Table of Contents

Advertisement

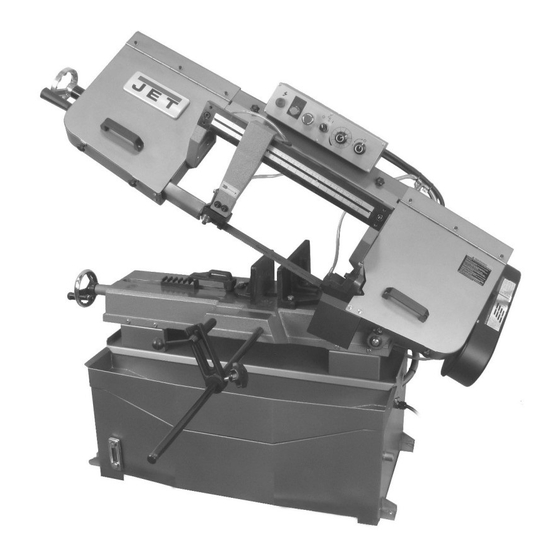

Operating Instructions and Parts Manual

Four-speed Pulley Horizontal Band Saw

Models HBS-916, HBS-1018

HBS-916 shown

For HBS-916 and HBS-1018

manufactured 01-2020 and later

JET

427 New Sanford Road

LaVergne, Tennessee 37086

Ph.: 800-274-6848

www.jettools.com

1

This .pdf document is bookmarked

Part No. M-414468

I

Revision

10/2019

Copyright © 2019 JET

Advertisement

Table of Contents

Need help?

Do you have a question about the HBS-916 and is the answer not in the manual?

Questions and answers