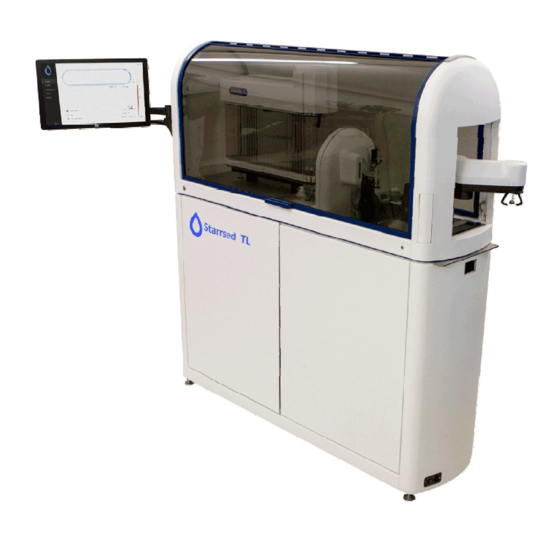

RR Mechatronics STARRSED TL Manuals

Manuals and User Guides for RR Mechatronics STARRSED TL. We have 5 RR Mechatronics STARRSED TL manuals available for free PDF download: User Manual, Instructions For Use Manual, Installation Manual, Work Instructions

RR Mechatronics STARRSED TL User Manual (249 pages)

Brand: RR Mechatronics

|

Category: Laboratory Equipment

|

Size: 9 MB

Table of Contents

Advertisement

RR Mechatronics STARRSED TL User Manual (224 pages)

Brand: RR Mechatronics

|

Category: Laboratory Equipment

|

Size: 7 MB

Table of Contents

RR Mechatronics STARRSED TL Instructions For Use Manual (137 pages)

Brand: RR Mechatronics

|

Category: Measuring Instruments

|

Size: 5 MB

Table of Contents

Advertisement

RR Mechatronics STARRSED TL Installation Manual (61 pages)

Brand: RR Mechatronics

|

Category: Measuring Instruments

|

Size: 2 MB

Table of Contents

RR Mechatronics STARRSED TL Work Instructions (5 pages)

Replace gripper arm assembly

Brand: RR Mechatronics

|

Category: Measuring Instruments

|

Size: 0 MB