Jet HBS-1018W Operator's Manual

Jet tools operator's manual bandsaws hbs-916w & 1018w

Hide thumbs

Also See for HBS-1018W:

- Operating instructions and parts manual (32 pages) ,

- Brochure (56 pages) ,

- Operating instructions manual (18 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Jet HBS-1018W

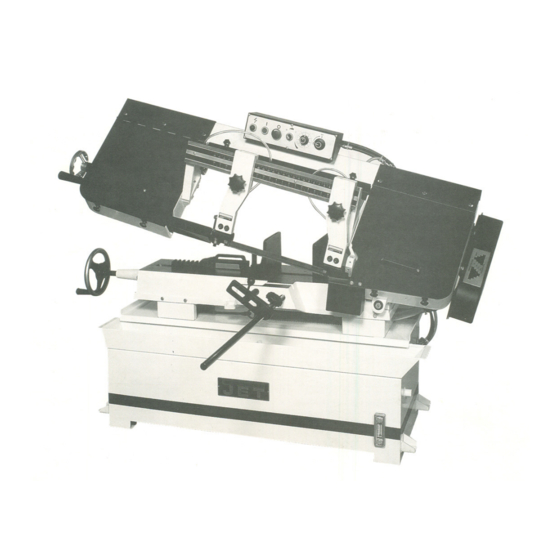

- Page 1 ..JET OPERATOR'S MANUAL HBS-916W & 1018W Bandsaws JET EQUIPMENT &.TOOLS, INC. A WMH Company www.jettools.com EQUIPMENT & TOOLS P.O. BOX 1349 Auburn, WA 98071-1349 e-mail jet@jettools.com ------- 253-351-6000 Fax 253-939-8001 M-414468 2/99...

- Page 2 Important Information 1-YEAR LIMITED WARRANTY REPLACEMENT PARTS Replacement parts for this tool are available directly form JET Equipment & Tools. To place an order, call 1-800-274-6848. Please have the following information ready: 1. Visa, MasterCard, or Discover Card number 2. Expiration date 3.

- Page 3 WARNING Read and understand the entire instruction manual before attempting assembly or operation. All JET bandsaws are designed and intended for use by properly trained and experienced personnel only. If you are not familiar with the proper and safe operation of a bandsaw, do not use until proper training and knowledge have been obtained.

-

Page 4: Table Of Contents

..0..0 ..0 ..0 0 0..0 0.0...0 0"...0..0,,0 ..0 """"""""" """"""","""""""'" 00"""..0...0.0.0..0 ""0 000""""""""""""0 HBS-1018W ..414473 10" 8-1/2" 2" x 18" - 10" x 15" 10" x 8-112" 1.0" x 0.032" x 130" 13" SFPM 2HP, 1Ph, 230V .230V only 43"... -

Page 5: Uncrating And Cleanup

Remove all bolts attaching machine to shipping base. Leave packing material between vice clamps and saw head intact until bandsaw has been lifted to its final position. Clean all rust protected surfaces with kerosene or diesel oil to remove protective coating. - Page 6 Remove two hex cap bolts and washers (A, Fig. 3) from the right side of the saw arm. Slide belt cover (8, Fig. 3) around pulley shafts and attach to saw with two hex cap bolts and two washers.

-

Page 7: Electrical Connections

115 volt from the factory. The HBS1018Wis rated at 230V, 1Ph. only. Confirm power available at the saw's location is the same as the saw is wired. To switch the HBS-916Wfrom 115V to 230V, the following items will have to be... -

Page 8: Prior To Operation

Select proper speed and feed rate for material being cut. See speed selection chart found in the enclosed "Guide to Bandsawing" booklet supplied with this saw. Material to be cut must be securely held in vise. Check to see that coolant level is adequate and turn on coolant pump if material to be cut requires it. -

Page 9: Adjusting Vise Square To Blade

Adjusting Vise Square to the Blade Disconnect the machine from the power source. Place a machinist's square on the table against the blade and the vise. The square should lie along the entire length of the vise and blade without a gap. If adjustment is necessary, loosen bolts holding the vise and adjust vise so square lines up properly. -

Page 10: Adjusting Feed Rate

Insufficient pressure rapidly dulls the blade. Material chips or shavings are the best indicator of proper speed and pressure. The ideal chip is thin, tightly curled, and warm to the touch. -

Page 11: Blade Tracking Adjustment

Connect machine to power and run freely for approximately two minutes. 12. Turn power off and re-check blade tension and wire brush adjustment. If further adjustment is necessary, disconnect saw from power source, make adjustments, and re-connect to power. Blade Tracking Adjustment Blade tracking has been set at the factory and should require no adjustment. -

Page 12: Automatic Shut-Off Adjustment

(A - Fig. 9). Note: Left guide roller has two hex socket cap screw; right guide roller has one (HBS- 916Wonly) The HBS-1018W has two screws on each guide.. Move guide seat (B) up or down until a clearance of .003"... -

Page 13: Guide Roller Adjustment

Connect machine to the power source. Bow Weight Adjustment Bow weight is one of the most important adjustments of the saw. If the bow weight is not set properly, one can expect poor performance, crooked cuts, tooth stripping, stalling, and the blade popping off the blade wheels. -

Page 14: Viseadjustment

The scale should indicate approximately 18-20 Ibs. for the HBS-916W. For the HBS-1018W, it should indicate 22-24 Ibs. Adjust tension to approximately 18-20 Ibs.(or 22-24 Ibs.) by turning the adjustable C-bolt found at the end of the coil spring on the rear of the bandsaw. - Page 15 To check level of gear box lubricant, place saw arm in down position and allow a few minutes to pass so that oil drains down. Check level in sight glass on side of gear casing. Correct level is the dot in the middle of sight glass.

-

Page 16: Parts Breakdown

<t" ---~ 69-( < "C "C 12161 ,_./'-~ W)JiJJ~... - Page 17 175111 J:IJ < 121(3) < & ~i"" 9O(" ) ('f)

- Page 18 171, &~ HBS 916W 112(41 113141 1 14 ) 1084010914) <1( " O9-1(4 """" > ""'" 96-1...

-

Page 19: Parts List

Parts List for the HBS-916W/-1018W Bandsaws Index Part Description HBS916W-01 Base (SIN 8081108 and lower) HBS916W-01A Base (SIN 8081109 and higher) HBS1018W-01 Base (SIN 808718 and lower) HBS1018W-01A Base (SIN 808719 and higher) TS-1492071 ,... Hex Cap Bolt TS-1540081 Hex Nut HBS916W-CP Coolant Pump TS-1531051. - Page 20 Lock Washer TS-1503011 Hex Socket Cap Bolt 69-1 ,HBS916W-69-1 , Nut HBS916W-70 Electrical Panel Cover (SIN 8081108 and lower HBS-916W) HBS916W-70 " Electrical Panel Cover (SIN 808718 and lower HBS-1018W) M12x40 S-22 M8x25 M8x20 M6x12 S-20 S-25 M10x30 " M1Ox30 M12x50 "...

- Page 21 HBS916W-70A Electrical Panel Cover HBS916W-70A Electrical Panel Cover (SIN 808719 and higher HBS-1018W) HBS916W-71 Fuse Block HBS916W-71A Fuse 3A .. HBS916W-72B Magnetic Switch HBS1018W-72 Magnetic Switch HBS916W-72-1 Contactor (main motor) HBS916W-72A-1 Overload Relay HBS916W-72A-2 Contactor (pump) HBS916W-73A Transformer HBS1 018W-73...

- Page 22 HBS916W-124 Guide Bracket -left HBS916W-124A Guide Bracket Assembly -left HBS1018W-124A Guide Bracket Assembly -left HexSocketCapScrew(HBS-916W) 124-1 ...TS-1504031 TS-1504031 Hex Socket Cap Screw (HBS-1018W) """"'''' TS-1540061 Washer BB-6201W Ball Bearing HBS916W-127 Eccentric Sleeve (outside) (HBS916W) HBS1 018W-127 EccentricSleeve(outside)(HBA 1018W) 127-1 HBS916W-127-1 Sleeve (inside-not show) (HBS916W) .HBS1018W-127-1...

- Page 23 Hex Socket Cap Screw TS-1503071 Hex Socket Cap Screw 130-1 ...TS-1550041 Washer HBS916W-131 Blade Guide TS-1504081 Hex Socket Cap Screw (HBS-916W) TS-1504081 Hex Socket Cap Screw (HBS-1018W) TS-1551081 Lock Washer (HBS-916W) TS-1551081 Lock Washer (HBS-1018W) 133-1 ...TS-1550081... Washer (HBS-916W) TS-1550081... Washer (HBS-1018W) HBS916W-134...

- Page 24 160-1 ... HBS916W-160-1 Clamp 160-2 ...TS-1551 041 Lock Washer 160-3... TS-1482021 Hex Cap Bolt HBS916W-161A Power Indicator Light HBS916W-162 Start Switch HBS916W-163 ""'''''''''''''' Stop Switch HBS916W-164 Pump Switch HBS916W-165S Feed HBS916W-165S-1 Speed Control Valve HBS916W-165S-1-K Knob for Speed Control Valve HBS916W-165S-K Knob for On/Off Valve HBS916W-166...

- Page 25 HBS916W-208 Hose TS-1550071 Washer HBS1018W-214 Clamp 215 ...". HBS916W-215 Cu Connector HBS1018W-215 Cu Connector TS-1504051 Hex SocketCap Screw HBS916W-217 SlideBracket HBS916W-218 LeadScrewBracket HBS916W-219 Rack Block HBS1018W-219 Rack Block. HBS916W-220 Rack HBS1018W-220 Rack. HBS916W-221 M8x25...

- Page 26 w--~ G> ""'I 't:I u, -'jf ~~\~ >< :t> C" '< +::0 ~--~ +::0...

- Page 27 Parts List For The Gear Speed Reducing Box Assembly Index Part Description HBS916W-94-01 OIL .SEAL HBS916W-94-02 BEARING HBS916W-94-03 BEARING HBS916W-94-04 SHAFT '"'''''''''''''''''''''''''''''''''''''''''''''''''''''''' HBS916W-94-05 HBS916W-94-06 GEAR WHEEL HBS916W-94-07 BEARING HBS916W-94-08 OUTPUT SHAFT COVER HBS916W-94-09 OUTPUT HEX CAP SCREW HBS916W-94-10 INPUT HEX CAP SCREW HBS916W-94-11 INPUT SHAFT COVER HBS916W-94-12...

-

Page 28: Panel Layout

Electrical Schematic for the HBS-916W STOP Selec-Sw Pump AC 110/220V 220V Electrical Panel Layout 0 4-1 T U, v, W, U, v, W, a 1 2 3 4 51 0 1 15V 11 5V 230V R 230 0 115 TR 11OV /220V U2V2 U, V,... -

Page 29: Electrical Schematic

Electrical Schematic STOP AC 1~ 220V 110V 220V Electrical Panel 0 Lt-i T U, V, w, U, v, W, 0 1 2 3 4 51 230V R 230 0 11 5 u. v. for the HBS-1 a 18W Selec-Sw Pump Layout 0 11 5V U,V,...

Need help?

Do you have a question about the HBS-1018W and is the answer not in the manual?

Questions and answers