RR Mechatronics STARRSED TL User Manual

Hide thumbs

Also See for STARRSED TL:

- User manual (249 pages) ,

- Instructions for use manual (137 pages) ,

- Installation manual (61 pages)

Summary of Contents for RR Mechatronics STARRSED TL

- Page 1 STARRSED TL USER MANUAL Version 1.00 MRN-171-EN Master Registration Number: MRN-171-EN...

- Page 3 Postal address: 1620 AE Hoorn The Netherlands De Corantijn 13 Office address: 1689 AN Zwaag The Netherlands © Copyright RR Mechatronics Manufacturing B.V. All rights reserved. Subject to changes without prior notice. Issued by the Support Department of RR Mechatronics...

- Page 5 Published date Wednesday, 17 October 2018 Issue No Date Revised Section(s) Changes Authorised Manual updated up to latest 1.00 Oct. 2018 H. Schavemaker configuration and software version 6.11 First issue DRAFT H. Schavemaker 2016 Starrsed TL User Manual Page 3 Version 1.00 MRN-171-EN...

-

Page 7: Table Of Contents

5.2.3. General laboratory practices: ................ 25 5.2.4. Specific laboratory practices and requirements: ........... 26 5.3. E.C. Declaration Starrsed TL ................... 27 5.4. Labels and stickers on containers ................28 6. STARRSED TL PROGRAM ..................29 6.1. Software version ...................... 29 ... - Page 8 6.6.4.2. Dilution error detection 0 till 25% .............. 74 6.6.4.3. Auto dilution adjust ................... 75 6.6.4.4. Diluent flow check..................75 6.6.5. Limit error settings ..................76 6.6.6. QC Settings ....................77 6.7. Service screen ......................79 Page 6 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 9 Turn off sequence ..................107 10. QUALITY CONTROL ....................108 10.1. Control pipettes ....................108 10.2. Monitoring measurement quality with Starrsed Control ........108 10.2.1. Limitations ....................108 10.2.2. Expected value range ................. 108 Starrsed TL User Manual Page 7 Version 1.00 MRN-171-EN...

- Page 10 Rinse pump failure ..................134 15.1.4. Sample probe is not washed after aspiration ..........134 15.1.5. Pipettes not dry after washing and drying cycle ......... 135 15.2. Liquid level sensor not sensing ................135 Page 8 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 11 Trouble-shooting ethernet interface ............... 152 15.23. Sampling process stops ................. 152 15.24. Piercing error ....................153 15.25. Sensor errors ....................153 15.26. Not reading the barcode ................. 153 15.27. Quality control trouble shooting ..............154 Starrsed TL User Manual Page 9 Version 1.00 MRN-171-EN...

- Page 12 Contents 16. APPENDIX FOR STARRSED TL ................157 17. WORK INSTRUCTION STARRSED TL ..............178 18. GLOSSARY OF TERMS .................... 217 19. INDEX ......................... 219 Page 10 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 13: Introduction

For professional use in medical laboratories only. To be used for all patient populations, not restricted by age or any other anatomical or physiological particulars. 1.2. Indication for use of device For screening and follow-up of patients with (suspected) inflammatory conditions. Starrsed TL User Manual Page 11 Version 1.00 MRN-171-EN... -

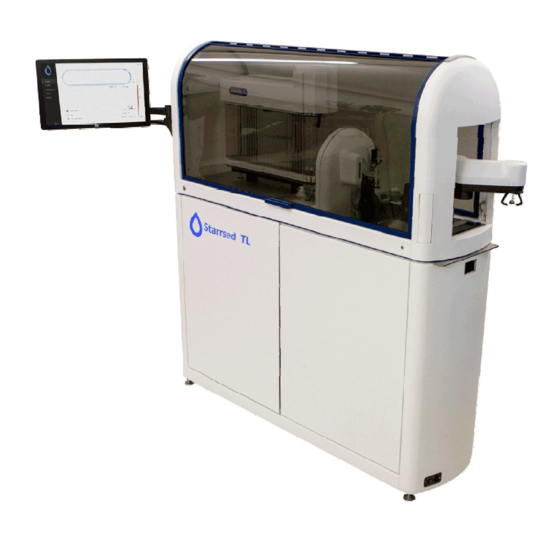

Page 14: Instrument Overview

ICSH , using closed sample tubes filled with citrate or EDTA blood. The Starrsed TL is an advanced ESR system that offers many unique features and benefits over the traditional ESR procedures. Automating this method has the following advantages: ... -

Page 15: Explanation Of Symbols

Warning sign to prevent personal injury due to hot surfaces. Warning sign to prevent personal injury due to electrical shocks. General warning. General note. This symbol indicates a reference to this or other product documentation Starrsed TL User Manual Page 13 Version 1.00 MRN-171-EN... -

Page 16: Eqas

Each customer can sign up for our portal, available through our website http://www.rrmechatronics.com. 1.6. Explanation of available documentation Manuals for the Starrsed TL are available on three levels: for the operator, the supervisor and the service engineer. The following manuals are available: 1. -

Page 17: Dilution Principle

Introduction 1.8. Dilution principle The principle of adding Diluent to a flow of whole blood is unique. The Starrsed TL has the capability of monitoring the air displacement during the aspiration cycle. This is called on-line dilution. The CPU receives data from the airflow sensor and calculates the syringe speed. Diluter accuracy is ±... -

Page 18: Instrument Description

2. INSTRUMENT DESCRIPTION The Starrsed TL picks a tube from the track and moves the tube to a barcode reading position. Barcode label is read and checked if an ESR is requested. The tube is then moved to the mix position into the tube disk and the blood is rotated 12 times, as recommended by the ICSH. - Page 19 Instrument description The Starrsed TL analyzer consists of the following parts: ESR analyser unit ESR measuring unit with a belt holding 84 precision's bore glass Westergren pipettes. Automated dilution of EDTA blood sample with citrate Automated measurement of ESR after 30 or 60 minutes ...

-

Page 20: Technical Specifications

Instrument description 2.1. Technical specifications Technical specifications for the Starrsed TL: Model name Catalogue number (REF) Instrument model Starrsed TL TLAX109100 Westergren method ESR method ICSH J. M. Jou; Int. Journal of Laboratory Hematology 2011; 33: 125-132 CLSI Procedures for the Erythrocyte Sedimentation Rate Test;... -

Page 21: Accessory Kit

Storage capacity indication 2.2. Accessory kit Most common replacement parts are listed in the Article reference list (on page 158). Parts for repair and replacement use are mentioned in Replacement parts Starrsed TL. Starrsed TL User Manual Page 19 Version 1.00 MRN-171-EN... -

Page 22: Used Reagents

Starrsed Cleaning Agent is used to remove protein deposition from the Westergren pipettes of Starrsed ESR analyzers. Starrsed Cleaning Agent needs to be prepared for a cleaning procedure which is used in level 4 maintenance. Page 20 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 23: General Safety Instructions

3.1. Safety warning When there was an incident with the Starrsed TL which caused damage to the instrument, please notify your superior and your local equipment dealer before you continue using the instrument. Example: ... -

Page 24: Moving Parts Warning

Do not open the safety cover during sampling! Some components are moving to another position before operation finally stops and sample mode is automatically switched OFF. Switch "S " always OFF before opening the cover for any reason. AMPLE MODE Page 22 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 25: Installation

The instrument must be unpacked, installed and checked by a trained engineer prior to first operation. Detailed installation instructions are given in the Starrsed TL Installation manual. Connect the instrument only to a properly earthed power connection. Starrsed TL User Manual Page 23 Version 1.00 MRN-171-EN... -

Page 26: Standard Operating Procedures (S.o.p.)

Transfer materials according to federal and international regulations. Be familiar with written instructions for laboratory procedures and proper responses to emergencies. Report spills, exposures, illnesses, and injuries immediately. Page 24 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 27: For Working With Bio Hazardous Materials

Departmental Safety Guidelines and bio safety Policy. Each user is responsible to leave a clean, disinfected and tidy work place. All biohazard waste must be properly disposed. Starrsed TL User Manual Page 25 Version 1.00 MRN-171-EN... -

Page 28: Specific Laboratory Practices And Requirements

Dispose of gloves into a biohazard container. The use of eye protection is advised while processing samples. Remove and properly dispose of gloves and wash hands before leaving the laboratory. Page 26 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 29: Declaration Starrsed Tl

Standard Operating Procedures (S.O.P.) 5.3. E.C. Declaration Starrsed TL Starrsed TL User Manual Page 27 Version 1.00 MRN-171-EN... -

Page 30: Labels And Stickers On Containers

Standard Operating Procedures (S.O.P.) 5.4. Labels and stickers on containers Stickers of the reagents containers Page 28 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 31: Starrsed Tl Program

Starrsed TL program 6. STARRSED TL PROGRAM The Starrsed TL is controlled via an external computer on which runs the Starrsed TL software. The software functions are grouped on six tabbed screens. The software is controlled by mouse pointer or directly via the touch screen. A virtual keyboard is automatically displayed on screen, when numerical or alphanumerical input is required. -

Page 32: Sample Screen

ESR analyser unit in the normal AMPLE operation mode. If the software is set to service mode is this indicated with a yellow bar next to the menu. Page 30 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 33 For instance the ESR time is set back to 60 minutes or 30 minutes according the used method. The User Manual button is at the bottom of the menu. Click this button to open the Starrsed TL User manual.

-

Page 34: Sample Screen Sections Explanation

ESR is required and waiting to be done. ESR was measured successfully. ESR was measured, but with fill errors. After processing the sample, the information is transferred to the D (on page ISPLAY SAMPLE HISTORY 37) screen. Page 32 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 35 Information about the current status of the instrument is shown here, such as the selected mode (EDTA or Citrate), selected method (60 or 30 minute) and symbols that draw attention to certain maintenance conditions or QC sample status (if applicable). Starrsed TL User Manual Page 33 Version 1.00 MRN-171-EN...

-

Page 36: Sample Screen With Keyboard

A virtual number pad is shown. Type the number of the requested pipette and press the OK button. The pipette information screen is shown. 6.2.3. Pipette information Page 34 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 37: History Screen

(on page 36) ISPLAY PIPETTE DATA Use button P to send the selected data to the printer. RINT (on page 37) ISPLAY SAMPLE HISTORY (on page 38) ISPLAY FULL PATIENT RESULT Starrsed TL User Manual Page 35 Version 1.00 MRN-171-EN... -

Page 38: Display Pipette Data

After measuring the pipette, the pipette data is transferred to the sample history files. In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. Page 36 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 39: Display Sample History

The default column ESR TC can be changed to ESR30 and/or ESR60 and/or ESR TC in Display settings (on page 68). Starrsed TL User Manual Page 37 Version 1.00 MRN-171-EN... -

Page 40: Display Patient Results

ESR 60 min When the 60 minute method is used, this is the measured 60 minutes value. When the 30 minutes method is used, this is the calculated 60 minutes value. Page 38 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 41: History Sample Analyse Option

6.3.2.2. History sample analyse option Make a selection for all or today's results between start time and end time or make a selection for: A specific number of past days. 2. A specific date. Starrsed TL User Manual Page 39 Version 1.00 MRN-171-EN... -

Page 42: Set Start/End Date

Starrsed TL program 3. A range of days from start date to end date. 6.3.2.3. Set start/end date Enter the Start/End date and time. Page 40 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 43: Esr Statistics Screens

ESR errors (%) Increasing ESR errors may indicate the need for maintenance, see ESR Error (on page 99) Number of samples This can be used to document variations in work load. Starrsed TL User Manual Page 41 Version 1.00 MRN-171-EN... -

Page 44: Qc Results Screens

Note: This part of the software can only be used in combination with Starrsed Control as quality control material. 6.3.4.1. QC Normal results (table) The results from Starrsed Control level N are shown. See chapter Level A for further explanation. Page 42 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 45: Qc Abnormal Results (Table)

This is the temperature corrected mean value (incorporated in the Starrsed barcode) and the accepted range of deviation. The applicable values for the acceptable range depend on the user setting. ESR 60: Uncorrected result from QC sample. Starrsed TL User Manual Page 43 Version 1.00 MRN-171-EN... - Page 46 Results can be exported to a .CSV file and imported in an MS Excel file for further analyses. ATCH All used batches of Starrsed Control are shown, results are shown for chosen batch ID. LOSE Return to History screen (on page 35). Page 44 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 47: Qc Abnormal Results (Graph)

Number of QC results This graph gives a first indication of the measuring stability of the Starrsed TL. Further analysis and identification of systematic errors have to be performed in the user's Quality Control System. LOSE Return to History screen (on page 35). -

Page 48: Qc Abnormal Results Screen Extended

Starrsed TL program 6.3.4.4. QC abnormal results screen extended After scrolling the general data from the QC results are shown. 6.3.4.5. Display sample history (QC) Page 46 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 49: Linked Qc Id's

4. Attach the Lab ID label on the Starrsed Control sample tube so that the original barcode is completely covered to ensure that only the Lab ID barcode can be scanned by the Starrsed TL. If the Starrsed Control sample ID is not correct or the expiry date is exceeded, a message will be shown and the ID's are not added to the list. -

Page 50: Qc Result Analysis

By selecting Dilution <= 90 all the samples with a dilution rate <= 90 are displayed in the table. In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. Page 48 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 51: History Analyse Results Dilution

In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. 6.3.7. History aspect Starrsed TL User Manual Page 49 Version 1.00 MRN-171-EN... -

Page 52: History Analyse Error

In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. 6.3.9. History analyse warning Page 50 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 53: Reagents Screen

The message Not allowed now! See R ! appears. Processing of new samples EAGENTS is stopped. A log is available for all reagents and can be accessed by clicking on D ISPLAY REAGENT (on page 52) HISTORY Starrsed TL User Manual Page 51 Version 1.00 MRN-171-EN... -

Page 54: Display Reagent History

Select the reagent type on the right side. For external use of the information all the logged reagent data can be exported to EXCEL .CSV format by clicking Export to Excel (CSV). 6.4.2. New reagent input Page 52 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 55: New Reagent Input (Cont)

3. Enter / read the Expiry date (if barcode reader is used: cursor has to be in one of the two boxes) 4. If necessary, adjust the date when the reagent was placed. 5. Check if the preview box shows the correct information, then press OK. Starrsed TL User Manual Page 53 Version 1.00 MRN-171-EN... -

Page 56: Maintenance Screen

LEAN 2. C (on page 58) HECK SENSORS 3. D (on page 61) ISPLAY RROR HISTORY 4. D . (on page 62) ISPLAY AINTENANCE HIST 5. M (on page 63) AINTENANCE Page 54 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 57: Prime / Clean

During a pipette rinse cycle, a small amount of disinfectant is flushed around the bottom of the pipette and into the waste system. When the Starrsed TL has been idle for more than eight hours, there might be some backflow of reagents due to gravity. Prime all tubing before sampling by using the function: ... - Page 58 This function fills all pipettes with a cleaning agent and removes the cleaning agent after a specified time. End-of-day wash: All pipettes will be washed once and needle, fill-nozzle and rinse-nozzle (wash station) are primed. Page 56 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 59: Fill And Clean Screen

See chapter Maintenance Fill and clean procedure (on page 121) for more information. 6.5.1.2. End-of-day-wash procedure End-of-day wash: All pipettes will be washed once and needle, fill-nozzle and rinse-nozzle (wash station) are primed. Starrsed TL User Manual Page 57 Version 1.00 MRN-171-EN... -

Page 60: Check Sensors

Check Separator sensor: Click the Check button, the OK sign is shown if the sensor value is in range. Check Flow sensor: Click the Check button, the OK sign is shown if the sensor value is in range. Page 58 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 61 When a test pipette is installed at the measuring position the result of the test pipette is displayed in the field "ESR (mm)". When the sensor is out of range and a red "X" is shown, the sensor values can be checked by turning on the service mode. Starrsed TL User Manual Page 59 Version 1.00 MRN-171-EN...

-

Page 62: Check Sensors In Service Mode

Check Flow sensor: The vacuum unit switches on and the values must be in this range: For Starrsed TL Flow: 0925-0980-1020 Abs: 0330- 360 -0390 Note: If for example the yellow orifice is blocked the flow will be: Offset: 0045-0050-0055. -

Page 63: Display Error History

NOTE: Clean sensors first before executing this function. NOTE: When a test pipette is installed at the measuring position the result of the test pipette is displayed in the field "ESR (mm)". 6.5.3. Display error history Starrsed TL User Manual Page 61 Version 1.00 MRN-171-EN... -

Page 64: Display Maintenance History

When there is a sensor alarm, an alarm indicator is shown in the tab M AINTENANCE All performed maintenance functions are logged automatically. This log can be saved e.g. to a memory stick by clicking button Save As ... Page 62 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 65: Maintenance Info

End-of-day wash procedure will start to wash all pipettes, needle, fill-nozzle and rinse-nozzle (wash station). The function can be set up for automatic execution in the following screen. Close program will only close down the program. Starrsed TL User Manual Page 63 Version 1.00 MRN-171-EN... -

Page 66: End-Of-Day-Wash Options

Daily: The function runs on a daily base at the selected time. Custom: To define customised working days (sunday till saturday) Activate option "Automatically restart sample mode when finished" if needed. Page 64 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 67: End-Of-Day-Wash Schedule Settings

2. Display settings (on page 68) 3. Carousel control (on page 69) 4. Diluter settings (on page 74) 5. Limit error settings (on page 76) 6. QC Settings (on page 77) Starrsed TL User Manual Page 65 Version 1.00 MRN-171-EN... - Page 68 Starrsed TL. EDTA OFF: Samples are presented in pre-diluted CITRATE sample tubes. Dilution on MODE the Starrsed TL is switched OFF. 3. T ORRECTION ON: A temperature corrected value for the ESR is shown besides the actual ...

-

Page 69: On And Off Selection

Starrsed TL. EDTA OFF: Samples are presented in pre-diluted CITRATE sample tubes. Dilution on MODE the Starrsed TL is switched OFF. 3. T ORRECTION ON: A temperature corrected value for the ESR is shown besides the actual ... -

Page 70: Display Settings

ON: The dilution rates of all samples are shown in the status line on the ISPLAY DILUTION screen directly after aspiration. OFF: Dilution rates are only shown if they are outside the selected accepted ISPLAY DILUTION range. Page 68 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 71: Carousel Control

Sample history table column(s): To show ESR30, ESR60 and/or ESR TC as a column in the Sample history screen. Possible settings depends on general settings (ESR30 ON/OFF and Temperature correction ON/OFF). 6.6.3. Carousel control Starrsed TL User Manual Page 69 Version 1.00 MRN-171-EN... - Page 72 Each individual pipette is tested and results are sent to the printer. ELETE PIPETTE DATA This function will erase all pipette data. Make sure that there are no samples on the pipette belt. Page 70 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 73: Pipette Flow Tests

This test is a useful function for checking the pipette position adjustment, vacuum adjustment and filling height sensor positioning adjustment. Each individual pipette is tested and results are displayed in their own line of the diagram. Potentiometer mean test: Starrsed TL User Manual Page 71 Version 1.00 MRN-171-EN... - Page 74 Starrsed TL program Flow: Absolute flow test: Leakage test: Page 72 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 75: Set New Rinse Position

Starrsed TL program Fillsensor air flow test: Fillsensor glass flow test: 6.6.3.2. Set new rinse position Starrsed TL User Manual Page 73 Version 1.00 MRN-171-EN... -

Page 76: Diluter Settings

Example: Dilution error detection is set at 10%. When the dilution error is outside the 10% range, in the last column of the report EDTA 079 or EDTA 121 is printed which indicating this sample is 21% under or over diluted. Page 74 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 77: Auto Dilution Adjust

When the flow sensor is still giving errors after trouble shooting and there are no detectable faults in the liquid flow, use the switch OFF function. This check is now not active, call for service. Starrsed TL User Manual Page 75 Version 1.00 MRN-171-EN... -

Page 78: Limit Error Settings

YES: always transmit results with bubbles on top warning to the output. set to NO: transmit no results to the output when there is generated a warning for bubbles on top. Page 76 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 79: Qc Settings

Note: If limit error filters in the LIMS are not corresponding with the limit error settings on the instrument it is possible that not all expected results are send to the LIMS. 6.6.6. QC Settings Starrsed TL User Manual Page 77 Version 1.00 MRN-171-EN... - Page 80 This link will stay active if there is no result or a general ESR error is generated. This setting is useful when the lab issues a new and unique Lab ID for every QC sample. Page 78 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 81: Service Screen

There are no restrictions for the file AVE SETTINGS AS name. is used for storing software settings after settings are changed or altered. AVE SETTINGS Starrsed TL User Manual Page 79 Version 1.00 MRN-171-EN... -

Page 82: Tlax Settings

Starrsed TL program 6.7.1. TLAX settings 6.7.1.1. Service Page 80 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 83 EAD BARCODE barcode reading position (and label is in readable position) On this screen is also presence of tubes on: Track, Tube disk, Rack input or Gripper position are shown. Starrsed TL User Manual Page 81 Version 1.00 MRN-171-EN...

- Page 84 2. Press start. 3. Adjust the gripper to the maximum setting with "+" button at first. 4. Adjust the gripper to the correct width with the "-" button. 5. Press S Page 82 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 85 4. Move robot arm on the correct horizontal position: centered just above the tube cap. 5. Move robot arm downwards until the fingers from the gripper are just below the tube cap. 6. Press "S ". ET LOCATION Starrsed TL User Manual Page 83 Version 1.00 MRN-171-EN...

- Page 86 ", the robot arm moves to the first barcode reader. The robot arm is set free ALIBRATE and can be moved manually. 4. Move robot arm carefully (and if necessary the tube itself) by hand until the barcode appears as expected on the screen. Page 84 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 87 ", the robot arm moves to the rack input position ALIBRATE 5. Move robot arm carefully by hand until the fingers of the gripper arms are just below the tube cap. 6. Press "S ". ET LOCATION Starrsed TL User Manual Page 85 Version 1.00 MRN-171-EN...

-

Page 88: Service Monitor

On tab Info is indicated if all positions are calibrated. Track position is set with default values from the factory and has to be re-calibrated before first use. 6.7.1.2. Service Monitor The following settings can be monitored: Tube disk Gripper Rack feeder Robot: Status Page 86 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 89: Lims Settings

*When the selection button is pressed, the virtual keyboard pops up. Type the correct numbers into the numerical fields, for instance in the baud rate field 9600. TCP/IP: Select IP Address and TCP Port as supplied locally. Starrsed TL User Manual Page 87 Version 1.00 MRN-171-EN... -

Page 90: Set Protocol Settings

When selected the following keys will pop-up. Checksum On/Off. 30 Minute method On/Off. 16. Advia 120 17. Advia 120 unidirectional 18. InteRRliner For more details see Section 9 Protocols (on page 97) and the Appendix Page 88 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 91: Esr Unit Settings

ESULT (year/month/day) is created by the software. USB IO D EVICE Switch ON if a Status indicator is part of the Starrsed TL. If switched ON a device can be selected at USB IO Device number. If S is OFF, this file cannot be selected in the history window. -

Page 92: Manual Control

Note: If vacuum pump is OFF rinse solution will spill over the unit OFF: LL PUMPS All active pumps will be switched OFF. The waste pump is switched ON for one minute. Page 90 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 93: Needle Control

INSE NOZZLE UP 4. R : The Rinse nozzle is send to the rinse nozzle home position. INSE NOZZLE DOWN Nozzle status Status check for the fill- and rinse nozzle is displayed. Starrsed TL User Manual Page 91 Version 1.00 MRN-171-EN... -

Page 94: Valve Control

6. V : Inner needle vacuum valve ACUUM VALVE Actuators 1. R : Rinse solenoid active, rinse valve-block down. INSE ACTUATOR 2. F : Fill solenoid active, fill valve-block down. ILL ACTUATOR Page 92 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 95: Display Error History (Service)

This list contains a log of all the maintenance what is done which can be useful for the field engineer to check the problems with the instrument in the past. The key C will delete all errors from the list. LEAR Starrsed TL User Manual Page 93 Version 1.00 MRN-171-EN... -

Page 96: Getting Started

In all other situations, the options should be set to NO to avoid that results associated with exceeded limits are transmitted to LIMS and/or printed. 7.2. Liquid levels The Starrsed TL has liquid level sensors. When the level sensor alarm appears, replace reagent as soon as possible. 7.3. Reagents preparation Use the genuine Mechatronics bulk reagent containers with level sensors. - Page 97 2. Install the level sensors and spacers according the following pictures. Make sure to place the appropriate level sensors in the containers by matching the color codes on the tube and on the container: Starrsed TL User Manual Page 95 Version 1.00 MRN-171-EN...

-

Page 98: Starrsed Cleaning Agent

Starrsed Cleaning Agent is used to remove protein deposition from the Westergren pipettes of Starrsed ESR analyzers. Starrsed Cleaning Agent needs to be prepared for a cleaning procedure which is used in level 4 maintenance. Page 96 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 99: Reporting

Reporting 8. REPORTING The Starrsed TL is able to handle different types of protocols. The selection is made in S ERVICE LIMS- SETTINGS 8.1. Protocols A protocol is a set of rules governing the communication and the transfer of data between machines, as in a computer system. - Page 100 Sample results with a text error. This sample gives Too many borders found. Result of a pipette possibly filled with air bubbles. 905008 Sample result with a text error. This sample is given limit error L_err(---/ 84/ 75/200) Page 98 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 101: Report 30 Minute Mode

ESR "ERROR" and "WARNING" code messages. This code appears in the "sample data record" at column 10. Error: No ESR result is given Warning: Result should be reviewed before release. The following codes are defined: Starrsed TL User Manual Page 99 Version 1.00 MRN-171-EN... - Page 102 Limit error Error One of the following limits are out of the setting range: ESR Time Column height Dilution Bubbles on top Hazy aspect Temperature Page 100 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 103: Limit Error Settings

When the 30-minute method is used the minimum reported value is also 1 mm but then as ESR30 result. The ESR60 result is therefore automatically calculated to a result of 2 mm. Starrsed TL User Manual Page 101 Version 1.00 MRN-171-EN... -

Page 104: Aspect Hazy

(darkest = 100 % and the lightest = 0 % absorption respectively). By definition the levels are: 87.5% Cells/ plasma separation 75.0% Hazy detection 50.0% Meniscus detection Graphic showing typical absorption values of a sample Page 102 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 105: Analyser "Hazy" Code Messages

Sample is clear. Sample is Hazy < 10 Sample is Hazy < 25 Sample is Hazy > 25 Results with hazy aspect can be suppressed in the menu Limit error settings. Starrsed TL User Manual Page 103 Version 1.00 MRN-171-EN... -

Page 106: Operation

3. Starrsed in status "Online" in Laboratory system. 4. Check if Starrsed Software is in NORMAL mode and not in SERVICE mode. 9.1.3. Liquid levels The Starrsed TL has liquid level sensors. When the level sensor alarm appears, replace reagent as soon as possible. Page 104 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 107: Checks During Operation

Remove rack, place a new rack or start with track feeding again. With pressing button M ANUAL INPUT the adapter moves in again. Sampling results of manual input are always visible in patient history and, depending on LIMS communication settings, also send to the LIMS. Starrsed TL User Manual Page 105 Version 1.00 MRN-171-EN... -

Page 108: Priming The Fluid System

ASTE SYSTEM tube connected to the pipette wash station. When the Starrsed TL has been idle for more than eight hours, there might be some backflow of reagents due to gravity. Prime all tubing before sampling by using the function: ... -

Page 109: End Of Day

Always be aware of the dangers of infection, especially during maintenance. Take the appropriate precautions. Note: The Starrsed TL may remain switched ON continuously. However, the customer should consider environmental issues such as energy consumption when the instrument is not to be used for some time. -

Page 110: Quality Control

10. QUALITY CONTROL 10.1. Control pipettes The correct function of the hardware and software of the Starrsed TL measurement unit should be checked at regular intervals with the aid of Mechatronics Control Pipettes (Order nr. QTST049000). More information can be found in the Control Pipette User Manual (MRN-019). -

Page 111: Temperature Correction

ESR procedure, depending on users Quality Control schedule. Quality Control scheduling is the responsibility of the user. The Starrsed software does not provide Quality Control scheduling functionality. Starrsed TL User Manual Page 109 Version 1.00 MRN-171-EN... -

Page 112: Quality Control Procedure

The applicable values for the acceptable range depend on the user setting. See chapter "QC Settings (on page 77)" for more information. If applicable, the QC result is reported to LIMS using the chosen LIMS settings and limit error settings. Page 110 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 113: Qc Error Messages

The uncorrected result is within range, but the corrected result is out of range. See Quality control trouble shooting (on page 154) and QC Results screen (on page 42) for more details. Starrsed TL User Manual Page 111 Version 1.00 MRN-171-EN... -

Page 114: Qc Result Analysis

QC sample step before releasing patient results. If results are not send to the LIMS QC Results can be exported to MS Excel CSV files for further analysis in lab's own Quality Control data system. Page 112 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 115: Esr Analyser Unit System Messages

During the start-up sequence all the positioning sensors are tested, if incorrect the instrument will generate a Test message, 1. Switch printer on (If applicable). 2. Test fill-nozzle unit. 3. Test rinse-unit. 4. Test measure-unit. 5. Test needle-unit. 6. Test drive-unit. Starrsed TL User Manual Page 113 Version 1.00 MRN-171-EN... -

Page 116: System Time-Out

7. Rinse head up error. 8. Measure head not home error. 9. Separator full error. The explanation of all these messages can be found in Appendix - Error list Starrsed TL (on page 161) Page 114 Starrsed TL User Manual... -

Page 117: Waste Handling

Waste handling 12. WASTE HANDLING The Starrsed TL has to be connected on a centralised waste system according local regulations and specifications. 12.1. Waste line connection to central waste system Before the waste line is connected to a centralised waste collection system, the following requirements must be met: 1. -

Page 118: General Maintenance

The purpose of the weekly maintenance is to carry out the daily maintenance and additionally check the optical sensor of the measure head and the vacuum pressure. Detailed instructions of this procedure can be found in the Work Instruction Weekly maintenance. (on page 194) Page 116 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 119: Check The Sensors In Service Mode

Detailed instructions of this procedure can be found in the Work Instruction Cleaning liquid separator (on page 207). Symptoms of a dirty separator: 1. Separator errors. 2. Foam in the separator. 3. Waste pump cannot sufficiently remove the waste from the separator. Starrsed TL User Manual Page 117 Version 1.00 MRN-171-EN... -

Page 120: Level 4 Maintenance

(on page 197). 13.3.1. Pump tubes replacement New tube replacement: Pump A ESRI090902 Ø5x7 mm Pump B ESRI090903 Ø2.5x4.5 mm The pumps can be reached best via the lower cabinet part. Page 118 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 121 5. Place one end of the tube in the pump plate holder. 6. Pull the new tube over the peristaltic pump rotor. 7. Pull pump tube slightly downwards and at the same time towards the back of the Starrsed TL. Starrsed TL User Manual Page 119 Version 1.00 MRN-171-EN...

- Page 122 Remove the old tube from the pump as shown: Pull the tube from the connectors and install the new tube in the reverse order. Check that all connecting tubes and the tube cover are attached. Page 120 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 123: Replace Bacterial Filter

Check for air in the dummy sample tube. 5. Select Starrsed TL on the track management system and put instrument "offline" 6. Ensure that the Starrsed TL is in Service mode, the status is also indicated with orange LED light. - Page 124 15. When all the pipettes are filled, the needle goes back to the home position. 16. Open the hood and remove the adapter unit. 17. Solve any outstanding errors on the track information system. 18. Close the hood 19. Put the Starrsed TL back online. Page 122 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 125: Replace Needle O-Ring

1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. Starrsed TL User Manual Page 123 Version 1.00 MRN-171-EN... - Page 126 Needle assembly 1. Place the needle back on the instrument. 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. Page 124 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 127: Level 3 Maintenance

See Work Instruction WI-181 Dis- and re-assembly diluter syringe (on page 190)/WI-188 Replace diluter tip (on page 186) Detailed instructions can be found in: WI Level 2 maintenance (on page 205). Starrsed TL User Manual Page 125 Version 1.00 MRN-171-EN... -

Page 128: Level 2 Maintenance

1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. Page 126 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 129 6. Remove the C-clip QWBM0500080 from the needle holder TLAX090009. 7. Use a small screwdriver to remove the distance tube TLAX090011 from the fastening block. Store the inner needle in a safe place. Starrsed TL User Manual Page 127 Version 1.00 MRN-171-EN...

- Page 130 2. Connect a syringe with air to the inner needle and immerse it in water. 3. Pressurize it with the syringe - air bubbles should not be visible. 4. Dry all parts. Page 128 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 131: Reagents Replacement

NOTE: Dismantle the needle assembly only in case of a breakdown. This is to prevent injury. 13.8. Reagents replacement The Starrsed TL is equipped with the genuine Mechatronics bulk reagent containers with level sensors. Each container has a specific position, see Reagent location label. - Page 132 4. Install the level sensors and spacers according the following pictures. Make sure to place the appropriate level sensors in the containers by matching the color codes on the tube and on the container: Page 130 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 133 After each reagents change, the fluid system must be primed: 1. Select M -> P AINTENANCE RIME LEAN 2. Perform the applicable prime step to fill the relevant tubes with reagent and remove air. Starrsed TL User Manual Page 131 Version 1.00 MRN-171-EN...

-

Page 134: Data Safety Management

Data safety management 14. DATA SAFETY MANAGEMENT The Starrsed TL has its own external PC. This means that all collected data is stored on the hard- disk of the external computer. This means that all raw data and results are kept, irrespective of a power failure or if the instrument is un-intentionally turned off. -

Page 135: Trouble Shooting

Refer to the Service manual for more information (available only in English). The error numbers are displayed in the PC software. 15.1. Peristaltic pumps The Peristaltic pumps are located under the steel plate. 15.1.1. Rinse solution not primed through the system Starrsed TL User Manual Page 133 Version 1.00 MRN-171-EN... -

Page 136: Rinse Solution Spilling Over The Instrument

It may be worn or leak. (See Level 4 maintenance). An incorrectly fitted diluent peristaltic pump (pump B) tube may cause the same problem. One of the tubes carrying diluent maybe blocked or bended. Page 134 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 137: Pipettes Not Dry After Washing And Drying Cycle

If there is no liquid flow and no reagent alarm: 1. Unscrew the cap of the deionized water container to check. 2. One of the de-ionized water lines may be blocked or kinked. Starrsed TL User Manual Page 135 Version 1.00 MRN-171-EN... -

Page 138: Disinfectant

3. Check if all tubes are still connected. 4. Check if the 2 tubes (ESRI070508) are still connected with the tubes ESRI070406. 5. Check if the 2 tubes positioned correctly in the pinch valve. Page 136 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 139: Diluter Errors

2. Diluter power cable loose. 3. A defective diluter motor. 4. Top or bottom position sensor failure. 5. Broken flexible print cable or connector. 6. Motor tacho failure. For Diluter failure technical assistance is needed. Starrsed TL User Manual Page 137 Version 1.00 MRN-171-EN... -

Page 140: Air Bubbles Entering The Diluent System

Diluent to the tubing and fill system manually. 1. Check pick-up tube at the Diluent container, it may be kinked. 2. One of the Diluent lines has become blocked or kinked. Page 138 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 141: Vacuum

WI-179 Replace blue air filter (on page 185) 6. Defective flow sensor board. Needs replacement, fatal error. 7. Outer needle valve is not functioning correctly and vacuum is leaking away, check outer needle valve. Starrsed TL User Manual Page 139 Version 1.00 MRN-171-EN... -

Page 142: Vacuum Error

5. Blockage in the 3 way vacuum manifold. Fatal error, technical assistance is needed. 15.8. Needle system As soon as the barcode is accepted, the sample will be processed. Page 140 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 143: Needle Not In Top Position

3. A scratched valve body. 4. Valve on top of the pipette is dirty or damaged. 5. Check pipette bottom, glass may be chipped. 6. Check the pipette valve for contamination or wear. Starrsed TL User Manual Page 141 Version 1.00 MRN-171-EN... -

Page 144: Air Bubbles

O-ring. 3. Check for air in diluter system. 4. Check that the sample probe O-ring is not leaking. 5. Check transparent mixing- piece block for cracks. Page 142 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 145: Pipette Looks Like Zebra Crossing

1. If just one air bubble is found about 5mm below the meniscus, the filling speed may be too high. 2. The blood column should not exceed the filling height sensor by more than 10mm. One air bubble can result in ESR Error 3. Starrsed TL User Manual Page 143 Version 1.00 MRN-171-EN... -

Page 146: One Air Bubble Rising In Pipette

Small air bubbles result in ESR Error 3. 15.10.6. Random air bubbles in pipette 1. Check Diluent flow by priming the diluter system. 2. Insufficient sample volume. Random air bubbles result in ESR Error 3. Page 144 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 147: Rinse Nozzle (Wash Station) Alignment

When there are still many reports, it is recommended to fill the diluter system with a 5% chlorine solution. See WI-240 Cleaning the diluent system (on page 211). A picture example of haziness Starrsed TL User Manual Page 145 Version 1.00 MRN-171-EN... -

Page 148: Hazy Reports After Cleaning

The measure sensor housing could be worn out. Replace the measure sensor. 15.13. Contaminated instrument The Starrsed TL has bacterial and micro organism's growth. Clean the instrument monthly with a strong cleaning agent. See work instructions WI-237 Fill and Clean with adapte (on page 191)r and WI-240 Cleaning the diluent system (on page 211) for details. -

Page 149: Fill Time-Out Error

2. Filling procedure stopped by operator. 3. Insufficient sample volume. Should be at least 1.4 ml. 4. Faulty filling nozzle or filling nozzle washer/O-ring. Check filling nozzle and washer/O-ring. Starrsed TL User Manual Page 147 Version 1.00 MRN-171-EN... -

Page 150: Carousel Position Error

There was a difference found in the pipette memory position table and the actual measured position of the position sensor. A position error can occur if the Starrsed TL is switched OFF while the carousel is moving to the next position or when the Rinse nozzle sticks up. -

Page 151: Sampling And Results Trouble Shooting

Check in LIMS settings if the correct protocol is used. Tubes are replaced on track or rack without aspiration: -Barcodes cannot be read (visible as red flags on tube in sample screen) -No ESR is requested from LIMS Starrsed TL User Manual Page 149 Version 1.00 MRN-171-EN... -

Page 152: Separator Error

30 days. is sensitive for bacterial growth. The solution should be discarded if it becomes turbid or ILUENT infected. Page 150 Starrsed TL User Manual Version 1.00 MRN-171-EN... -

Page 153: Reagents Alarm

The fill nozzle did not reach the home top sensor with a certain time limit. Fill nozzle motor faulty. Fill nozzle motor driver is faulty. Fill nozzle is blocked. Fatal error call distributor. Starrsed TL User Manual Page 151 Version 1.00 MRN-171-EN... -

Page 154: Communications

When those addresses and port settings are not in line, no data transfer is possible between Starrsed TL and LIMS. Both dynamic or static IP-addresses can be used for transferring data between the Starrsed instrument PC and LIMS. (Can be found via advanced TCP/IP settings in Internet protocol settings/Ethernet settings) 15.23. -

Page 155: Piercing Error

In some cases the barcode is not accepted because the format of the code is not correct. Check the settings of the external barcode reader or check the label on the sample tube. Starrsed TL User Manual Page 153 Version 1.00 MRN-171-EN... -

Page 156: Quality Control Trouble Shooting

Check general ESR data, QC result with ESR error no ESR Result is given see ESR Error (on page 99) Check sample tube volume Try new QC sample tube Page 154 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 157 Continuing could not within acceptable range. to decide whether the produce incorrect results! Do Starrsed TL may run patient you still want to continue? samples depending on the the nature of errors Press "Yes" to continue sampling without performing a new QC, press "No"...

- Page 158 Note: QC Error messages are only shown and stored in QC results and not send to LIMS. QC result is given with the same general errors and warnings as a normal patient ESR-result Page 156 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 159: Appendix For Starrsed Tl

Appendix for Starrsed TL 16. APPENDIX FOR STARRSED TL Appendix section Starrsed TL User Manual Page 157 Version 1.00 MRN-171-EN... - Page 160 Appendix for Starrsed TL Appendix - Spare part list Starrsed TL The Starrsed TL is delivered with a complete accessories kit ESRI110994. This reference list is for article order numbers only. QEDV130021 Fuse 4 A. (230V) Slow 5x20 mm. QEDV130023 Fuse 6.3 A.

- Page 161 Appendix for Starrsed TL Appendix - Maintenance schedule Maintenance Schedule Starrsed TL (Example) Sample volume: 450 per day (5 working Parts Total days) amount/ye Or earlier after number of samples 91.000 Perform End-of-day wash Check tubing/diluent syringe Clean instrument Clean Fill nozzle...

- Page 162 Appendix for Starrsed TL Replace Pipette valves bodies (84 pieces) X QTST040001 Replace all tubing (Tubing set) X TLAX079200 Grease needle holder/drive spindle X Molykote EM-30L Page 160 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 163 Appendix for Starrsed TL Appendix - Error list Starrsed TL Last updated: 08-10-2018 Error Extra explanation Reason/Solution Power cable not connected E2: Communication error! Communication lost after 3 on the communication (Board: %s (%x), Command: retries between Computer and...

- Page 164 Appendix for Starrsed TL Check diluent flow sensor E12: Dilution error: wrong or Diluter malfunction no diluent flow. Check the Check tubes diluter system diluter! Fill nozzle motor is faulty. E13: Fillnozzle not in home Fill nozzle did not reach the ...

- Page 165 Appendix for Starrsed TL Check result path setting E29: Result path not found. Selected result path is not Switched to default (D:\). valid. Software is using the Check if network or USB Check "Result Path" setting. default setting devices are used.

- Page 166 Appendix for Starrsed TL Check communication E221: No response from LAS LAS system did not response cable between Starrsed TL system! to a message from Starrsed and the LAS system. Check serial port settings. E222: NACK received from LAS system rejected “Status”...

- Page 167 Appendix for Starrsed TL Reprogram slave unit. E233: TLAX slave 1 unit error! Faulty TLAX slave unit Replace slave unit. Reprogram slave unit. E234: TLAX slave 2 unit error! Faulty TLAX slave unit. Replace slave unit.

- Page 168 Appendix for Starrsed TL Tube too deep in tube E245: Tube detected in Tube detected in ‘up’-position holder. Tube may only be shaker up position! during mixing at the shaker detected in ‘down’-position. position. Faulty tube detection sensor (shaker position).

- Page 169 Appendix for Starrsed TL Faulty gripper ‘close’- E254: Error while preparing to Error in ‘prepare to open’- sensor detection open gripper! routine. Faulty gripper ‘open’- E255: Error while opening Error in ‘open’-routine. sensor detection. gripper! Faulty internal mechanics of the gripper.

- Page 170 Appendix for Starrsed TL Faulty gripper sensor(s). E262: Tube not present in After trying to pick up a tube, gripper ! the tube is not present in the Faulty internal mechanics closed gripper. Tube maybe of the gripper.

- Page 171 Appendix for Starrsed TL Appendix - Tube connections Starrsed TL After modification with TLAX120900 Starrsed TL User Manual Page 169 Version 1.00 MRN-171-EN...

- Page 172 Appendix for Starrsed TL As delivered originally: Page 170 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 173 Appendix for Starrsed TL Appendix - PC connections for Starrsed TL (Windows 10) QTST109002: The computer has the following connections: 1. Connection to PC reset on cabinet 2. Connection to PC indicator light 3. When a printer is used connect the printer cable onto the 25 pin printer port connector (via External connection bracket) 4.

- Page 174 Appendix for Starrsed TL QTST109003: The computer has the following connections: 1. Connection to reset on cabinet 2. Connection to Power button 3. When a printer is used connect the printer cable onto the 25 pin printer port connector (via External connection bracket) 4.

- Page 175 Appendix for Starrsed TL Appendix - Article reference list Starrsed TL The Starrsed TL is delivered with a complete accessories kit TLAX110990. This reference list is for article order numbers only. Article Description ESRI010246 Pinch Valve Tube ESRI030903 Westergren Pipette assembly...

- Page 176 Appendix for Starrsed TL TLAX110023 Needle holder TLAX110026 Locking strip assembly TLAX110905 Track Sensor Assembly TLAX110906 Fill & Clean Container Assembly Page 174 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 177 Appendix for Starrsed TL Appendix - Default settings Starrsed TL General settings [S ] > G ETTINGS ENERAL SETTINGS Software Factory Setting Client Settings Default Setting 30 min. Method EDTA mode Temp correction Check for duplicate ID's Virtual keyboard Print after measurement Temperature 18 °C...

- Page 178 Appendix for Starrsed TL Software Factory Setting Client Settings Default Setting Send results when time exceeded Send results with dilution errors Send results with column height errors Send results with bubbles on top warning Send results with hazy aspect Send results with temperature exceeded ] >...

- Page 179 Appendix for Starrsed TL Result path Search in example history Starrsed TL User Manual Page 177 Version 1.00 MRN-171-EN...

-

Page 180: Work Instruction Starrsed Tl

Work instruction Starrsed TL 17. WORK INSTRUCTION STARRSED TL Work instruction section Page 178 Starrsed TL User Manual Version 1.00 MRN-171-EN... - Page 181 Instrument: Starrsed TL Revision: 001, October 2008 Remove of the top cover 1. Switch Starrsed TL OFF. 2. Remove the two rear screws of the top cover. 3. Lift the top cover carefully from the instrument. Pipette valve check or replacement: Hold the top pipette clamp and remove the valve body QTST040002 2.

- Page 182 MS 40..50..60 by using the C HECK function. MEASURE SENSOR 3. If not in range repeat cleaning the inner part of the measuring sensor. 4. When in range switch OFF the Starrsed TL. Starrsed TL User Manual Page 180 Version 1.00 MRN-171-EN...

- Page 183 6. Check for leakage with Fill & Clean. Replace the top cover: 1. Put the cover carefully over the instrument. 2. Fasten the two rear screws of the top cover. (If present/if needed). Switch ON the Starrsed TL. Starrsed TL User Manual Page 181 Version 1.00 MRN-171-EN...

- Page 184 Safety: Bio Hazard area Instrument: Starrsed TL Revision: Version 2,March 2017 Remove of the top cover 1. Switch Starrsed TL OFF. 2. Remove the two rear screws of the top cover. 3. Lift the top cover carefully from the instrument. Pipette removal Push and pull vertically the pipette from the holding position of the belts.

- Page 185 6. Check for leakage with Fill & Clean. Replace the top cover: 1. Put the cover carefully over the instrument. 2. Fasten the two rear screws of the top cover. (If present/if needed). Starrsed TL User Manual Page 183 Version 1.00 MRN-171-EN...

- Page 186 1. Prepare a Fill and Clean arrangement. 2. Run the fill and clean sequence. When all the pipettes are filled, the needle goes back to the home position. 3. Remove the Fill and clean arrangement. Starrsed TL User Manual Page 184 Version 1.00 MRN-171-EN...

- Page 187 Instrument: Compact Revision: Version 1, October 2007 Remove of the top cover 1. Switch Starrsed TL OFF. 2. Remove the two rear screws of the top cover. 3. Lift the top cover carefully from the instrument. Air filter replacement QWLV040003 Pull both tube connectors out of the blue filter.

- Page 188 3. Calculate the mean of the 10 samples. 4. Make dilution adjustment if necessary in S > D ETTINGS ILUTER SETTINGS Go to tab S > G and select D ETTINGS ENERAL SETTINGS ISPLAY DILUTION Starrsed TL User Manual Page 186 Version 1.00 MRN-171-EN...

- Page 189 Safety: Bio Hazard area Instrument: Starrsed TL Revision: 001, February 2005 Instructions for disassembling and assembling the fill nozzle Note: For the O-ring replacing, only take the top part away from the fill nozzle. Starrsed TL User Manual Page 187 Version 1.00 MRN-171-EN...

- Page 190 Work instruction Number 247 Page 1 of 2 Purpose: Check sensor values Safety: Bio Hazard area Instrument: Starrsed TL Revision: 001, October 2018 Check sensor values in Service mode: Starrsed TL User Manual Page 188 Version 1.00 MRN-171-EN...

- Page 191 AINTENANCE HECK SENSOR HECK LIQUID SENSOR Check liquid sensor: Press test. When test is finished, the OK signs are shown at Rinse and Drain if the liquid sensor is active. Starrsed TL User Manual Page 189 Version 1.00 MRN-171-EN...

- Page 192 Work instruction Number 181 Page 1 of 1 Purpose: Replace diluter syringe plunger/teflon tip/O-ring Safety: None Bio Hazard area Instrument: Starrsed TL with new Revision: October 2001 diluter version Repair set QWLV030901 contains: QWLV050001 O-ring QWLV030006 Teflon tip Disassembly of the diluter syringe: 1.

- Page 193 Check for air in the dummy sample tube. 5. Select Starrsed TL on the track management system and put instrument "offline" 6. Ensure that the Starrsed TL is in Service mode, the status is also indicated with orange LED light.

- Page 194 15. When all the pipettes are filled, the needle goes back to the home position. 16. Open the hood and remove the adapter unit. 17. Solve any outstanding errors on the track information system. 18. Close the hood 19. Put the Starrsed TL back online. Page 192 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 195 11. Check if the suction tube in the guide fork is free of clogging, remove clogging if needed. 12. Wipe stainless steel plates below the pipettes with disinfectant. 13. Close cover/front doors and activate the instrument in the LAS. Starrsed TL User Manual Page 193 Version 1.00 MRN-171-EN...

- Page 196 Change instrument status in the LAS from "online" to "offline" 1. Clean Fill nozzle The use of a toothbrush and detergent is recommended. 1. Carefully scrub the fill nozzle inner part. 2. Use a tissue to dry the fill nozzle. Starrsed TL User Manual Page 194 Version 1.00 MRN-171-EN...

- Page 197 C. A little silicon grease on the rim of separator will make the assembling and adjustment easier. D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing Starrsed TL User Manual Page 195 Version 1.00 MRN-171-EN...

- Page 198 9. Clean needle top with disinfectant. 10. Check if the suction tube in the guide fork is free of clogging, remove clogging if needed. 11. Wipe stainless steel plates below the pipettes with disinfectant. Page 196 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 199 Clean fill nozzle and exchange O-ring Fill Nozzle The use of a toothbrush and detergent is recommended. 1. Carefully scrub the fill nozzle inner part. 2. Use a tissue to dry the fill nozzle. Starrsed TL User Manual Page 197 Version 1.00 MRN-171-EN...

- Page 200 C. A little silicon grease on the rim of separator will make the assembling and adjustment easier. D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing Page 198 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 201 - Place red cap on dummy sample tube and turn adapter again, fill the adapter completely. Check for air in the dummy sample tube. 5. Ensure that the Starrsed TL is in Service mode, the status is also indicated with orange LED light.

- Page 202 Needle removal 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. Page 200 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 203 8. Place the O-ring screw over the inner needle so that the internal hexagonal hole is facing the inside of the needle holder. The small hole in the O-ring screw should stay about 2 mm above the holder. Starrsed TL User Manual Page 201 Version 1.00 MRN-171-EN...

- Page 204 4. Dry all parts. Needle assembly Place the needle back on the instrument. 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. Page 202 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 205 ] function. RIME ILUENT 7. Clean needle top with disinfectant. 8. Wipe stainless steel plates below the pipettes with disinfectant. 9. Close cover/front doors and activate the instrument in the LAS. Starrsed TL User Manual Page 203 Version 1.00 MRN-171-EN...

- Page 206 Clean liquid separator Exchange peristaltic pump tubes Fill & Clean Sensor check Exchange waste pump tube Exchange pinch valve Final cleaning and preparation Air filter replacement Page 204 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 207 Fill & Clean Sensor check (std) Final preparation Exchange waste pump tube Exchange pinch valve Final preparation Air filter replacement (std) Replace diluter syringe tip Starrsed TL User Manual Page 205 Version 1.00 MRN-171-EN...

- Page 208 1. Needle assembly TLAX090901 2. Replace pipette valve bodies (84 pieces) QTST040001. Check: 1. Adjustment of fill nozzle and rinse nozzle. Greasing: 1. Spindle of needle drive 2. Inner part of Needle holder Starrsed TL User Manual Page 206 Version 1.00 MRN-171-EN...

- Page 209 C. A little silicon grease on the rim of separator will make the assembling and adjustment easier. D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing Starrsed TL User Manual Page 207 Version 1.00 MRN-171-EN...

- Page 210 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. Starrsed TL User Manual Page 208 Version 1.00 MRN-171-EN...

- Page 211 2. Insert the needle holder in the needle assembly block. 3. Put a smear of grease (from the accessory-set) on the inside of the needle holder. 4. Insert the inner needle. Starrsed TL User Manual Page 209 Version 1.00 MRN-171-EN...

- Page 212 2. Check with use of the software if the needle moves up and down smoothly. NOTE: Dismantle the needle assembly only in case of a breakdown. This is to prevent injury. Page 210 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 213 3. Reconnect the diluent container. 4. Perform another [P RIME 5. After the prime sequence stops press [P ] again to fill the dispenser system with the new RIME diluent solution. Starrsed TL User Manual Page 211 Version 1.00 MRN-171-EN...

- Page 214 5. Push the tube in the pinch valve. Replace peristaltic pump tubes New tube replacement: Pump A ESRI090902 Ø5x7 mm Pump B ESRI090903 Ø2.5x4.5 mm The pumps can be reached best via the lower cabinet part. Starrsed TL User Manual Page 212 Version 1.00 MRN-171-EN...

- Page 215 6. Pull the new tube over the peristaltic pump rotor. 7. Pull pump tube slightly downwards and at the same time towards the back of the Starrsed TL. If the tube is not fitted correctly or is worn the following symptoms can occur: ...

- Page 216 Page 214 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 217 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. Starrsed TL User Manual Page 215 Version 1.00 MRN-171-EN...

- Page 218 Needle assembly 1. Place the needle back on the instrument. 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. Page 216 Starrsed TL User Manual Version 1.00 MRN-171-EN...

-

Page 219: Glossary Of Terms

Bidirectional communication means that 18.1.1.1.6. Host there is two-way communication from the Starrsed TL to the HOST (sample requests In this manual, the term HOST is used to and results) and from the HOST to the indicate the computer system and associated... - Page 220 18.1.1.1.11. Unidirectional Unidirectional communication means that there is only one-way communication from the Starrsed TL to the HOST. Only sample results and result related messages are send. 18.1.1.1.12. WI is short for Work Instruction and is used with an index number for a range of work instructions.

-

Page 221: Index

Display maintenance history • 54, 62 Display maintenance history (Service) • 79, Appendix - Default settings Starrsed TL • 179 Appendix - Error list Starrsed TL • 114, 143, Display patient results • 35, 37, 38 Display pipette data • 35, 36 Appendix - Maintenance schedule •... - Page 222 Limit filter settings • 94 QC abnormal results (graph) • 45 Limitations • 108 QC abnormal results (table) • 43 LIMS settings • 79, 87 QC abnormal results screen extended • 46 Page 220 Starrsed TL User Manual Version 1.00 MRN-171-EN...

- Page 223 Reagents preparation • 94 Reagents replacement • 129 Starrsed Rinse solution • 20 Reagents screen • 29, 30, 51, 131 STARRSED TL PROGRAM • 29 Replace bacterial filter • 121 System calibration • 82 System messages • 113 Replace needle O-ring • 123 System time-out <xxxx>...

- Page 224 Index WORK INSTRUCTION STARRSED TL • 182 Page 222 Starrsed TL User Manual Version 1.00 MRN-171-EN...

Need help?

Do you have a question about the STARRSED TL and is the answer not in the manual?

Questions and answers