE OF MANUF.

DATE OF PUTTING INTO OPERATION

COMMENTS

CONNECTING THE LANYARD IN THE FALL ARREST SYSTEM (EN 354)

1. One snap hook of the lanyard connect to the structural anchor point of resistance min. 15 kN :

- directly (1);

LB100

- with line connector (2) or quick hook (3);

- by puting around (4) - attention: the minimal radial of the construction element should be10 mm.

2. Second snap hook connect to the energy absorber.

3. This assembly (the energy absorber+lanyard) connect directly to the back or front attaching buckle of the safety

harness.

Structural

Anchor

Point

min. 15 kN

loop with

plastic thimble

xx - code of

ATTENTION!:

THE STRUCTURAL ANCHOR POINT SHOULD BE SITUATED ABOVE THE WORKING PLACE AND THE SHAPE

OF THE STRUCTURAL ANCHOR POINT SHOULD NOT LET SELF- A CTING DISCONECTION OF THE LANYARD.

THE MAXIMAL LENGTH OF THE ENERGY ABSORBER+LANYARD LB 100 IS 2 m - ACCORDING TO

EN 354 & EN 355.

The safety lanyard LB 100 without the energy absorber is not a fall protection.

It is strictly forbidden to connect the harness attaching buckle to the structural anchor point

with the lanyard without energy absorber.

Energy absorber

INITIALS

OF COMPETENT

PERSON

OTE-PROTEKT

93-403 Lodz

ul. Starorudzka 9

Poland

tel: (+48 42) 680 20 83

fax: (+48 42) 680 20 93

e-mail: protekt@protekt.com.pl

Structural

Structural

Anchor

Anchor

Point

Point

min. 15 kN

min. 15 kN

1

2

5

6

CORRECT

lanyard

Structural

Anchor

Point

min. 15 kN

3

4

INCORRECT

lanyard

EC type examination done by

CETE APAVE SUDEUROPE

BP 193, 13322 Marseille

France - 0082

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Protekt LB100

- Page 1 CONNECTING THE LANYARD IN THE FALL ARREST SYSTEM (EN 354) 1. One snap hook of the lanyard connect to the structural anchor point of resistance min. 15 kN : - directly (1); LB100 UNIVERSAL ADJUSTABLE - with line connector (2) or quick hook (3);...

- Page 2 using the lanyard as a work positioning lanyard each snap hook must be connected to the USAGE THE LANYARD AS THE WORK POSITIONING LANYARD (EN 358) different side buckle of the work positioning belt. 1. Connect one of the lanyard snap hooks to the selected attaching buckle of the work positioning belt (1). it is strictly forbidden: 2.

Need help?

Do you have a question about the LB100 and is the answer not in the manual?

Questions and answers