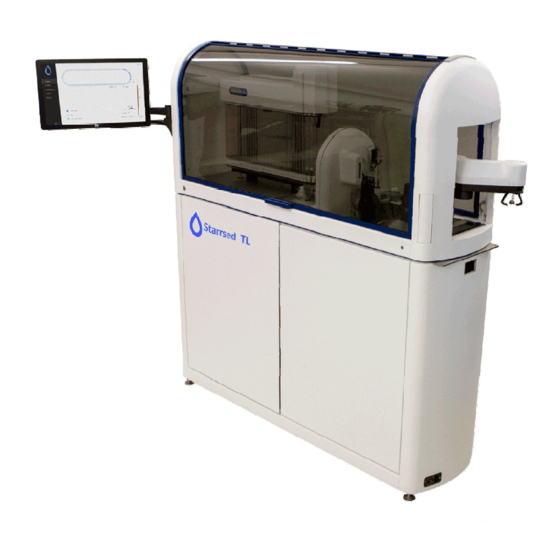

RR Mechatronics Starrsed TL Instructions For Use Manual

Hide thumbs

Also See for Starrsed TL:

- User manual (249 pages) ,

- Installation manual (61 pages) ,

- Work instructions (5 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for RR Mechatronics Starrsed TL

- Page 1 Instructions for Use Starrsed TL MRN-164_2-EN Version 1.08...

-

Page 3: Table Of Contents

............MRN-164_2-EN Version 1.08 Starrsed TL... - Page 4 ............MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 5 ..........MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 6 Terms............MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 7 - Index..............MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 8: Document History Overview

Instrument description H. Schavemaker • ESR Error reporting Reporting • Minor corrections • Fill and clean procedure with 1.01 March 2016 H. Schavemaker adapter • Minor corrections • First issue 1.00 Feb. 2016 H. Schavemaker MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 9: Introduction

For professional use in medical laboratories only. To be used for all patient populations, not restricted by age or any other anatomical or physiological particulars. 1.2 - Indication for use of device For screening and follow-up of patients with (suspected) inflammatory conditions. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 10: Instrument Overview

1.4 - Explanation of symbols The following symbols can be used in this manual and for the instrument: Warning sign to prevent personal injury due to biohazard. Warning sign to prevent personal injury due to rotating parts. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 11: Eqas

This symbol indicates a reference to this or other product documentation 1.5 - EQAS EQAS is RR Mechatronics' comprehensive tool to periodically assess the performance of the Starrsed instrument at your lab. Through EQAS, the test results of the instrument, obtained with Starrsed Control are objectively compared with a worldwide peer group using the same type of instrument. -

Page 12: Starrsed Line Of Esr Instruments

All absorption figures are relative to the darkest and lightest reading (darkest = 100 % and the lightest = 0 % absorption respectively). By definition the levels are: 87.5% Cells/ plasma separation 75.0% Hazy detection 50.0% Meniscus detection MRN-164_2-EN Version 1.08 Starrsed TL... - Page 13 Introduction Graphic showing typical absorption values of a sample MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 14: Instrument Description

ESR measuring unit with a belt holding 84 precision's bore glass Westergren pipettes. ▪ Automated dilution of EDTA blood sample with citrate ▪ Automated measurement of ESR after 30 or 60 minutes ▪ Automated cleaning and drying of pipettes MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 15: Pc Operation And User Interface

A pictorial representation of the pipette at the measuring position and a graph of the optical density over the length of the entire pipette is shown on the side. This data is retained in memory for subsequent retrieval if required. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 16: Technical Specifications

QRR 010934 Starrsed Rinse solution De-ionized water Track and tube types: Inpeco FlexLab (Inpeco, Siemens Aptio, Abbott ), GLP Systems Track types Track Brands/types as recommended by track supplier. Sample tube types Closed tubes with concentric cap only. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 17 140 kg Weight empty LIS connectivity: Ethernet (TCP/IP), bi-directional according various protocols Communication Data storage: Hard disk on external PC Storage medium approx. 5 Mb per 1000 samples (results and raw data) Storage capacity indication MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 18: Used Reagents

Starrsed Cleaning Agent is used to remove protein deposition from the Westergren pipettes of Starrsed ESR analyzers. Starrsed Cleaning Agent needs to be prepared for a cleaning procedure which is used in level 4 maintenance. Starrsed Cleaning agent is supplied in 100 ml bottles. QRR010905: 1 bag of 2 bottles MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 19: General Safety Information

Do not open the safety cover during sampling! Some components are moving to another position before operation finally stops and sample mode is automatically switched OFF. Switch "Sample mode" always OFF before opening the cover for any reason. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 20: Status Signals

During processing three coloured signals are used after activating manual input: ▪ Green: manual rack input can be started ▪ Orange: the instrument is performing another process, please wait ▪ Red: the sampling process is in progress, do not remove rack or tubes MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 21: Installation

The instrument must be unpacked, installed and checked by a trained engineer prior to first operation. Detailed installation instructions are given in the Interrliner Installation manual. Connect the instrument only to a properly earthed power connection. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 22: Starrsed Tl Program

Note: In the next sections move the mouse over the tab and click the left mouse button. Click again on the same tab for detailed information on the subject. Sample screen History screen Reagents screen Maintenance screen MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 23: Software Version

5.1 - Software version The latest software and manuals for the Interrliner can be downloaded from the RR Mechatronics website; www.rrmechatronics.com. (Login-part) The following program description is valid for software from version 6.12.1 and up and up. - Page 24 Do not open the safety cover during sampling! Some components are moving to another position before operation finally stops and sample mode is automatically switched OFF. Switch "Sample mode" always OFF before opening the cover for any reason. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 25: Sample Screen Sections Explanation

When a pipette is filled successfully, a blue dot marks the filled pipette. In case of a failure, the pipette is marked with a flashing red dot. All the sample information can be found in tab History MRN-164_2-EN Version 1.08 Starrsed TL... - Page 26 Barcode was read correctly, but ESR is not required for this sample. ESR is required and waiting to be done. ESR was measured successfully. ESR was measured, but with fill errors. After processing the sample, the information is transferred to the screen. Display sample history MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 27: Sample Screen With Keyboard

To view the status of a specific pipette, click directly on the pipette itself or click the open space in the center of the belt representation. A virtual number pad is shown. Type the number of the requested pipette and press the OK button. The pipette information screen is shown. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 28: Pipette Information

Starrsed TL program 5.2.3 - Pipette information The following information is shown: MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 29: History Screen

In Display sample history are the following options available: Print: Send the selected result to the printer. header: Only if option Settings-General settings "Print after measurement" is switched it is Print result possible to print a result header. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 30: Display Pipette Data

In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 31: Display Sample History

In the header of the table the names of the columns are shown. Double-click the header of any column to sort the table by this column in ascending order. The default column ESR TC can be changed to ESR30 and/or ESR60 and/or ESR TC in Display settings. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 32: Display Patient Results

When the 30 minutes method is used, this is the value. ESR 60 min T.Corr Temperature correction is used. This is the 60 minutes value corrected to 18°C. Date / time Date and time of the measurement of the result. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 33: Esr Statistics Screens

Increasing samples with bubbles indicate the need for maintenance of the aspiration system, see Foam in column ▪ ESR errors (%) Increasing ESR errors may indicate the need for maintenance, see ESR Error ▪ Number of samples This can be used to document variations in work load. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 34: Qc Results Screens

This part of the software can only be used in combination with Starrsed Control as quality control material. 5.3.4.1 - QC Normal results (table) The results from Starrsed Control level N are shown. See chapter Level A for further explanation. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 35: Qc Abnormal Results (Table)

The applicable values for the acceptable range depend on the user setting. ESR 60: Uncorrected result from QC sample. ESR 60 T.Corr.: Temperature corrected result from QC sample. T(°C): Temperature at which the sample was measured. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 36: Qc Abnormal Results (Graph)

Results can be exported to a .CSV file and imported in an MS Excel file for further analyses. Batch All used batches of Starrsed Control are shown, results are shown for chosen batch ID. Close Return to History screen 5.3.4.3 - QC abnormal results (graph) MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 37: Qc Abnormal Results Screen Extended

Quality Control System. Close Return to History screen 5.3.4.4 - QC abnormal results screen extended After scrolling the general data from the QC results are shown. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 38: Display Sample History (Qc)

QC samples, related patient results may span over multiple days and are listed per date. All general ESR data and errors of QC samples are shown here. 5.3.4.6 - Linked QC IDs MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 39: Qc Result Analysis

QC sample step before releasing patient results. If results are not sent to the LIMS QC Results can be exported to MS Excel CSV files for further analysis in lab's own Quality Control data system. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 40: History Sample Analyse Option

Make a selection for all or today's results between start time and end time or make a selection for: 1. A specific number of past days. 2. A specific date. 3. A range of days from start date to end date. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 41: Set Start/End Date

Starrsed TL program 5.3.6 - Set start/end date Enter the Start/End date and time. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 42: History Analyse Results

By selecting one of the three Hazy aspect codes, all the samples with this aspect code are displayed in the table, also in case of an error. Error By selecting one of the error codes, all the samples with this error code are displayed in the table. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 43: Reagents Screen

Reagents alarm is also set when the expire date of the reagent is exceeded or opened more than three months. The message Not allowed now! See Reagents! appears. Processing of new samples is stopped. A log is available for all reagents and can be accessed by clicking on Display reagent history MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 44: Display Reagent History

This screen shows the history of the used reagents. Select the reagent type on the right side. For external use of the information all the logged reagent data can be exported to EXCEL .CSV format by clicking Export to Excel (CSV). MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 45: New Reagent Input

Input screen for new reagents. Make a selection to add new (default setting) or delete the current information and continue with "Next". 5.4.2.1 - New reagent input (cont) Data can be entered with the keyboard or with a barcode reader. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 46: Maintenance Screen

5.5 - Maintenance screen When there is a sensor alarm, an alarm indicator is shown in the tab This screen has 5 sub screens: Prime / Clean Check sensors Display Error history Display Maintenance hist. Maintenance Info MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 47: Prime / Clean

When the Interrliner has been idle for more than eight hours, there might be some backflow of reagents due to gravity. Prime all tubing before sampling by using the function: ▪ Prime all units All priming functions are sequentially performed one time. Clean: MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 48: Fill And Clean Screen

This cycle takes about 90 minutes. The Fill & Clean function is part of the monthly maintenance procedure. A warning is shown on the display: <Pipette data will be lost!>. See chapter Maintenance Fill and clean procedure for more information. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 49: End-Of-Day-Wash Procedure

"activated". After finishing the test, both indicators must be shown as "activated". ▪ Check Separator sensor: Click the Check button, the OK sign is shown if the sensor value is in range. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 50 When a test pipette is installed at the measuring position the result of the test pipette is displayed in the field "ESR (mm)". When the sensor is out of range and a red "X" is shown, the sensor values can be checked by turning on the service mode. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 51: Display Error History

This list can be used by field engineers to check the status of the instrument and locate possible problems. This log can be saved e.g. to a memory stick by clicking button Save As ... MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 52: Display Maintenance History

When there is a sensor alarm, an alarm indicator is shown in the tab Maintenance. All performed maintenance functions are logged automatically. This log can be saved e.g. to a memory stick by clicking button Save As ... 5.5.5 - Maintenance info MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 53: Close

The following settings can be selected for the function: ▪ No End-of-day wash: The function is not active. ▪ Immediately: The function runs immediately after pressing the button OK. ▪ Only once: The function runs only once at the selected time. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 54: End-Of-Day-Wash Schedule Settings

Settings Instructions For Use. 5.7 - Service screen screen is for specially trained engineers and outside the scope of the Instruction For Use. Service MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 55: Operation

Check if Starrsed Software is in NORMAL mode and not in SERVICE mode. 6.1.4 - Priming the fluid system Select and perform all prime sequences manually. Check fluid flow through the Maintenance -> Prime / Clean applicable tubing. repeat a step if fluid flow is not correct. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 56: Liquid Levels Sensors

Sample mode button. Sample 6.5 - Manual sampling If LIMS communication is active : add sample identification in the LIMS. The manual input can be feeded with one rack at a time. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 57 Remove rack, place a new rack or start with track feeding again. With pressing button Manual input adapter moves in again. Sampling results of manual input are always visible in patient history and, depending on LIMS communication settings, also send to the LIMS. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 58: End Of Day

The correct function of the hardware and software of the Interrliner measurement unit should be checked at regular intervals with the aid of Mechatronics Control Pipettes (Order nr. QTST049000). More information can be found in the Control Pipette User Manual (MRN-019). MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 59: Reporting

3. ESR=Not corrected 60-minute ESR (see on page 135) result. 4. Tc=60-minute ESR result in millimeters, corrected for 18°C. (only in use if temperature correction is active). 5. Aspect (clear, hazy (see on page 135)). MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 60: Report 60-Minute Mode

Sample results with a text error. This sample gives Too many borders found. Result of a pipette possibly filled with air bubbles. 905008 Sample result with a text error. This sample is given limit error L_err(---/ 84/ 75/200) MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 61: Report 30 Minute Mode

Air bubbles on top of the ESR. See Section Troubleshooting Air bubbles Limit error Error One of the following limits are out of the setting range: • ESR Time • Column height • Dilution • Bubbles on top • Hazy aspect • Temperature MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 62: Reporting Range

All absorption figures are relative to the darkest and lightest reading (darkest = 100 % and the lightest = 0 % absorption respectively). By definition the levels are: 87.5% Cells/ plasma separation MRN-164_2-EN Version 1.08 Starrsed TL... - Page 63 Hazy area >25 mm Hazy >25 mm Hazy area >10 mm <25 mm Hazy <25 mm Hazy area >3 mm < 10 mm Hazy <10 mm Hazy area < 3 mm CLEAR <3 mm MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 64: Waste Handling

Waste handling Waste handling The Interrliner has to be connected on a centralised waste system according local regulations and specifications. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 65: Data Safety Management

If a power failure occurs it is recommended that the Interrliner is switched by the power reset switch. When the power returns, the instrument can be switched ON. After the standard start-up process the Interrliner will continue to process the remaining samples. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 66: Maintenance

The purpose of the weekly maintenance is to carry out the daily maintenance and additionally check the sensors, inspect the sample needle and the vacuum pressure. Detailed instructions of this procedure can be found in the Work Instruction Weekly maintenance. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 67: Check The Sensors In Service Mode

Check on daily base if blood or other fluid is collected in the drip tray. 1. Remove the drip tray. 2. Clean it in case of containment 3. Place the drip tray back in the instrument. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 68: Cleaning Liquid Separator

3. Mix the solution well. 4. Fill adapter TLAX110906 with the cleaning solution. - Turn adapter upside down and remove red cap (from dummy tube) and start filling the adapter until the dummy sample tube is filled without air. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 69 15. When all the pipettes are filled, the needle goes back to the home position. 16. Open the hood and remove the adapter unit. 17. Solve any outstanding errors on the track information system. 18. Close the hood 19. Put the Interrliner back online. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 70: Replace Needle O-Ring And Check Needle

1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. O-ring replacement MRN-164_2-EN Version 1.08 Starrsed TL... - Page 71 2. Connect a syringe with air to the inner needle and immerse it in water. 3. Pressurize it with the syringe - air bubbles should not be visible. 4. Dry all parts. Needle assembly MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 72: Cleaning Liquid Sensor

5. Replace the silicone tube into middle slot of Liquid sensor and test under Maintenance - Check sensors- The Rinse and Drain should show two blue check marks. Check Liquid Sensor-Test. 10.4 - Pump tubes replacement MRN-164_2-EN Version 1.08 Starrsed TL... - Page 73 Remove the old tube from the pump as shown: ▪ Pull the tube from the connectors and install the new tube in the reverse order. ▪ Check that all connecting tubes and the tube cover are attached. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 74: Reagents Replacement

WARNING: Wrongly placed pickup tubes causes incorrect results or instrument malfunction. Make sure to place the appropriate level sensors in the containers by checking the colored labels/colored tubes matching the color codes on the containers. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 75 Reagents screen After each reagents change, the fluid system must be primed: 1. Select -> Maintenance Prime / Clean. 2. Perform the applicable prime step to fill the relevant tubes with reagent and remove air. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 76: Cleaning Touch Screen Display

Always spray the glass cleaner on a microfiber cloth or towel and then clean the touchscreen. Glass cleaner sprayed directly on the monitor could possibly leak inside a non-sealed unit and cause damage. Dirt and fingerprints do not affect the operation of a properly sealed touch display. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 77: Troubleshooting

If expired reagent has been used accidentally, the results obtained with these reagents may only be used, when the expiry date was not exceeded more than 30 days. is sensitive for bacterial growth. The solution should be discarded if it becomes turbid or infected. Diluent MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 78: Reagents Alarm

Normally the fill sequence takes about 3 seconds. However, if the fill sequence exceeds 10 seconds, a fill time-out error will be generated. The ESR analyser unit aborts the fill sequence and this error message will be shown on the display and reported. Fill time-out error may be caused by: MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 79: Hazy Reports

2. Check after a day's run if haziness is decreased. See History analyse results 3. When there are still many reports, it is recommended to clean the diluter system. See WI-240 Cleaning the diluent system MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 80: Leaking Pipettes

Tubes are replaced on track or rack without aspiration: Barcodes cannot be read (visible as red flags on tube in sample screen) No ESR is requested from LIMS Sampling with manual input does not start: MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 81: Robot Arm Error - General Procedure

ESR result is reported. Usually bubbles are caused by a leakage at the bottom of the pipette. If air bubbles are visible in the pipette, check the following : MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 82: Pipette Looks Like Zebra Crossing

▪ Inspect for any cracks or deep scratches in the base that holds the fill nozzle washer or O-ring. 3. Check for air in diluter system. 4. Check that the sample probe O-ring is not leaking. 5. Check transparent mixing- piece block for cracks. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 83: One Air Bubble About 5 Mm Under Meniscus

4...5mm at the bottom of each pipette. 2. Insufficient sample volume. ▪ Need more blood in the sample tube. One air bubble rising can result in ESR Error code 3. MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 84: Small Air Bubbles Rising In Pipette

E115: QC expired, not sampled! ▪ Check expire date The used Starrsed Control is out of date, no ESR result is given ▪ Use a new batch of Starrsed Control E116: QC is out of acceptable range! MRN-164_2-EN Version 1.08 Starrsed TL... - Page 85 The last QC sample was not within acceptable range or has no result ▪ Press "Accept" to continue sampling without performing a new QC, continuing could produce incorrect results. ▪ Press "Cancel" to return. Try new QC sample tube (normal samples will be finished) MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 86 QC result is not visible in QC History A specific QC result cannot be found in the list of results. Check Lab-ID link Deviating results Systematic QC errors with a shift in control values (QC results are out of range) MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 87 Systematic QC errors with a trend in control values (QC results out of the range or nearly out of the range) ▪ Irregular or insufficient maintenance can cause The measured control values change gradually upwards unnecessary QC errors and ESR errors/warnings or downwards. MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 88: Work Instruction Interrliner

Work instruction Interrliner Work instruction Interrliner Work instruction section MRN-164_2-EN Version 1.08 Starrsed TL... - Page 89 6. Ensure that the Interrliner is in Service mode, the status is also indicated with orange LED light. 7. Enable "Sample Mode On" 8. Ensure the needle is in "Down" position. 9. Select Maintenance; Prime/Clean, Fill & Clean. 10. Select button OK. Now the tube disk can be moved freely. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 90 15. When all the pipettes are filled, the needle goes back to the home position. 16. Open the hood and remove the adapter unit. 17. Solve any outstanding errors on the track information system. 18. Close the hood 19. Put the Interrliner back online. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 91 11. Check if the suction tube in the guide fork is free of clogging, remove clogging if needed. 12. Wipe stainless steel plates below the pipettes with disinfectant. 13. Close cover/front doors and activate the instrument in the LAS. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 92 Clean Fill nozzle Clean fill nozzle The use of a toothbrush and detergent is recommended. ▪ Carefully scrub the fill nozzle inner part. ▪ Use a tissue to dry the fill nozzle. Clean Liquid separator Removing MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 93 B. Use some acid free vaseline on the screw-thread of the glass jar. Cleaning C. A little silicon grease on the rim of separator will make the assembling and adjustment easier. D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 94 6. Check tubing from the syringe for trapped air bubbles. 7. Check Diluent syringe for trapped air bubbles. 8. If trapped air bubbles are found, go to tab click button and perform the [Maintenance], [Prime / Clean] [Prime function. Diluent] MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 95 10. Check if the suction tube in the guide fork is free of clogging, remove clogging if needed. 11. Wipe stainless steel plates below the pipettes with disinfectant. 12. Close cover/front doors and activate the instrument in the LAS. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 96 Clean fill nozzle and exchange O-ring Fill Nozzle 6. Clean fill nozzle The use of a toothbrush and detergent is recommended. ▪ Carefully scrub the fill nozzle inner part. ▪ Use a tissue to dry the fill nozzle. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 97 Work instruction Interrliner Clean liquid separator Removing A. Clean all parts with hot water and a brush. B. Use some acid free vaseline on the screw-thread of the glass jar. Cleaning MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 98 - Place red cap on dummy sample tube and turn adapter again, fill the adapter completely. Check for air in the dummy sample tube. 5. Ensure that the Interrliner is in Service mode, the status is also indicated with orange LED light. 6. Enable "Sample Mode On" MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 99 14. When all the pipettes are filled, the needle goes back to the home position. 15. Remove the adapter unit. Replace needle O-ring For assembling and disassembling the special needle holder tool TLAX110023 and spanner TLAX110026 are needed. Needle removal MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 100 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. O-ring replacement MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 101 4. Dry all parts. Needle assembly 1. Place the needle back on the instrument. 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 102 (shown in red circles). 5. Replace the silicone tube into middle slot of Liquid sensor and test under Maintenance - Check sensors-Check The Rinse and Drain should show two blue check marks. Liquid Sensor-Test. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 103 [Maintenance], [Prime / Clean] [Prime function. Diluent] 7. Clean needle top with disinfectant. 8. Wipe stainless steel plates below the pipettes with disinfectant. 9. Close cover/front doors and activate the instrument in the LAS. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 104 Clean fill nozzle and exchange O-ring Fill Nozzle 6. Clean fill nozzle The use of a toothbrush and detergent is recommended. ▪ Carefully scrub the fill nozzle inner part. ▪ Use a tissue to dry the fill nozzle. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 105 Work instruction Interrliner Clean liquid separator Removing MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 106 D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing Exchange peristaltic pump tubes New tube replacement: Pump A ESRI090902 Ø5x7 mm Pump B ESRI090903 Ø2.5x4.5 mm The pumps can be reached best via the lower cabinet part. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 107 Remove the old tube from the pump as shown: ▪ Pull the tube from the connectors and install the new tube in the reverse order. ▪ Check that all connecting tubes and the tube cover are attached. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 108 5. Ensure that the Interrliner is in Service mode, the status is also indicated with orange LED light. 6. Enable "Sample Mode On" 7. Ensure the needle is in "Down" position. 8. Select Maintenance; Prime/Clean, Fill & Clean. 9. Select button OK. Now the tube disk can be moved freely. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 109 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 110 5. Remove the O-ring QWLV050002. 6. If needed: Grease the outside of the inner needle base by removing TLAX090011 (use acid free vaseline). 7. Fit a new O-ring QWLV050002 carefully, and press the O-ring into the recess. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 111 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. Check/Clean liquid sensor The Liquid sensor on the Processing unit has to be checked on regular base and cleaned if necessary. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 112 (shown in red circles). 5. Replace the silicone tube into middle slot of Liquid sensor and test under Maintenance - Check sensors-Check The Rinse and Drain should show two blue check marks. Liquid Sensor-Test. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 113 Check liquid sensor Check liquid sensor: Press test. When test is finished, the OK signs are shown at Rinse and Drain if the liquid sensor is active. Exchange pinch valve Replace the pinch valve tube ESRI010246 MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 114 9. Close cover/front doors and activate the instrument in the LAS. Air filter replacement Air filter replacement QWLV040003 1. Pull both tube connectors out of the blue filter. 2. Place new blue filter 3. Reconnect the tube connectors on the filter MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 115 B. Use some acid free vaseline on the screw-thread of the glass jar. Cleaning C. A little silicon grease on the rim of separator will make the assembling and adjustment easier. D. If applicable replace the bacterial HEPA filter (For Maintenance Level 4: Exchange filter QWLV040002) Replacing MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 116 Work instruction Interrliner MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 117 2. Clean the bottle with new hot de-ionized water (80°C) 3. Reconnect the diluent container. 4. Perform another [Prime] 5. After the prime sequence stops press again to fill the dispenser system with the new diluent solution. [Prime] MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 118 1. Remove drip tray (metal sheet under needle unit, behind door) 2. Disconnect both tubes. 3. Loosen the knurled knob. 4. Remove the complete needle assembly outside the instrument. 5. Clean the needle with a disinfectant. O-ring replacement MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 119 4. Dry all parts. Needle assembly 1. Place the needle back on the instrument. 2. Fasten the knurled knob, do not fasten too tight 3. Connect both tubes to the needle. 4. Place drip tray. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 120 Work instruction Interrliner MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 121: Appendix For Interrliner

Appendix for Interrliner Appendix for Interrliner Appendix section MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 122: Appendix - Maintenance Schedule

91.000 Replace Fill nozzle O-ring QWLV050004 Replace bacterial air filter (HEPA) QWLV040002 Replace peristaltic tube assembly (2x) ESRI090902/903 Run Fill and clean Check/Clean Liquid sensor Replace O-ring inner needle QWLV050002 Replace waste pump tube QWLV090011 MRN-164_2-EN Version 1.08 Starrsed TL... - Page 123 Note: Periodical Maintenance Kit TLAX110985, containing all parts for yearly maintenance Two years Periodical Maintenance Kit: ESRI120906 ESRI070924 Fill tube assembly to regulator ESRI070924 Fill tube assembly from regulator QWLV030021 Diluter Syringe QWLV080002 Quad Ring MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 124: Spare Part List Starrsed Tl

Appendix for Interrliner 13.2 - Spare part list Starrsed TL The Interrliner is delivered with a complete accessories kit ESRI110994. This reference list is for article order numbers only. Since 01-01-2020 new ordering numbers are used by RR Mechtronics for all spare parts and consumables. - Page 125 Appendix for Interrliner TLAX079200 STLAX079200 Tubing set Starrsed TL MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 126: Appendix - Error List Interrliner

• Check diluent flow sensor E12: Dilution error: wrong or no Diluter malfunction diluent flow. Check the diluter! • Check tubes diluter system MRN-164_2-EN Version 1.08 Starrsed TL... - Page 127 See E30 sending 'Sample data record'! time limit after 3 attempts. E35: No response from host after No response from Host within a certain See E30 sending 'Sample flag record'! time limit after 3 attempts. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 128 • Check communication cable E221: No response from LAS system! LAS system did not response to a message from Starrsed TL between Starrsed TL and the LAS system. • Check serial port settings. E222: NACK received from LAS system LAS system rejected “Status” message See E221 after sending "Status"...

- Page 129 • Faulty rack feeder. • Faulty TLAX PCB(s). • Gripper blocked. E239: TLAX gripper timeout! The gripper did not close or open within a certain time limit • Faulty gripper. • Faulty TLAX PCB(s). MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 130 Incorrect tube (e.g. diameter too small). • Faulty tube holder. E247: Not possible to place tube in rack. Original position in rack not empty! E248: Connection with TSM server lost! E249: CAN bus connection with AccesPoint lost! MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 131 • • Clear error to see specific E257: Error while picking up a tube! Something went wrong while picking up a tube. Clear this error to see the error. specific error prior to this error. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 132 E266: Tube not present at location After placing a tube, the tube is not after placing! present at the concerning location. the concerning location Tube maybe lost or still in the gripper. • Tube lost. • Tube stuck in gripper. MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 133 Sample mode stops. • Check tubing • Check Liquid sensor E272: Needle system failure. Liquid Drain failures detected during drying. detected in needle tube before Sample mode stops. • Check tubing sampling! MRN-164_2-EN Version 1.08 Starrsed TL...

-

Page 134: Appendix - List Of Supported Tube Types Interrliner

Appendix for Interrliner 13.4 - Appendix - List of supported tube types Interrliner Supported tube types Note: Sarstedt Monovette is currently not supported. This will be available in future updates MRN-164_2-EN Version 1.08 Starrsed TL... -

Page 135: Glossary Of Terms

Interrliner to the HOST. Only sample results and result related messages are send. is short for Work Instruction and is used with an index number for a range of work instructions. MRN-164_2-EN Version 1.08 Starrsed TL... - Page 136 ..EQAS......MRN-164_2-EN Version 1.08 Starrsed TL...

- Page 137 ....Reporting......MRN-164_2-EN Version 1.08 Starrsed TL...

Need help?

Do you have a question about the Starrsed TL and is the answer not in the manual?

Questions and answers