Table of Contents

Advertisement

Advertisement

Table of Contents

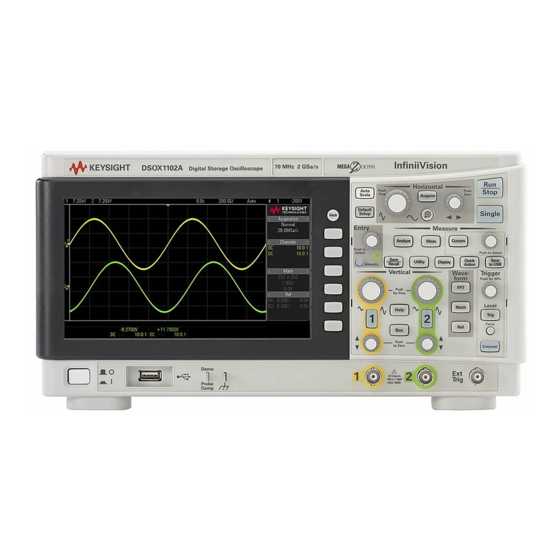

Summary of Contents for Keysight Technologies InfiniiVision 1000 X-Series

- Page 1 Keysight InfiniiVision 1000 X-Series Oscilloscopes Service Guide...

- Page 2 Notices © Keysight Technologies, Inc. 2008-2018 material in this document that conflict with computer software pursuant to the FAR and these terms, the warranty terms in the sepa- the DFARS and are set forth specifically in No part of this manual may be reproduced in rate agreement shall control.

-

Page 3: In This Service Guide

This manual is divided into these chapters: Characteristics and Specifications This chapter contains a partial list of characteristics and specifications for the Keysight InfiniiVision 1000 X-Series oscilloscopes. Testing Performance This chapter explains how to verify correct oscilloscope operation and perform tests to ensure that the oscilloscope meets the performance specifications. - Page 4 Abbreviated instructions for pressing a series of keys Instructions for pressing a series of keys are written in an abbreviated manner. Instructions for pressing Key1, then pressing Softkey2, then pressing Softkey3 are abbreviated as follows: Press [Key1] & Softkey2 & Softkey3. The keys may be front panel keys, or softkeys, which are located directly below the oscilloscope display.

-

Page 5: Table Of Contents

Contents In This Service Guide / 3 Figures / 9 Tables / 11 Characteristics and Specifications Power Requirements / 13 Measurement Category / 14 Measurement Category / 14 Measurement Category Definitions / 14 Transient Withstand Capability / 14 Environmental Conditions / 15 Specifications / 16 Contact Us / 16 Testing Performance... - Page 6 Contents Test External Trigger Sensitivity / 36 Keysight 1000 X-Series Oscilloscopes Performance Test Record / 39 Calibrating and Adjusting User Calibration / 42 To perform User Cal / 42 User Cal Status / 42 Troubleshooting Solving General Problems with the Oscilloscope / 44 If there is no display / 44 If there is no trace display / 44 If the trace display is unusual or unexpected / 44...

- Page 7 Contents Index 1000 X-Series Oscilloscopes Service Guide...

- Page 8 Contents 1000 X-Series Oscilloscopes Service Guide...

-

Page 9: Figures

Figures Figure 1. Setting up Equipment for DC Vertical Gain Accuracy Test / 24 Figure 2. Using a Blocking Capacitor to Reduce Noise / 25 Figure 3. Setting Up Equipment for Bandwidth (-3 dB) Verification Test / 27 Figure 4. Setting Up Equipment for Internal Trigger Sensitivity Test / 34 Figure 5. - Page 10 Figures 1000 X-Series Oscilloscopes Service Guide...

-

Page 11: Tables

Tables Table 1. List of test equipment / 19 Table 2. Conventions / 20 Table 3. DC Vertical Gain Accuracy Test Limits / 21 Table 4. Equipment Required to Verify DC Vertical Gain Accuracy / 21 Table 5. Settings Used to Verify DC Vertical Gain Accuracy / 22 Table 6. - Page 12 Tables 1000 X-Series Oscilloscopes Service Guide...

-

Page 13: Characteristics And Specifications

This chapter contains a partial list of characteristics and specifications for the Keysight InfiniiVision 1000 X-Series oscilloscopes. For a full list of Keysight InfiniiVision 1000 X-Series oscilloscopes characteristics and specifications see the data sheets. The data sheets are available at www.keysight.com/find/1000X-Series. -

Page 14: Measurement Category

Characteristics and Specifications Measurement Category Measurement Category The InfiniiVision 1000 X-Series oscilloscope is intended to be used for measurements in Measurement Category I. Use this instrument only for measurements within its specified measurement category. WARNING Measurement Category Definitions Measurement category I is for measurements performed on circuits not directly connected to MAINS. -

Page 15: Environmental Conditions

Category Category II, which is typical of cord-and-plug connected equipment. Pollution Degree The InfiniiVision 1000 X-Series oscilloscopes may be operated in environments of Pollution Degree 2 (or Pollution Degree 1). Pollution Degree Pollution Degree 1: No pollution or only dry, non-conductive pollution occurs. -

Page 16: Specifications

Characteristics and Specifications Specifications Please see the InfiniiVision 1000 X-Series Oscilloscopes Data Sheet for complete, up-to-date specifications and characteristics. To download a copy of the data sheet please visit: www.keysight.com/find/1000X-Series. Or go to the Keysight home page at www.keysight.com and search for 1000 X-Series oscilloscopes data sheet. -

Page 17: Testing Performance

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 2 Testing Performance Overview / 18 List of Test Equipment / 19 To verify DC vertical gain accuracy / 21 To verify band width (-3 dB) / 26 To verify time base accuracy / 30... -

Page 18: Overview

Testing Performance Overview Let the Equipment Warm Up Before Testing For accurate test results, let the test equipment and the oscilloscope warm up 30 minutes before testing. Verifying Test Results During the tests, record the readings in the Performance Test Record on page To verify whether a test passes, verify that the reading is within the limits in the Performance Test Record. -

Page 19: List Of Test Equipment

Testing Performance List of Test Equipment Below is a list of test equipment and accessories required to perform the performance test verification procedures. Table 1 List of test equipment Equipment Critical Specifications Recommended Model/ Part Number Digital Multimeter 0.1 mV resolution, 0.005% accuracy Keysight 34401A Power Splitter Outputs differ by 0.15 dB... -

Page 20: Conventions

Testing Performance Conventions The following conventions will be used when referring to oscilloscope models throughout this chapter. Table 2 Conventions Models Referred to as: EDU1002A, EDU1002G 50 MHz Models DSOX1102A, DSOX1102G 70 MHz Models DSOX1102A, DSOX1102G with DSX1B7T12 upgrade 100 MHz Models 1000 X-Series Oscilloscopes Service Guide... -

Page 21: To Verify Dc Vertical Gain Accuracy

Testing Performance To verify DC vertical gain accuracy This test verifies the accuracy of the analog channel DC vertical gain for each channel. In this test, you will measure the dc voltage output of an oscilloscope calibrator using the oscilloscope’s Average - Full Screen voltage measurement and compare the results with the multimeter reading. -

Page 22: Table 5. Settings Used To Verify Dc Vertical Gain Accuracy

Testing Performance 3 Set up the oscilloscope. a Adjust the horizontal scale to 200.0 us/d iv. b Set the Volts/Div setting to the value in the first line and column of Table c Adjust the channel’s vertical position knob to place the baseline (reference level) at 0.5 major division from the bottom of the display. - Page 23 Testing Performance d Press the [Acquire] key. e Then press the Acq Mode softkey and select Averaging. f Then press the #Avgs softkey and set it to 64. Wait a few seconds for the measurement to settle. 4 Add a measurement for the average voltage: a Press the [Meas] key.

-

Page 24: Figure 1. Setting Up Equipment For Dc Vertical Gain Accuracy Test

Testing Performance Oscilloscope Oscilloscope Calibrator BNC Tee Digital Multimeter BNC (f) to dual bananna adapter Figure 1 Setting up Equipment for DC Vertical Gain Accuracy Test 7 Adjust the output so that the multimeter reading displays, as close as possible, the first Volts/div calibrator setting value in Table 8 Wait until the measurement settles. -

Page 25: Figure 2 Using A Blocking Capacitor To Reduce Noise

Testing Performance The difference in average voltage readings should be within the test limits of Table If a result is not within the test limits, go to the “Troubleshooting” chapter. Then return here. 11 Disconnect the oscilloscope calibrator from the oscilloscope. 12 Repeat this procedure to check the DC vertical gain accuracy with the remaining Volts/div setting values in Table... -

Page 26: To Verify Bandwidth (-3 Db)

Testing Performance To verify bandwidth (-3 dB) This test checks the bandwidth (-3 dB) of the oscilloscope. In this test you will use a signal generator and a power meter. Table 6 Band width (-3 dB) Test Limits Models Test Limits 100 MHz Models All channels (-3 dB), dc to 100 MHz 70 MHz Models... -

Page 27: Figure 3. Setting Up Equipment For Bandwidth (-3 Db) Verification Test

Testing Performance Oscilloscope Signal Generator 50 Ohm Feedthrough N to BNC Adapter Power Splitter Power Sensor N Cable Power Meter Figure 3 Setting Up Equipment for Band width (-3 dB) Verification Test 2 Set up the power meter. Set the power meter to display measurements in units of watts. 1000 X-Series Oscilloscopes Service Guide... - Page 28 Testing Performance 3 Set up the oscilloscope. a Press the [Defaul t Setup] key. b Set channel 1 Coupling to DC. c Set the time base to 500 ns/div. d Set the Volts/Div for channel 1 to 200 mV/div. e Press the [Acquire] key, then press the Averaging softkey. f Turn the Entry knob to set # Avgs to 8 averages.

- Page 29 Testing Performance 11 Set the oscilloscope sweep speed according to the following: • 100 MHz Models: 5 ns/div • 70 MHz Models: 5 ns/div • 50 MHz Models: 5 ns/div 12 Note the oscilloscope AC RMS - Cyc(1) reading at the bottom of the screen. 13 Note the reading on the power meter and covert to Vrms using the expression: ×...

-

Page 30: To Verify Time Base Accuracy

Testing Performance To verify time base accuracy This test verifies the accuracy of the time base. In this test you will measure the absolute error of the time base oscillator and compare the results to the specification. Table 8 Equipment Required to Verify Time Base Accuracy Equipment Critical Specifications Recommended Model/Part... - Page 31 Testing Performance 4 Make the measurement. a Set oscilloscope horizontal sweep speed control to 1 ms/div. b Set horizontal position control to +1 ms (rotate control CCW). c Set the oscilloscope horizontal sweep speed control to 5 ns/div. d Record the number of nanoseconds from where the rising edge crosses the center horizontal grid line to the center vertical grid line.

-

Page 32: To Verify Trigger Sensitivity

Testing Performance To verify trigger sensitivity These tests verify the trigger sensitivity. In these tests, you will apply a sine wave to the oscilloscope at two bandwidths: 10 MHz and the maximum bandwidth of the oscilloscope. For each sine wave, you will decrease the amplitude of the signal to a specified level and check to see if the oscilloscope still triggers. -

Page 33: Test Internal Trigger Sensitivity

Testing Performance Test Internal Trigger Sensitivity Table 10 Internal Trigger Sensitivity Specifications Oscilloscope Internal Trigger Sensitivity Specification Band wid th Models <= 10 MHz Maximum Band wid th 50 MHz greater of 0.6 div or 2.5 mV greater of 0.9 div or 3.8 mV 70 MHz greater of 0.6 div or 2.5 mV greater of 0.9 div or 3.8 mV... -

Page 34: Figure 4. Setting Up Equipment For Internal Trigger Sensitivity Test

Testing Performance Oscilloscope Signal Generator 50 Ohm Feedthrough N to BNC Adapter N Cable Figure 4 Setting Up Equipment for Internal Trigger Sensitivity Test 4 Set the output frequency of the signal generator to 10 MHz. 5 Perform these steps to test at the 10 MHz setting: a Set the signal generator amplitude to about 20 mV b Press the [AutoScale] key. - Page 35 Testing Performance The trigger is stable when the displayed waveform is stable. If the trigger is not stable, try adjusting the trigger level. If adjusting the trigger level makes the trigger stable, the test still passes. If adjusting the trigger does not help, see the “Troubleshooting”...

-

Page 36: Test External Trigger Sensitivity

Testing Performance Test External Trigger Sensitivity Table 11 External Trigger Sensitivity Specifications Oscilloscope Range External Trigger Sensitivity Specification Band wid th Models Setting <= 10 MHz Maximum Band wid th 50 MHz 250 mVpp 500 mVpp 70 MHz 250 mVpp 500 mVpp 1.6 V 50 mVpp... -

Page 37: Figure 5 Setting Up Equipment For External Trigger Sensitivity Test

Testing Performance Oscilloscope Signal Generator 50 Ohm Feedthrough N to BNC Adapter Power Splitter Power Sensor N Cable Power Meter Figure 5 Setting Up Equipment for External Trigger Sensitivity Test 1000 X-Series Oscilloscopes Service Guide... - Page 38 Testing Performance 2 Set up the oscilloscope. a Press the [Defaul t Setup] key. b Press the [Mode/Coupling] key; then, press the Mode softkey to select Normal. 3 Change the signal generator output frequency to 10 MHz or the maximum bandwidth of the oscilloscope.

-

Page 39: Keysight 1000 X-Series Oscilloscopes Performance Test Record

Testing Performance Keysight 1000 X-Series Oscilloscopes Performance Test Record Serial No. ______________________________________ Test by _____________________________ Test Interval ____________________________________ Work Order No. ______________________ Recommended Next Testing ________________________ Temperature ____________ DC Vertical Gain Accuracy Range Power Supply Setting Test Limits Channel 1 Channel 2 10 V/Div 70 V 67.6 V to 72.4 V... - Page 40 Testing Performance Internal Trigger Sensitivity Generator Setting Test Limits, greater of Channel 1 Channel 2 100 MHz models: 10 MHz 0.6 div or 2.5 mV ________ ________ Max BW (100 MHz) 1.2 div or 5 mV ________ ________ 70 MHz models: 10 MHz 0.6 div or 2.5 mV ________...

-

Page 41: Calibrating And Adjusting

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 3 Calibrating and Adjusting This chapter explains how to adjust the oscilloscope for optimum operating performance. You should perform user calibration according to the following recommendations: • Every five years or after 10000 hours of operation •... -

Page 42: User Calibration

Calibrating and Adjusting User Calibration Perform user-calibration: • Every five years or after 10000 hours of operation. • If the ambient temperature is >10° C from the calibration temperature. • If you want to maximize the measurement accuracy. The amount of use, environmental conditions, and experience with other instruments help determine if you need shorter User Cal intervals. -

Page 43: Troubleshooting

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 4 Troubleshooting Solving General Problems with the Oscilloscope / 44 Verifying Basic Operation / 46 Read All Cautions and Warnings Before you begin any troubleshooting, read all Warning and Cautions in the “Troubleshooting” section. -

Page 44: Solving General Problems With The Oscilloscope

Check that the circuit under test is powered on. Press the [Auto Scale] key. Obtain service from Keysight Technologies, if necessary. If the trace display is unusual or unexpected Check that the Horizontal time/division setting is correct for the expected frequency range of the input signals. -

Page 45: If You Cannot See A Channel

Troubleshooting Ensure that the probe’s ground lead is securely connected to a ground point in the circuit under test. For high-speed measurements, each probe’s individual ground lead should also be connected to a ground point closest to the signal point in the circuit under test. Check that the trigger setup is correct. -

Page 46: Verifying Basic Operation

Troubleshooting Verifying Basic Operation To power-on the oscilloscope 1 Connect the power cord to the rear of the oscilloscope, then to a suitable ac voltage source. The oscilloscope power supply automatically adjusts for input line voltages in the range of 100 to 240 VAC. Ensure that you have the correct line cord. The power cord provided is matched to the country of origin. -

Page 47: To Perform Front Panel Self Test

Troubleshooting Successfully passing Hardware Self Test does not guarantee 100% of the oscilloscope's functionality. Hardware Self Test is designed to provide an 80% confidence level that the oscilloscope is operating properly. To perform front panel self test Pressing [Utility] > Service > Front Panel Sel f Test lets you test the front panel keys and knobs as well as the oscilloscope display. -

Page 48: Figure 6 Default Setup Screen

Troubleshooting • 0 V level. • channel 1 source. • dc coupling. • rising edge slope. • 60 ns holdoff time. • Display: • 20% grid intensity. • persistence off. • Other: • Acquire mode normal. • Run/Stop to Run. •... -

Page 49: To Perform An Auto Scale On The Probe Comp Signal

Troubleshooting To perform an Auto Scale on the Probe Comp signal 1 Press the [Defaul t Setup] key. The oscilloscope is now configured to its default settings. 2 Connect an oscilloscope probe from channel 1 to the Probe Comp signal terminal on the front panel. -

Page 50: To Compensate Passive Probes

Troubleshooting To compensate passive probes You should compensate your passive probes to match their characteristics to the oscilloscope’s channels. A poorly compensated probe can introduce measurement errors. 1 Perform the procedure “To perform an Auto Scale on the Probe Comp signal"... -

Page 51: Replacing Assemblies

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 5 Replacing Assemblies The service policy for all 1000 X-Series oscilloscopes is unit replacement, so there are no instructions for replacing internal assemblies in this service guide. - Page 52 Replacing Assemblies 1000 X-Series Oscilloscopes Service Guide...

-

Page 53: Replaceable Parts

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 6 Replaceable Parts Because the service policy for 1000 X-Series oscilloscopes is unit replacement, no replaceable parts are available for the Keysight 1000 X-Series oscilloscopes. - Page 54 Replaceable Parts 1000 X-Series Oscilloscopes Service Guide...

-

Page 55: Safety Notices

Keysight InfiniiVision 1000 X-Series Oscilloscope Service Guide 7 Safety Notices This apparatus has been designed and tested in accordance with IEC Publication 1010, Safety Requirements for Measuring Apparatus, and has been supplied in a safe condition. This is a Safety Class I instrument (provided with terminal for protective earthing). -

Page 56: Warnings

Safety Notices Warnings Before turning on the instrument, you must connect the protective earth terminal of the instrument to the protective conductor of the (mains) power cord. The mains plug shall only be inserted in a socket outlet provided with a protective earth contact. -

Page 57: To Clean The Instrument

Safety Notices To clean the instrument If the instrument requires cleaning: (1) Remove power from the instrument. (2) Clean the external surfaces of the instrument with a soft cloth dampened with a mixture of mild detergent and water. (3) Make sure that the instrument is completely dry before reconnecting it to a power source. -

Page 58: Safety Symbols

Safety Notices Safety Symbols Instruction manual symbol: the product is marked with this symbol when it is necessary for you to refer to the instruction manual in order to protect against damage to the product. Hazardous voltage symbol. Earth terminal symbol: Used to indicate a circuit common connected to grounded chassis. - Page 59 Index accuracy, DC vertical gain, Keysight self test, front panel, assemblies contact information, self test, hardware, replacing, self-alignment, user cal, self-tests, specifications, LED, startup sequence, startup sequence, bandwidth status, User Cal, verification, status, user cal, measurement category, definitions, calibration, test certificate of calibration, equipment, channels...

- Page 60 Index 1000 X-Series Oscilloscopes Service Guide...

Need help?

Do you have a question about the InfiniiVision 1000 X-Series and is the answer not in the manual?

Questions and answers