AUTOFLAME Mini Mk8 M.M. Installation & Commissioning Manual

Hide thumbs

Also See for Mini Mk8 M.M.:

- Installation and commissioning manual (125 pages) ,

- Manual (150 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AUTOFLAME Mini Mk8 M.M.

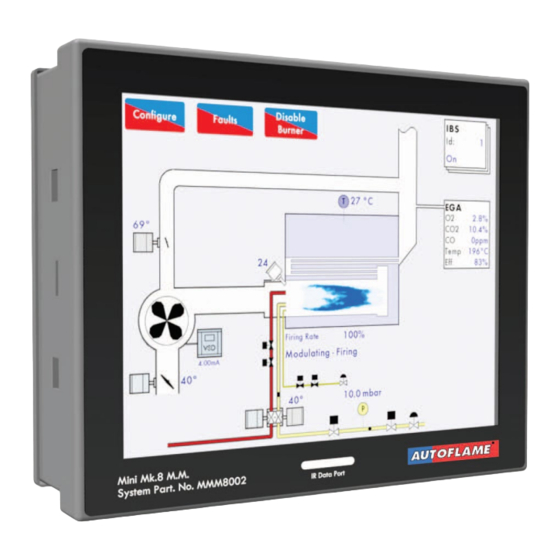

- Page 1 Mini Mk8 M.M. Installation & Commissioning Guide...

- Page 3 Department: This manual and all the information contained herein is copyright of Autoflame Engineering Ltd. It may not be copied in the whole or part without the consent of the Managing Director. Autoflame Engineering Ltd’s policy is one of continuous improvement in both design and manufacture.

-

Page 5: Important Notes

Autoflame product range, i.e. combustion, electrical and control. The sale of Autoflame’s systems and equipment referred to in this Manual assume that the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high... -

Page 7: Table Of Contents

Adjusting the Servomotor Potentiometer............... 44 3.3.2 Servomotor Feedback Voltage ..................45 3.3.3 Servomotors – Direction Change .................. 46 3.3.4 Servomotors with Autoflame Valves ................47 Commissioning Fuel and Air Positions ................... 48 3.4.1 Starting Commissioning ....................49 3.4.2 Enter CLOSE Position ....................50 3.4.3... - Page 8 3.4.7 Commissioning VSD ...................... 56 3.4.8 Set GOLDEN START Position ..................57 3.4.9 Set FGR START Position ....................59 3.4.10 Set HIGH Position ......................61 3.4.11 Set INTER Position......................62 3.4.12 Set INTER or START Position ..................63 3.4.13 Save Commission ......................64 Fuel Flow Commissioning ......................

-

Page 11: Dimensions And Wiring

1 Dimensions and Wiring DIMENSIONS AND WIRING Mini Mk8 MM 12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 1... -

Page 12: Fixing Holes And Dimensions

1 Dimensions and Wiring 1.1.1 Fixing Holes and Dimensions Page 2 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019... -

Page 13: Wiring Schematic

1 Dimensions and Wiring Wiring Schematic Fuse Terminals Protected Mains voltage output terminals 57 – 63 Low voltage terminals and switched neutral outputs 12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 3... -

Page 14: Electrical Specifications

1 Dimensions and Wiring Electrical Specifications 1.3.1 Classifications Classification according to EN298 Mains Supply: 230V, +10%/-15%} 47-63 Hz, unit max. consumption 140W 120V, +10%/-15%} Climate: Min. Temperature C (32 Recommended Temperature Less than 40 C (104 Max. Temperature C (140 Humidity 0 to 90% non-condensing Storage:... -

Page 15: Cable Specifications

STC OS1P24 Samples are available upon request. Low voltage and data cable can be ordered directly from Autoflame Engineering, please contact Autoflame Sales Department. When using a VSD, please review the manufacturer’s guidelines on installations to prevent EMC including the recommendations for reactors and filters. -

Page 16: Terminals Description

Digital communications connections to an Autoflame IR scanner (MM70017), Autoflame air pressure sensor and/or Autoflame gas pressure sensor 0V supply to an Autoflame temperature or pressure detector or 0-10V external modulation input Signal input from an Autoflame temperature or pressure detector or 0-10V external... - Page 17 1 Dimensions and Wiring Connections to a flame rod Mains voltage input – burner on/off signal, running interlock circuit Mains voltage input – air proving switch Mains voltage input - proving circuits, e.g. gas valve proof of closure Mains voltage output – call for heat Mains voltage output –...

-

Page 18: Connection Between Mini Mk8 Mm And Mk8 Ega

1 Dimensions and Wiring Connection Between Mini Mk8 MM and Mk8 EGA EVO Page 8 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019... -

Page 19: Connection Between Mini Mk8 Mm And Mk7 Dti

1 Dimensions and Wiring Connection Between Mini Mk8 MM and Mk8 DTI 12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 9... -

Page 20: Sequencing Connection Diagram

1 Dimensions and Wiring Sequencing Connection Diagram Page 10 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019... -

Page 21: Options And Parameters

Options Note: The Options and Parameters must only be changed by factory trained and certified technicians who have a thorough appreciation of the Autoflame combustion systems and the combustion process in general. Any person changing these set-ups who does not have the correct factory training and understanding of these settings/adjustments may place themselves and others in a potentially dangerous situation. - Page 22 2 Options and Parameters Figure 2.1.i Enter Password “Enter Commissioning Password” is displayed. Use the keypad to enter the password, then press . Press on to change the value of an incorrect entry. Note: The commissioning password should not be distributed to anyone who is not a factory trained and a certified engineer.

- Page 23 2 Options and Parameters Figure 2.1.ii Commission Mode The “Commission Mode” screen gives information on which fuel is selected, how many times the unit has been commissioned, serial number, bootloader, and BC, MM and Display software. In the Commission Mode screen, all the options/ parameters can be adjusted, the gas pressure sensor can be commissioned, the commissioned IR data can be uploaded, the fault logs and system diagnostics can be viewed.

- Page 24 2 Options and Parameters Figure 2.1.iii Options Any number of options and parameters can be changed at one time. By pressing MM, PID, EGA, DTI or BC at the bottom of the screen, the options/ parameters can be grouped together by feature. When the changes have been made to suit the application’s needs, press Exit to go back to the Commission Mode screen.

- Page 25 2 Options and Parameters Option Default Range Description Boiler Temperature/Pressure Sensor Type Terminals 37, 38, and 39 are used for the load detector. Temperature MM10006 0 – 400 C (0 – 752 Low pressure MM10010 0.0 – 3.4 Bar (0.0 – 50.0 PSI) Medium pressure MM10008 0 –...

- Page 26 2 Options and Parameters Option Default Range Description Integral Time Every ‘n’ seconds, 10% of the present offset from the required setpoint is added or subtracted when below or above the setpoint, respectively, to the present proportional value. The value of ‘n’ is the number of seconds set in this option;...

- Page 27 2 Options and Parameters Option Default Range Description EGA Functionality For settings 2 or 3, the E.G.A will trim on the channel 2 air damper, once trim data has been added. If option 12 is set to 0 or 1, then trim can be added at a later date by changing this to 2 or 3 in online changes, going through single point change, and added trim data for each fuel-air position.

- Page 28 2 Options and Parameters Option Default Range Description Upper Limit Offset If the current CO value is above this offset limit from the commissioned value, an alarm/ warning will occur (see option 13), for option 12 set to 3. Disabled 1 –...

- Page 29 2 Options and Parameters Option Default Range Description Golden Start Golden start allows an optimum ignition position to be set in the fuel-air curve, which is not necessarily low flame or part of the standard modulating index. Parameter 15 sets how long golden start position is maintained and from which point to start counting down.

- Page 30 2 Options and Parameters Option Default Range Description Derivative Time The time taken to add/ remove an additional 10% to the firing rate based on the actual value and the required value. Disabled 1 – 200 Seconds Derivative Deadband This deadband is the margin above and below the required setpoint in which no derivative control occurs.

- Page 31 2 Options and Parameters Option Default Range Description Cold Start Routine On burner start-up, if the actual value is at 30% or below of the required setpoint, then the burner will be held at low fire for the number of minutes set in this option.

- Page 32 2 Options and Parameters Option Default Range Description Alarm Output Operation (Terminal T79) This is a switched neutral output to select how the alarm function operates. Relay normally off, on during alarm Relay normally on, off during alarm Fuel Flow Metering Fuel flow metering determines the firing rate.

- Page 33 2 Options and Parameters Option Default Range Description Channel 2 Purge Position Channel 2 to purge position Channel 2 to remain closed for purge Channel 3 Purge Position Channel 3 to purge position Channel 3 to remain closed for purge Unused Unused Unused...

- Page 34 2 Options and Parameters Option Default Range Description Channel 1 Servo Control Method Autoflame servomotor, 0.1 degree control Autoflame servomotor, 0.5 degree control Industrial servomotor, 0.1 degree control Industrial servomotor, 0.5 degree control Channel 2 Servo Control Method Autoflame servomotor, 0.1 degree control Autoflame servomotor, 0.5 degree control...

- Page 35 2 Options and Parameters Option Default Range Description VSD Channel 5 Feedback Fault Tolerance This is used to check that the feedback varies from high to low fire. For example, if high fire feedback is 20mA and this option is set to 4%, the tolerance that is allowed while firing is ±0.8mA.

- Page 36 2 Options and Parameters For safety reasons, options 110 – 160 also have to be entered in as Parameters. It is the responsibility of the commissioning engineer to ensure that all settings are set in accordance with the appropriate standards, local codes and practices. If options 110 – 160 are not identical with the parameters 110 – 160, then the MM will go straight to Commissioning Mode and an option/ parameter conflict message will appear.

- Page 37 2 Options and Parameters Option Default Range Description Post-Purge Time If set, a post-purge will occur after a normal burner shutdown. The timer begins once all channels have gone to their post-purge positions. The flame is not checked during post-purge. See option/ parameter 135 for NFPA post-purge.

- Page 38 Fuel Pressure Sensor Mode – Fuel 1 For setting 1, valve proving and pressure limits are checked by an Autoflame gas sensor or valve proving by a low pressure switch. For setting 2, pressure limits are checked by the gas sensor. See option/parameters 136 and 137 for gas pressure limits.

- Page 39 2 Options and Parameters Option Default Range Description Gas Valve Proving Time This is the time period for when both gas valves are closed to detect a change in air pressure for the ‘VPS air proving’ phase, or change in gas pressure for ‘VPS gas proving’...

- Page 40 This is the minimum air pressure that must be detected by the MM during purge, when using an Autoflame air pressure sensor. If this is set to 0, then MM will look for the minimum air pressure set in option/ parameter 149.

- Page 41 This is the minimum air pressure that must be detected by the MM during normal firing and during purge when option/ parameter 141 is set to 0, when using an Autoflame air pressure sensor. See option/ parameter 146 for air pressure display units. If post-purge is enabled in option/parameter 118 then the purge air threshold cannot be set higher than the running threshold in option 149.

- Page 42 2 Options and Parameters Option Default Range Description Terminal T81 Function For setting 1, terminal 81 acts as an input for a mechanical end stop. It must be made for the whole of the timed purge and post purge phases otherwise a lockout is generated.

-

Page 43: Parameters

2 Options and Parameters Parameters Please refer to section 2.1 Options for instructions on accessing and changing parameters. Figure 2.2.i Parameters Figure 2.2.i shows the Parameters screen. Like with the Options, the Parameters can be easily viewed by feature by pressing the tabs MM, PID, EGA, DTI and BC. A full list of parameters are detailed on the next pages. - Page 44 2 Options and Parameters Para- Default Range Description meter Sequence Scan Time Set When Units Goes Offline If a sequenced MM drops out of the sequence loop, there is a time delay before the next scan time. 0 – 20 Minutes Unused Number of Boilers Initially On...

- Page 45 2 Options and Parameters Para- Default Range Description meter Trim Reset Angular Rate This is the change time in the fuel valve angle per minute that will reset the trim correction. 0 – 900 0.0 – 90.0 degrees per minute Golden Start Time This is the time period for how long the servomotors and VSDs are held at the golden start position from the point of main flame, see option 29.

- Page 46 2 Options and Parameters Para- Default Range Description meter Absolute High Setpoint The MM will shut down the burner or inhibit it from starting if the load (pressure or temperature) reaches this value regardless of any other setpoint in use. This setpoint will also operate in Commission Mode. If this setpoint is reached during Single Point Change, the MM will exist Single Point Change and offer to save any current changes.

- Page 47 2 Options and Parameters Para- Default Range Description meter Integral Band This is the percentage of the proportional band over which the integral control is active. 0 – 100 0% - 100% Unused Unused Unused External Load Detector – Number of Decimal Places This affects parameter the external load detector maximum and minimum values set in parameters 53 and 55.

- Page 48 2 Options and Parameters Para- Default Range Description meter Backlight On Time If the screen is not pressed and this timer elapses, the backlight will dim. Disabled 1 – 1800 Seconds Hot Water Sequencing For setting 0 the boilers, the lag boilers will be off. For setting 1, the lag boiler will operate as steam sequencing, as set in option 41.

- Page 49 2 Options and Parameters Para- Default Range Description meter Unused Display Diagnostic Values Disabled Enabled Unused Modulation Exerciser Period If the modulation exerciser period is enabled, then the MM will repeatedly run between high fire and low fire. This value sets how long the MM will remain at the high fire and low fire positions.

- Page 50 2 Options and Parameters Para- Default Range Description meter Exhaust Temperature Upper Limit Offset If the current exhaust temperature value is above this offset limit from the commissioned value, an EGA error will occur, for option 12 set to 3. See options 13 and 65.

- Page 51 2 Options and Parameters Para- Default Range Description meter Gas Pressure Warning Upper Offset This is an offset upper limit from the commissioned gas pressure, see option/parameter 131 for the gas pressure display units. These limits are also tested during main flame proving. See option/ parameter 125 and 126 to enable the pressure limits.

-

Page 52: Commissioning Fuel-Air Curve

Micro-Modulation system must have an adequate understanding of combustion plant. In the wrong hands hazardous conditions could be made to exist. The Autoflame products must only be installed, set up, commissioned and adjusted by an Autoflame certified technical engineer. -

Page 53: Installation Checks

The reliability of the equipment may be impaired if used in environments where strong electromagnetic fields exist e.g. if the equipment is installed in a boiler house where radio systems exist then additional EMC (Electro Magnetic Compatibility) measures may have to be considered. Please contact Autoflame for more information. -

Page 54: Servomotors

3 Commissioning Fuel-Air Curve Servomotors Autoflame supply three standard sizes of servomotors – small, large and industrial, which can be used for all channels. Autoflame fuel valves require small or large servomotors only. Both small and large servomotors can be configured to drive clockwise or counter clockwise to open a valve or damper. -

Page 55: Servomotor Feedback Voltage

For fuel servomotors carry out the following procedure: On Autoflame gas, oil and gas/oil piggy-back valves it is necessary to remove the servomotor. Manually position the oil/gas valve slot to its closed position. Observe the position of the drive pin on the servomotor. -

Page 56: Servomotors - Direction Change

3 Commissioning Fuel-Air Curve 3.3.3 Servomotors – Direction Change Page 46 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019... -

Page 57: Servomotors With Autoflame Valves

3 Commissioning Fuel-Air Curve 3.3.4 Servomotors with Autoflame Valves On threaded valves, the pin on the top of the valve is 90 degrees opposite from the position of the butterfly valve. On flanged valves, the pin on the top of the valve is in line with the position of the butterfly valve. -

Page 58: Commissioning Fuel And Air Positions

3 Commissioning Fuel-Air Curve Commissioning Fuel and Air Positions The following procedure is shown for commissioning the EGA with option 12 set to 0 (Not Optioned), or 1 (Monitoring only). Trim can be added later by setting option 12 to 2 (Applies trim) or 3 (Applies trim, combustion limits tested). -

Page 59: Starting Commissioning

3 Commissioning Fuel-Air Curve 3.4.1 Starting Commissioning Figure 3.4.1.i Starting Commissioning Once the options and parameters have been set, press on the Commission Mode screen in Figure 2.1.ii. If the MM has already been commissioned, then press on the Home Display. Figure 3.4.1.i shows the Commissioning screen. -

Page 60: Enter Close Position

3 Commissioning Fuel-Air Curve 3.4.2 Enter CLOSE Position Figure 3.4.2.i Enter CLOSE Position The MM is now waiting for the CLOSE position to be entered. Press to enter this position. Note: No error checking of the servomotors is enabled at this stage, therefore, do not to drive the servomotors/ dampers beyond any mechanical limitations that may be present on the damper/valve. -

Page 61: Enter Open Position

3 Commissioning Fuel-Air Curve 3.4.3 Enter OPEN Position Figure 3.4.3.i Enter OPEN Position Press and then drive the fuel and air servomotors to their OPEN position. The button hold facility allows multiple channels to be driven up or down at the same time. Press on the blue circles next to the channels;... -

Page 62: Enter Start Position

3 Commissioning Fuel-Air Curve 3.4.4 Enter START Position Figure 3.4.4.i Enter START Position Once the system has purged (see options/ parameters 75 and 112), the message ‘Set up START Position’ will display on the MM. Press and drive the servomotors to their START position. To enter a fuel START position which is less than 10 degrees below the OPEN position, you must drive the servomotor below this band, and then back open. -

Page 63: Phase Hold

3 Commissioning Fuel-Air Curve 3.4.5 Phase Hold When the system is in commissioning mode only, the Phase Hold feature enables the commissioning engineer to pause the ignition sequence of the burner to make adjustments to the start gas flame if needed. -

Page 64: Add Trim Data During Commissioning

3 Commissioning Fuel-Air Curve 3.4.6 Add Trim Data During Commissioning If the option 12 is set to 2 or 3 during commissioning, then when setting the servomotors for the HIGH, INTER, GOLDEN START, FGR START and START positions, the trim data will also need to be saved for the fuel rich and air rich trim conditions. - Page 65 3 Commissioning Fuel-Air Curve Figure 3.4.6.ii After you press to save those servomotor positions, the EGA will carry out its fuel rich and air rich trim. Once these trim values have been saved, the system will continue with the commissioning process. Note: If the MM has not been enabled for trim during commissioning, this can be added later by setting option 12 for trim, and going into Single Point Change to add trim to each point, see section 3.7.

-

Page 66: Commissioning Vsd

3 Commissioning Fuel-Air Curve 3.4.7 Commissioning VSD Figure 3.4.7.i Commissioning VSD Press on the VSD tab to view the VSD output and input signal during commissioning. If the MM has been enabled with VSD for commissioning and then disabled, or vice versa, a conflict message will appear ‘VSD configuration does not match commissioning.’... -

Page 67: Set Golden Start Position

3 Commissioning Fuel-Air Curve 3.4.8 Set GOLDEN START Position If Golden Start has been enabled in option 29 on a new system which has not been commissioned, the message ‘Set Golden Start Position’ will display after the START position has been entered. Figure 3.4.8.i Set GOLDEN START Position Press to enter the GOLDEN START position. - Page 68 3 Commissioning Fuel-Air Curve Position’ will appear; press to enter the stored GOLDEN START position and continue with the full commissioning procedure. in section 3.4.9 if FGR START has been enabled, or 3.4.10 if no FGR START is enabled. Alternatively, to just add the Golden Start position and not go through the whole commissioning procedure, press on the home screen, and once the system has gone through its internal relay tests the message ‘Select Commissioning’...

-

Page 69: Set Fgr Start Position

3 Commissioning Fuel-Air Curve 3.4.9 Set FGR START Position Flue Gas Recirculation (FGR) is a method whereby a quantity (approximately 15%) of the boiler flue gases are fed back to the burner and mixed with the combustion air. The virtue of FGR is the reduction of NOx gases. - Page 70 3 Commissioning Fuel-Air Curve Enabling FGR Start on a Commissioned System If the system has already been commissioned without FGR Start enabled, go into Commission Mode and set option 48, 49 or 50 to enable FGR Start. The forced commission message will appear as ‘FGR optioned but not commissioned.’...

-

Page 71: Set High Position

3 Commissioning Fuel-Air Curve 3.4.10 Set HIGH Position Figure 3.4.10.i Set HIGH Position Once all the START, GOLDEN START and FGR START positions have been entered, the message ‘Set HIGH Position’ will appear. Press and drive the servomotors (and VSD if optioned) to the HIGH position by opening the air damper and fuel valve some degrees alternatively, so that more fuel is added gradually. -

Page 72: Set Inter Position

3 Commissioning Fuel-Air Curve 3.4.11 Set INTER Position Figure 3.4.11.i Set INTER Position Once the HIGH position has been entered, the message ‘Set INTER Position’ will appear. Press to drive the servomotors (and VSD) to the first INTER position. The message ‘Move fuel and air positions’... -

Page 73: Set Inter Or Start Position

3 Commissioning Fuel-Air Curve 3.4.12 Set INTER or START Position Figure 3.4.12.i Set INTER or START Position Once the minimum 3 INTER points have been added, you will be prompted to either enter another INTER point or the START/LOW FIRE position. Press to drive the servomotors (and VSD) to the START/ LOW FIRE position, and then press... -

Page 74: Save Commission

3 Commissioning Fuel-Air Curve 3.4.13 Save Commission 3.4.13.i Save Commission Once the START position has been entered, press to store this commission curve. The message ‘Commission Complete’ will appear and press to go normal firing mode. If the burner has been previously commissioned then the new saved curve will overwrite the previous data for the fuel selected. -

Page 75: Fuel Flow Commissioning

3 Commissioning Fuel-Air Curve Fuel Flow Commissioning Figure 3.5.i Home Screen – No Fuel Flow Data Once the burner has been commissioned, fuel flow metering must be commissioned to calculate the firing rate. The fuel flow metering is used to rate the size or burner and calculate the firing rate. If fuel flow metering is not commissioned and sequencing is optioned, then MM will assume a default burner rating which is based on the fractional fuel valve angle. - Page 76 3 Commissioning Fuel-Air Curve For example: Burner Rating: 5.4MW; Turndown Ratio: 5:1. 5.4 − ( = 0.48 Giving the range (5.40, 4.92, 4.44, 3.96, 3.48, 3.00, 2.52, 2.04, 1.56, 1.08) Fuel flow metering serves to totalise the amount of fuel being used at each position. If any changes are made to the curve through Single Point Change, then fuel flow will need to be re-commissioned.

- Page 77 3 Commissioning Fuel-Air Curve Figure 3.5.iii Fuel Flow Commissioning There are 10 points which need to be entered across the commission curve from low fire to high fire, with high fire being point 1, and low fire point 10. Type in the heat value using the keypad and press the return key to save that fuel flow point. Note: The servomotors will drive up to the high fire position, and then drive down as the fuel flow commissioning points are entered.

-

Page 78: Calorific Fuel Data

3 Commissioning Fuel-Air Curve 3.5.1 Calorific Fuel Data Stats Kerosene Gas Oil Light fuel Medium Heavy CI/SH Oil SG fuel Oil Fuel Oil Relative density 15.6°C (60°F) approx. 0.79 0.835 0.93 0.94 0.96 / = litres x = kg Flash point (closed) min °C 37.8 (100) 65.6 (150) 65.6 (150) -

Page 79: Conversion Factor For Imperial Gas Flow Meters

3 Commissioning Fuel-Air Curve 3.5.2 Conversion Factor for Imperial Gas Flow Meters Required Data: Pressure of gas at meter in “wg Required gas flow in ft³/min Calculations: Correction factor = (pressure of gas at meter x 0.00228 ) + 0.948 Reading on gas meter = required gas flow / correction factor Example: Pressure of gas at meter = 58”... -

Page 80: Gas Volume Conversion Factors

3 Commissioning Fuel-Air Curve 3.5.4 Gas Volume Conversion Factors Assumed gas temperature 10 °C 50 °F Standard pressure e 760 mmHg 101.3612 Kpa Standard temperature 15.56 °C Ambient pressure 101.325 Kpa Wg " mmH2O mmHg mBar Conversion factor 0.036 25.4 1.867 0.249 2.49... - Page 81 3 Commissioning Fuel-Air Curve How to use this information:- 1. Measure Volumetric flow of gas for 1min in ft3 (i.e. ft3/min). Note 1m3 = 35.31ft3 2. Multiply this volume flow by 60 to give volumetric flow per hour (i.e. ft3/hr). 3.

-

Page 82: Gas/ Air Pressure Commission

3 Commissioning Fuel-Air Curve Gas/ Air Pressure Commission To re-commission the gas pressure sensor, go to Commission Mode and press The MM will then run through the points to store the gas pressure values. If the VPS is optioned on, the unit will run through this process. The MM will go from Low Fire to High Fire and store the gas pressure values along the curve. -

Page 83: Single Point Change

3 Commissioning Fuel-Air Curve Single Point Change Figure 3.7.i Single Point Change Press in the system configuration screen and enter the password to access Single Point Change mode. Select the point to be edited or added trim to by pressing go up and down the fuel curve, then press 12.04.2019 Mini Mk8 MM Installation and Commissioning Guide... - Page 84 3 Commissioning Fuel-Air Curve Figure 3.7.ii Changes To edit a previously entered point press and make adjustments to the positions as needed. To enter a new point press Press to delete the next point on the commission curve. Or press to go back to the previous screen.

- Page 85 3 Commissioning Fuel-Air Curve Figure 3.7.iii Changing a Point Press to the fuel, air and/or VSD commissioned value of that point. Once the changes have been made, press to save this position. If a point is overwritten, the trim data is cleared. Press to remove the point;...

- Page 86 3 Commissioning Fuel-Air Curve Figure 3.7.iv Single Point Change – Trim The MM will store the trim values for this position. Page 76 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019...

- Page 87 3 Commissioning Fuel-Air Curve Figure 3.7.v Exit Single Point Change Once the adjustments have been made, go back to the Single Point Change home screen Figure 3.7.i and press Press to save the changes. Alternatively press to discard the changes and exit Single Point Changes. The fuel flow commissioning must be entered (again) if the following changes are made in single point change •...

-

Page 88: Online Changes

3 Commissioning Fuel-Air Curve Online Changes Figure 3.8.i Online Changes Screen The Online Changes is accessed by pressing on the system configuration screen, and then entering the password. The Online Changes feature allows the following: Fuel flow commissioning (section 3.5) •... -

Page 89: General Operation

3 Commissioning Fuel-Air Curve General Operation 3.9.1 Calibrating the Actual Value To calibrate the actual value, a new parameter has been added to allow the temperature/ pressure sensor to be adjusted. Parameter 29 allows you to adjust the actual value between a range of 80.0% and 120.0%. -

Page 90: Additional Functions

UL, FM or CE. Figure 3.9.3.i End Switch Wiring Schematic End Limit Switches are mounted on the end of bespoke valves (please contact Autoflame regarding bespoke valve manufacture) which are attached to the air and fuel valve and commissioned depending on the use of the End Limit Switches. -

Page 91: Remote Control

When using Modbus direct, e.g. connecting to Building Management System from the MM without a DTI, then neither Autoflame Intelligent Boiler Sequencing nor the DTI can be used. The MM communicates using an RS485 data link from terminals 27 (-ve) and 28 (+ve). Beldon 9501 data cable is recommended. -

Page 92: Configuration

4 Remote Control Configuration Option Description Setting Sequencing/DTI or Modbus function Modbus baud rate As required Modbus parity setting As required Modbus stop bits setting As required Modbus device ID As required Binary format As required The following terminals are used for direct Modbus. Terminal Description RS485 -... -

Page 93: Modbus Addresses

4 Remote Control Modbus Addresses There are 4 types of Modbus addresses: 0x Read/Write digital outputs – off/on commands These are binary values and have a 0/1 value indicating an off/on or 1x Read digital inputs – off/on signals/indications no/yes value. These are multiple integer values and 3x Read analogue inputs –... - Page 94 4 Remote Control Address Description Type 30102 Firing Status Read analogue • 0 = Non-modulating, 1 = Modulating • Returns value 0 single point change, fuel flow metering and commissioning 30104 Burner Rating Read analogue • MW x 10 • Metric units determined from fuel flow metering 30105 Actual Value...

- Page 95 4 Remote Control Address Description Type 30125 EGA Commissioned Exhaust Gas Temperature Read analogue • Metric: temperature x 10 • Imperial: temperature x 10 30126 EGA Commissioned Efficiency Value Read analogue • % x 10 30127 EGA Commissioned NO Value Read analogue •...

- Page 96 4 Remote Control Address Description Type 30139 Fuel 2 Flow Total Billions Read analogue • Metric GW/hr, imperial MMBTU / 1000 • Whole number of GW/hr or MMMBTU E.g. 1.5MW/hr gives 0 value and 15.1MMBTU gives 0 value 30140 Fuel 3 Flow Total Thousands Read analogue •...

- Page 97 4 Remote Control Address Description Type 30832 Fuel 2 Type Read analogue • 0 = Gas, 1 = Oil • Option/parameter 151 value 30839 Fuel 1 Hours Run Read analogue • Completed hours 30840 Fuel 2 Hours Run Read analogue •...

-

Page 98: Errors And Lockouts

• Check for noise on the mains input, wiring and voltages on all terminals EEPROM Error Fault communicating with the on board EEPROM • Contact Autoflame approved local Tech Centre Page 88 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019... - Page 99 5 Errors and Lockouts Error Message Description ADC Error Internal fault • Contact Autoflame approved local Tech Centre Watchdog Timeout Internal fault • Contact Autoflame approved local Tech Centre Processor Clock Error Internal fault • Contact Autoflame approved local Tech Centre...

- Page 100 5 Errors and Lockouts Error Message Description Air Pressure Commission Fault No air pressure trim data for a point with EGA trim • Check EGA trim and air pressure trim in fuel-air curve Gas Pressure VPS Commission Commissioned gas pressure during VPS is below option/ Fault parameter 133 threshold •...

-

Page 101: Burner Lockouts

5 Errors and Lockouts Burner Lockouts Lockouts occur when the MM detects a fault with the burner operation such as VPS, gas/air pressure sensor and flame scanners. The lockout must be cleared and investigated on the MM. Lockout Message Description CPI Input Wrong State Proof of closure switch opened during ignition sequence •... - Page 102 • Check gas pressure • Check option/ parameter 137 RAM Test Failed Hardware fault • Contact Autoflame approved local Tech Centre PROM Test Failed Hardware fault • Contact Autoflame approved local Tech Centre FSR Test 1A Internal relay test failed •...

- Page 103 Wrong gas pressure sensor detected • Check option/parameters 128 and 156 Gas Sensor Fault Internal pressure sensor fault • Contact Autoflame approved local tech centre UV Pot Fault Hardware fault • Contact Autoflame approved local tech centre Air Sensor Comms Signal lost from air pressure sensor •...

- Page 104 Check air pressure sensor value during VPS Air Sensor Signal High Air pressure reading is above 400mbar • Contact Autoflame approved local tech centre Air Sensor Error Window Air pressure outside of these limits for 3 seconds • Check air pressure •...

-

Page 105: Ega Errors

5 Errors and Lockouts Alarms and Warnings Alarms and warnings are faults detected with the system operation. If an alarm occurs, the burner will stop running, and if a warning occurs, the burner will continue to run. The following options/parameters set whether system operation faults are set as alarms or warnings: Option 13 EGA Fault Response Option 14... - Page 106 5 Errors and Lockouts Fault Message Description Exhaust Temperature Exhaust temperature is above absolute limit* Absolute Limit • Alarm or warning depending on option 13 • Check exhaust gas readings and parameter 97 Zero-Crossing Detection Internal fault • Alarm • Check mains supply going to unit is within acceptable voltage range Load Sensor Fault Incorrect/no load sensor detected...

-

Page 107: Troubleshooting And Further Information

This can cause internal damage to the MM Snubbers can be used on these old gas valves to protect the MM from these spikes; they should be fitted across the power terminals of the gas valves. Please contact Autoflame Sales for more information. -

Page 108: Channel Positioning Error

5 Errors and Lockouts 5.4.4 Channel Positioning Error The ‘Channel Positioning’ MM Error is caused by incorrect wiring and incorrect servomotor position. In addition to checking the wiring, and zeroing the potentiometer, please also check that the correct voltage is supplied to the servomotors, which should be ±10% of the required voltage, and the unit is earthed properly. -

Page 109: Setting Conflicts

5 Errors and Lockouts 5.4.7 Setting Conflicts Some of the option/parameter values may require another option/parameter to be set, as described in the table below. The MM will be forced into Commission mode. Setting Conflict Message (1) (45) External modulation cannot be used with external load sensor. •... - Page 110 5 Errors and Lockouts Setting Conflict Message (118) (141) (149) Purge air pres. threshold cannot be higher when post purge is optioned • If post purge is enabled, then the purge air pressure threshold cannot be set higher than the running air pressure threshold.

-

Page 111: Forced Commission

5 Errors and Lockouts 5.4.8 Forced Commission The MM will be forced into Commission mode if there is a setting conflict as in 5.4.6, and/or the following conditions occurs: Forced Commission Message Fuel not commissioned. • Selected fuel must be commissioned. Servo configuration does not match commissioning. - Page 112 5 Errors and Lockouts Forced Commission Message VSD feedback variation too small • VSD feedback variation is within optioned tolerance band meaning that a constant value can pass for any point on the curve. • Check option 99. Air channel configuration does not match commissioning •...

-

Page 113: Standards

5 Errors and Lockouts STANDARDS The Mini Mk8 MM has been tested and approved to the following standards: UL 372, 5 Edition C22.2 No. 199-M89 BS EN 298:2012 BS EN 12067-2:2004 BS EN 1643:2014 BS EN 1854:2010 ISO 23552-1:2007 AGA AS 4625-2008 AGA AS 4630-2005 12.04.2019 Mini Mk8 MM Installation and Commissioning Guide... - Page 114 NOTES...

- Page 118 Autoflame Engineering Ltd Unit 1-2, Concorde Business Centre Airport Industrial Estate, Wireless Road Biggin Hill, Kent TN16 3YN United Kingdom Tel: +44 (0)845 872 2000 www.autoflame.com...

Need help?

Do you have a question about the Mini Mk8 M.M. and is the answer not in the manual?

Questions and answers